Rolling slitting method for deep-fried dough stick dough strip

A technology for fritters and noodles, which is applied in the fields of dough forming machinery or equipment, baking, food science, etc., can solve the problems of large weight error of fritters, continuous cutting of noodles, affecting processes, etc., and achieves consistent thickness and width. The effect of sheet thickness repair and shape uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

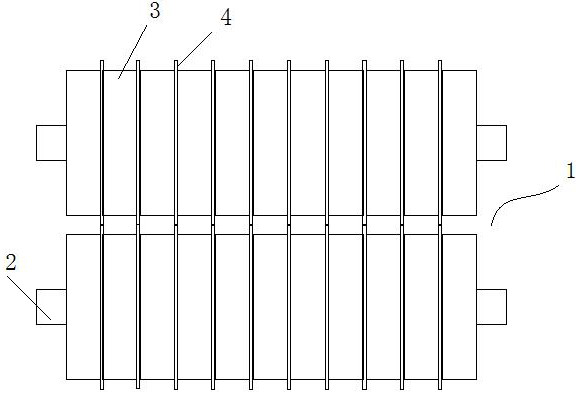

[0018] As a structural approach, such as figure 1 As shown, the rolling slitting refers to the use of two symmetrical rolling cutting wheels 1 .

[0019] As the specific structural design of the rolling cutting wheel, the rolling cutting wheel 1 refers to the repeated mode of the rolling plate 3, the cutter 4, the rolling plate 3, and the cutting knife 4 on the roller shaft 2, and according to the dough sheet Set the width of the rolling plate and the distance between two adjacent cutters according to the width of the cut out dough band, and set the thickness between the two rolling plates opposite to each other according to the thickness of the band after cutting the dough sheet And the diameter of the cutter head of the two relative cutters.

[0020] This design limits the size of the cantilever of the cutter because the rolling plate and the cutter need to meet the above conditions at the same time, and the thickness of the dough sheet can be repaired. Therefore, two comm...

Embodiment 2

[0023] As a structural method, the rolling slitting adopts a combination of a rolling cutting wheel and a smooth roller, and the thickness of the belt after cutting the dough sheet is the thickness between the rolling plate of the rolling cutting wheel and the roller surface of the smooth roller.

[0024] Wherein the structure of the rolling cutting wheel is the same as that of embodiment 1, and the smooth roller refers to the roller of a smooth roller. The thickness between the cylinder surface and the rolling plate is exactly the thickness of the noodle belt.

Embodiment 3

[0026] The rolling slitting adopts rolling slitting and refers to the combination of two concavo-convex alternate wheels, wherein the convex part of one wheel is equal to the concave part of the other wheel in size, and the concavo-convex parts of the two wheels are opposite to each other. The thickness of the belt is the depth of the concave part, and the thickness between the two wheels is adjustable, which is suitable for different thicknesses of fried dough sticks.

[0027] Through rolling and cutting, the cutting edge can be well set according to the width of the fried dough sticks. The depth of the knife edge is small and the size of the cantilever is reduced, which solves the problem of increasing the width error of the cut dough due to the large cantilever of the cutter or the large depth of the knife edge. The problem is that the roller plate presses and sorts the dough pieces during cutting, so that the thickness of the dough pieces can be restored, ensuring that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com