Novel special shearing roller for rail tyre particle slitting roller

A technology of rolling shears and shearing rollers, applied in recycling technology, plastic recycling, etc., can solve the problems of abnormal production, noise, and high cost, and achieve the effects of low maintenance, simple structure, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

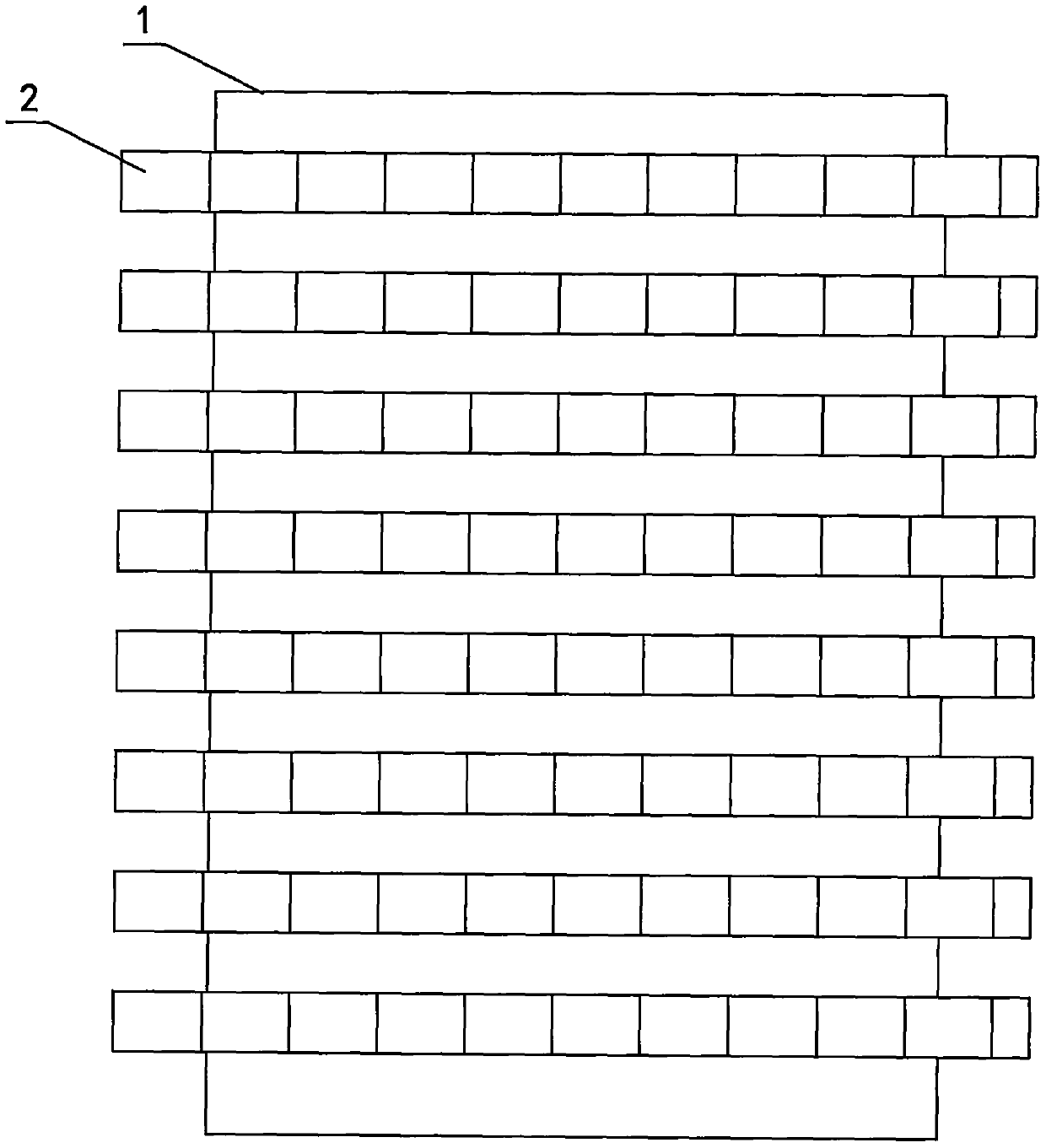

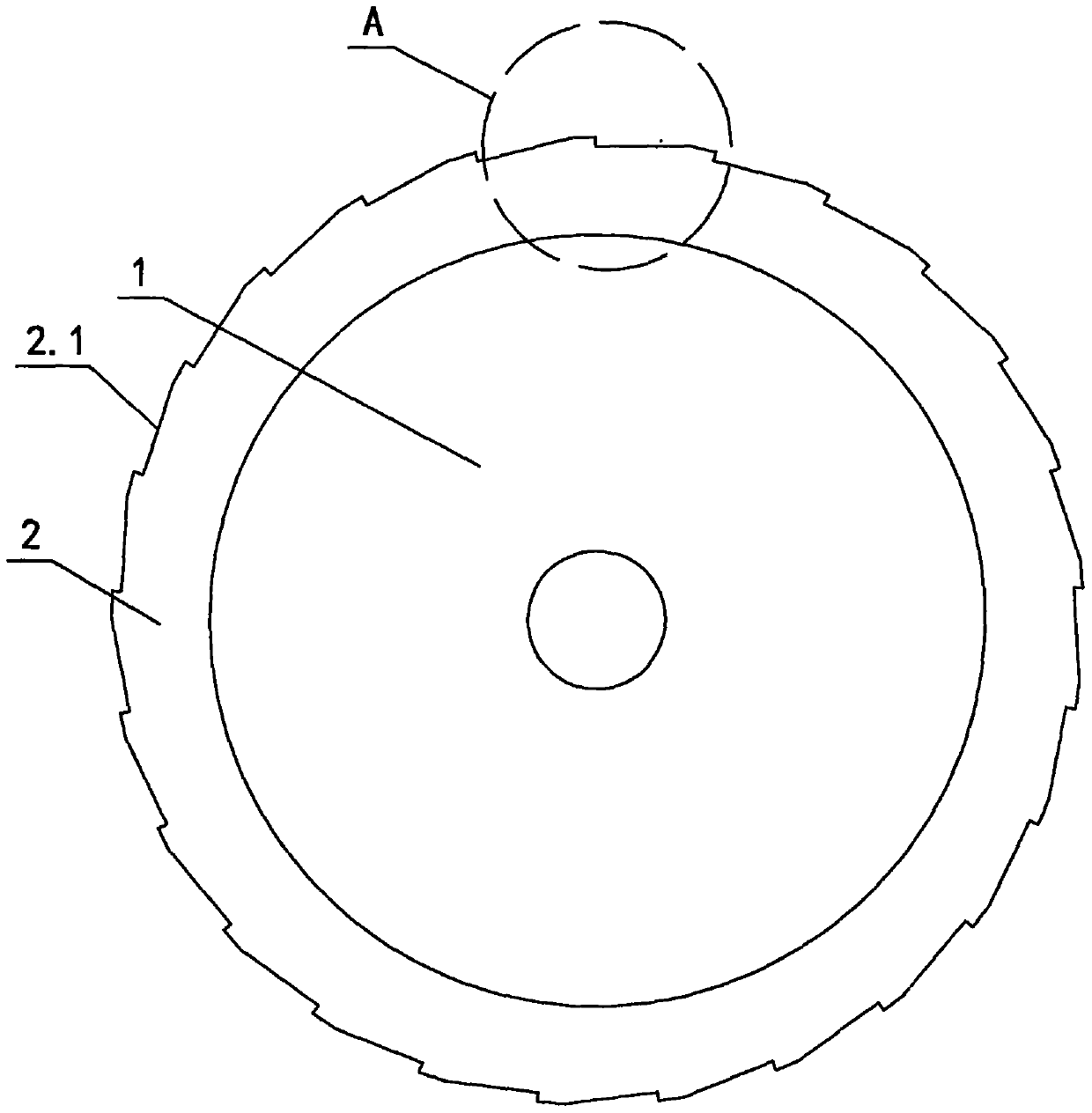

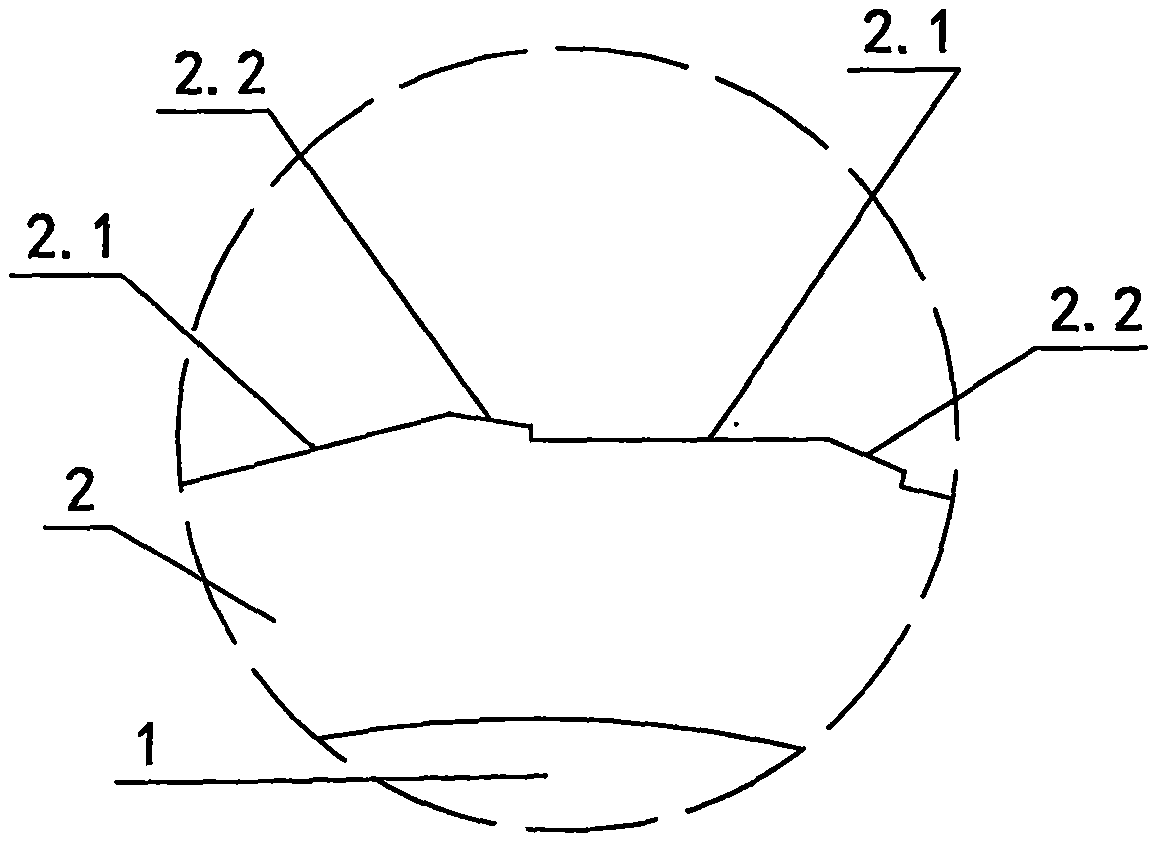

[0019] Such as figure 1 , figure 2 , image 3 As shown, the new type of special shearing roller for steel wire tire particle rolling shears includes a rotating shaft 1. A number of roller cutting discs 2 arranged at equal intervals for rotating and shearing are arranged on the rotating shaft 1. On the outer circumference of the roller cutting disc 2 are provided a number of primary anti-skid roller cutting surfaces 2.1.

[0020] Under the design of the section 2.1 of the anti-skid roller, it effectively prevents the tire from slipping and lays a solid foundation for safe production.

[0021] In this embodiment, the rotating shaft 1 and the roll cutting disc 2 are an integral structure. The integral structure is adopted to facilitate production and processing and reduce production and processing costs. Moreover, in the state of high torque cutting, the rotating shaft 1 and the roll cutting disc 2 It is not easy to separate, which greatly reduces the maintenance cost in the future;...

Embodiment 2

[0027] A change is made on the basis of the first embodiment, and the distance between the two adjacent roll cutting discs 2 is selected to be 2 mm larger than the thickness of the roll cutting disc 2; the first anti-skid roll cutting surface 2.1 is 25.

[0028] Others are the same as in Example 1.

Embodiment 3

[0030] A change is made on the basis of the first embodiment, and the distance between the two adjacent roll cutting discs 2 is selected to be 4 mm larger than the thickness of the roll cutting disc 2; the first anti-skid roll cutting surface 2.1 is 30.

[0031] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com