Adhesive tape mother roll slitting device

A technology of adhesive tape and parent roll, which is applied in metal processing and other directions, can solve the problems of adhesive sticking to the surface of the tool and the tool becoming blunt, and achieve the effects of improving slitting efficiency, increasing pull-down speed, and improving sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

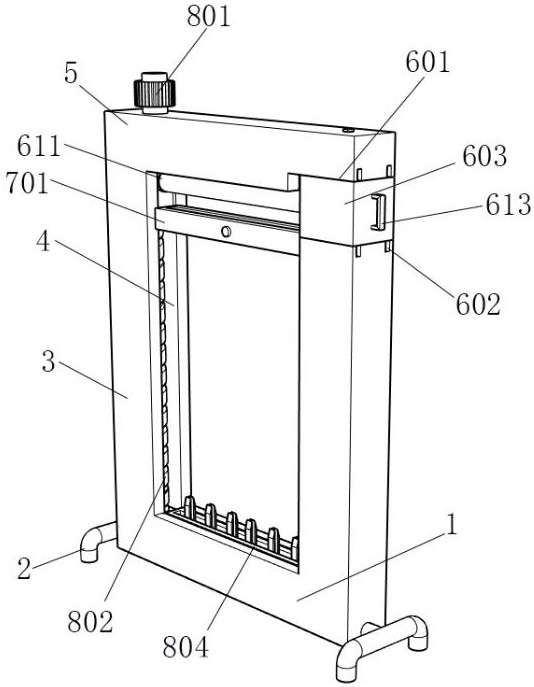

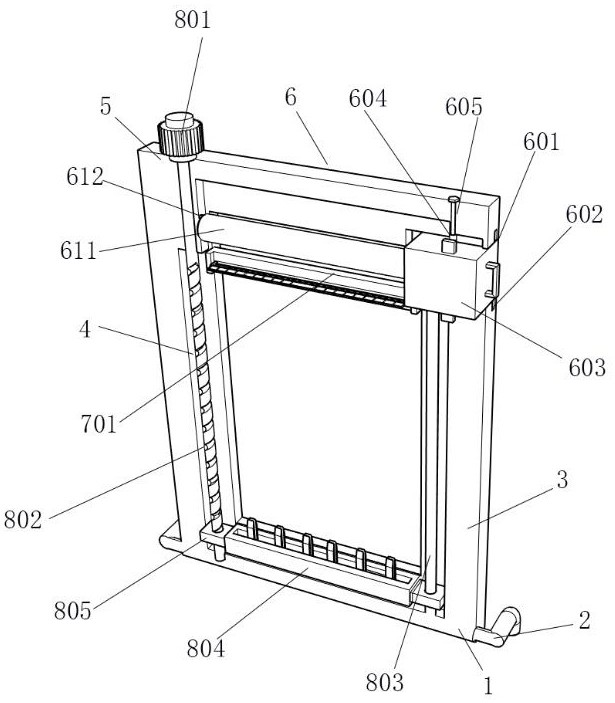

[0028] Embodiment one, by Figure 1-Figure 6 Given, the present invention comprises base plate 1, and support leg 2 is installed symmetrically on both sides of base plate 1, and side plate 3 is installed symmetrically on the top of base plate 1, and the side of two side plates 3 close to each other is provided with organic chute 4, and side plate The top of 3 is equipped with top plate 5, and the top of one of side plates 3 is equipped with discharging assembly 6, and cutting assembly 7 is installed between two side plates 3, and the inside of body chute 4 is equipped with pull-down assembly 8.

Embodiment 2

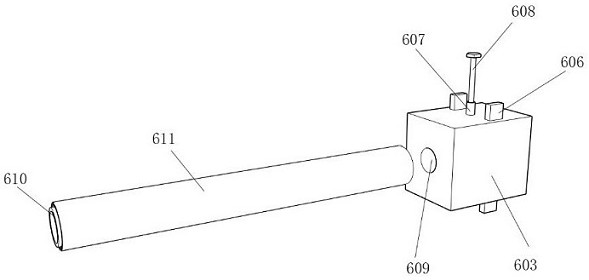

[0029] Embodiment 2, on the basis of Embodiment 1, the discharge assembly 6 includes a rotating groove 601 opened on the top of one of the side plates 3, and the top and bottom ends of the rotating groove 601 are symmetrically provided with limiting grooves 602, and the limiting grooves 602 Through to the outside of the side plate 3, a rotating block 603 is installed inside the rotating groove 601, and the top and bottom ends of the rotating block 603 are symmetrically installed with a limit block 606, and the limit block 606 is slidably connected to the inside of the limit groove 602. The top of 603 is equipped with sliding rotating rod 607, and sliding rotating rod 607 is slidably connected to the inside of top chute 604, and top chute 604 is offered at the bottom of top plate 5, and the top of sliding rotating rod 607 is threadedly connected with fixed screw rod 608, and fixed screw rod 608 is threadedly connected with the top screw groove 605, wherein the top screw groove 6...

Embodiment 3

[0031]Embodiment 3, on the basis of Embodiment 2, the cutting assembly 7 includes a fixed block 701 installed between the two side plates 3 , the inside of the fixed block 701 is provided with a through groove 702 , and the through groove 702 penetrates to the bottom of the fixed block 701 On the upper and lower sides, a cutting unit 703 is installed on the front of the through groove 702, and a cleaning unit 704 is installed on the back of the through groove 702. The cutting unit 703 includes a movable groove 7031 opened on the front of the through groove 702, and a movable plate is installed inside the movable groove 7031 7032, a cutting blade 7033 is installed on the back side of the movable plate 7032, an inner groove 7034 is provided on the back side of the movable plate 7032, and a spring 7036 is installed equidistantly inside the inner groove 7034, and one end of the spring 7036 is fixedly connected with the movable groove 7031, and the inner groove 7034 A magnetic block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com