Closed Gap Strip Threading Rolling Method in Double Stand Cold Rolling Mill

A closed roll gap and double-stand technology, applied in the field of strip steel cold rolling equipment and technology, can solve the problems of increased use and manufacturing costs, low yield, reduced production efficiency and benefits, etc., to improve rolling conditions, reduce Effect of production cost and reduction of rolling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

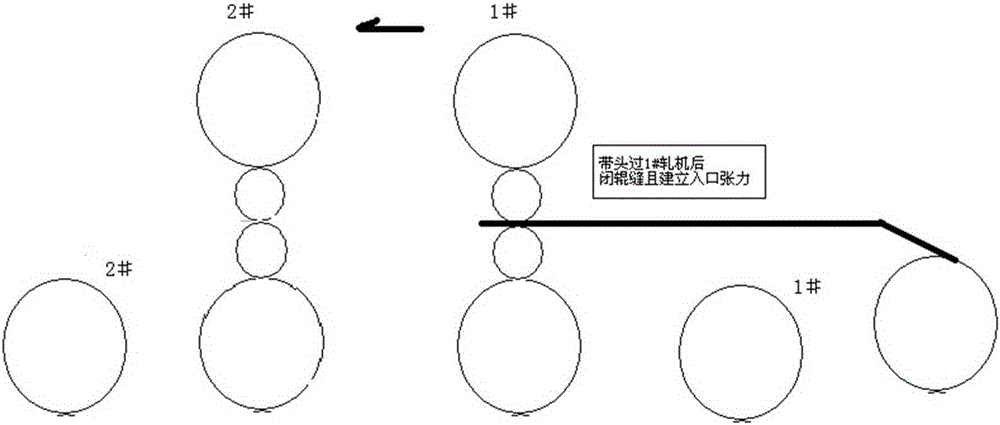

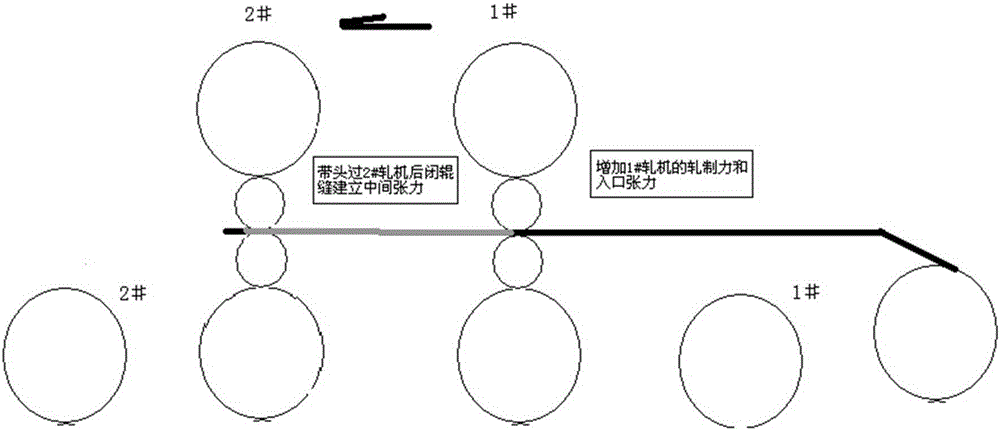

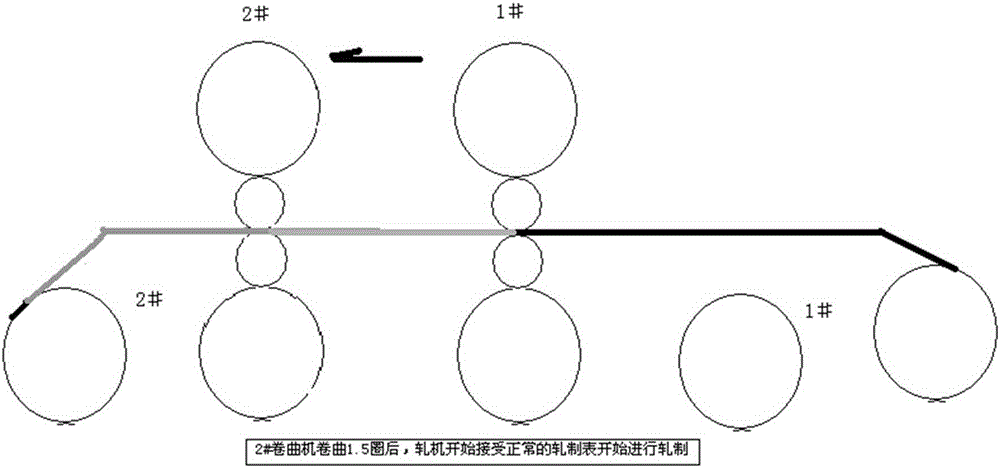

[0056] Combine Figure 1 to Figure 11 , A double-stand cold rolling mill closed roll gap threading rolling method, by adjusting the control sequence of the double-stand cold rolling mill tape threading process and the hydraulic pressure cylinder pressing sequence, the preset value of the closed roll gap and the strip Press rolling and threading, dynamically adjust the press system by adjusting the rolling force on both sides of the hydraulic press cylinder to avoid strip deviation, use different bending force and tension to adjust the strip to ensure the smoothness of products of various specifications Closed roll gap piercing rolling; using the lubrication and cooling effects of the emulsion to improve the rolling condition to reduce the rolling force, which is characterized by including the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com