Aluminum strip billet collating device on rewinding machine

A sorting device and recoiling machine technology, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of scrapping the whole roll blank, and the waste edge is easy to fly out and damage the board surface, so as to reduce labor and improve Efficiency of equipment usage and effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

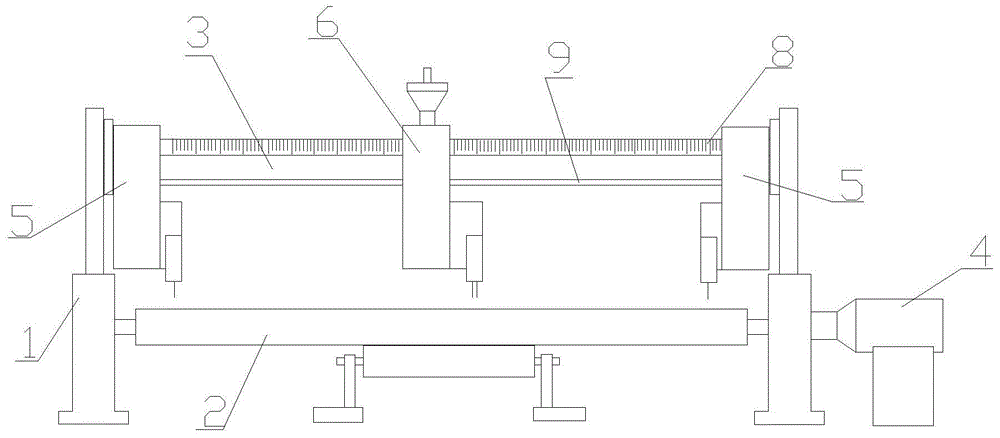

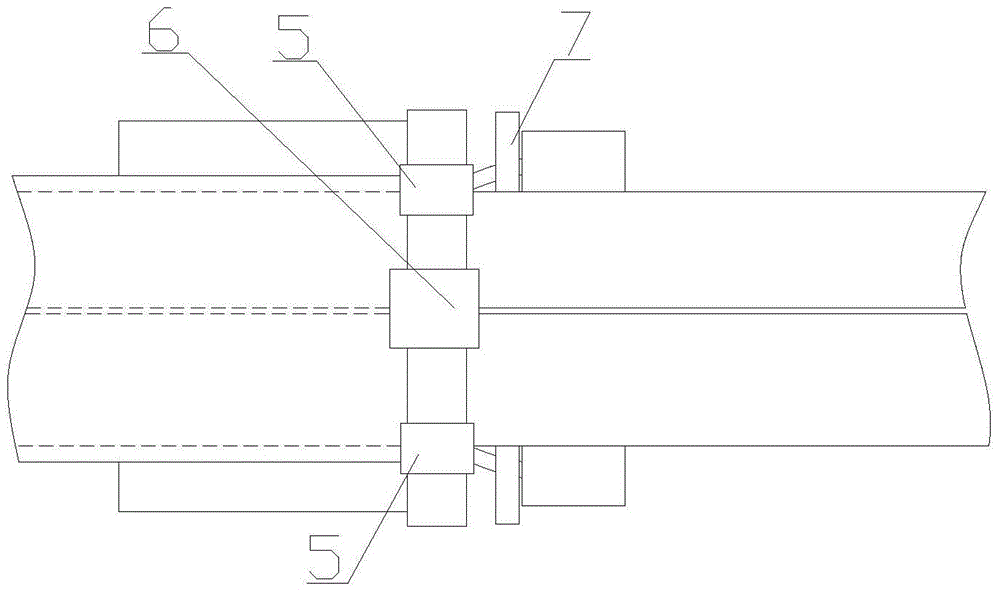

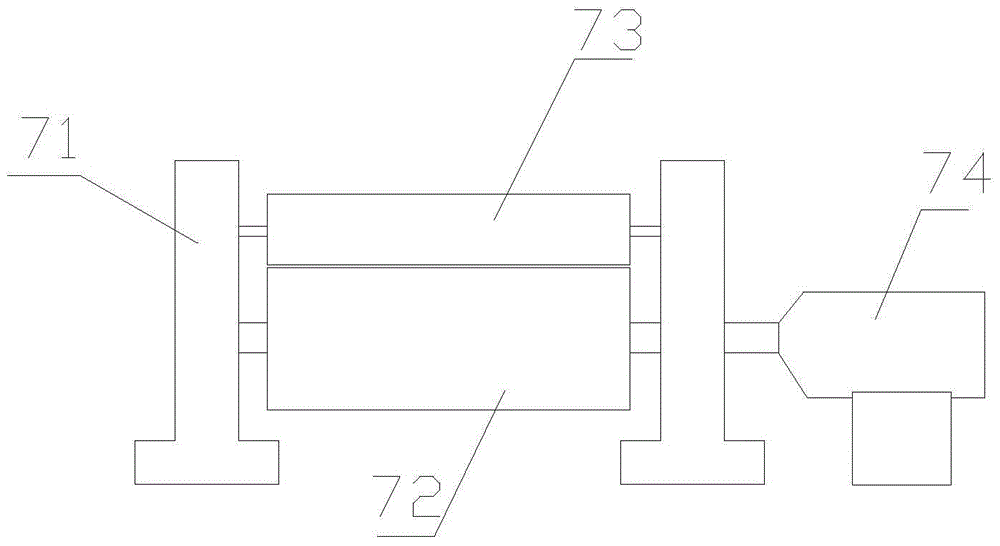

[0034] An aluminum strip billet sorting device on a recoiling machine, comprising a frame 1 set opposite to each other, between the two racks, an aluminum strip billet support shaft 2, a beam 3, an aluminum strip billet support shaft and a motor are arranged sequentially from bottom to top Ⅰ4 is connected, and the supporting shaft of the aluminum strip billet rotates, which can prevent the surface of the aluminum strip billet from being scratched and scratched; There are three slitting devices 6, and a waste edge lead-out device 7 is provided at each edge trimming device / slitting device;

[0035] The edge trimming device includes a knife seat and an edge trimming knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com