Tab laser cutting device and cutting block assembly thereof

A technology of laser cutting and block components, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor collection, waste of pole piece material, low material utilization rate, etc., to facilitate absorption and reduce material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

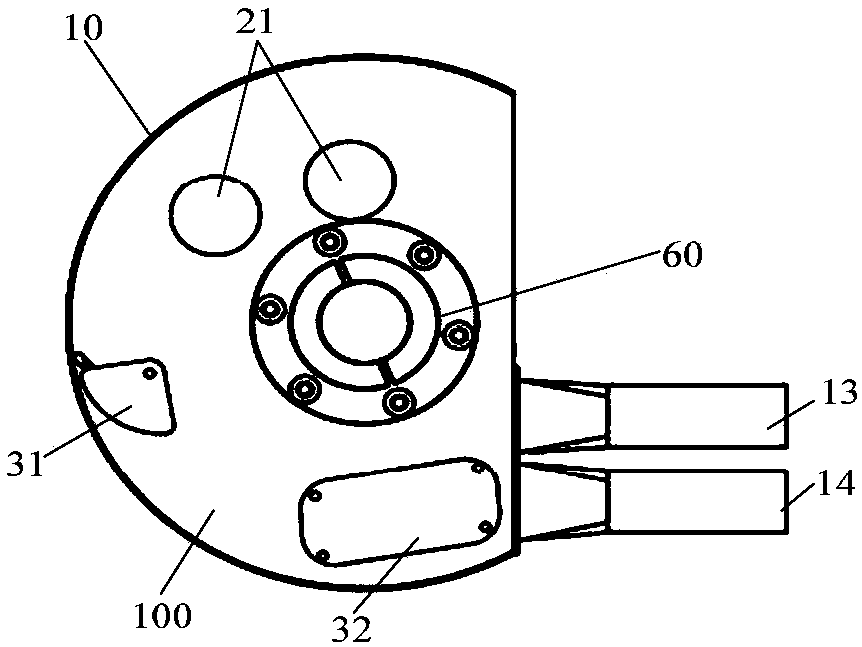

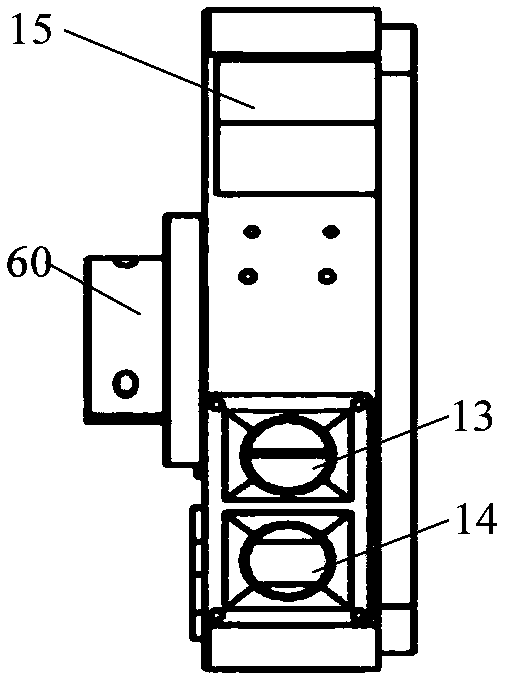

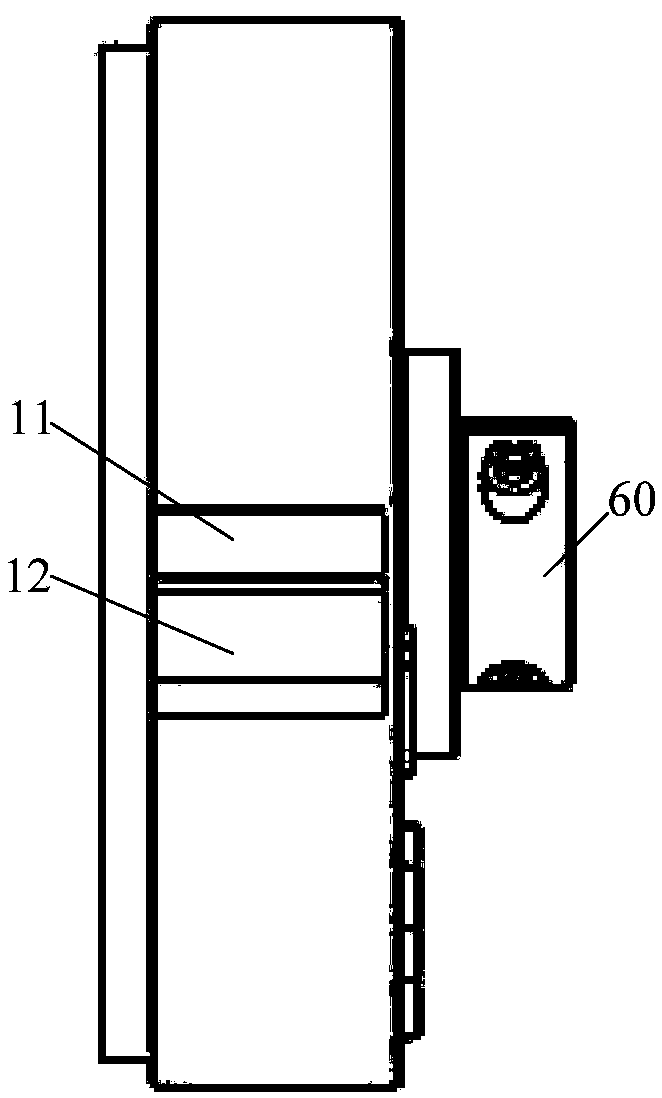

[0040] This embodiment provides a cutting block assembly of a laser tab cutting device, specifically a cutting block assembly for roll cutting. see Figure 1-Figure 4 As shown, the cutting block assembly includes a housing 100, the front of the housing 100 is provided with an arc-shaped support plate 10 for supporting the pole piece, and the support plate 10 is provided with a cutting opening 11 for laser cutting the pole lug and a Waste inlet 12 for collecting waste. Such as Figure 4 As shown, the interior of the housing 100 is configured as two independent cavity structures, namely a dust chamber 20 and a waste material chamber 30 ; the back of the housing 100 is provided with a dust outlet 13 and a waste material outlet 14 . Wherein, both the waste material inlet 12 and the waste material outlet 14 are connected to the waste material chamber 30 , and the cutting opening 11 and the dust outlet 13 are both connected to the dust chamber 20 . In this embodiment, the support...

Embodiment 2

[0048] This embodiment provides a laser tab cutting device, including the cutting block assembly described in the first embodiment. Since all the functions and features of the cutting block assembly are described in detail in the first embodiment, they will not be repeated here.

[0049] see Figure 13 and Figure 14 As shown, in this embodiment, the laser lug cutting device further includes: a first bracket 51, a second bracket 52, a first pressing block 53, a second pressing block 54, a roller 55, a first bearing 56, a second bearing 57, spacer sleeve 58 and roller shaft 59 etc.; The roller 55 is rotatably installed on the roller shaft 59, one end of the roller shaft 59 is installed on the first bracket 51, and the other end is installed on the second bracket 52; the first pressing block 53 is installed on the first bracket 51 To compress one end of the passing roller shaft 59, the second pressing block 54 is installed on the second bracket 52 to compress the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com