Adsorption type winding drum and winding device and method

An adsorption type and reel technology, which is applied in the field of winding devices and lithium battery adsorption type reels, can solve the problems of internal multi-layer folds, etc., and achieve the effects of reducing the amount of scrap, uniform force, and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

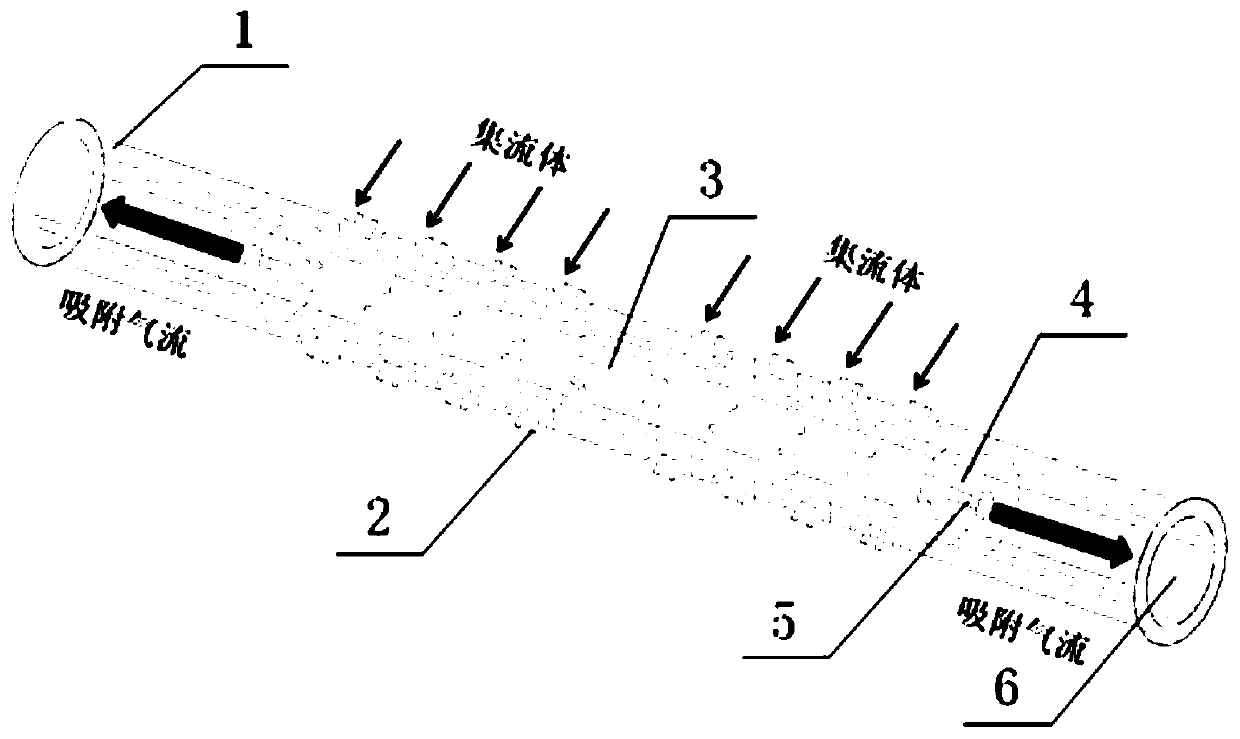

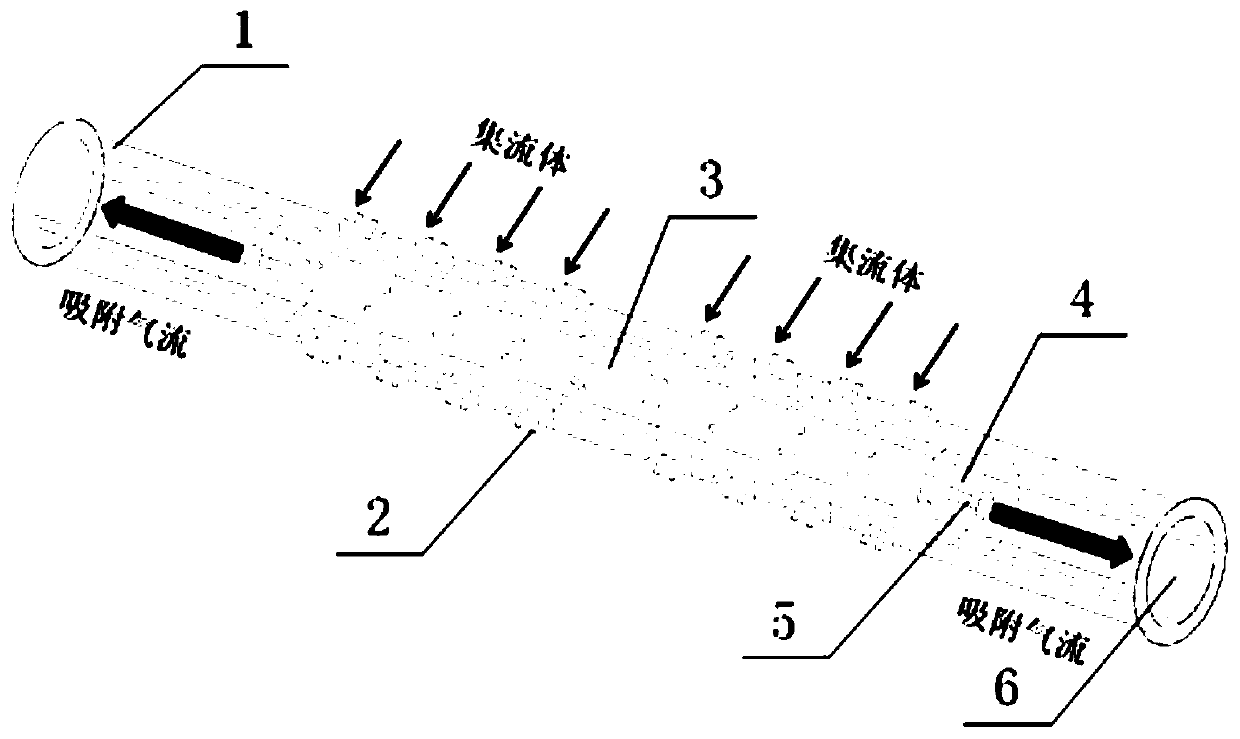

[0024] Such as figure 1 As shown, an adsorption reel of the present invention has a bearing capacity of 400 kg, and the reel is made of nylon material, including a hollow cylinder body 1 with openings at both ends, and two cavity plates 4 are symmetrically injected on the cylinder along the center line of the length direction of the reel The inner cavity, the inner cavity of the adsorption reel body 1 is divided into three parts, the two ends of the inner cavity of the inner cavity are air expansion holes 6, and the middle of the inner cavity of the inner cavity is the adsorption cavity 3. The sealing suction port 5 is a trumpet-shaped hole in the center of the cavity plate 4 , the large mouth end faces the air expansion hole 6 , and the small mouth end communicates with the adsorption cavity 3 as a communication channel between the air expansion hole 6 and the adsorption cavity 3 . On the surface of the outer cylinder 1 corresponding to the adsorption cavity 3, circular adsor...

Embodiment 2

[0028] Such as figure 1 As shown, an adsorption reel of the present invention has a bearing capacity of 600kg, is made of stainless steel, and includes a hollow cylinder body 1 with openings at both ends. The cavity plate 4 is integrally formed with the barrel body 1, and the inner cavity of the adsorption reel barrel body 1 is divided into three parts, the two ends of the barrel inner cavity are air expansion holes 6, and the middle of the barrel inner cavity is the adsorption cavity 3. The sealing suction port 5 is a trumpet-shaped hole in the center of the cavity plate 4 , the large mouth end faces the air expansion hole 6 , and the small mouth end communicates with the adsorption cavity 3 as a communication channel between the air expansion hole 6 and the adsorption cavity 3 . On the surface of the outer cylinder 1 corresponding to the adsorption cavity 3, circular adsorption holes 2 are symmetrically arranged along the center line of the cylinder 1 in the length direction...

Embodiment 3

[0032] Such as figure 1 As shown, an adsorption reel of the present invention has a bearing capacity of 600kg, is made of stainless steel, and includes a hollow cylinder body 1 with openings at both ends. The cavity plate 4 is integrally formed with the barrel body 1, and the inner cavity of the adsorption reel barrel body 1 is divided into three parts, the two ends of the barrel inner cavity are air expansion holes 6, and the middle of the barrel inner cavity is the adsorption cavity 3. The sealing suction port 5 is a trumpet-shaped hole in the center of the cavity plate 4 , the large mouth end faces the air expansion hole 6 , and the small mouth end communicates with the adsorption cavity 3 as a communication channel between the air expansion hole 6 and the adsorption cavity 3 . On the surface of the outer cylinder 1 corresponding to the adsorption cavity 3, circular adsorption holes 2 are symmetrically arranged along the center line of the cylinder 1 in the length direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com