Design method for conductor of special-shaped copper single-wire large-section submarine cable

A design method and large cross-section technology, applied in the field of power cables, can solve problems such as unsatisfactory cross-section conductor water resistance, immature conductor resistance measurement, and no consideration of copper single-wire twisting pitch, etc., to reduce the skin effect , Improve the water blocking effect and reduce the effect of proximity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

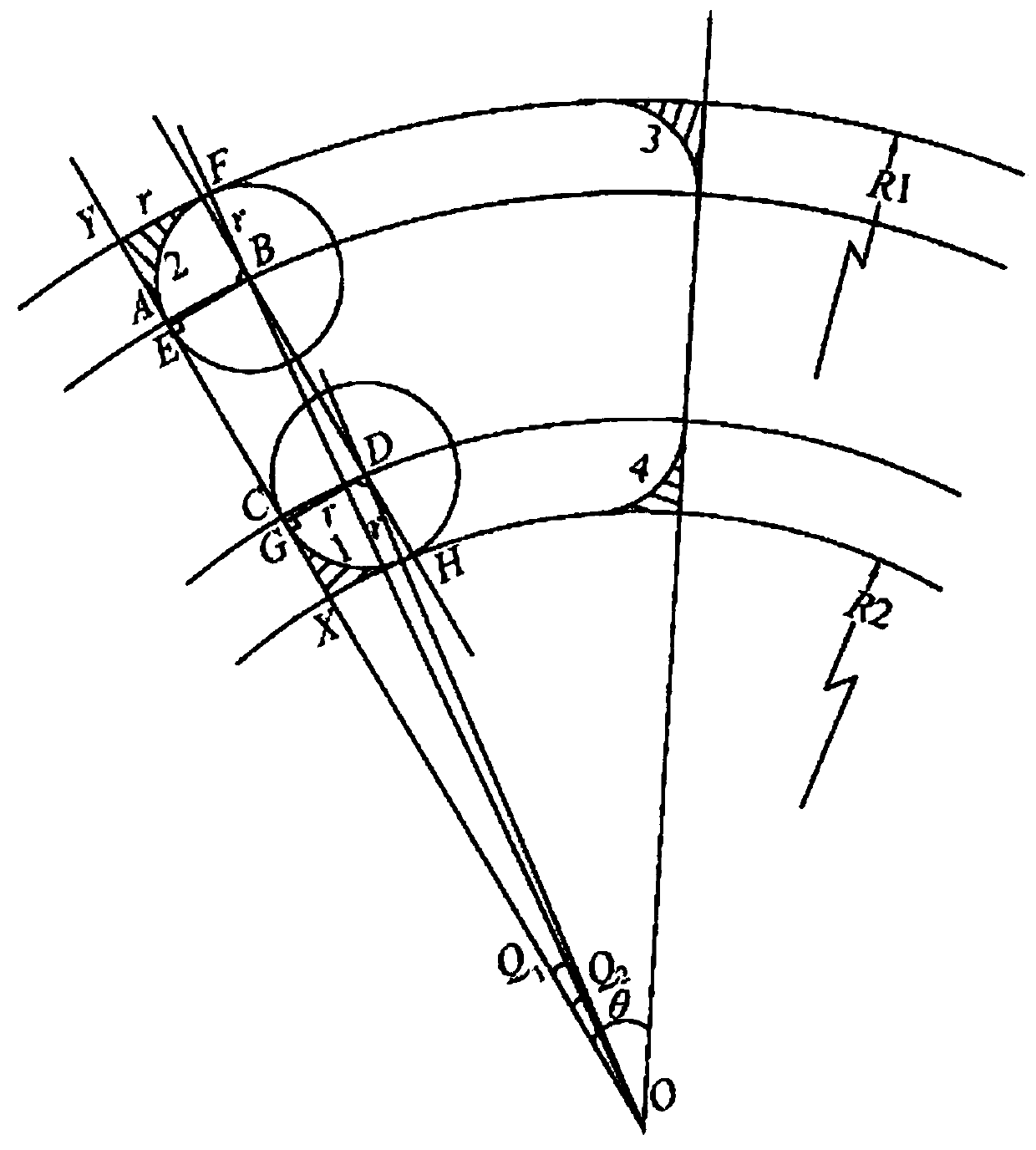

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

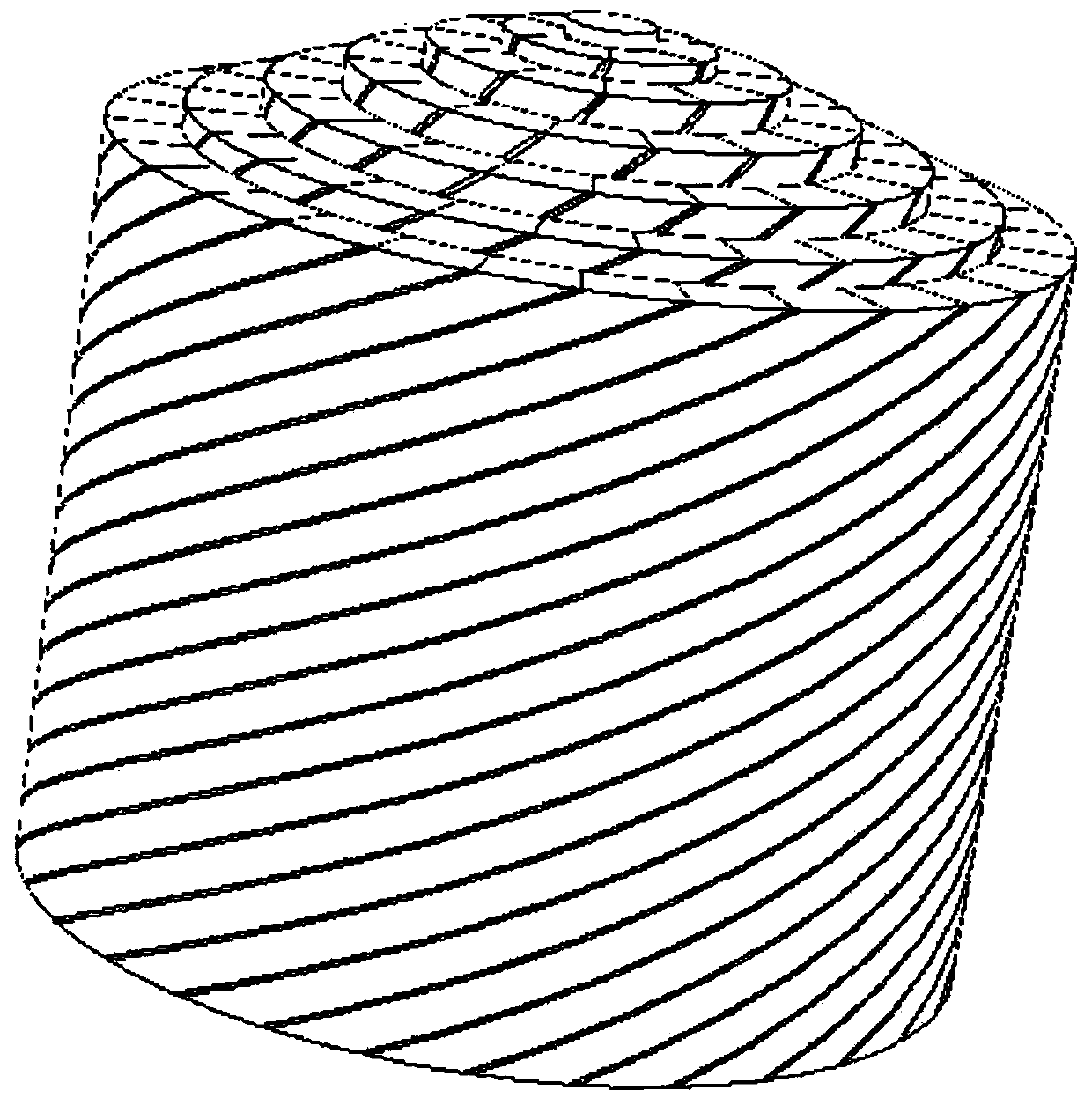

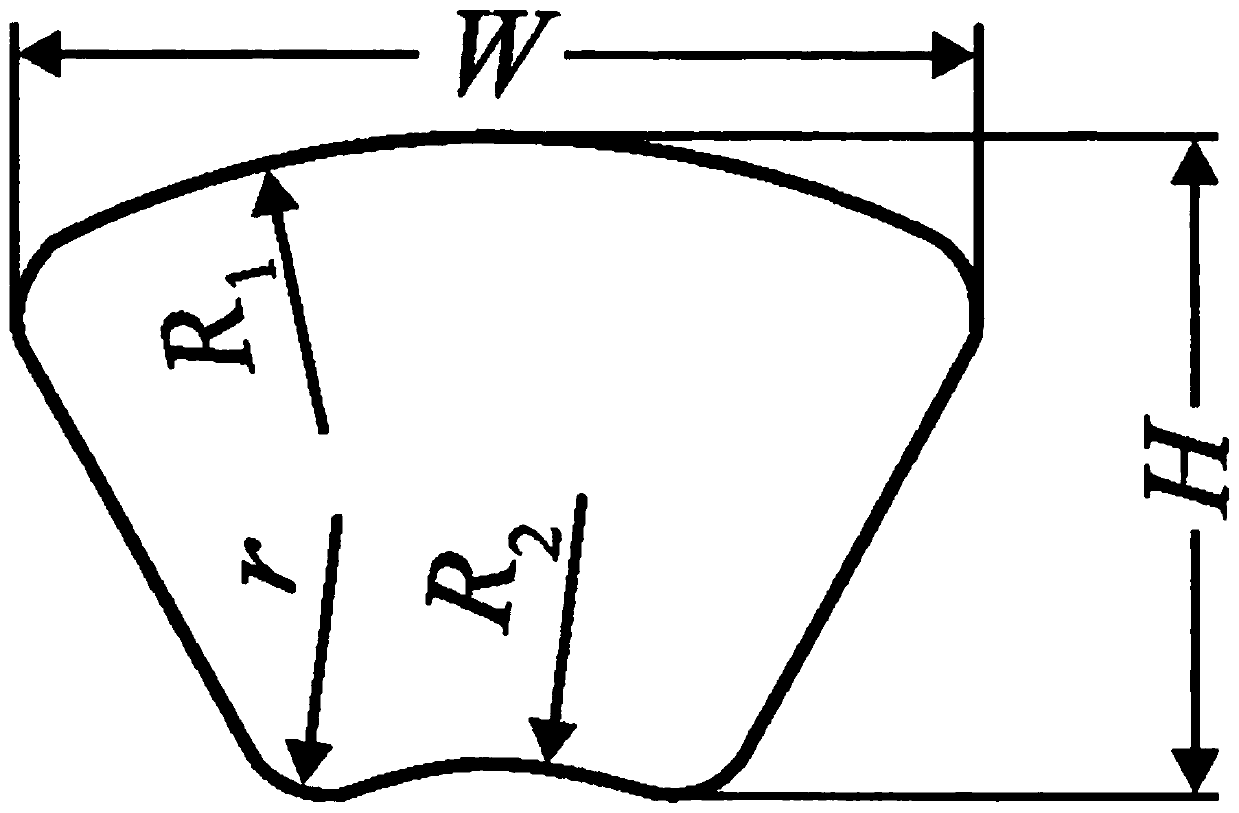

[0035] see Figure 1 to Figure 3 , the embodiment of the present invention includes: a special-shaped copper single-wire large-section submarine cable conductor design method, including:

[0036] Specific steps include:

[0037] 1) Calculation of outer diameter: First, calculate the conductor cross-sectional area S according to formula (1).

[0038] (1)

[0039] where k 1 is the conductor coefficient, k 2 is the twisting coefficient, ρ is the resistivity of the copper conductor, R is the resistance, in this embodiment k 1 Take the value 1.02, k 2 Take the value 1.03, ρ Take the value 1.724 1×10 –8 Ω m, R Taking the value of 0.006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com