Medium- and finish-rolling pass structure for four-strand slitting in continuous rolling of phi12 deformed bars

A technology of finishing pass and four-slicing, applied in metal rolling, metal rolling, metal rolling stand, etc., can solve the problem of inability to achieve ∮12mm screw four-segment rolling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

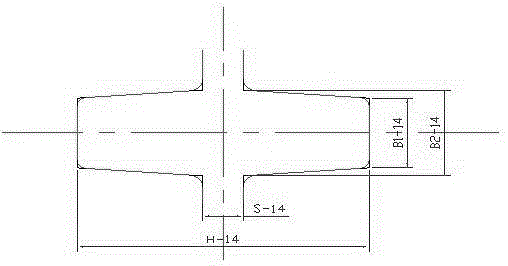

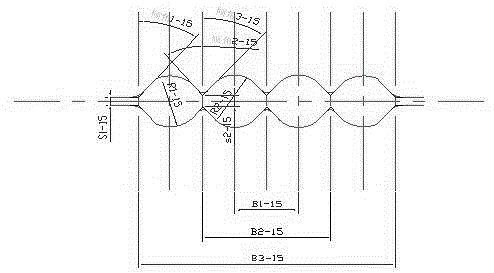

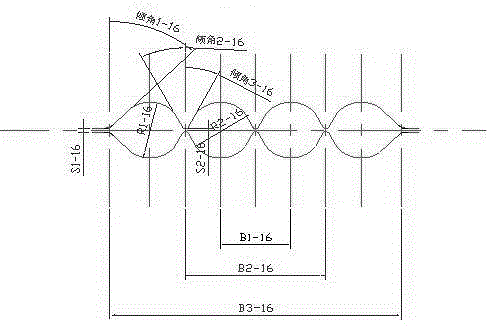

[0015] A bar continuous rolling ∮12 snail four-segment intermediate rolling and finishing rolling pass structure, the middle rolling mill 7﹟ to 10﹟ racks share the roll pass; when rolling four-segment Ф12mm screw, 10﹟ rolling mill exports steel The material size is ∮45mm, the 11﹟ stand rolling mill is flat roll without hole rolling, the 12﹟ vertical roll mill is empty; vertical box type, 15﹟ frame flat roll mill is pre-slit pass, 16﹟ frame vertical-horizontal conversion is flat roll split pass, 17﹟ flat roll mill is flat elliptical pass, 18﹟ frame Rolling mill vertical-horizontal conversion to flat roll finished pass.

[0016] The pass of the 15﹟ frame pre-splitting mill of the finishing mill is the pass of the middle two lines, and the pass of the two sides is compared with the pass of the two sides: the side wall inclination of the two li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com