Patents

Literature

88results about How to "Increase sharpness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

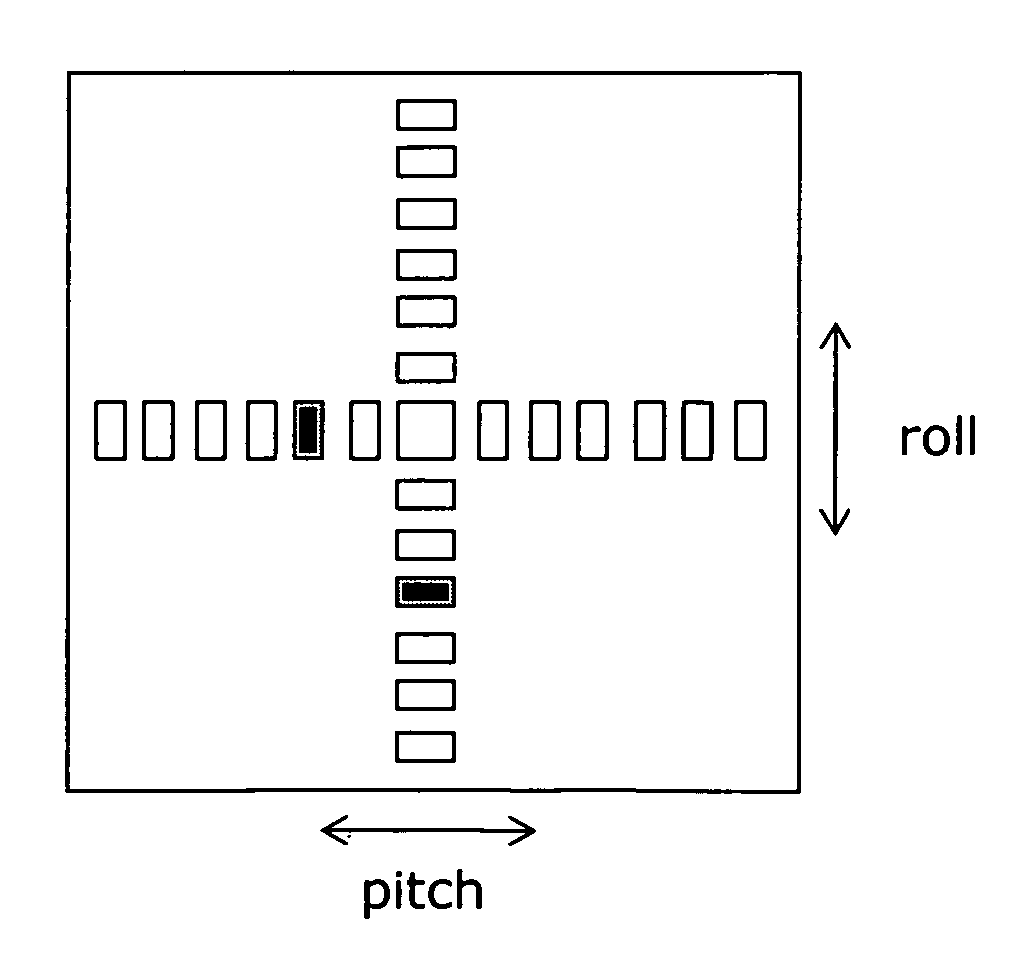

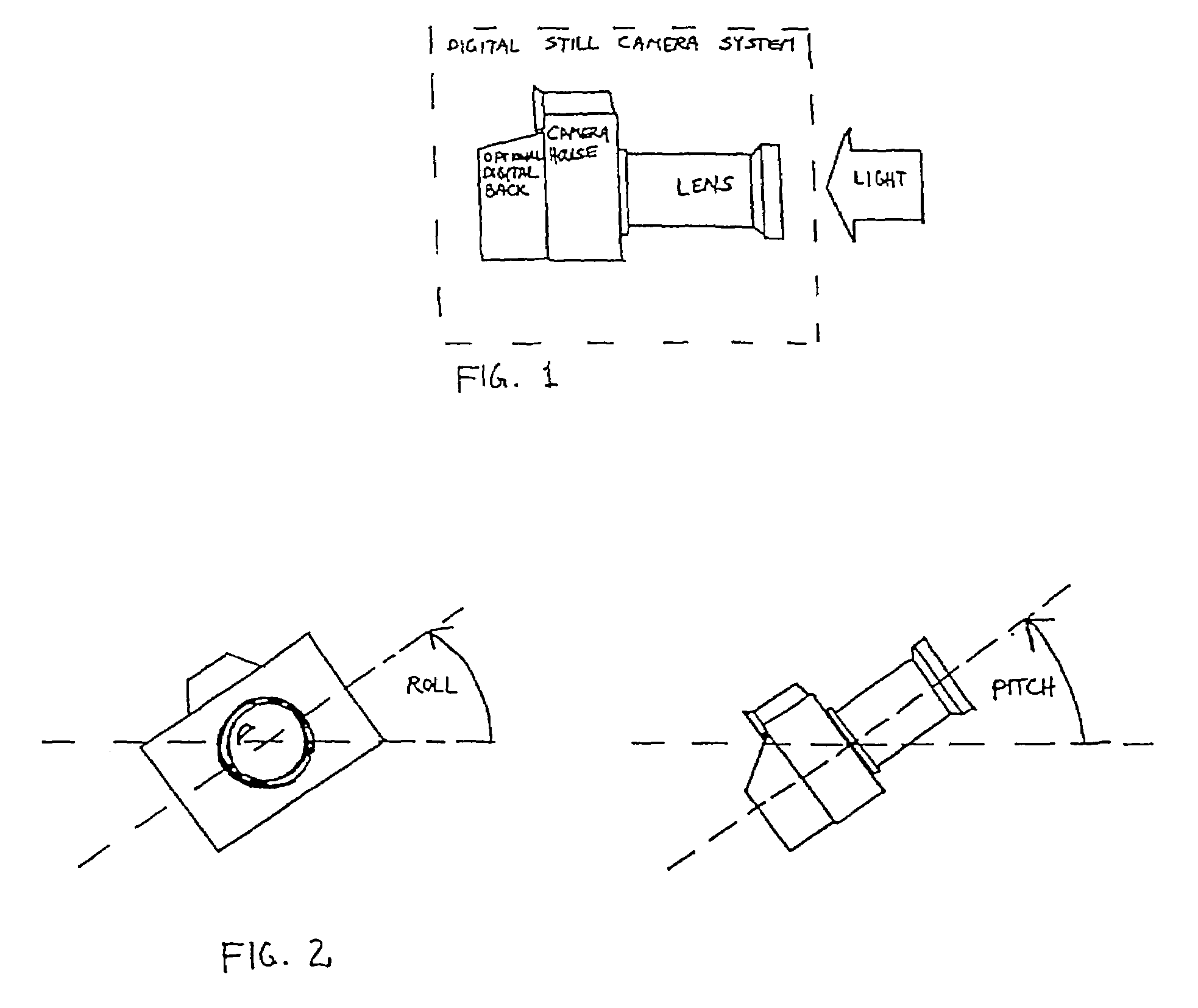

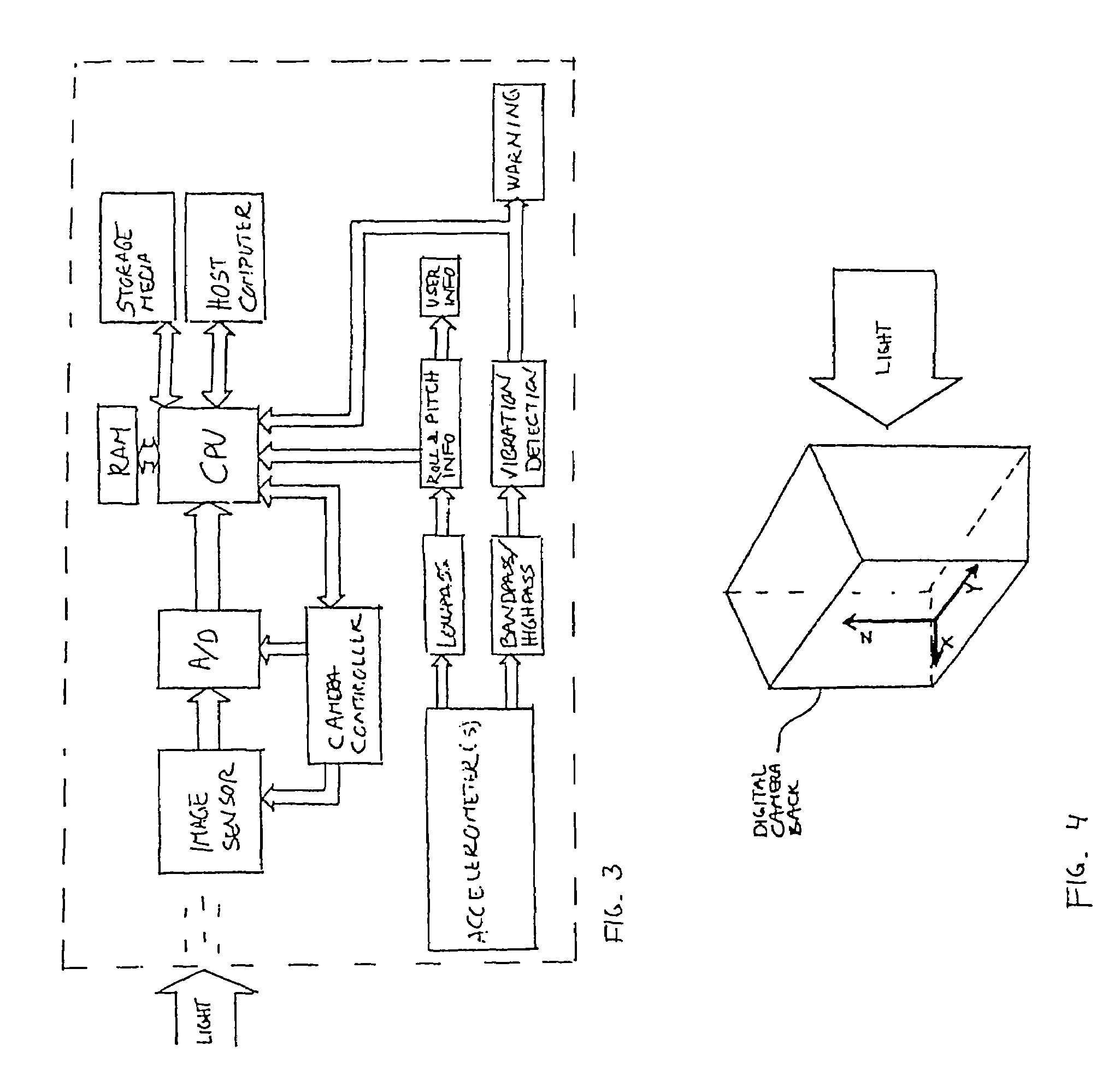

Digital camera with integrated accelerometers

ActiveUS7554578B2Reduce moiré image defectIncrease sharpnessTelevision system detailsTelevision system scanning detailsDigital cameraComputer graphics (images)

A digital camera system has integrated accelerometers for determining static and dynamic accelerations of the digital camera system. Data relating to static and dynamic accelerations are stored with recorded image data for further processing, such as for correcting image data for roll, pitch and vibrations and for displaying recorded images with a predetermined orientation using information about, e.g., roll. Data may also be used on-the-fly for smear suppression caused by vibrations.

Owner:PHASE ONE

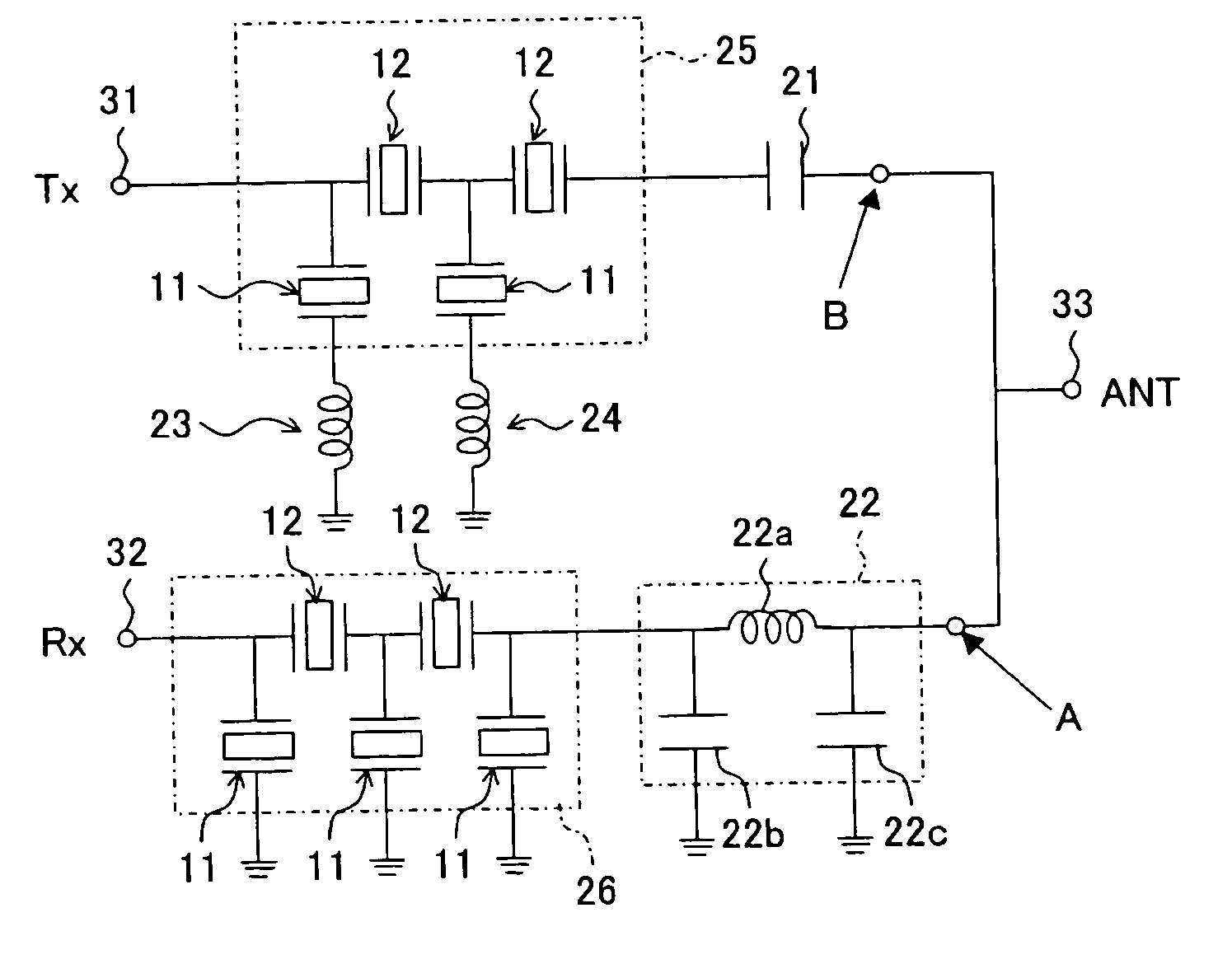

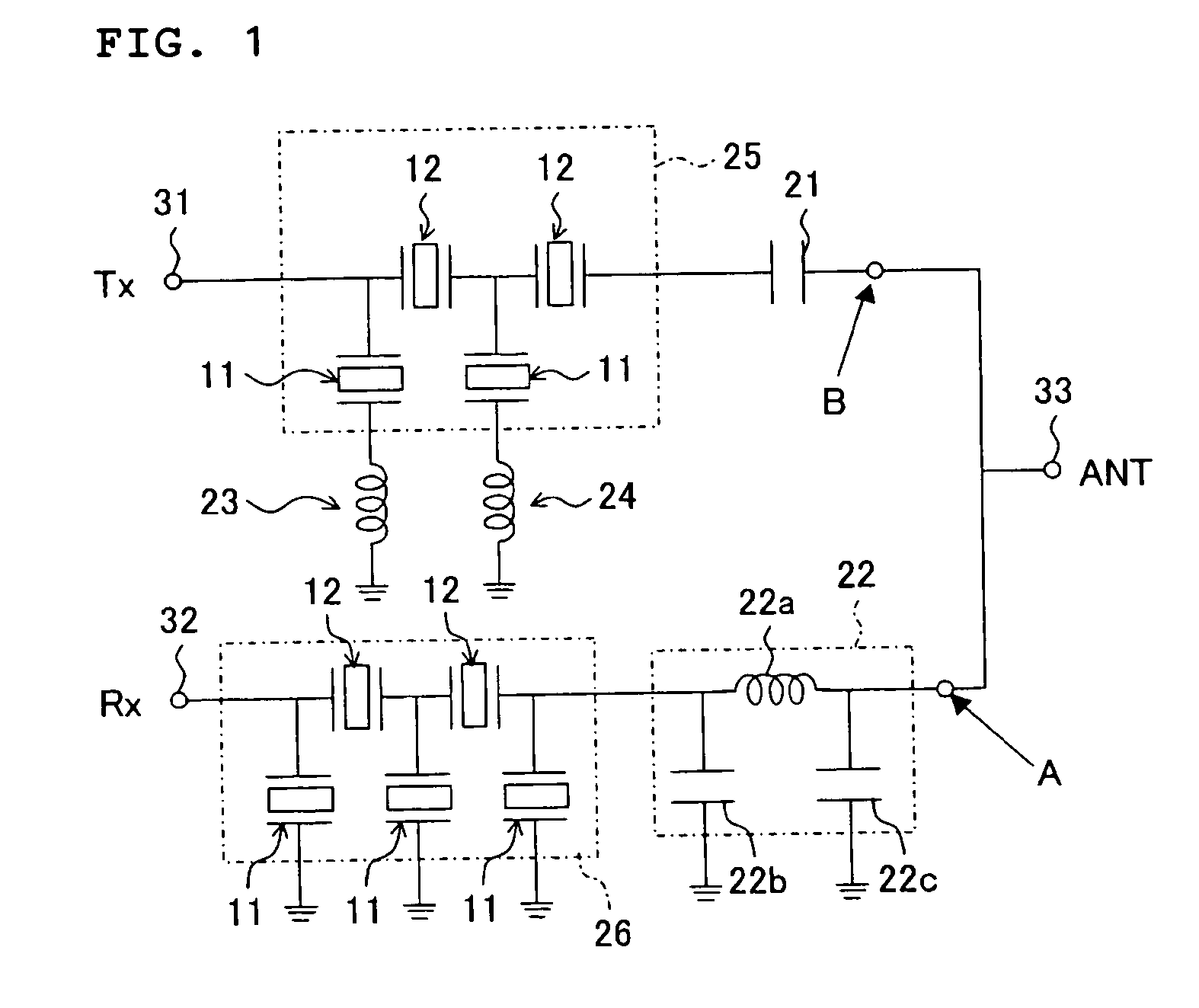

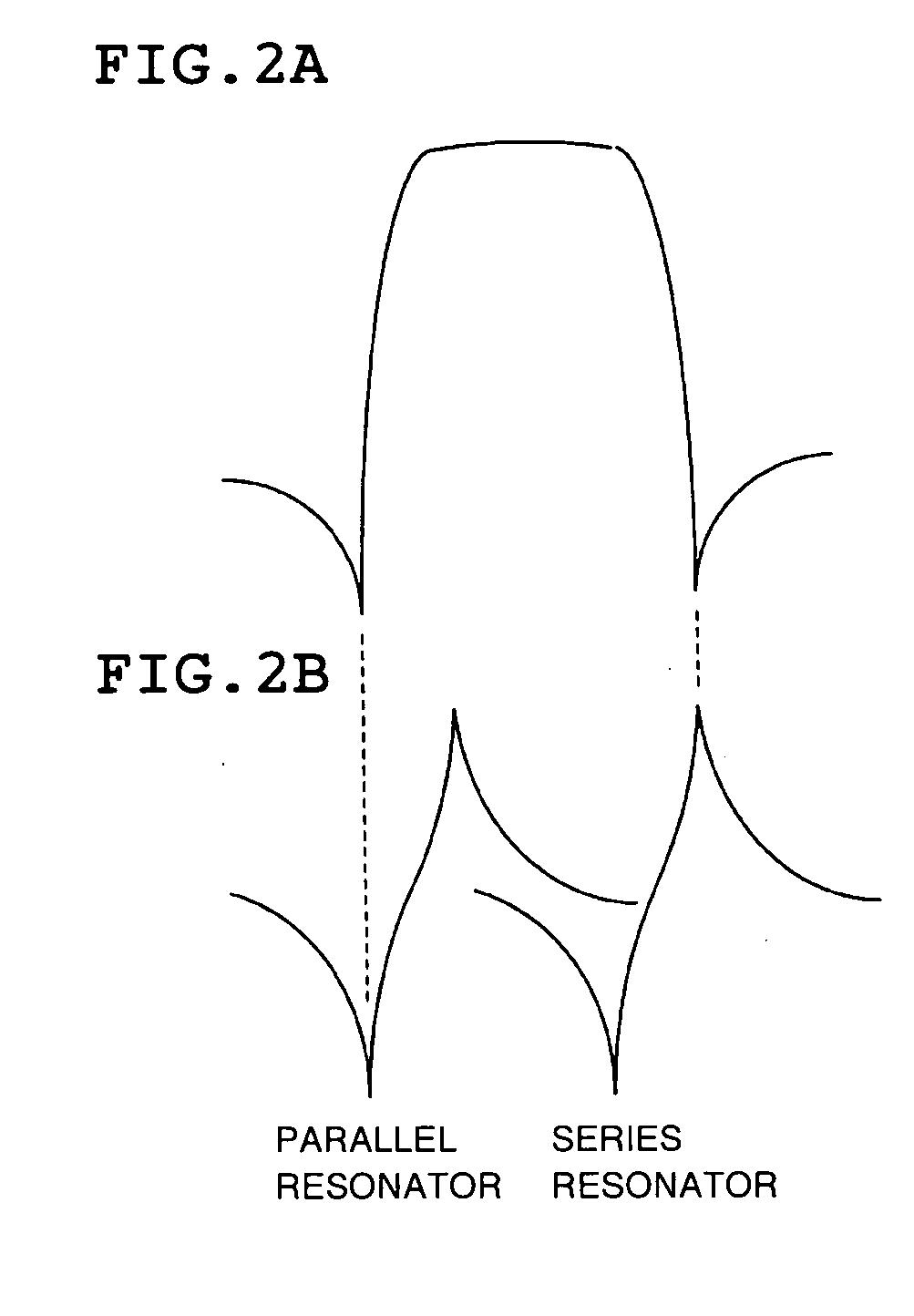

Branching filter and communication device

ActiveUS20050174192A1Excellent isolation characteristicIncrease sharpnessImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesPhysicsCapacitance

A branching filter includes an antenna terminal, a transmission-side filter and a reception-side filter which are connected in parallel to the antenna terminal, and a matching circuit positioned between the antenna terminal and the reception-side filter. The reception-side filter is a ladder-type filter in which the frequency of a series resonator is higher than the antiresonant frequency of a parallel resonator. The transmission-side filter is a ladder-type filter and is the capacitance in the passband of the reception-side filter, and, because of the capacitance, the inductance of the impedance of the reception-side filter, when seen from the antenna terminal side, is reduced.

Owner:MURATA MFG CO LTD

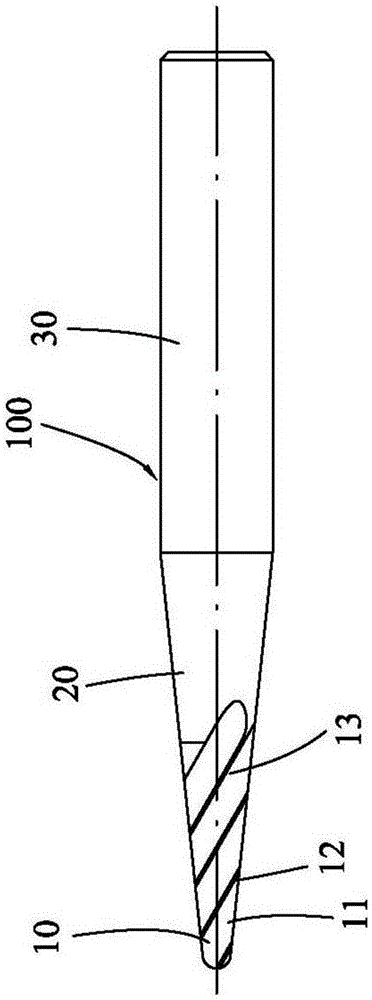

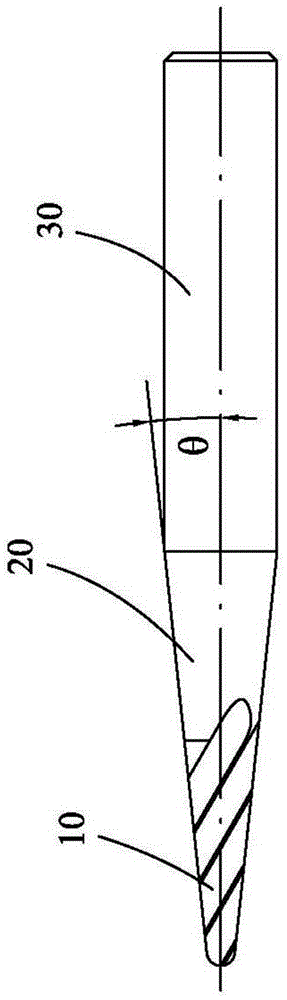

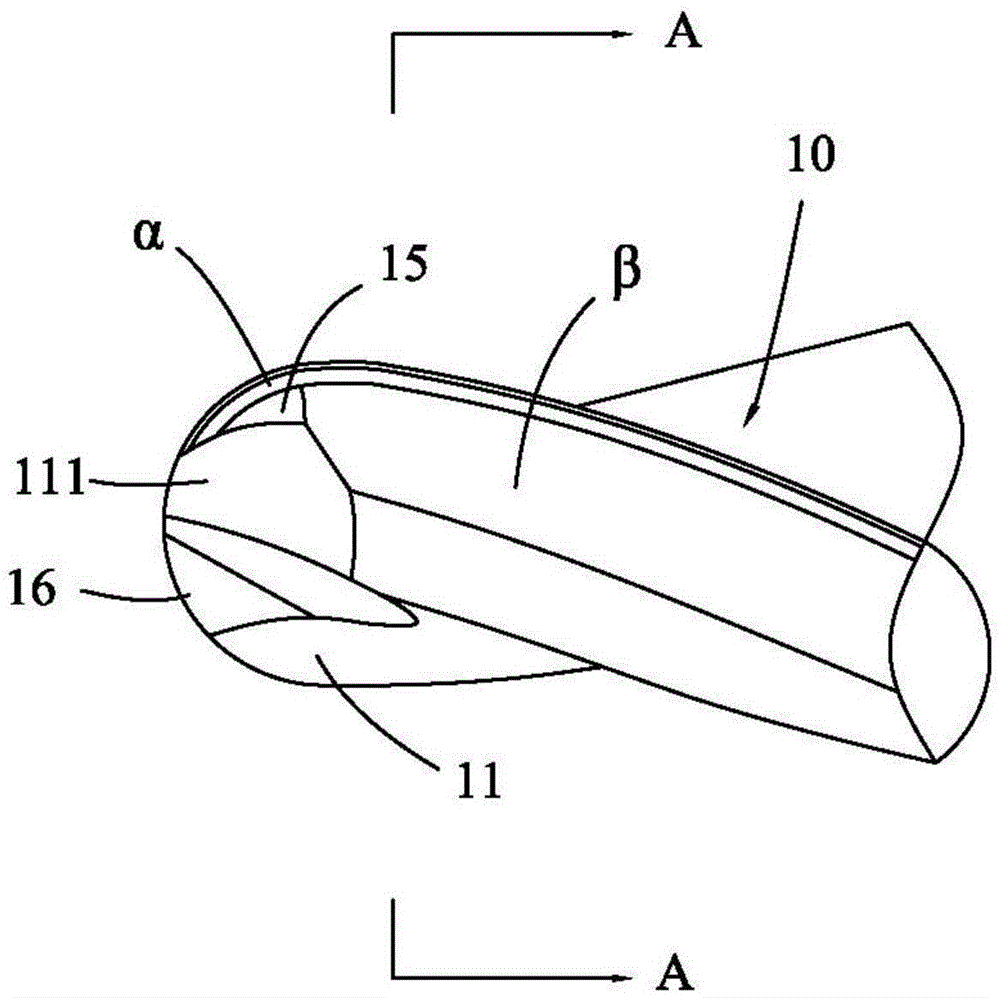

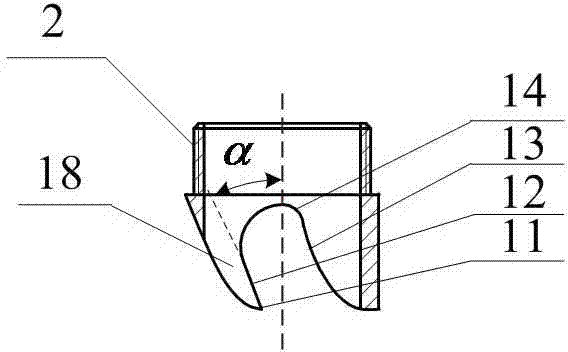

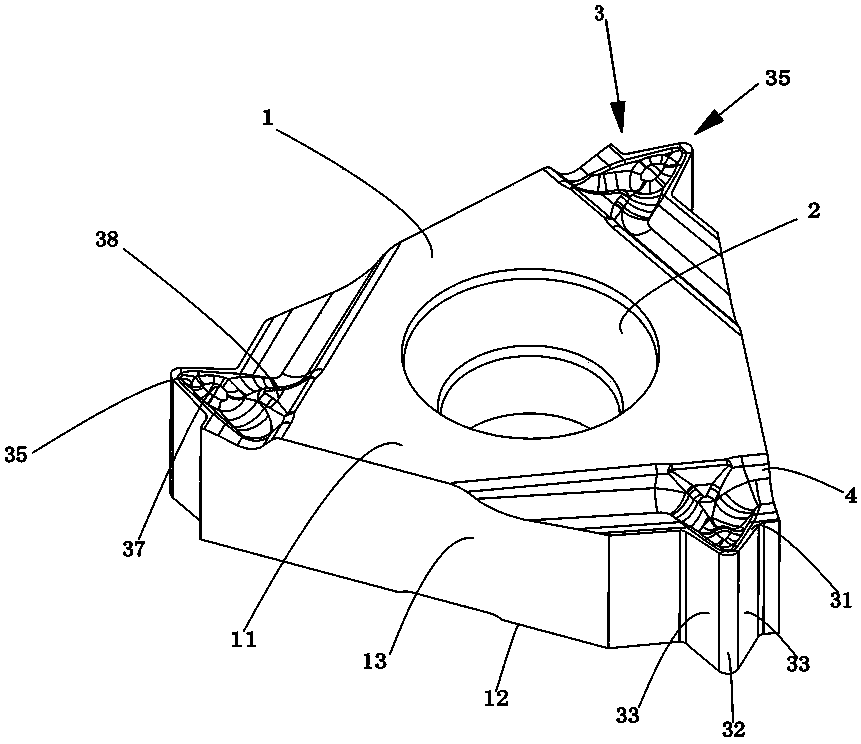

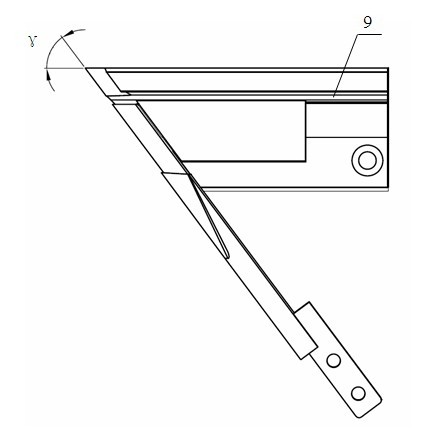

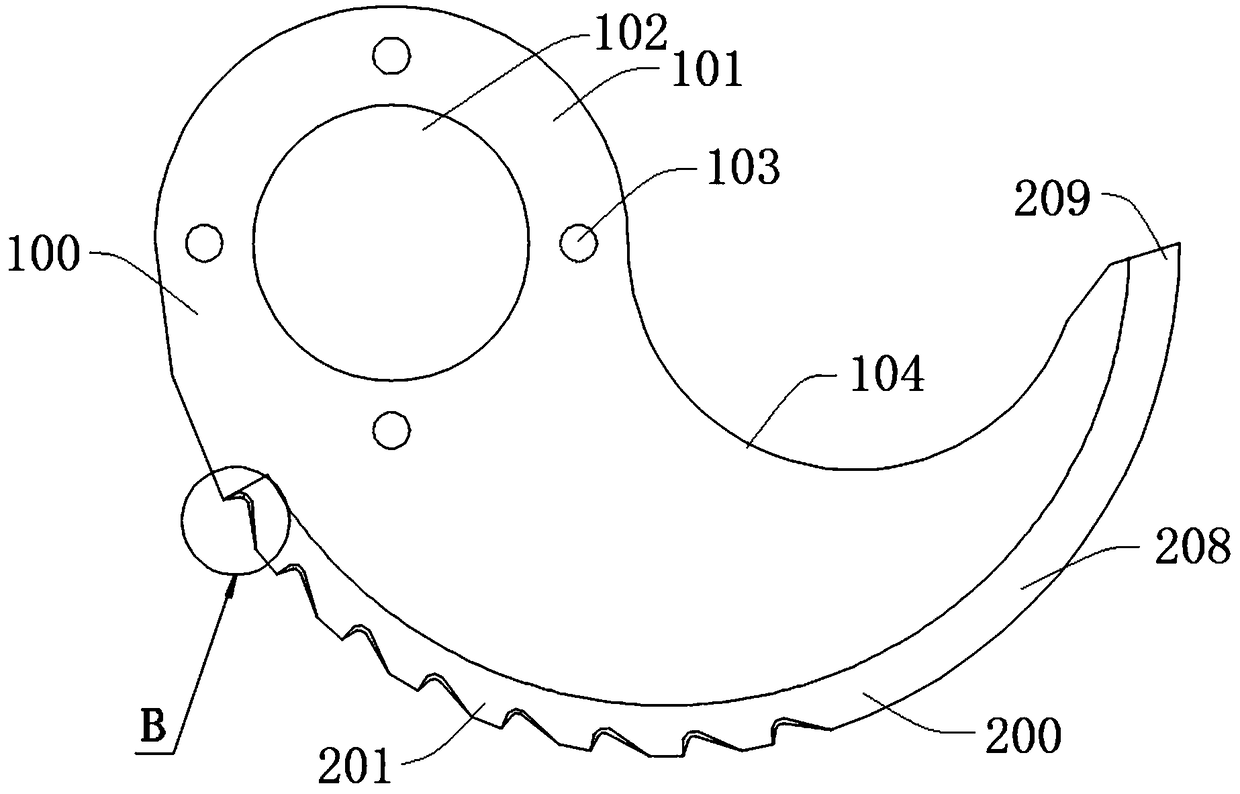

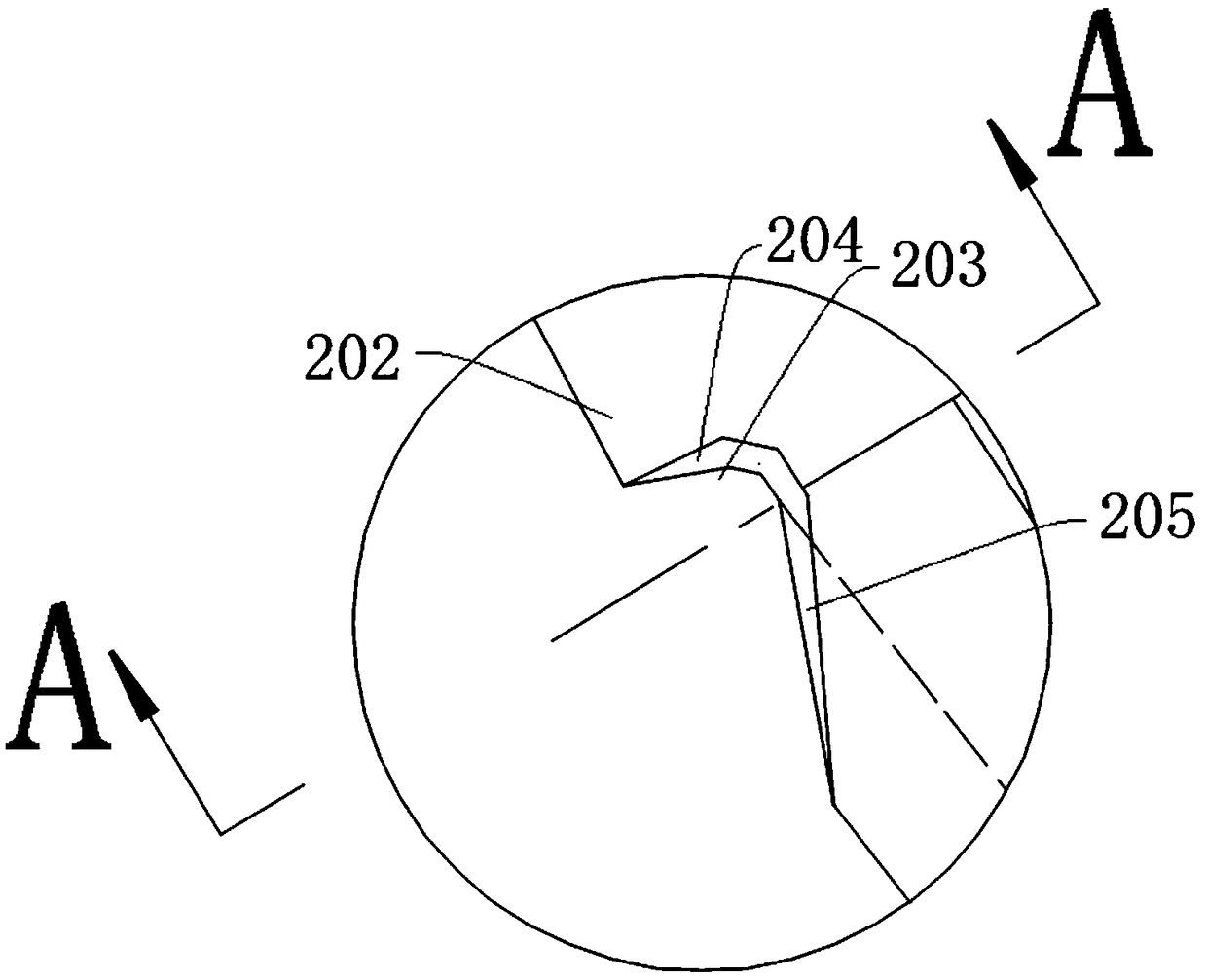

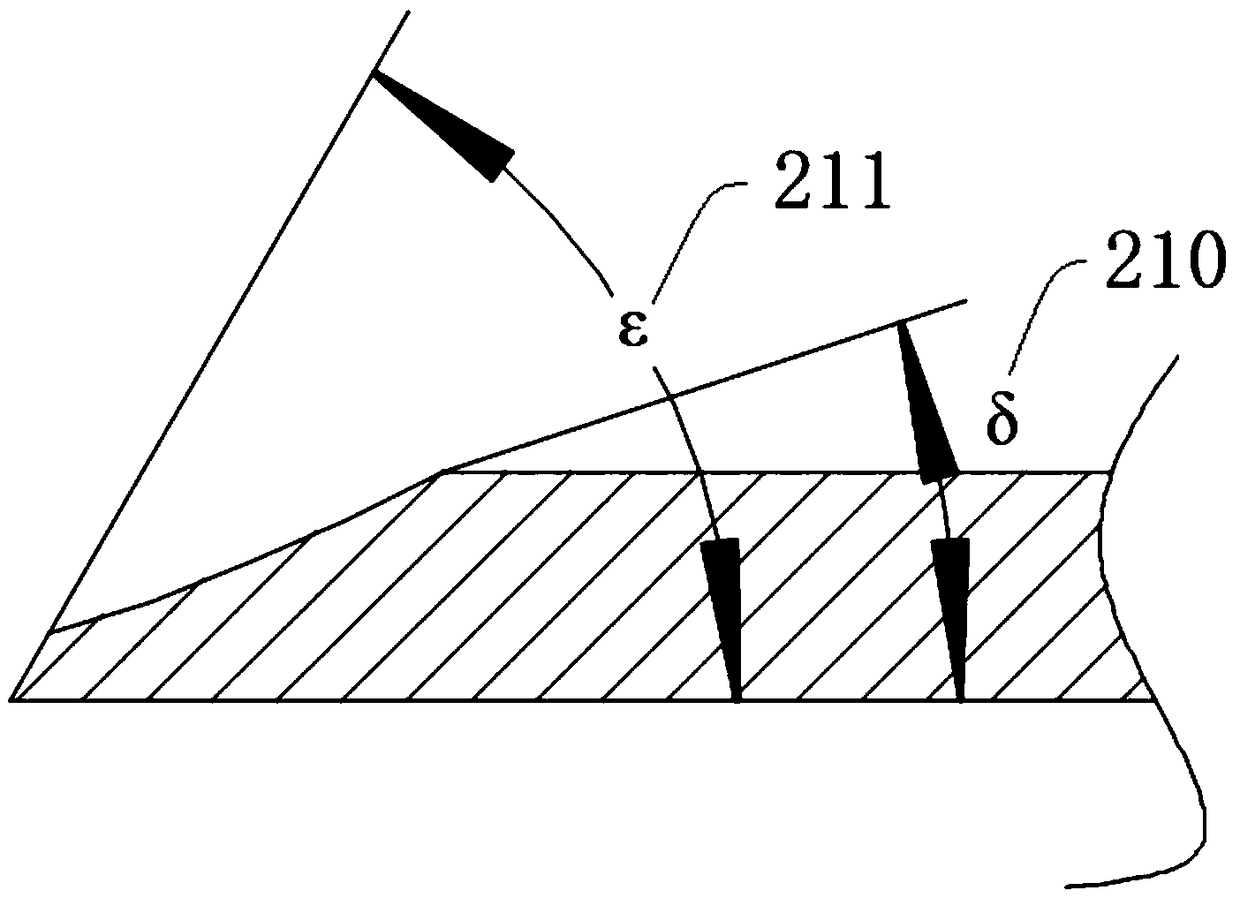

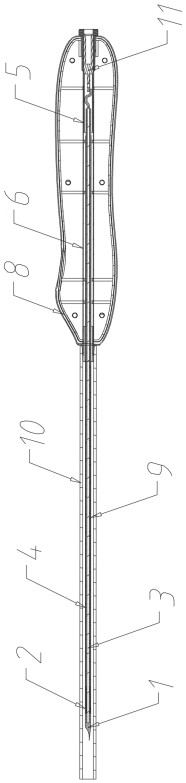

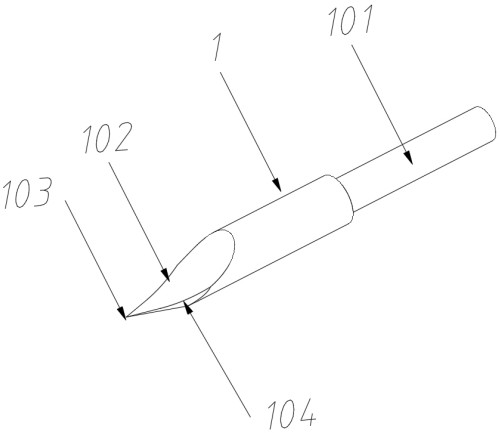

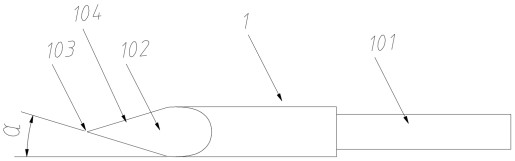

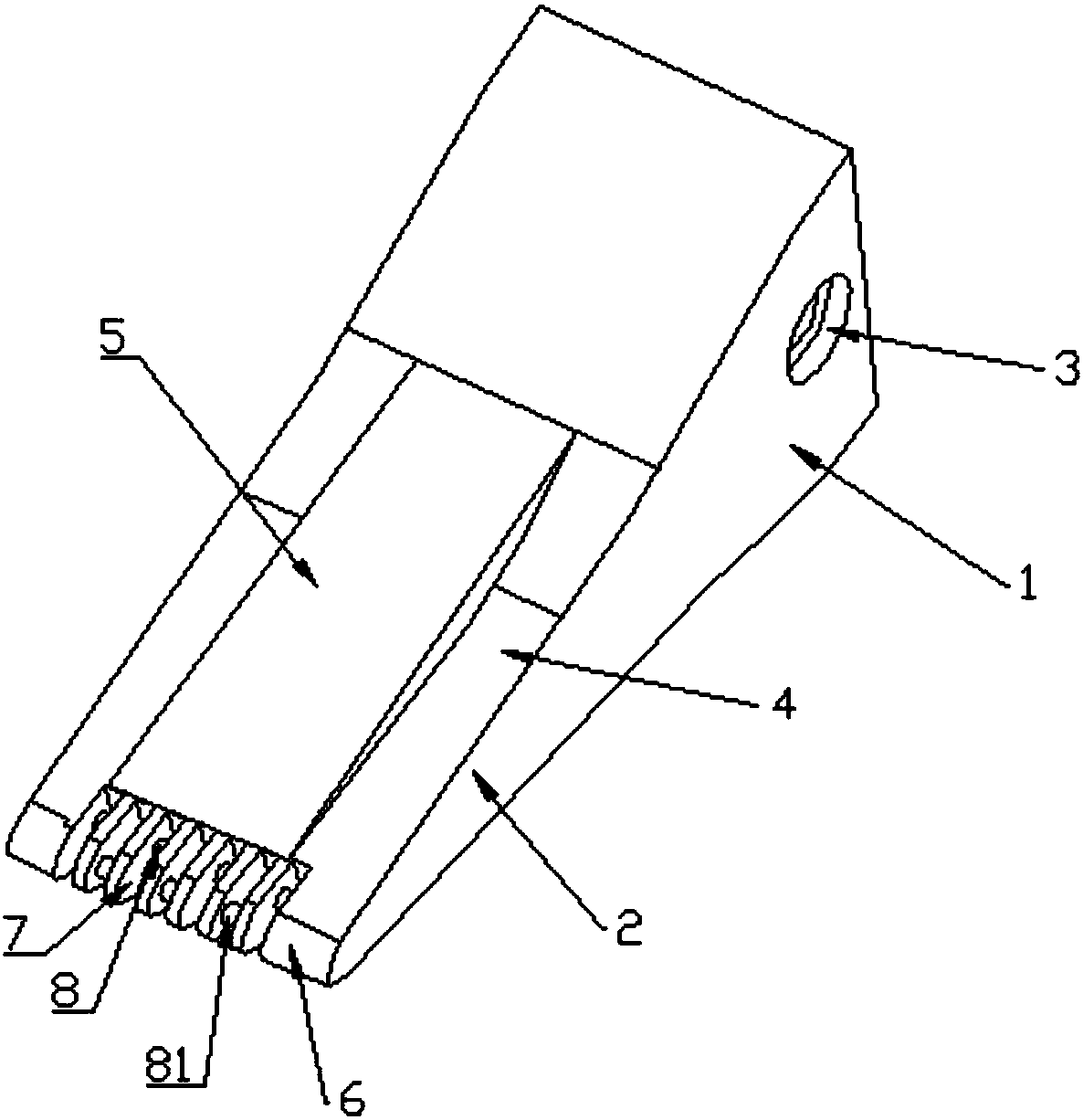

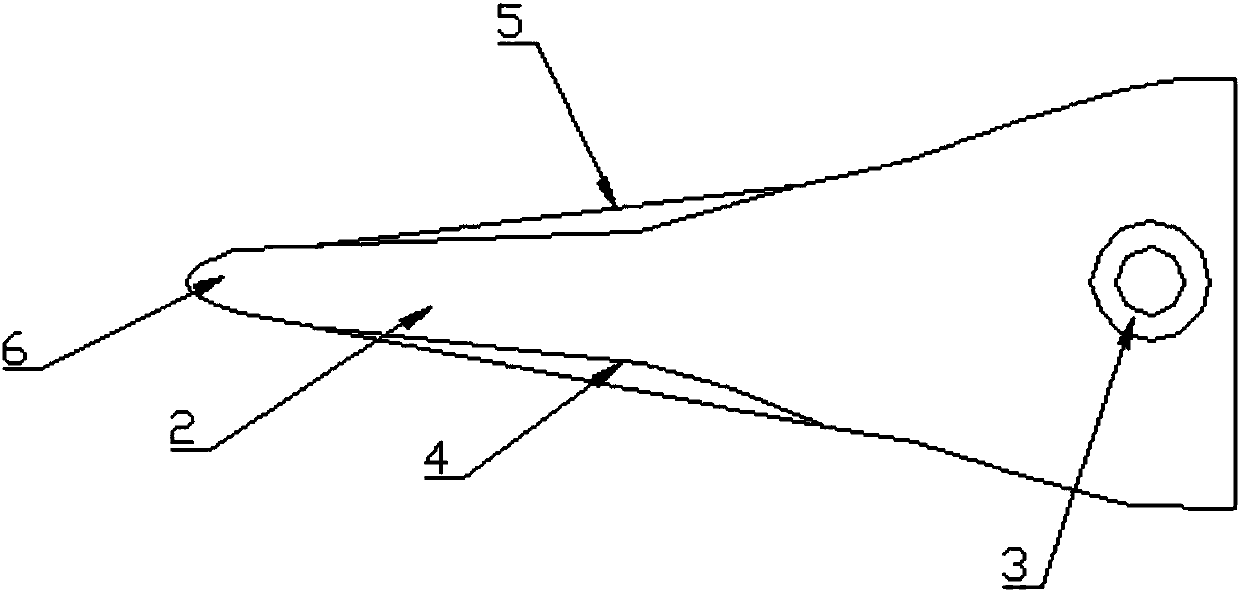

Taper and ball-end milling cutter

InactiveCN105642986AIncrease sharpnessGuaranteed StrengthMilling cuttersMilling cutting insertsMilling cutterNeck parts

The invention provides a taper and ball-end milling cutter. The milling cutter comprises a head part, a neck part connected with the head part, and a handle part connected with the neck part, wherein the head part is provided with a chip removal slot, an entity part used for forming the chip removal slot, and a cutting edge formed at an intersection line between the chip removal slot and the entity part, wherein the cutting edge is provided with a front cutter face and a rear cutter face, the front cutter surface and the rear cutter surface are contacted and form a front angle, and the rear cutter face of the cutting edge and a machining piece are contacted and form two rear angles, including the first rear angle and the second rear angle respectively. According to the taper and ball-end cutter provided by the invention, the front angle and the rear angles are reasonably designed, so that the rigidity of the milling cutter is guaranteed, the sharp degree of the milling cutter is guaranteed at the same time, and the probability of burr generation in a milling process is effectively reduced; the taper and ball-end milling cutter has a long service life and can keep good surface roughness when machining an aluminum alloy pressure wheel.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

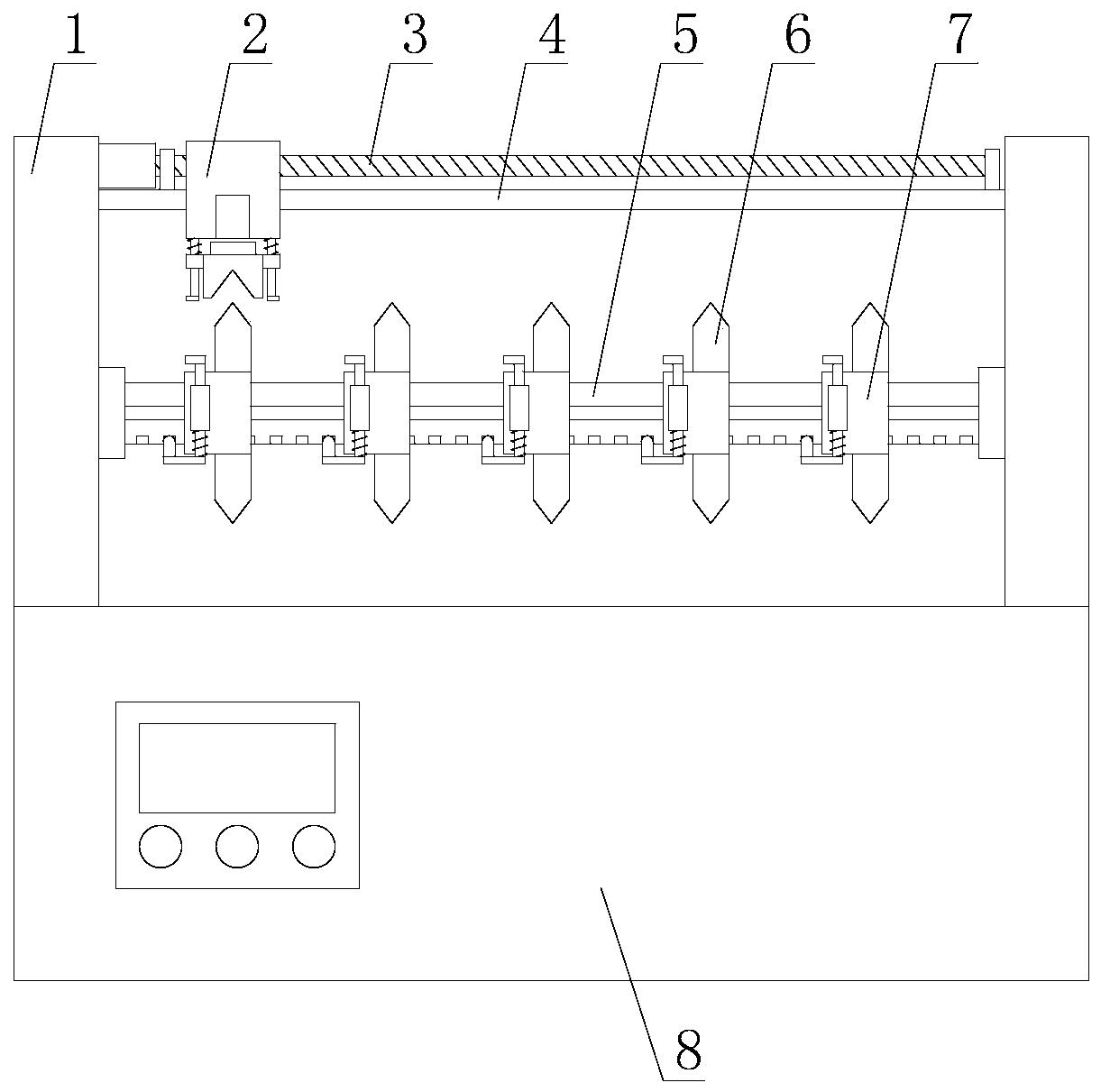

Splitting machine with adjusting function for film production

InactiveCN110065100AImprove practicalityImprove work efficiencyMetal working apparatusArticle deliveryKnife bladesElectromagnet

The invention relates to a splitting machine with an adjusting function for film production. The splitting machine comprises a base, two supports, a splitting mechanism and a polishing mechanism, wherein the splitting mechanism comprises a rotating roller, at least two limiting grooves and at least two cutting assemblies; each cutting assembly includes a moving sleeve, blades, a first support rod,a second support rod, a limiting rod, and two connection units; and the polishing mechanism comprises a guide rail, a driving assembly, a moving base, an electromagnet, a permanent magnet, a polishing block and two connection assemblies. According to the splitting machine with the adjusting function, the distance between each blade can be adjusted through the splitting mechanism so that the splitting machine can adjust the width of slit films according to the requirements; the practicability of the splitting machine is improved; and the abraded blades can be polished through the polishing mechanism, so that the sharpness of the blades is improved, the cutting capacity of the blades is improved, and the working efficiency of the splitting machine is improved.

Owner:夏士桀

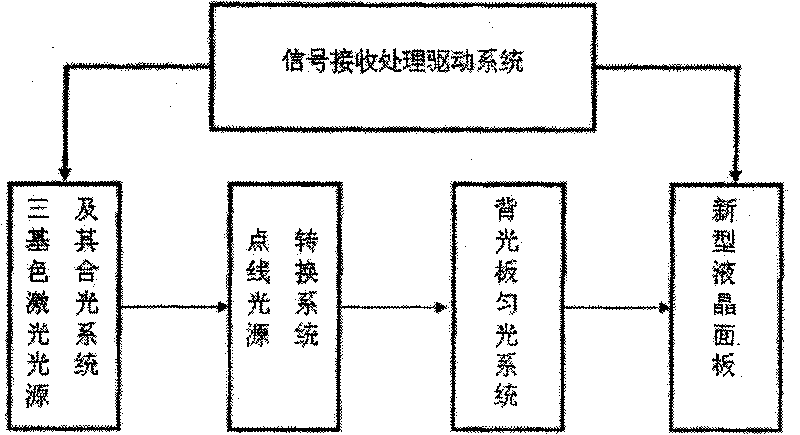

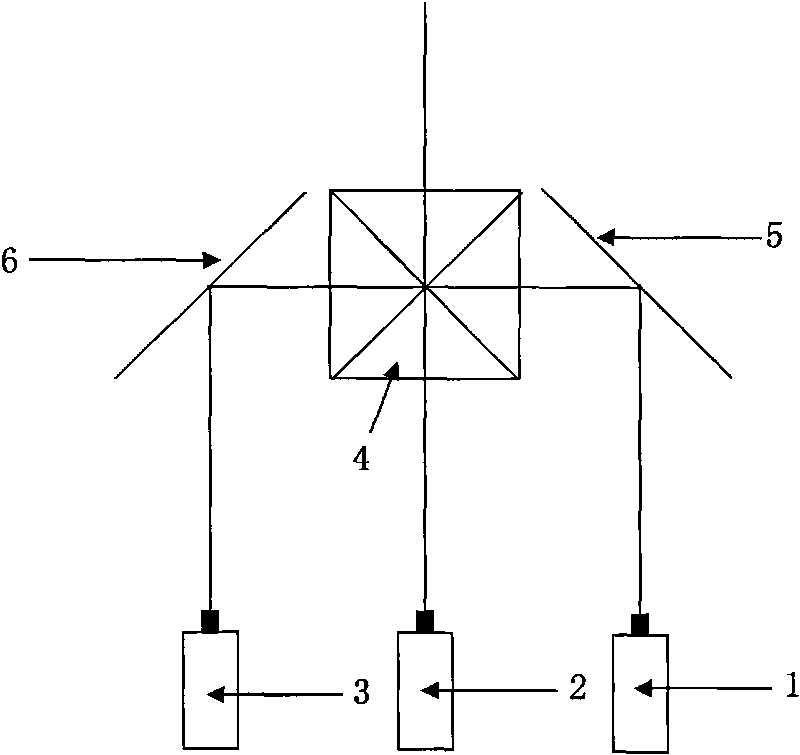

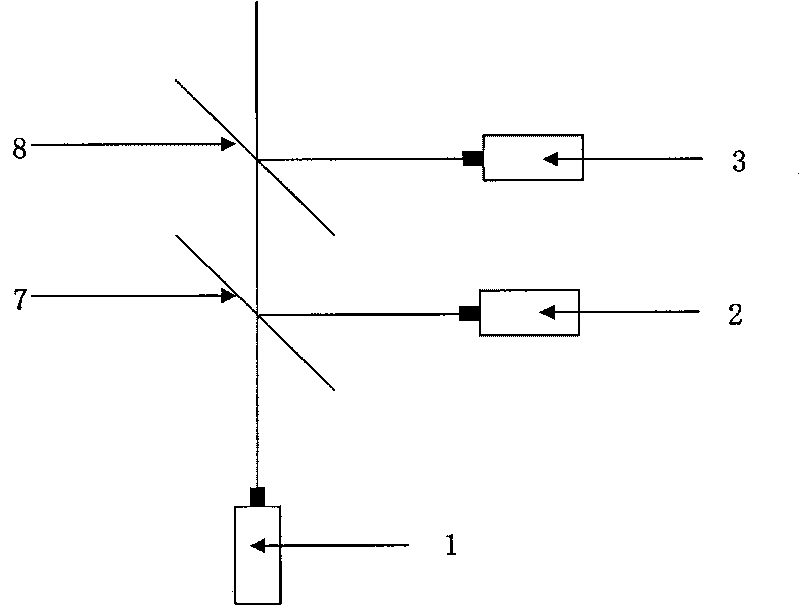

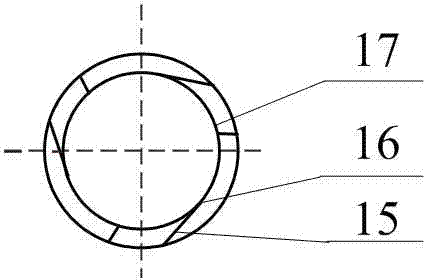

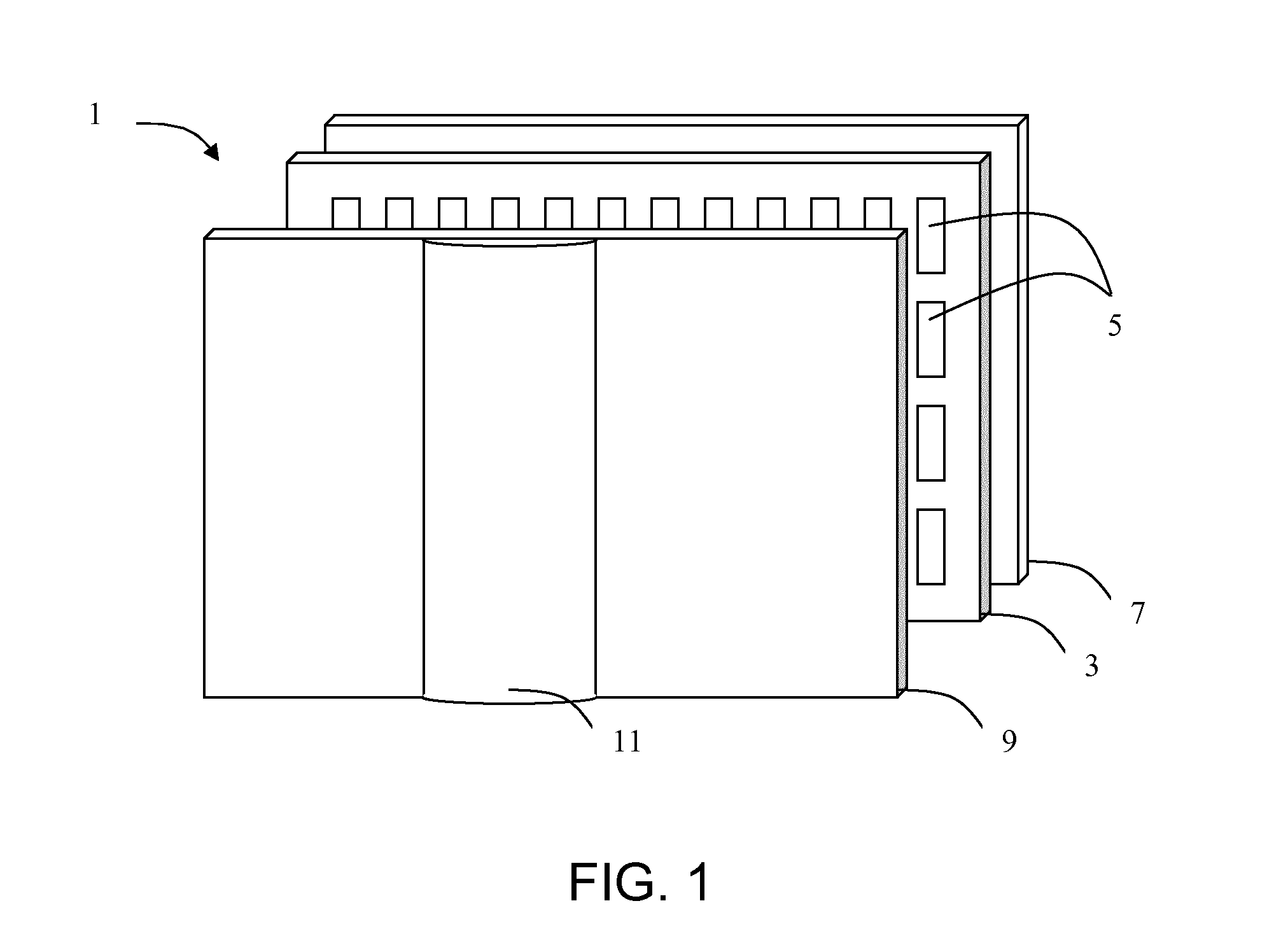

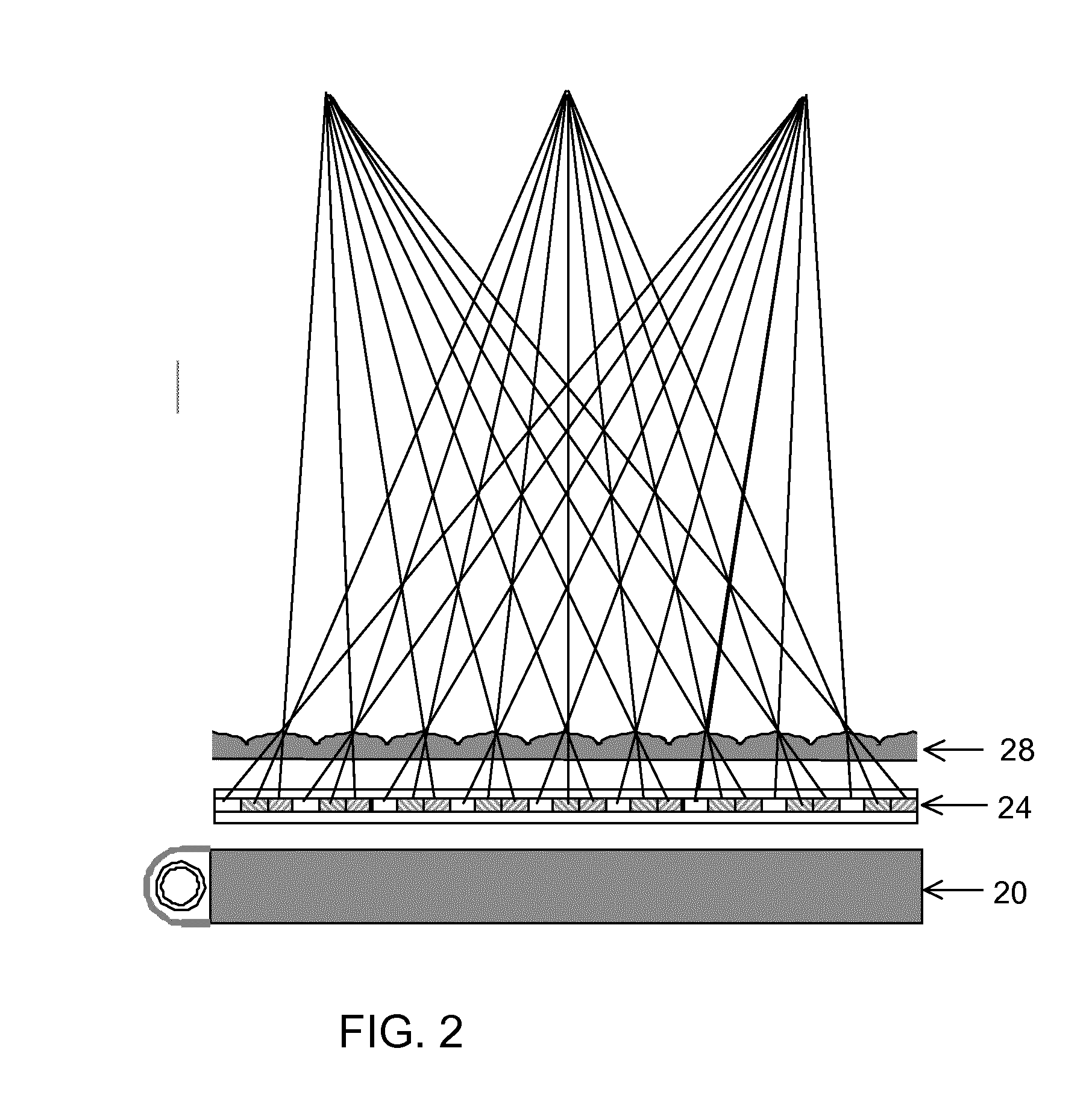

Laser backlight liquid crystal display (LCD) system

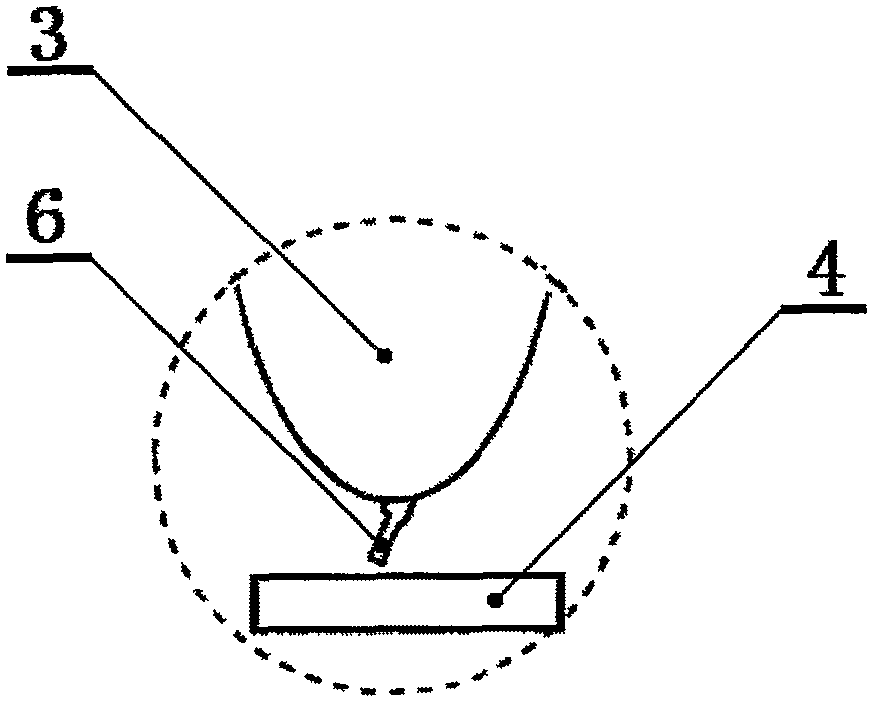

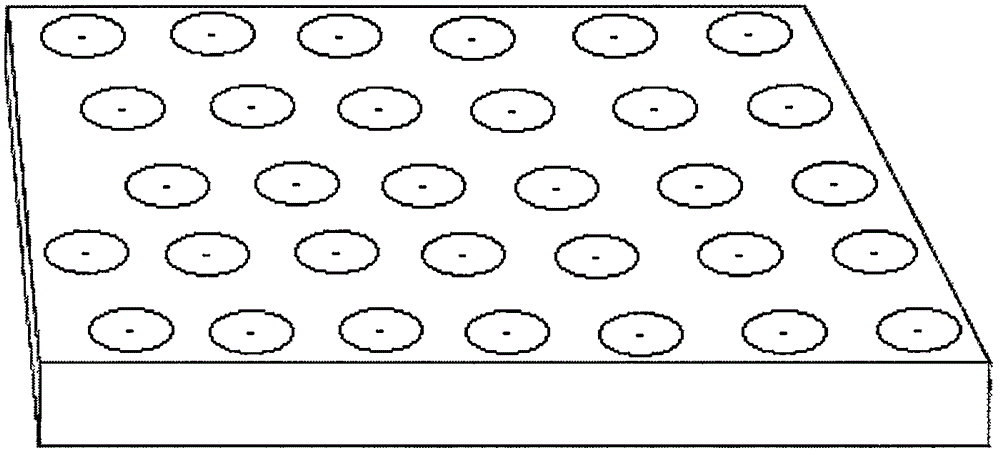

InactiveCN101702063AImprove color gamutImprove light energy utilization and spatial resolutionMechanical apparatusStatic indicating devicesPersistence of visionLight source

The invention provides a laser backlight liquid crystal display (LCD) system which comprises a laser source with three primary colors, a light combination system, dot line light source switching system(s), a backlight plate, a liquid crystal plate and a signal receiving and processing drive system, wherein the light combination system is positioned between the laser source and the dot line light source switching system(s), the dot line light source switching system(s) is / are positioned at one or two side(s) of the backlight plate, the liquid crystal plate is positioned on the backlight plate, and the liquid crystal plate is connected with the signal receiving and processing drive system. By adopting the laser with the three primary colors, high brightness and good monochromaticity as the backlight, and the liquid crystal plate without a colored filter film, the system can realize the laser sequential display way by controlling the sequential luminescence of a laser with the three colors by timing sequence, and utilizes the characteristic of persistence of vision of human eyes to realize time color mixture, thus greatly expanding the displayed color gamut, and improving the optical energy utilization rate and the space resolution rate; furthermore, as the front of the liquid crystal plate is stuck with a view field angle expanded film, the view field can be expanded.

Owner:SHANDONG UNIV

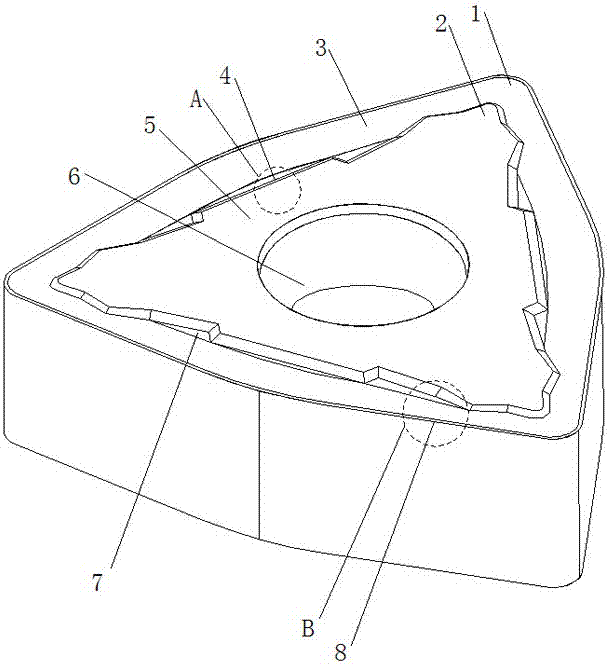

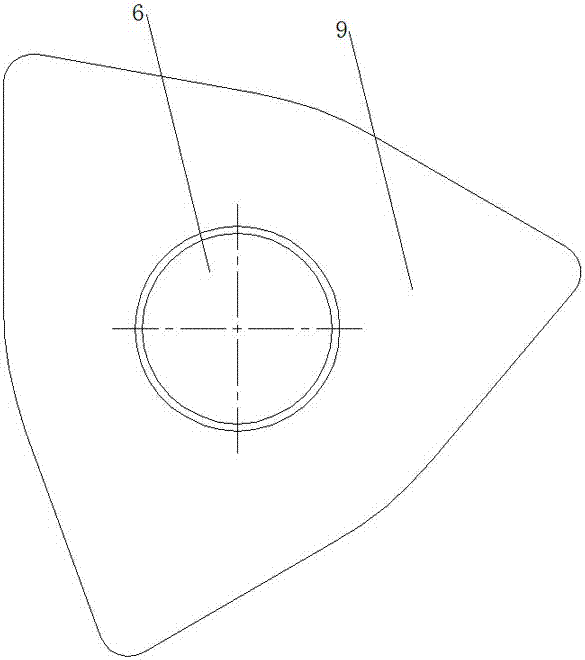

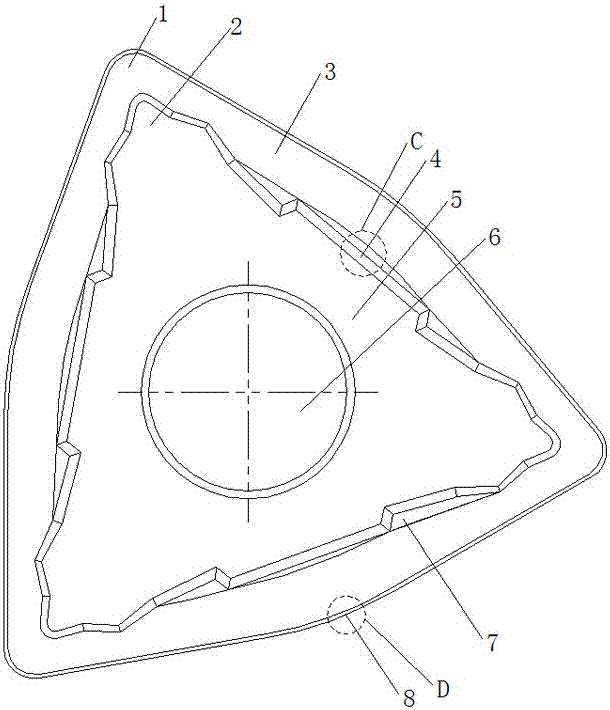

Reversible holes turning insert

The invention provides a variable-position turning cutter in polyton shape for accurately turning the internal hole, which comprises upper and lower surfaces and several side walls. Wherein, the side walls intersect the upper surfaces to form the cutting edge; and the upper surface forms the rack face of cutting edge. Said invention is characterized in that: two nearby side walls via taper surface are connected to form back face; upper surface, side wall and arc surface are intersected to form an angle of cutting edge; the cutting edges are symmetry distributed relative to the geometry bipartition of said angle of cutting edge to form spatial spiral line shape while the top edge is highest; a groove is arranged in the middle of top part of said cutting edge angle which also has a chip-breaker groove formed by spherical boss in said groove; the tail part of spherical boss via generatrix is connected to a cylinder surface with a ª’ relative to horizontal direction and the upper surface of cutting edge; the bottom of said groove is in ellipse shape and same height of the bottom of knife slit; and the side wall and the axes of blade have a included angle of ª‰. The inventive variable-position turning edge has sharp blade, controllable cutting direction and shape, which can remove chip successfully.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

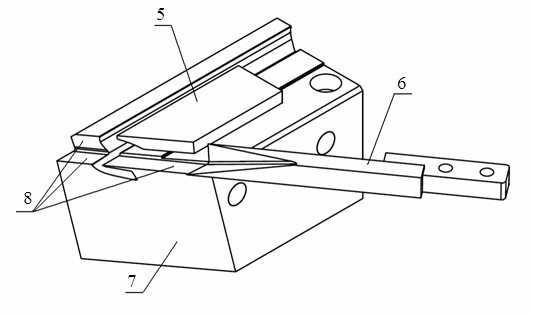

Flat and round cutter and manufacturing method thereof

ActiveCN104942879AIncrease sharpnessImprove securityFurnace typesMetal working apparatusEngineeringAlloy

The invention discloses a flat and round cutter and a manufacturing method thereof and belongs to the field of machining of cutters. The flat and round cutter comprises a center hole, a cutter head and a blade, wherein the center hole is located in the center of the cutter head, the blade is located on the outer ring of the cutter head, a cutting edge is arranged on the outer ring of the blade, the cutting edge angle delta of the cutting edge is in a range of 13-18 degrees, and threaded holes and mounting holes are formed in the cutter head. The flat and round cutter is manufactured from an alloy material comprising special elements under strictly controlled technological conditions through steps such as blank forging, isothermal spheroidizing, preliminary processing, heat treatment, rough grinding, leveling, tempering, deep processing and the like, the cutter has very high abrasion resistance while meeting the requirement for the sharpness, the service life is long, and the cutting edge is low in abrasion loss and free of cracking after long-term usage.

Owner:安徽华天机械股份有限公司

Ink jet recording method

InactiveUS6592218B1Increase sharpnessImprove clarityWater-repelling agents additionDuplicating/marking methodsWater dispersibleChemistry

The present invention describes an ink jet printing sheet comprised of a supporting substrate surface treated with a water soluble or water dispersible polyester composition, said polyester having polyoxyalklylene moieties in an effective amount to reduce ink feathering. The instant invention is also directed to papers and transparencies coated with surface treated with a water soluble or water dispersible sulfonated polyester composition, said polyester having polyoxyalkylene moieties in an effective amount to reduce ink feathering. A typical polyester resin useful in the present invention is the reaction product of 20-50% by weight of terephthalate polymer, 10-60% by weight of at least one glycol and 5-70% by weight of at least one oxyalkylated polyol.

Owner:AKZO NOBEL CHEM INC

Efficient motorized geotome without moisture loss

InactiveCN102445360AImprove flexural strengthImprove efficiencyWithdrawing sample devicesFlexural strengthEngineering

The invention provides an efficient motorized geotome without moisture loss. The efficient motorized geotome without moisture loss comprises a power source, wherein the power source is connected with a drill rod through drill rod threads; the drill rod is connected with a drill drum through drill drum threads; the drill drum is internally provided with a bulldozing screw rod, and the lower part of the drill drum is connected with a drill head through drill head threads; and the length of the drill drum is at least 30cm, and the length of the drill rod is at least 50cm. By utilizing the technical scheme of the invention, three cutting teeth are uniformly distributed on the drill head, the root parts of the cutting teeth are provided with cutter root circular arcs, thus the flexural strength of the cutting teeth is enhanced, and the service efficiency of the drill head is improved; and based on the design that the cutting face of the drill head is tangential to an inner cylindrical faceand the secondary cutting edge of the drill head is tangential to the cutter root circular arcs and is transitioned to a cutter tip structure through natural circular arcs, the one-time drilling depth of the drill head is ensured to be deeper, and the service efficiency of the drill head is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY

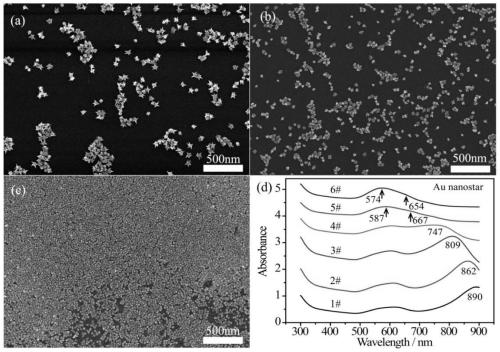

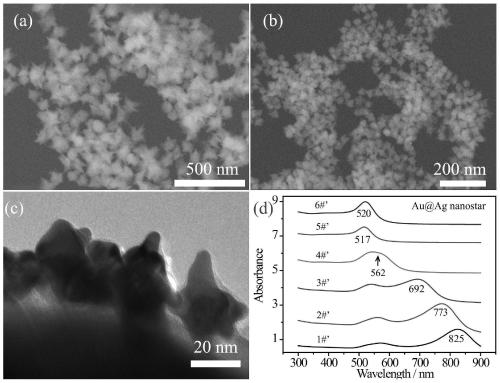

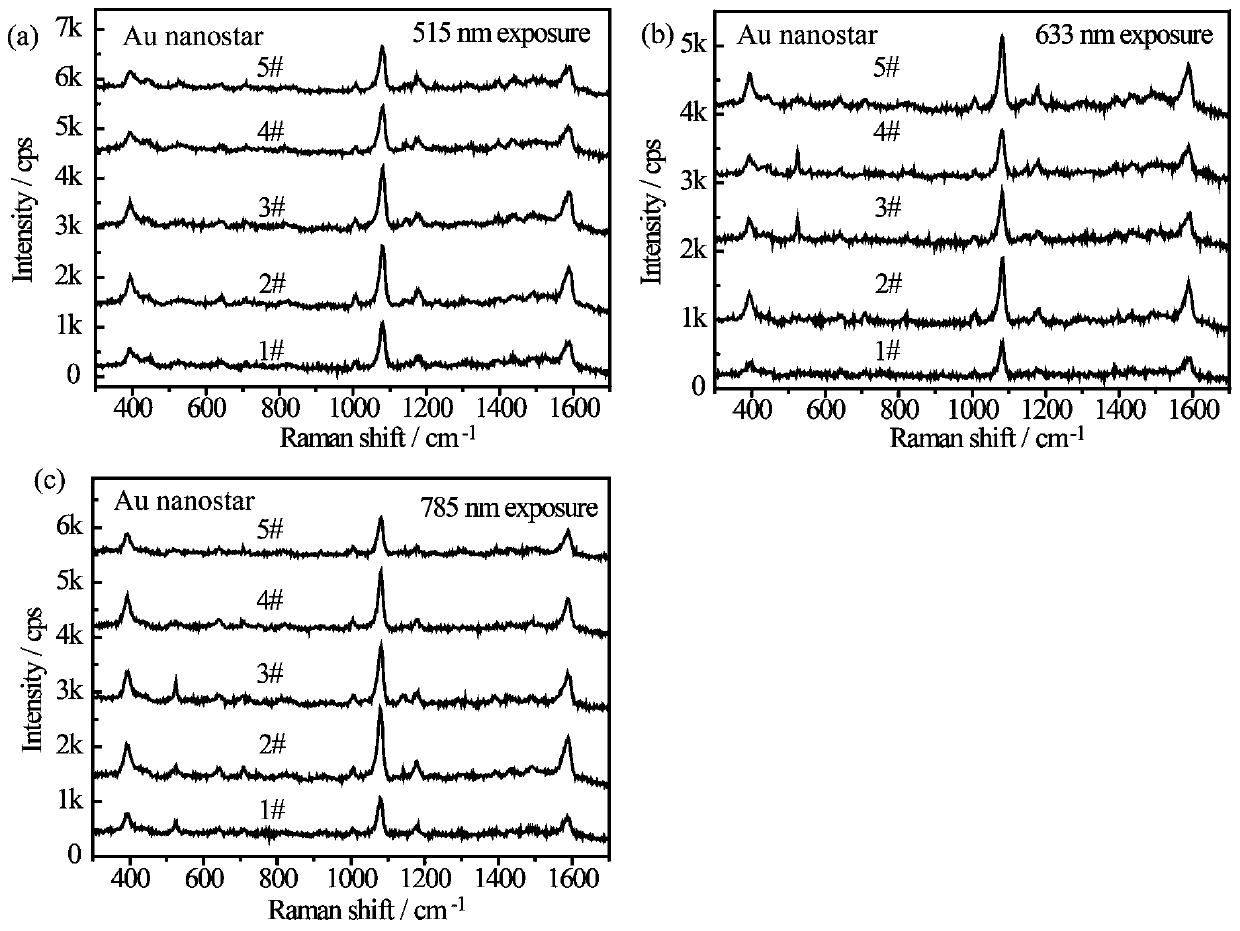

LSPR adjustable gold@silver core-shell nanostar and preparation method thereof

ActiveCN111299570AHigh activityLower conversion rateMaterial nanotechnologyTransportation and packagingPhotocatalytic reactionSolar chemical

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

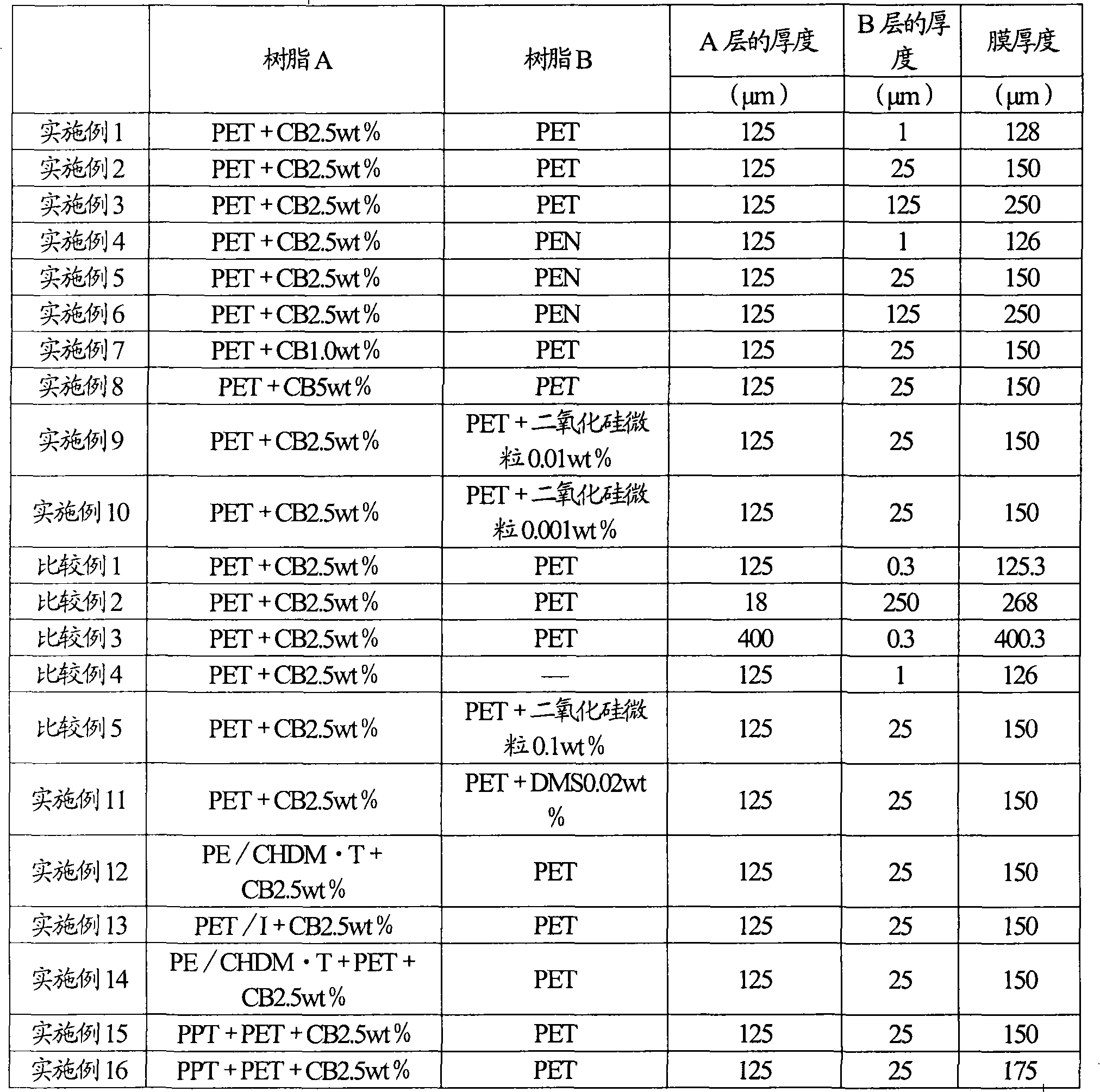

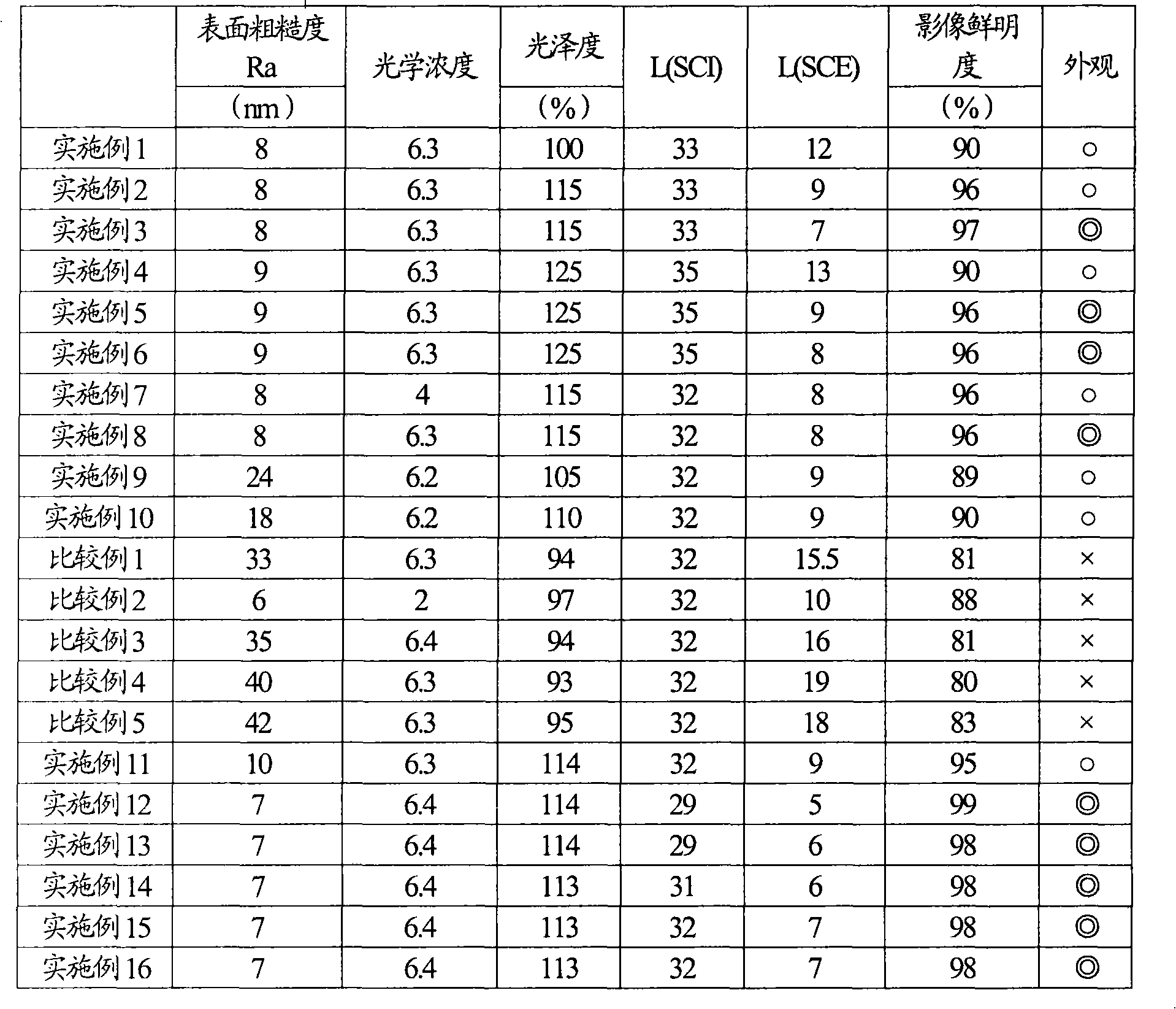

Laminated film and molded object

InactiveCN101610901AIncrease sharpnessPrevent damage and dirtSynthetic resin layered productsConstructions elementsPolymer chemistryMaterials science

A pitch-black decorative film in the surface of which highly clear images are reflected and which has a deep and glossy appearance like pianos. The laminated film is characterized by comprising at least one resin layer (layer (A)) containing a black ingredient and at least one resin layer (layer (B)) which is substantially colorless and transparent, the layer (A) having a thickness of 20-300 [mu]m and the layer (B) having a thickness of 0.5-200 [mu]m. The film is further characterized in that the layer (A) adjoins the layer (B) and the surface on at least one side has a surface roughness Ra of 1-25 nm.

Owner:TORAY IND INC

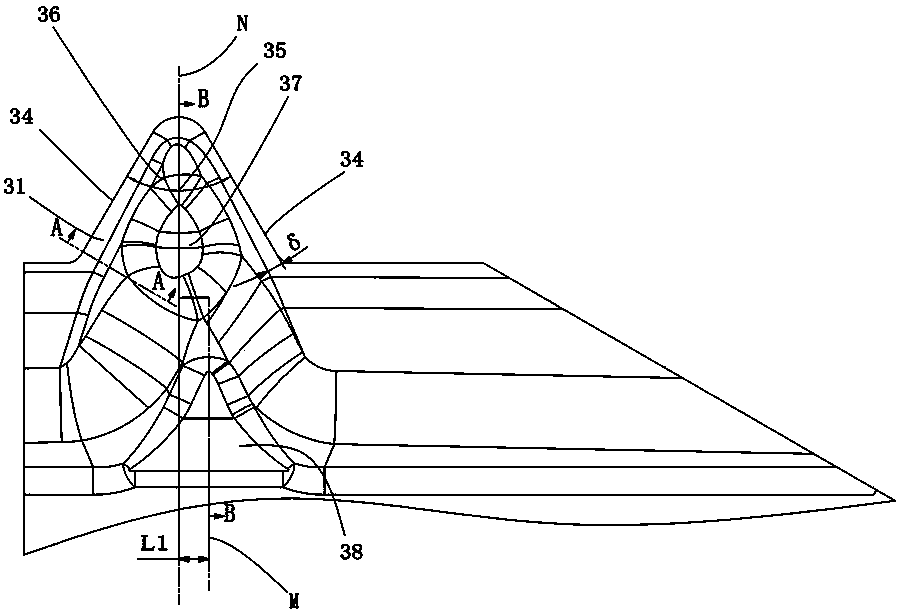

Thread machining blade

ActiveCN103639543AReduced contact area and frictionIncrease cooling areaThread cutting toolsMachiningEngineering

The invention discloses a thread machining blade which comprises a blade body. The blade body is provided with a blade center hole and cutting edge parts. Each cutting edge part is defined by a front blade surface, a cutting edge angle arc surface and two cutting edge angle side surfaces in an enclosed mode, wherein the two cutting edge angle side surfaces intersect with the front blade surface to form two side cutting edges, the included angle between the two side cutting edges is a cutting edge angle, the front blade surface is connected with the upper surface of the blade body through a connecting curved surface, the front blade surface is provided with a chip guiding groove which is arranged in a symmetric mode relative to the angular bisector N of the cutting edge angle, a spherical chip breaking boss higher than the front blade surface is formed in an outward protruding mode from the inside of the chip guiding groove, a triangular chip breaking boss is formed by extending from the connecting curved surface towards the inside of the chip guiding groove, and the triangular chip breaking boss is connected with the chip guiding groove in a circular arc transition mode. The thread machining blade has the advantages that machining is easy and fast, chips are low in friction in the flowing process, the degree of finish of a workpiece thread is high, the blade is high in strength, machining efficiency can be effectively improved, and production cost is lowered.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

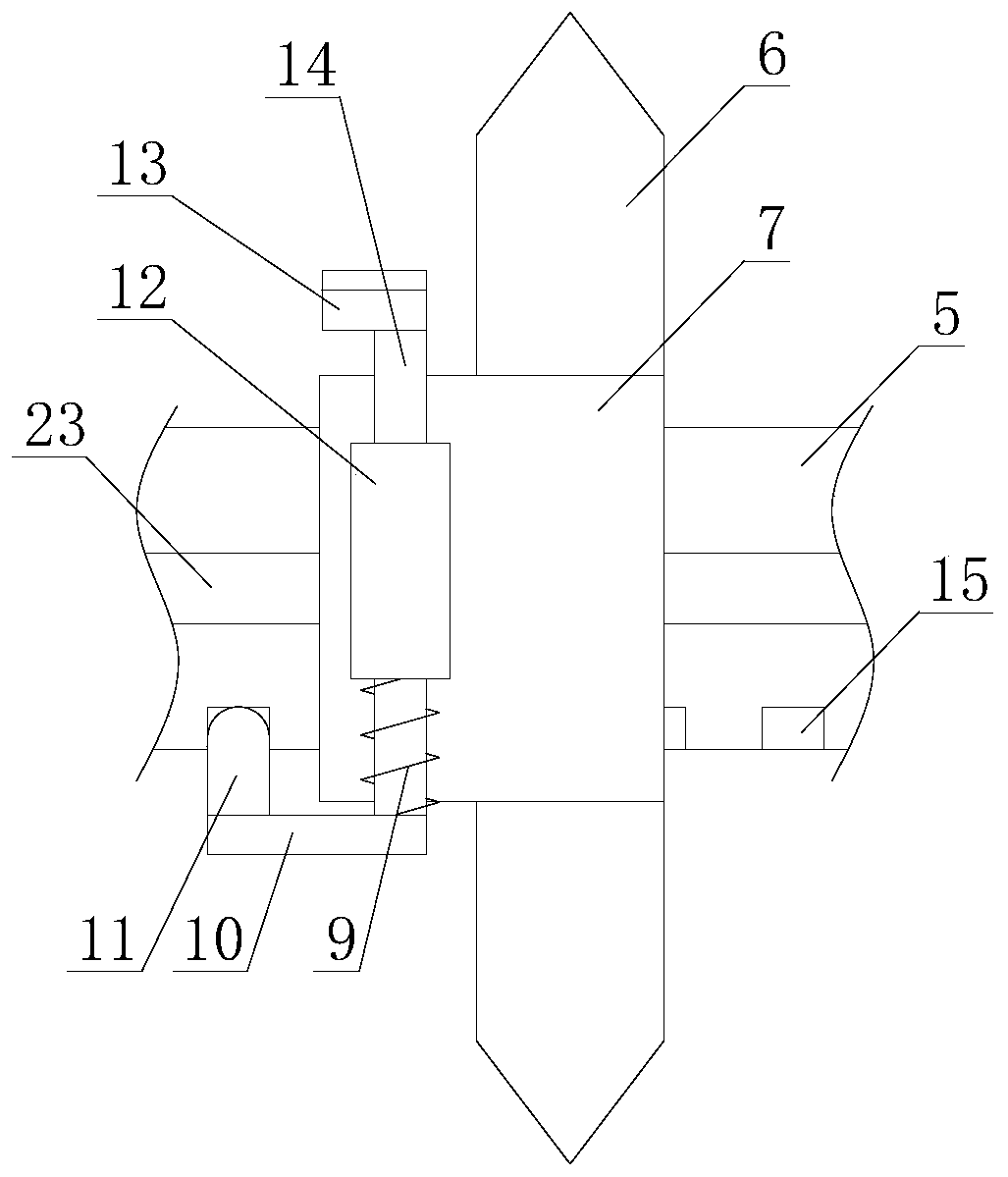

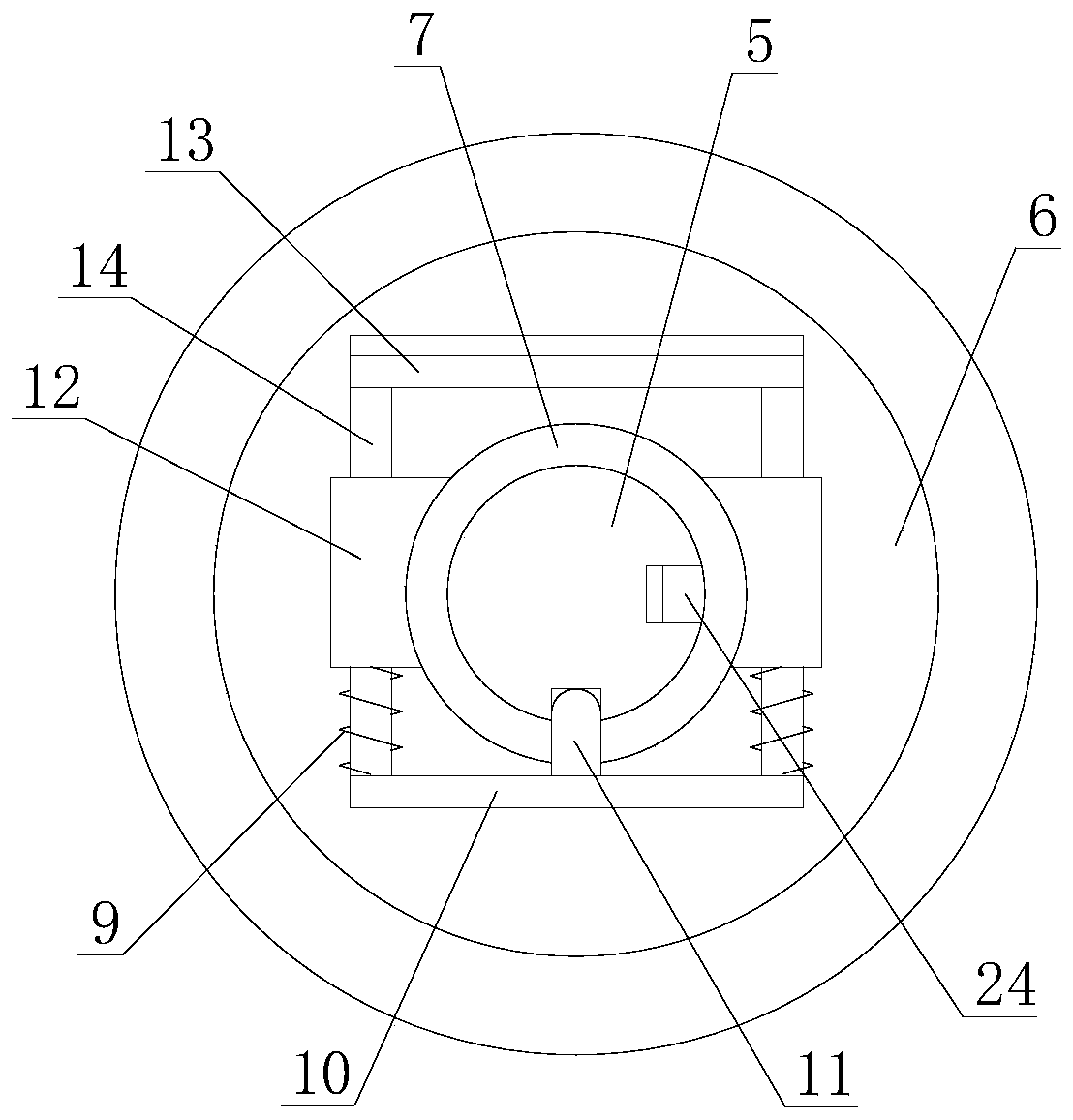

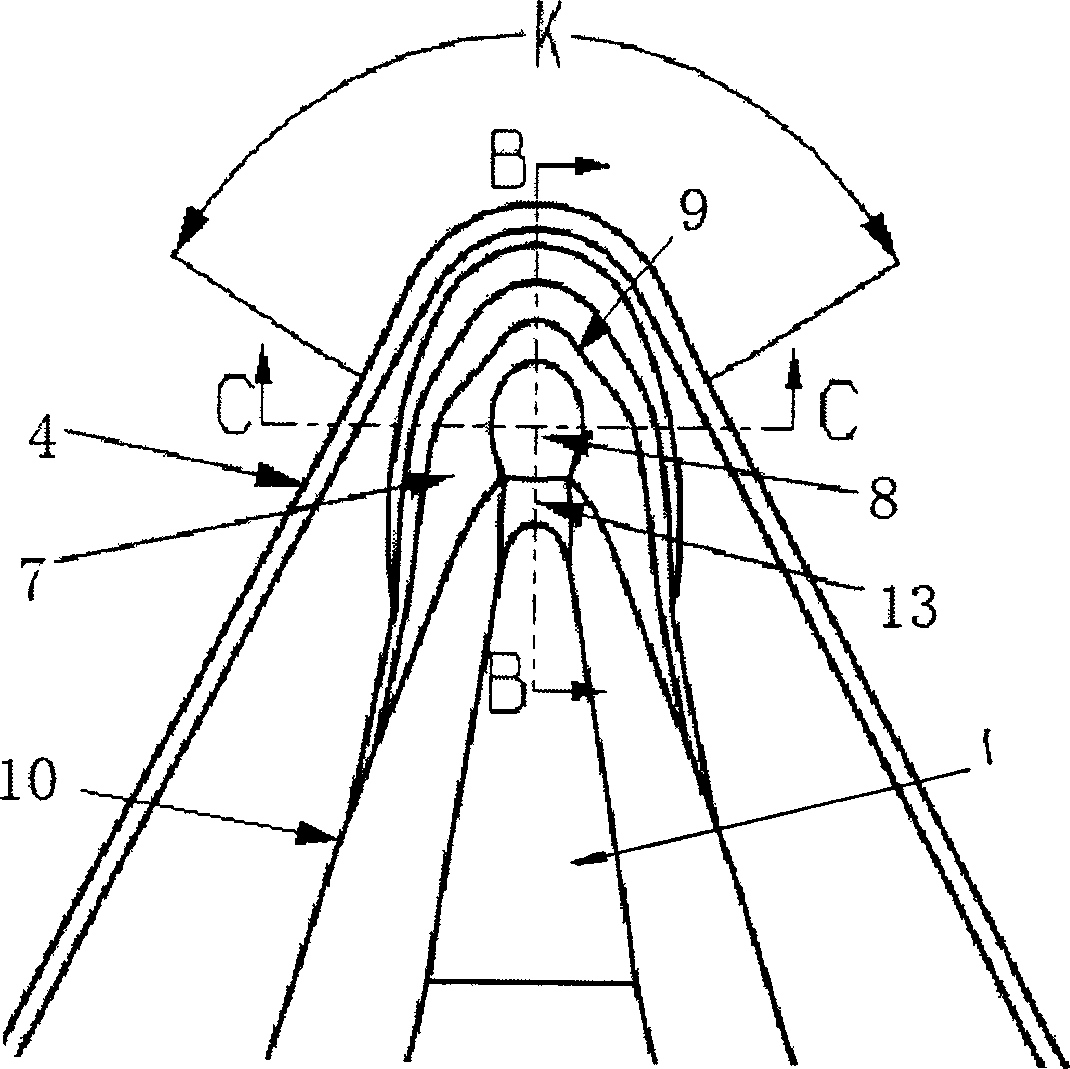

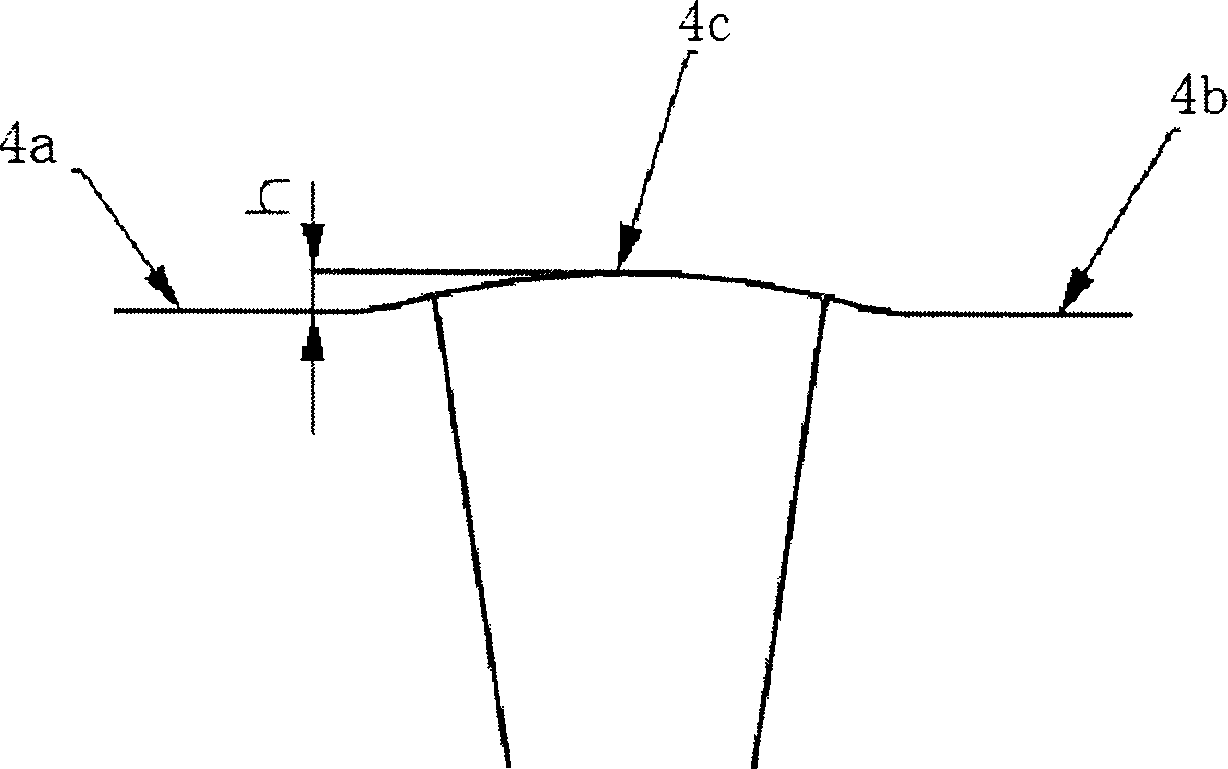

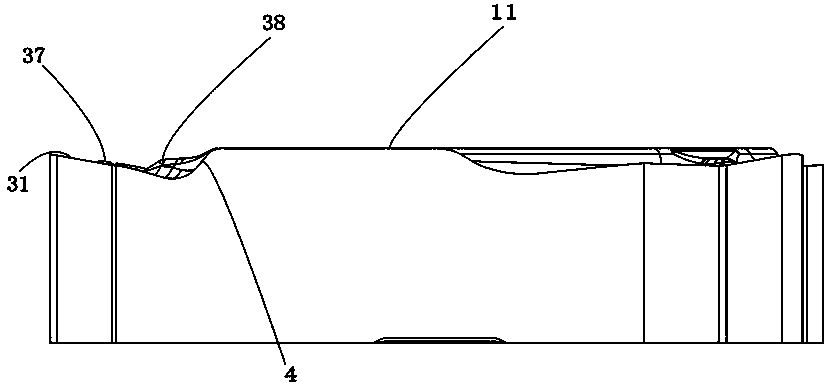

Punching device preventing automobile sealing strip with skeleton from machining deformation

A punching device preventing an automobile sealing strip with a skeleton from machining deformation comprises a female die 7, a pressure plate 5 and a cutter 6, and is characterized in that a groove 9 for placing the sealing strips and a guide mechanism 8 for guiding the cutter 6 to finish the punching operation are arranged on the female die 7; the guide mechanism 8 is intersected with the groove 9 to form a guiding included angle Gamma; the cutter 6 is provided with a horizontal cutting edge 12 and a vertical cutting edge 10; the moving direction of the horizontal cutting edge 12 and the moving direction of the cutter 6 form a cutting edge included angle Beta 1; one end, far from the pressure plate 5, of the horizontal cutting edge 12 inclines towards the punching advance direction of the cutter 6; the cutting edge included angle Beta 1 is smaller than the guiding included angle Gamma; in punching, the sealing strips are cut step by step by the horizontal cutting edge 12 at first, then are cut by the vertical cutting edge 10, so that the impulsive force of the cutter 6 on the sealing strips is reduced, and the deformation of the sealing strips is further reduced, the incision surfaces of the sealing strips are smooth, and the skeleton deformation is avooided.

Owner:瀚德(中国)汽车密封系统有限公司

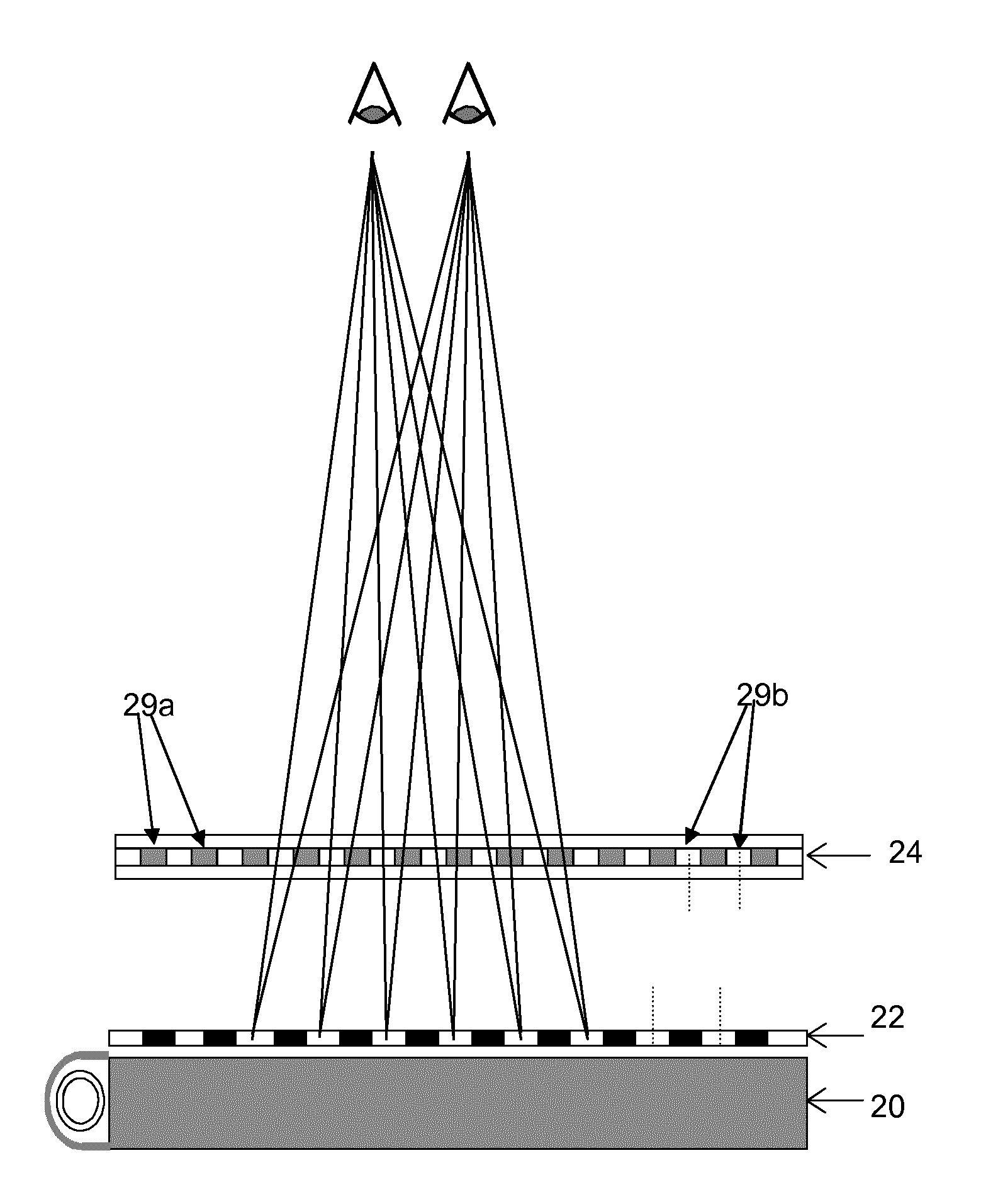

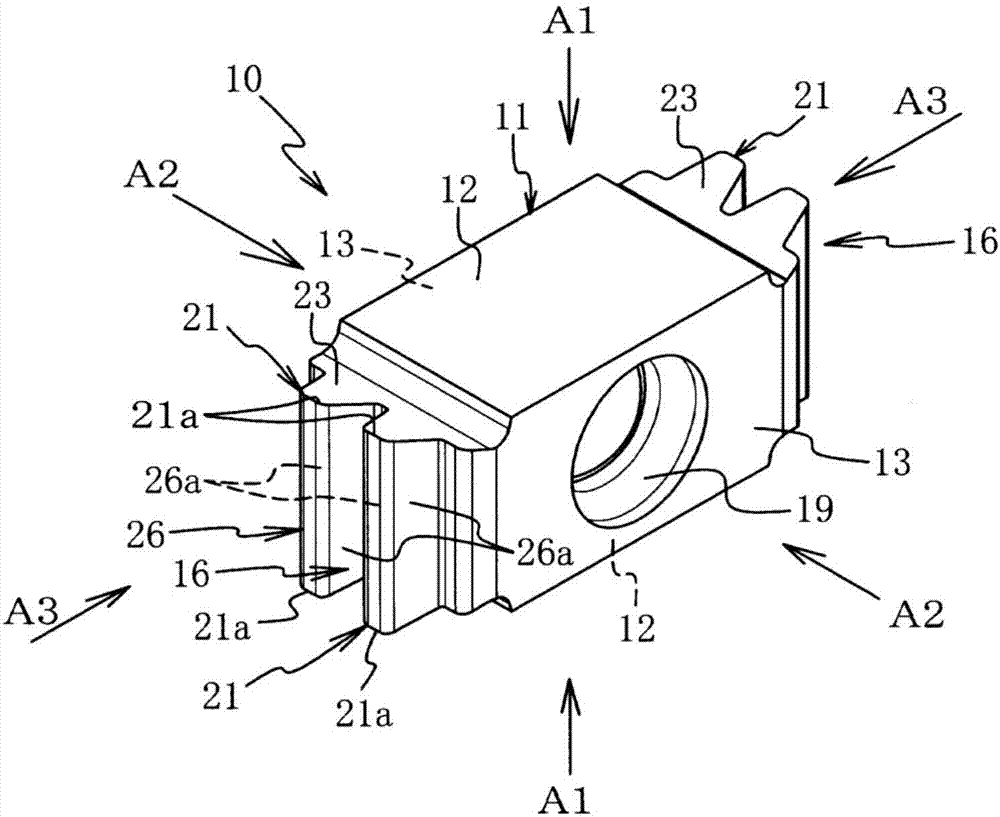

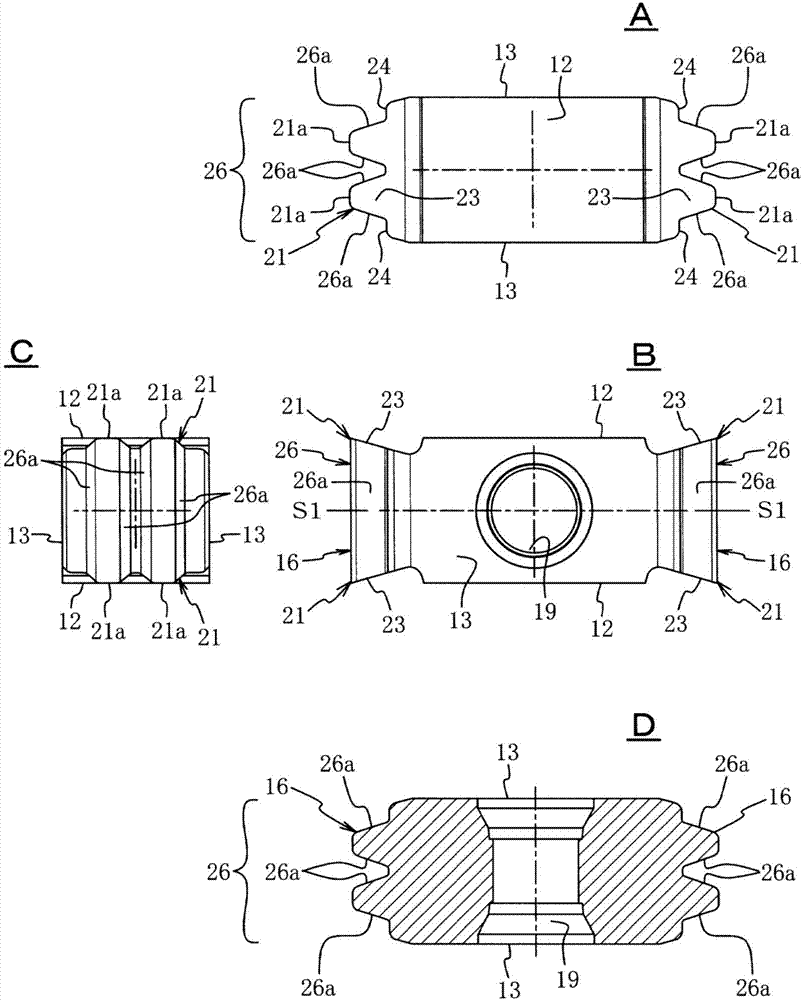

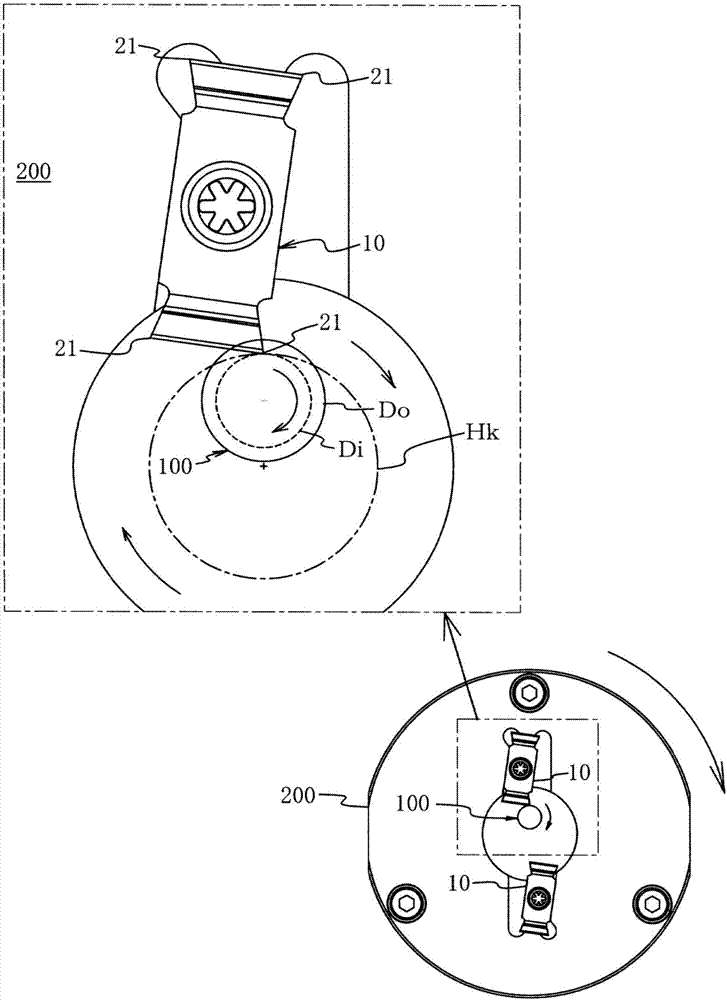

Autostereoscopic display device and drive method

ActiveUS20150281682A1Reduce numberIncrease sharpnessColor television detailsSteroscopic systemsComputer graphics (images)Display device

The invention provides an autostereoscopic display device in which a viewer tracking system determines a position of a viewer with respect to the display panel. The display panel is controlled to display a number of different views which is dependent on at least the distance of the viewer from the display panel. This enables the number of views to optimised with respect to the position and / or speed of movement of the viewer.

Owner:DIMENCO HLDG BV

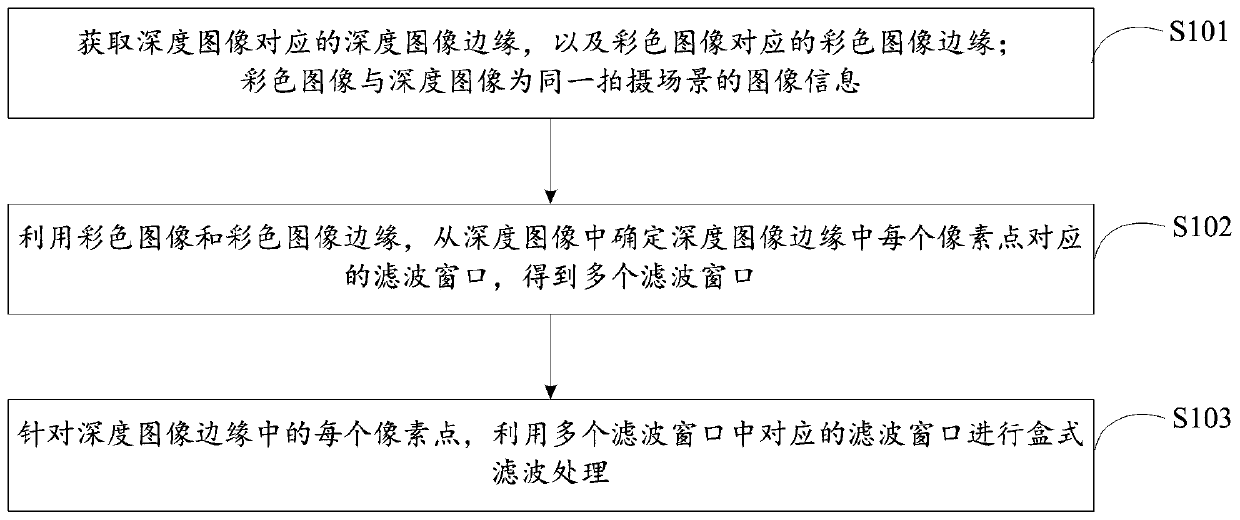

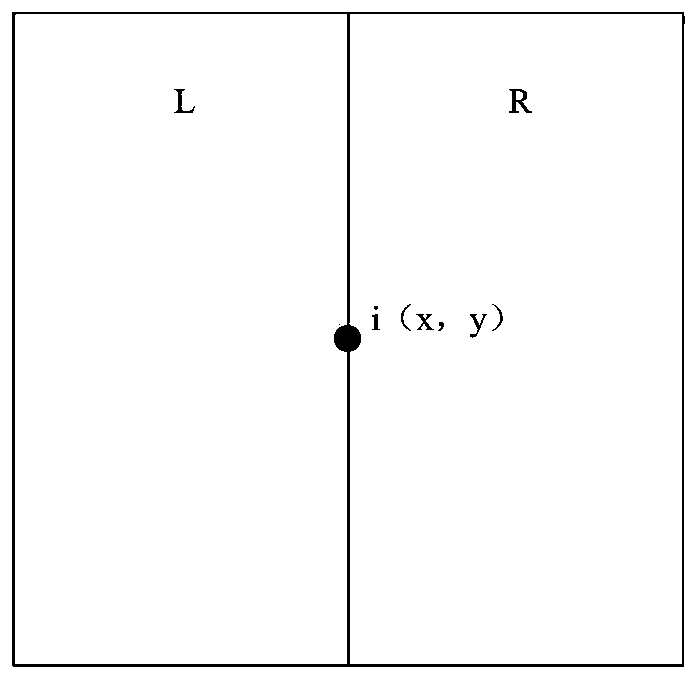

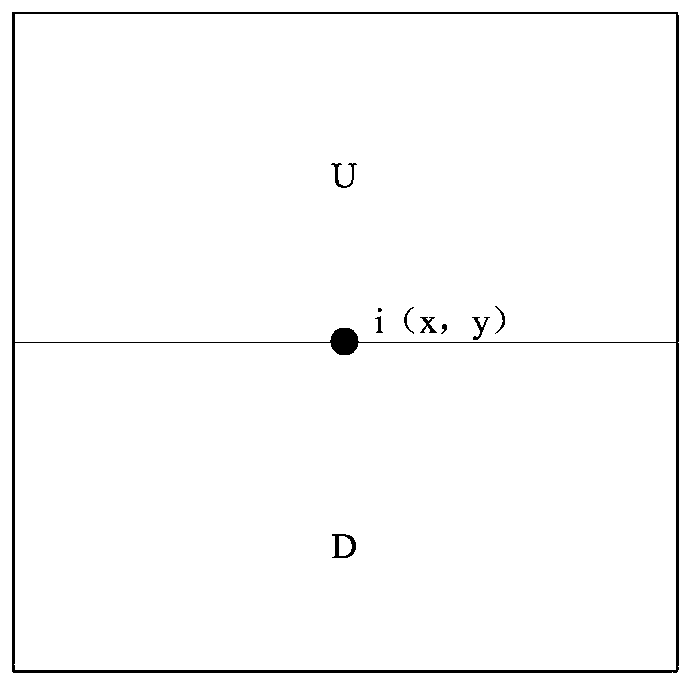

Image processing method and device and storage medium

ActiveCN111415310AIncrease sharpnessQuality improvementImage enhancementImage analysisColor imageImaging processing

Embodiments of the invention disclose an image processing method and device, and a storage medium. The method comprises the steps of obtaining a depth image edge corresponding to a depth image and a color image edge corresponding to a color image, wherein the color image and the depth image are image information of the same shooting scene; determining a filtering window corresponding to each pixelpoint in the depth image edge from the depth image by utilizing the color image and the color image edge to obtain a plurality of filtering windows; and for each pixel point in the depth image edge,carrying out box type filtering processing by utilizing the corresponding filtering window in the plurality of filtering windows.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

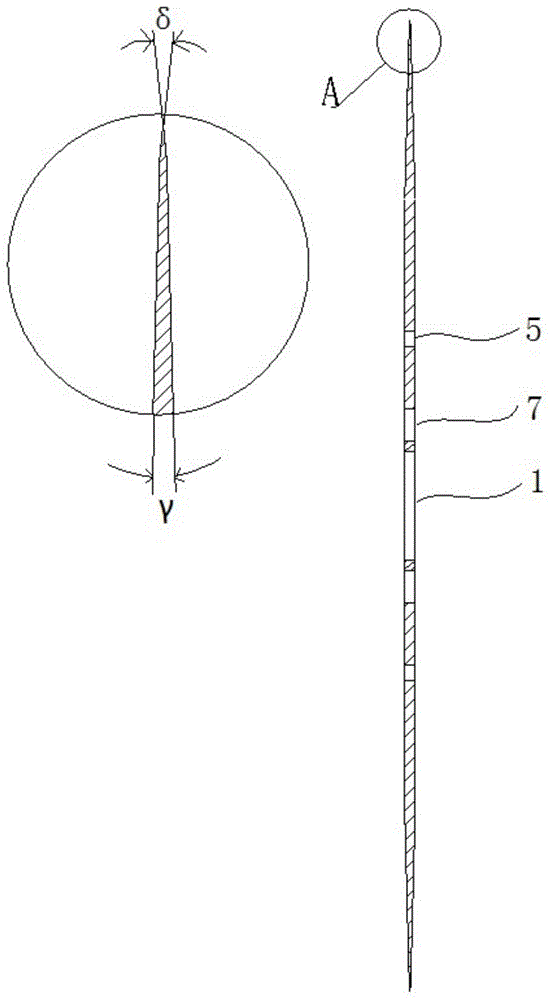

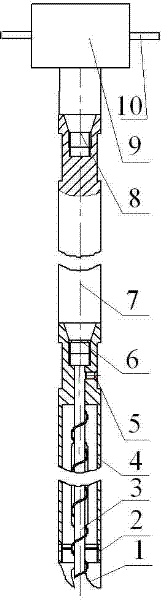

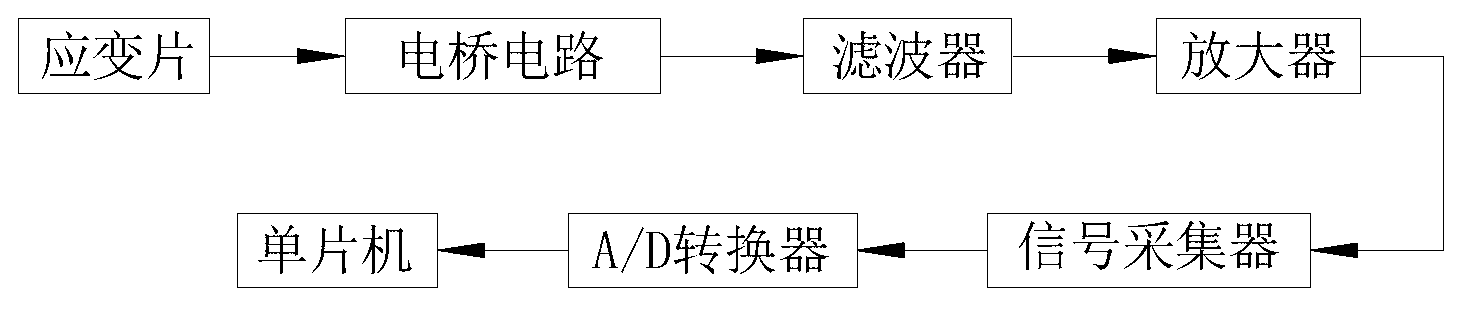

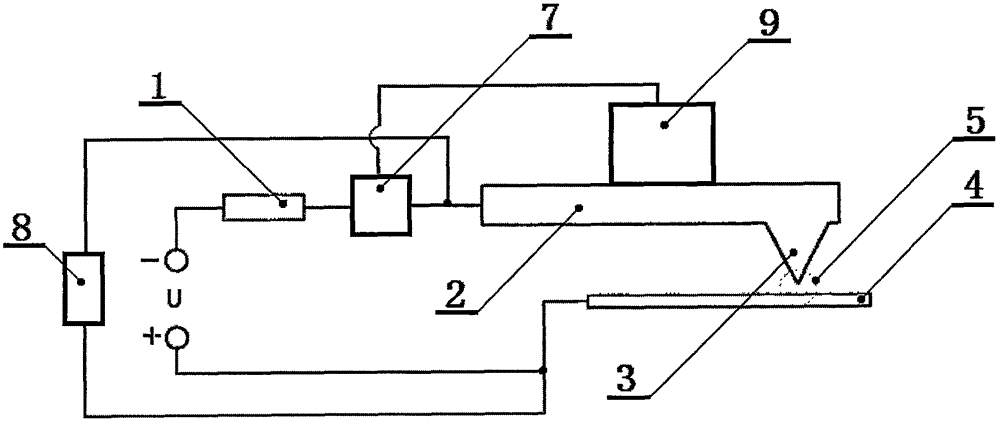

Axial-force-controllable surgical bone drill using brazed PCBN (Polycrystalline Cubic Boron Nitride) superhard material drill bit

The invention relates to an axial-force-controllable surgical bone drill using a brazed PCBN (Polycrystalline Cubic Boron Nitride) superhard material drill bit. The axial-force-controllable surgical bone drill has the advantages that the control accuracy is high and damages to brain tissues can be effectively avoided. A direct-current motor is arranged in the case of a drill body. The direct-current motor is connected with an intelligent integrated control system and a direct-current power supply. The output shaft of the direct-current motor is connected with a gear transmission device. The gear transmission device is connected with a drill bit chuck through a transmission shaft. A drill bit is installed on the drill bit chuck. A thrust bearing is arranged at the junction of the drill bit chuck and the transmission shaft. The thrust bearing is in close contact with a deformable element. The deformable element is in close contact with the case. The deformable element is positioned by using an elastic element. A resistance strain gage is bonded on the internal surface of the deformable element. The resistance strain gage is additionally connected with the intelligent integrated control system. A sealing device is arranged between the drill bit chuck and the case. The drill bit comprises a cylindrical basal body. A twist drill tip is arranged on the cylindrical basal body. A spiral groove is additionally arranged on the cylindrical basal body. PCBN superhard materials are arranged in the spiral groove and on the surface of the main rear blade of the drill bit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

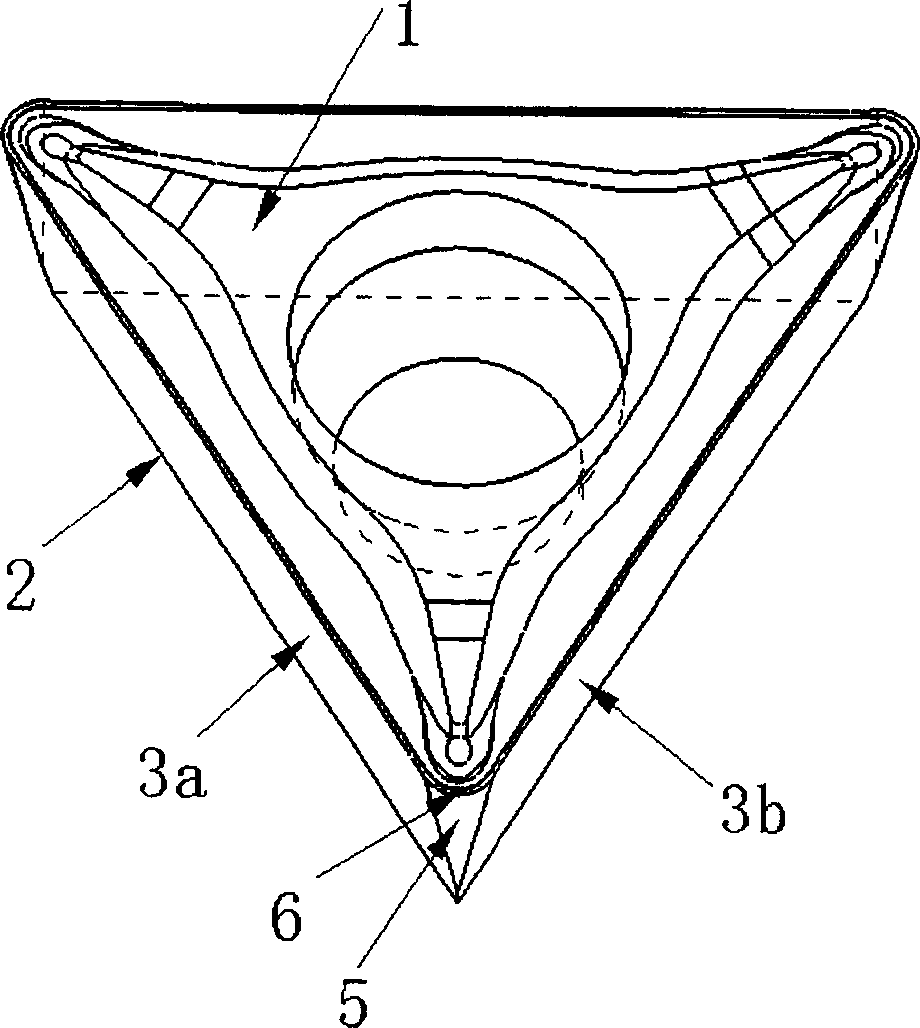

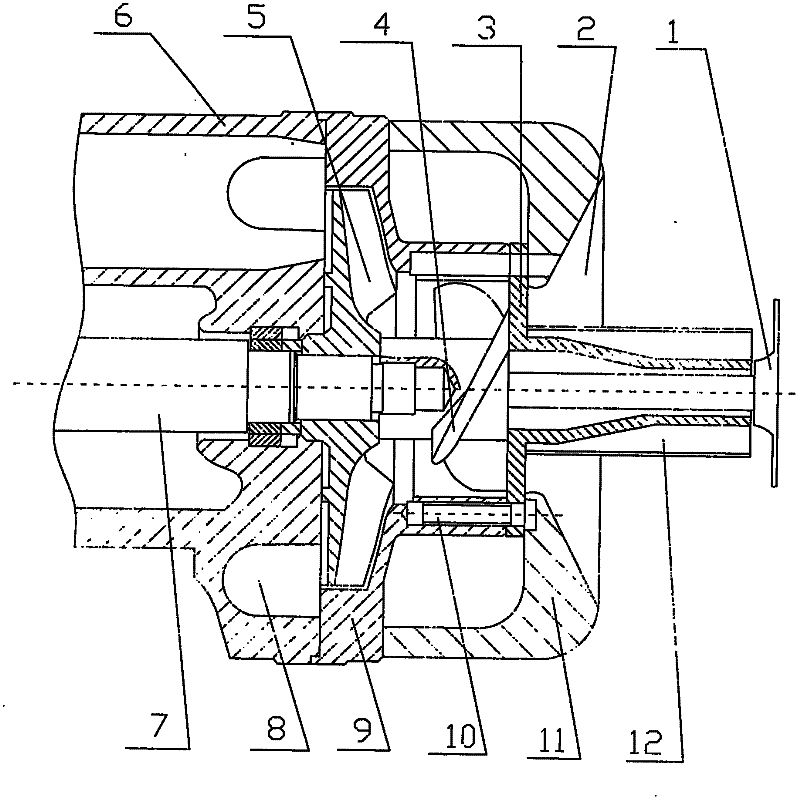

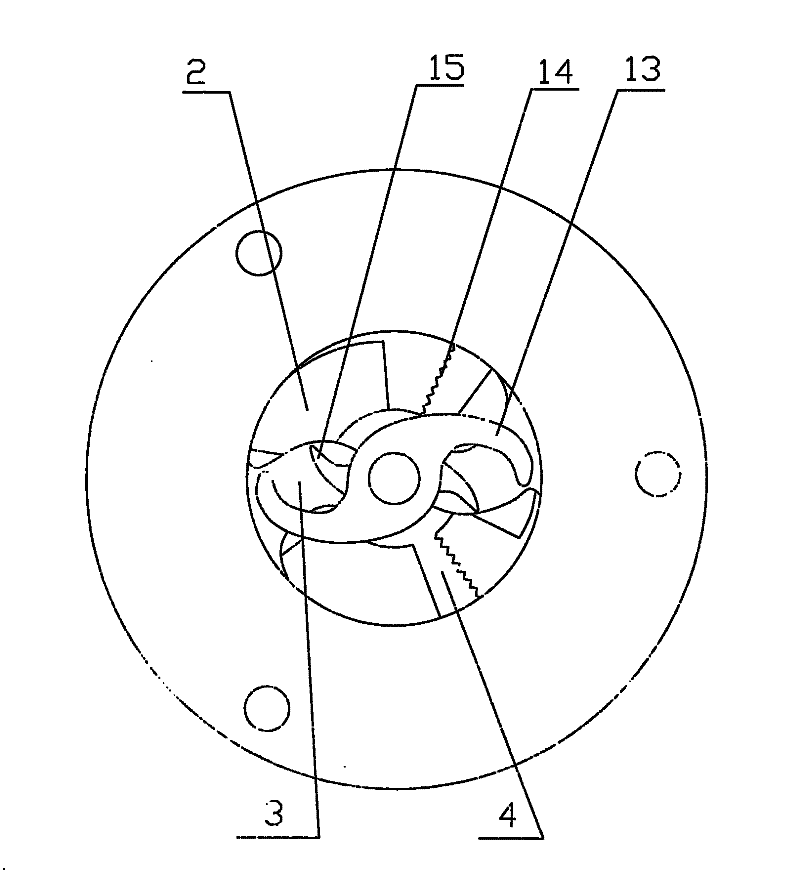

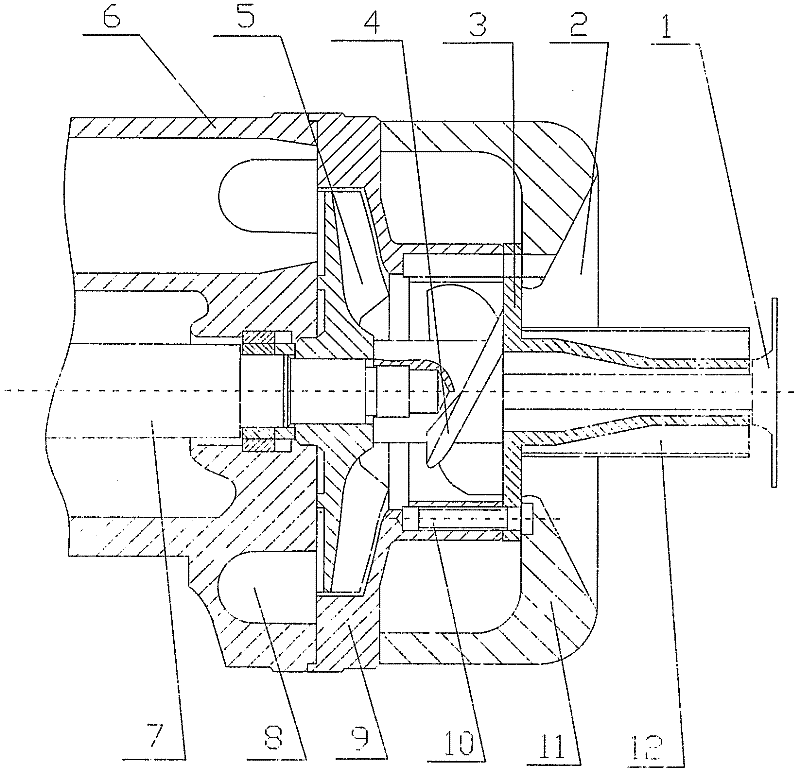

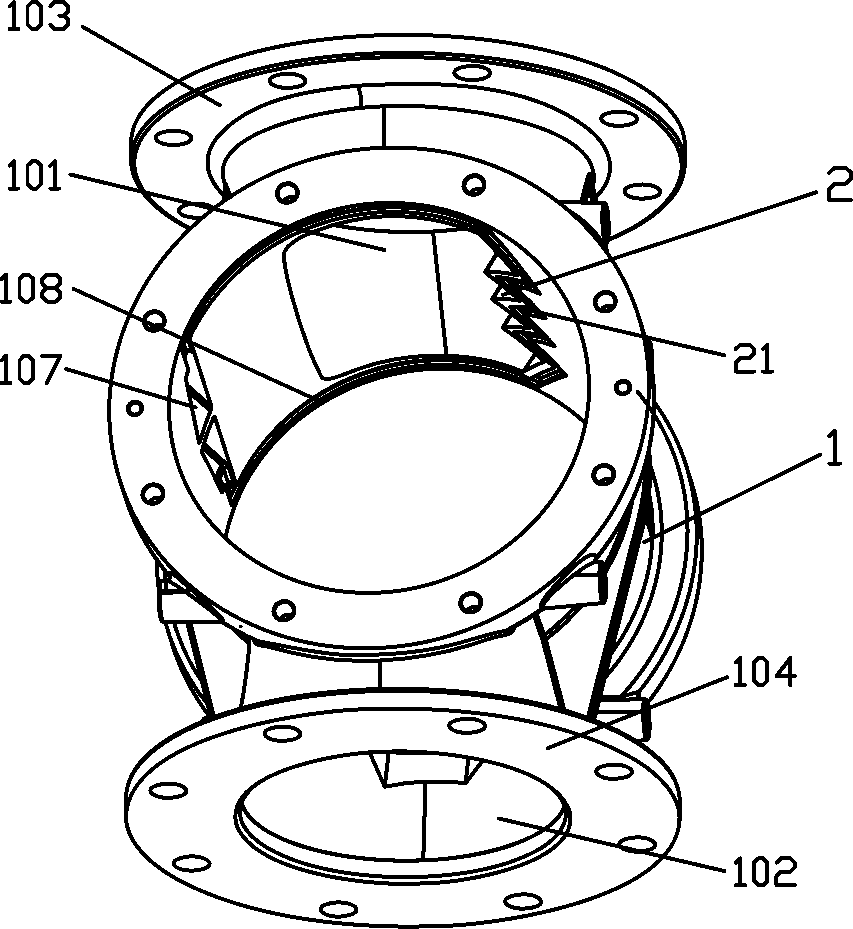

Centrifugal pump with cutting devices

The invention relates to a centrifugal pump with cutting devices. Triple cutting devices are arranged at the front section of the centrifugal pump. Firstly, the ingress of an S-shaped cutter is arranged, then a conical cutting edge with a sharp cutting tool is arranged, and finally a cutting impeller and a corresponding fixed cutting tool are arranged. The cutting edge on the cutting impeller adopts a sawtooth shape; all the cutting impeller, the S-shaped cutter and a main impeller rotate along with a pump shaft; and the fixed cutting tool and the conical cutting edge are fixed at the front end of the cutting impeller.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

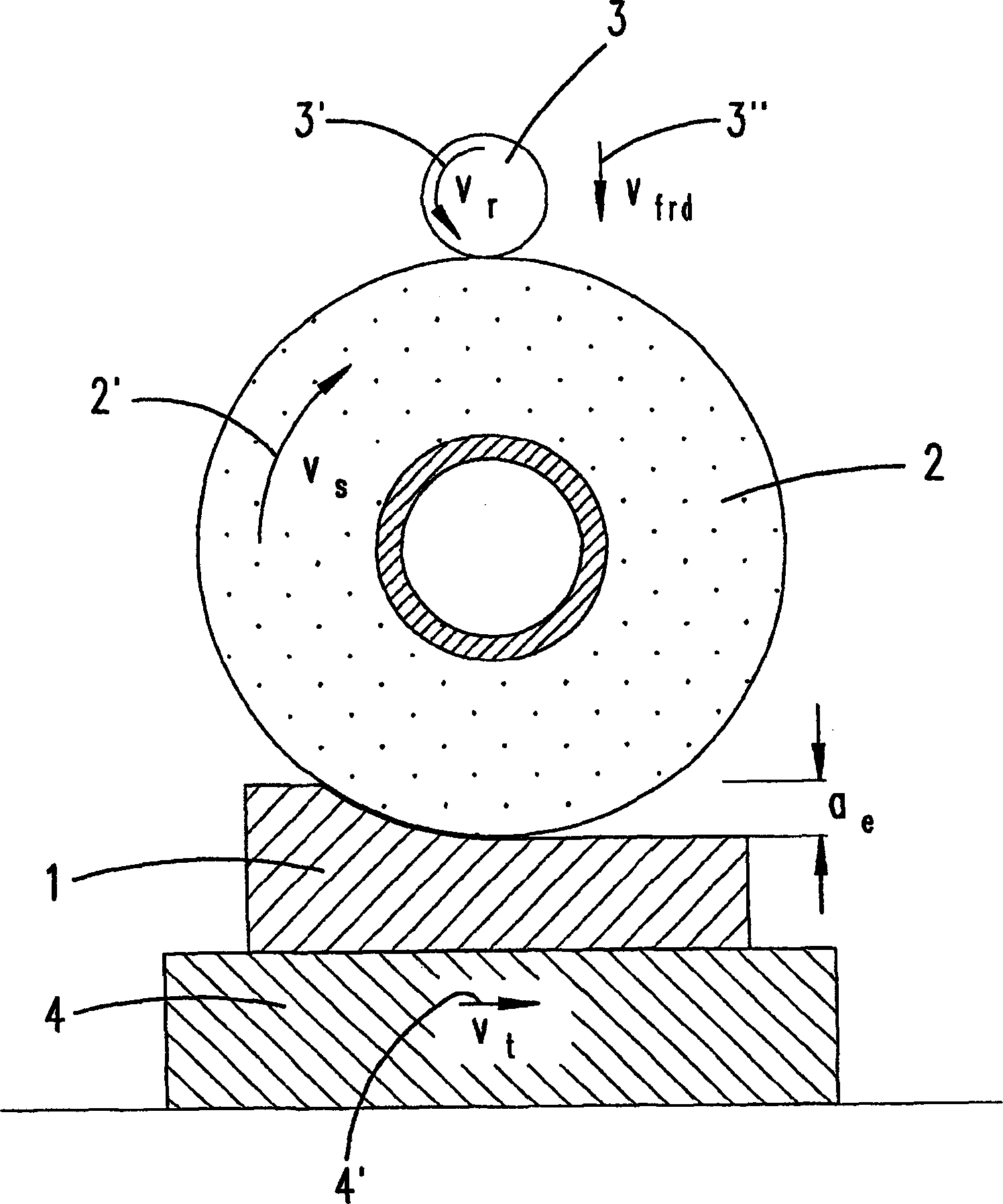

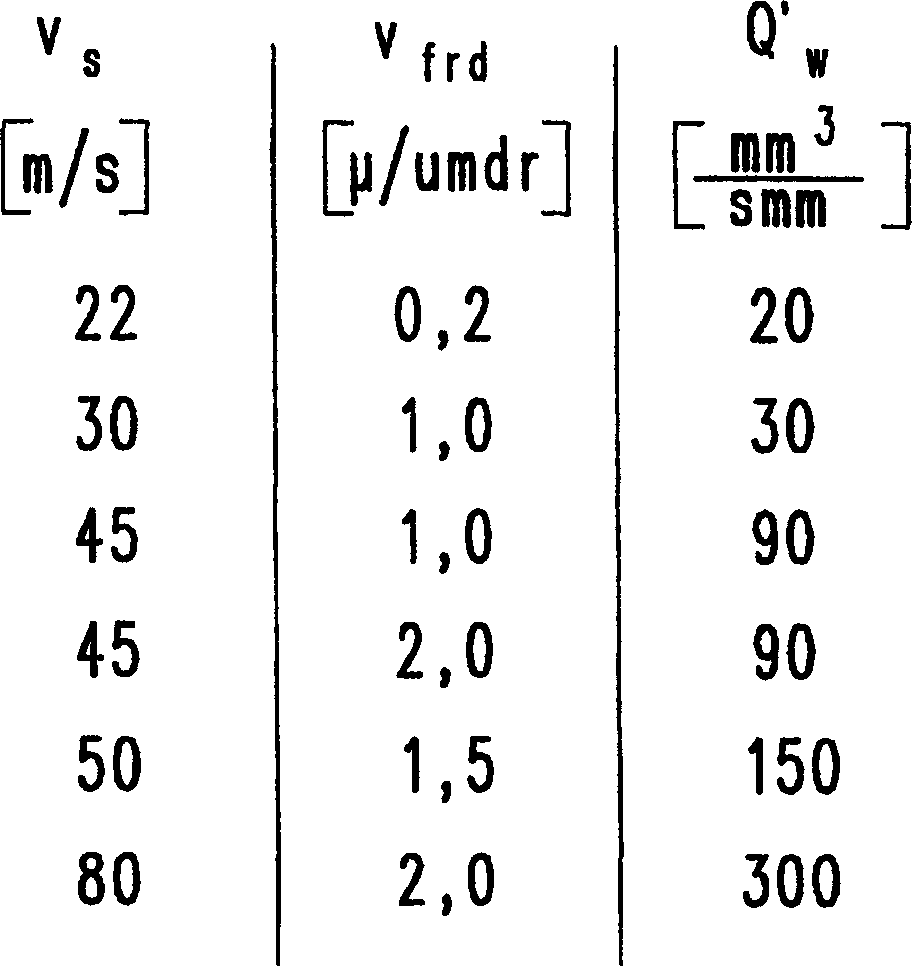

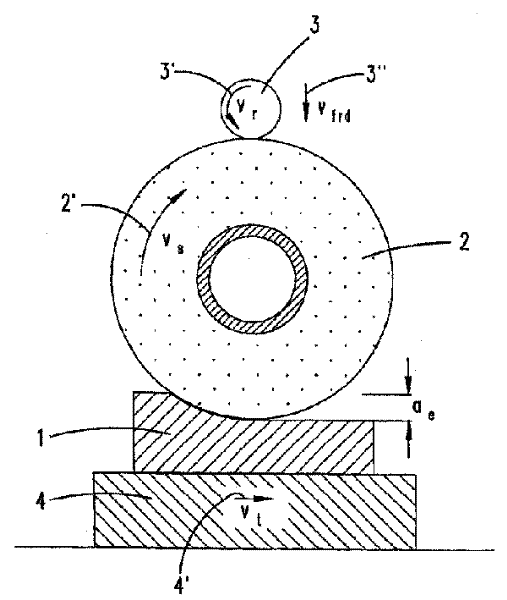

Method for grinding metallic workpieces containing, in particular nickel

InactiveCN1430546AHigh removal rateIncrease sharpnessBonded abrasive wheelsAbrasive surface conditioning devicesGrinding wheelMetallic Nickel

The invention relates to a method for grinding metallic workpieces containing, in particular, nickel, whereby a rotationally driven grinding wheel (2) is continuously dressed by a rotationally driven dressing wheel (3) during the grinding of the workpiece (1) by the continual advance (vfrd) of the dressing wheel. In order to increase the grinding capacity, the invention provides that with a dressing advance velocity of 1 to 2 mum per rotation of the grinding wheel and with a circumferential velocity of the grinding wheel (vs) of at least 45 m / s, the advance (table velocity vt) is set such that the rate of metal removal is at least 90 mm<3> / mms.

Owner:蒂罗利特研磨剂工厂斯瓦罗夫斯基两合公司

Indexable turning blade for high temperature alloy semifinishing under high-pressure cooling

InactiveCN107214353AReduce wearImprove chip breaking abilityCutting insertsTurning toolsEngineeringHigh pressure

The invention relates to an indexable turning blade for high temperature alloy semifinishing under high-pressure cooling, and belongs to the technical field of turning tools. The turning blade comprises a turning blade body, the shape of the outline of the horizontal cross section of the turning blade body is hexagon, a fastening screw hole is formed in the geometrical center of the hexagonal turning blade body, a front cutter face is arranged on the outer periphery of the top face of the hexagonal turning blade body, and the six vertex angles of the hexagonal turning blade body are composed of three 80-degree angles and three 160-degree angles which are sequentially and alternatively arranged; arc cutter tips are arranged at the three 80-degree angles of the hexagonal turning blade body, negative chamfered edge cutting edges are arranged at the six outer edges of the top face of the hexagonal turning blade body, and protrusions are arranged nearby each arc cutter tip; and fold line step-shaped chip breaker grooves are arranged on the top face of the hexagonal turning blade body and the corresponding positions of the 160-degree angles on the front cutter face, chip grooves are composed of the fold line step-shaped chip breaker grooves and the front cutter face, and the bottom face of the hexagonal turning blade body is a blade installing supporting face. The indexable turning blade is used for high temperature alloy semifinishing under high-pressure cooling.

Owner:HARBIN UNIV OF SCI & TECH

Method for preparing needle point of atomic force microscope

ActiveCN106771376AIncrease sharpnessEasy to replaceScanning probe microscopyMagnetic force microscopeAtomic force microscopy

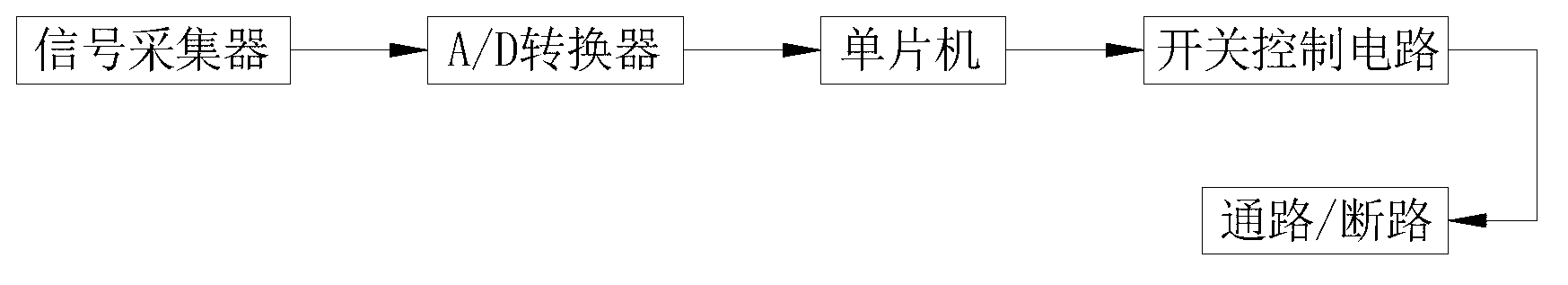

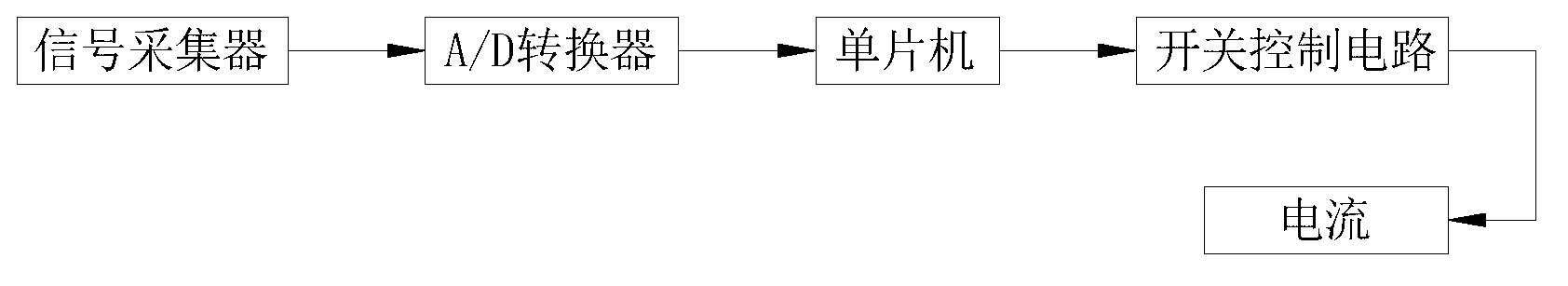

The invention relates to the field of atomic force microscopes, and provides a method for preparing a needle point of the atomic force microscope. A current feedback loop is composed of a power supply U, a resistor, a current feedback system, a cantilever, a needle point, a gap between the needle point and a sample, and the sample; concave pits with the diameter of 100nm and the depth of 30nm are formed in the surface of a first specific sample every 100nm; bulges with the height of 20nm and the diameter of 10nm are formed on the surface of a second specific sample every 20nm; a needle-shaped object is generated by the first specific sample, and a needle-shaped object, which is vertical to the surface of the sample, grows by utilizing the second specific sample; a parameter for determining whether the needle point is sharp or not is checked: the other sample with a relatively flat surface is used and works at a phase shaft mode; an initial amplitude is set to be AO, a scanning distance is set to be 15nm and a pre-set value is 0.6AO; if the phase shift on the flat surface is negative, the needle point is a sharp needle point capable of meeting experiment requirements; if the phase shift is not negative, a process of applying the power supply to form a high electric field in the gap between the needle point and the sample is repeated.

Owner:JINHUA VOCATIONAL TECH COLLEGE

Food cutter and manufacturing method thereof

PendingCN109483623AImprove cutting effectNot easy to dullMetal working apparatusEngineeringMechanical engineering

The invention discloses a food cutter and a manufacturing method thereof and belongs o the field of cutter machining. The food cutter comprises a cutter body and a cutter blade. The cutter body and the cutter blade form a food cutter body. The cutter body comprises a mounting portion located at one end of the cutter body. The profile of the cutter blade is in an arc shape and is a single-face arc-shaped blade. The arc-shaped blade comprises a toothed blade end and a non-toothed blade end. The toothed blade end and the non-toothed blade end are connected to form a cutter blade body. The side, not connected with the non-toothed blade end, of the toothed blade end is connected with the mounting portion. The food cutter can be used for cutting food smoothly and uniformly, food does not stick to the cutter, abrasion of the cutter blade edge is small, the service life is long, the manufacturing method of the food cutter is easy and convenient to implement and combined with practical production, and manufacturing is easy.

Owner:安徽华天机械股份有限公司

Transparent plastic product and printing method of transparent plastic product

InactiveCN102774229ATo achieve a pleasing effectLow priceSpecial ornamental structuresOther printing apparatusColor printingEngineering

The invention discloses a transparent plastic product and a printing method of the transparent plastic product. The transparent plastic product comprises a transparent plastic substrate, wherein color patterns are printed on the transparent plastic substrate, in addition, transparent patterns consisting of transparent parts are arranged on the transparent plastic substrate, and a group of light shielding points are arranged on the transparent patterns. The method comprises the steps of material selection, sliver ink printing, white ink printing, color printing, covering layer tearing off and transparent plastic product obtaining. The transparent plastic product and the printing method have the advantages that transparent plastic sheets are adopted for printing, various characters and patterns of the obtained product can project gaudy, colored and delicate characters and patterns by color LED (light emitting diode) lamps or other light sources when light sources exit, and the effect of feasting for the eyes is reached.

Owner:李太平

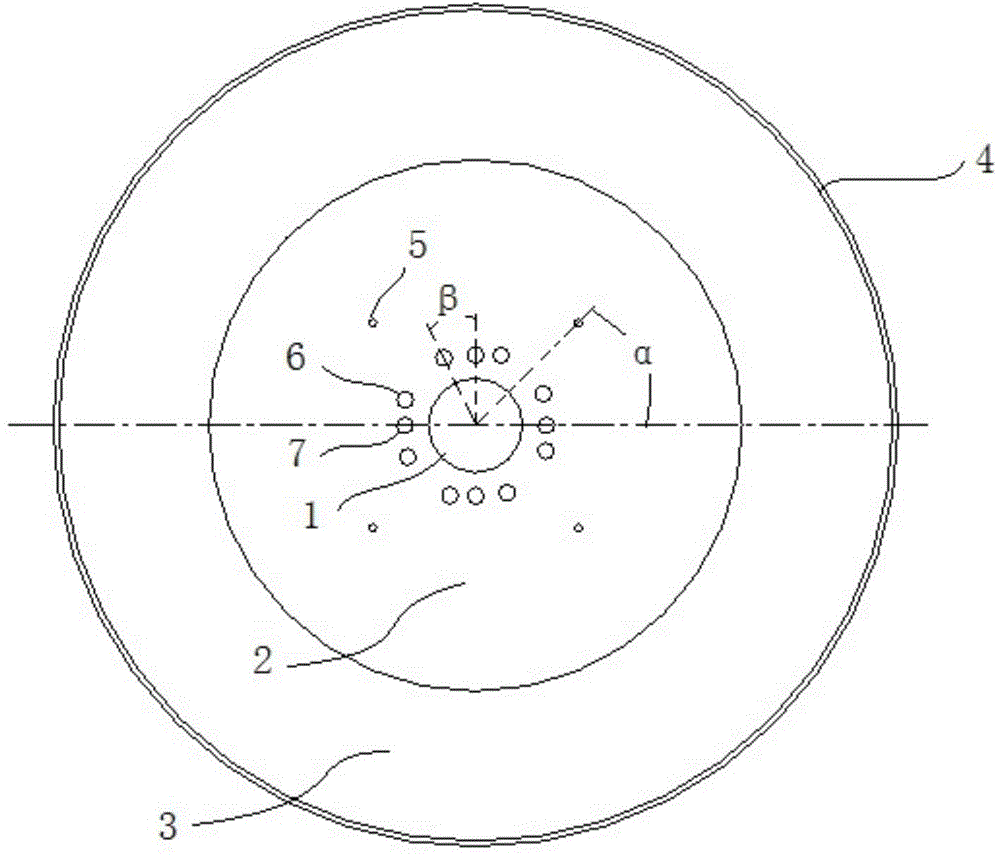

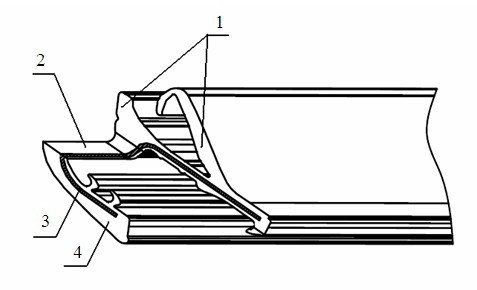

Disposable electrode device for hemorrhoid ablation operation

PendingCN112773502AIncrease surface areaAchieve reductionSurgical instruments for heatingSurgeryMaterials science

An electrode device for a hemorrhoid ablation operation comprises a needle tip (1), an insulating bush (2), an inner core cable (3), an insulating tube (4), a handle shell (8), a needle rod (9) and a conductive socket (11); the far end of the inner core cable (3) is connected with the needle tip (1), and the near end of the inner core cable (3) is connected with the conductive socket (11); the insulating tube (4) is arranged on the outer surface of the inner core cable (3); the insulating bush (2) is arranged between the needle tip (1) and the needle rod (9); and the insulating bush (2) is sleeved with the needle rod (9). The electrode device can effectively improve the efficiency and the effect of the ablation operation.

Owner:ANGEL MEDICAL TECH NANJING

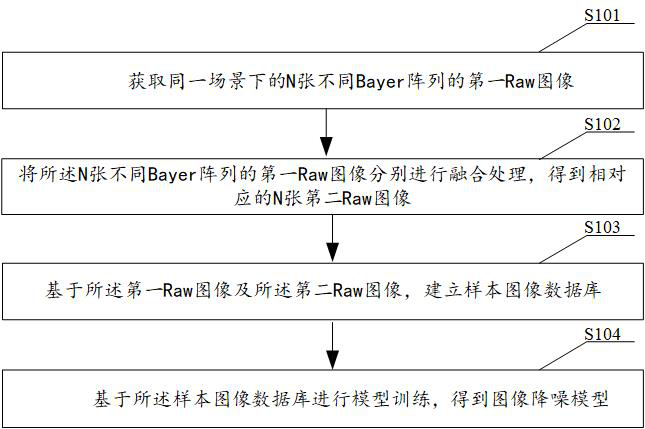

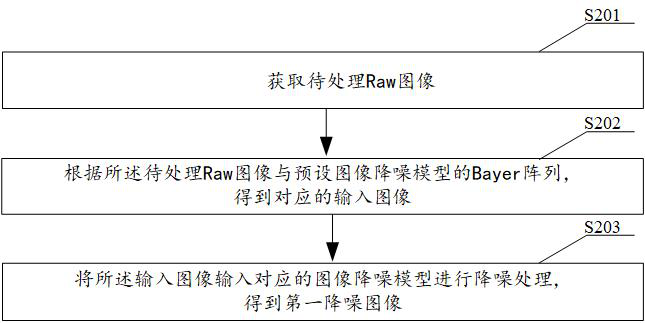

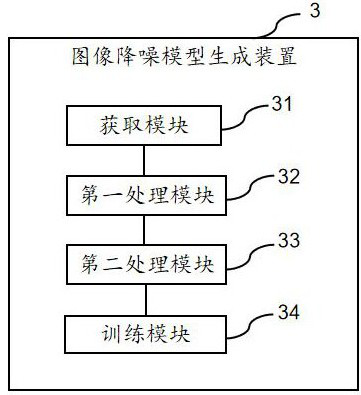

Image noise reduction model generation method, image noise reduction method and device, storage medium and equipment

PendingCN112381102AIncrease sharpnessComfortable lookCharacter and pattern recognitionMachine learningImage noise reductionSample image

The invention provides an image noise reduction model generation method and an image noise reduction method, and the method comprises the steps: obtaining N first Raw images of different Bayer arraysin the same scene, carrying out the fusion processing of the N first Raw images of different Bayer arrays, obtaining N corresponding second Raw images, building a sample image database based on the first Raw images and the second Raw images, and carrying out the model training, obtaining an image noise reduction model; and performing format conversion processing on the Raw image to be processed, inputting the processed Raw image into the image noise reduction model to obtain a first noise reduction image, and performing corresponding format conversion processing on the first noise reduction image to obtain a final noise reduction image. Automatic image noise reduction is realized based on the image noise reduction model generated by the method, image noise can be obviously reduced, and theimage noise reduction method is high in efficiency, good in universality and high in robustness.

Owner:SHENZHEN ARASHI VISION CO LTD

Manufacturing method of bucket teeth for excavating

InactiveCN107653925AIncrease sharpnessNot easy to bendSoil-shifting machines/dredgersEngineeringFront edge

The invention provides a manufacturing method of bucket teeth for excavating. The bucket teeth comprise a connecting base and tooth tips. The left side wall and the right side wall, away from one endsof the tooth tips, of the connecting base are provided with counter bores. The two sides of the upper end face and the lower end face of each tooth tip are provided with concave surfaces. The concavesurfaces extend to the front edges of the tooth tips from the connecting portions of the connecting base and the tooth tips. The reinforcing portion inclining downwards is arranged between every twoconcave surfaces. The free end portions of the tooth tips are provided with sharp teeth separated at equal intervals. A first reinforcing rib and a second reinforcing rib are arranged between every two adjacent sharp teeth. The first reinforcing ribs and the second reinforcing ribs are arranged in a staggered manner. The free end portions of the tooth tips are provided with the separated sharp teeth, the keenness degree of the tooth tips is improved, excavation is benefitted, the sharp teeth are provided with the first reinforcing ribs and the second reinforcing ribs in a penetrating manner, the first reinforcing ribs and the second reinforcing ribs are arranged in a staggered manner, impact force borne by the sharp teeth is dispersed, it is ensured that the sharp teeth cannot be bent or deformed under the larger impact force, and the service life of the bucket teeth can be effectively ensured.

Owner:TIANJIN CMC XIONGFENG CONSTR MACHINERY

Hydraulic clamp for electric maintenance

The invention discloses a hydraulic clamp for electric maintenance. The hydraulic clamp for electric maintenance comprises a movable switch and a secondary movable switch; a retainer ring is arrangedon the left side of the movable switch; a clamp handle is arranged on the inner side of a handle antiskid film; a secondary retainer ring is arranged on the left side of the secondary movable switch;an antiskid film is mounted on the inner side of the secondary retainer ring; a secondary movable rod is mounted in a movable handle; a connecting screw rod is arranged on the left side above the movable handle; a transition block is arranged on the left side of a clamping layer; a clamp head is arranged above the transition block; a slide block rail is arranged on the inner side of the clamp head; a lower pressing cutter is mounted on the inner side of a rail; an upper tooth-shaped blade is arranged above a lower tooth-shaped blade; and a fixed bolt is arranged on the left side of an upper pressing cutter. The hydraulic clamp for electric maintenance is more flexible and variable in fixed structure, facilitates disassembly and replacement of devices, and is suitable for multiple conditions.

Owner:青岛市光明电力服务有限责任公司胶州分公司

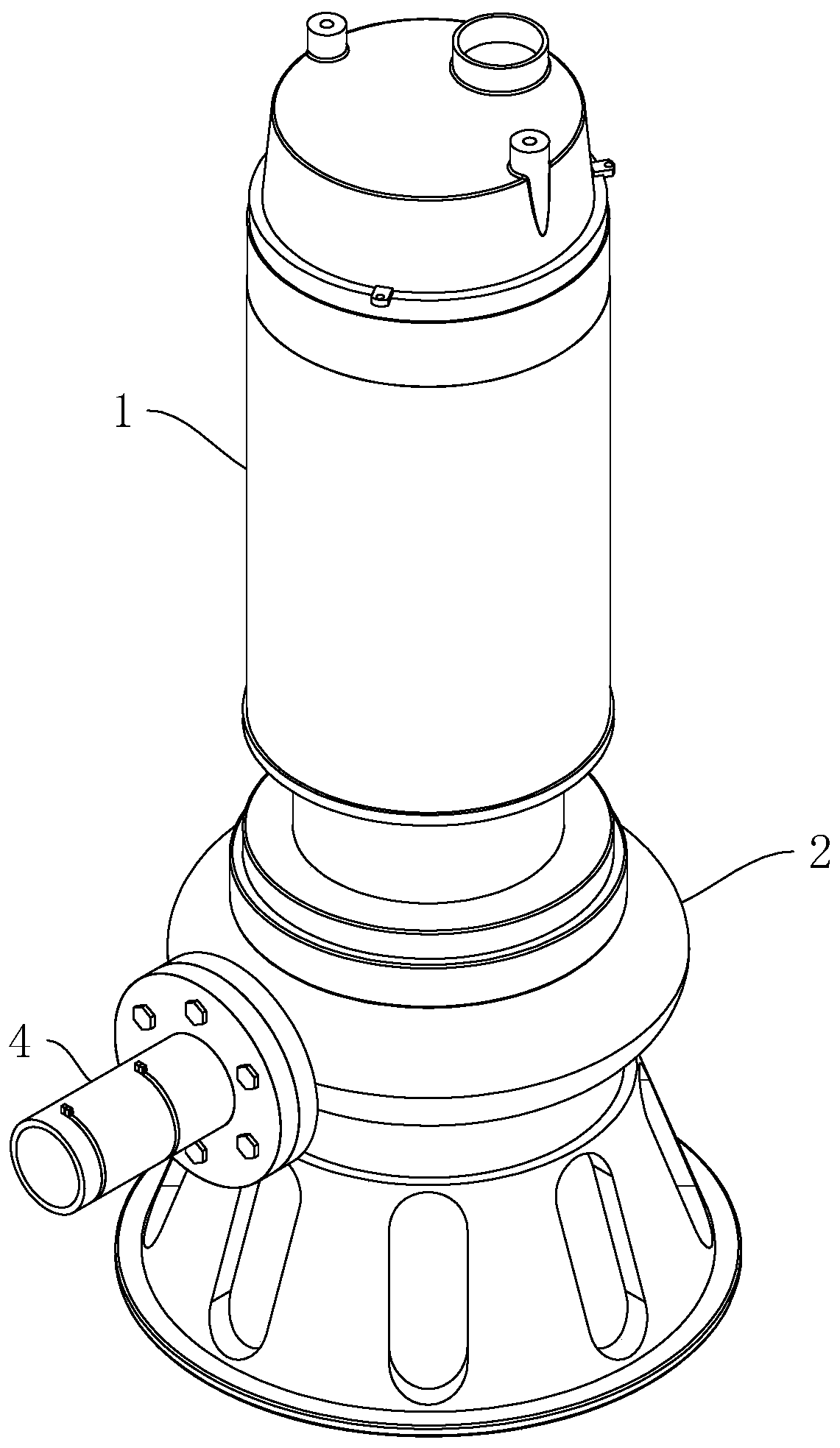

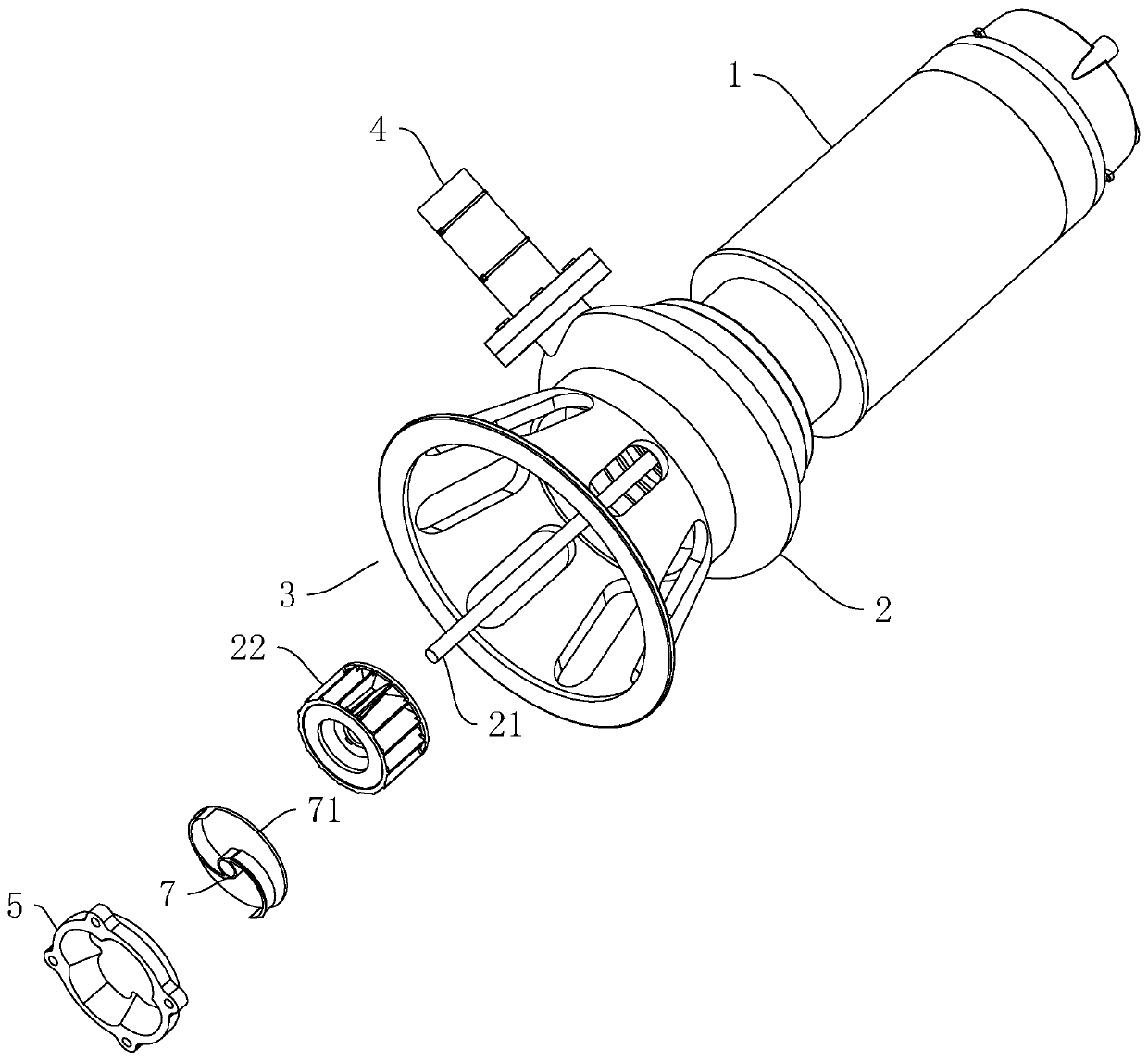

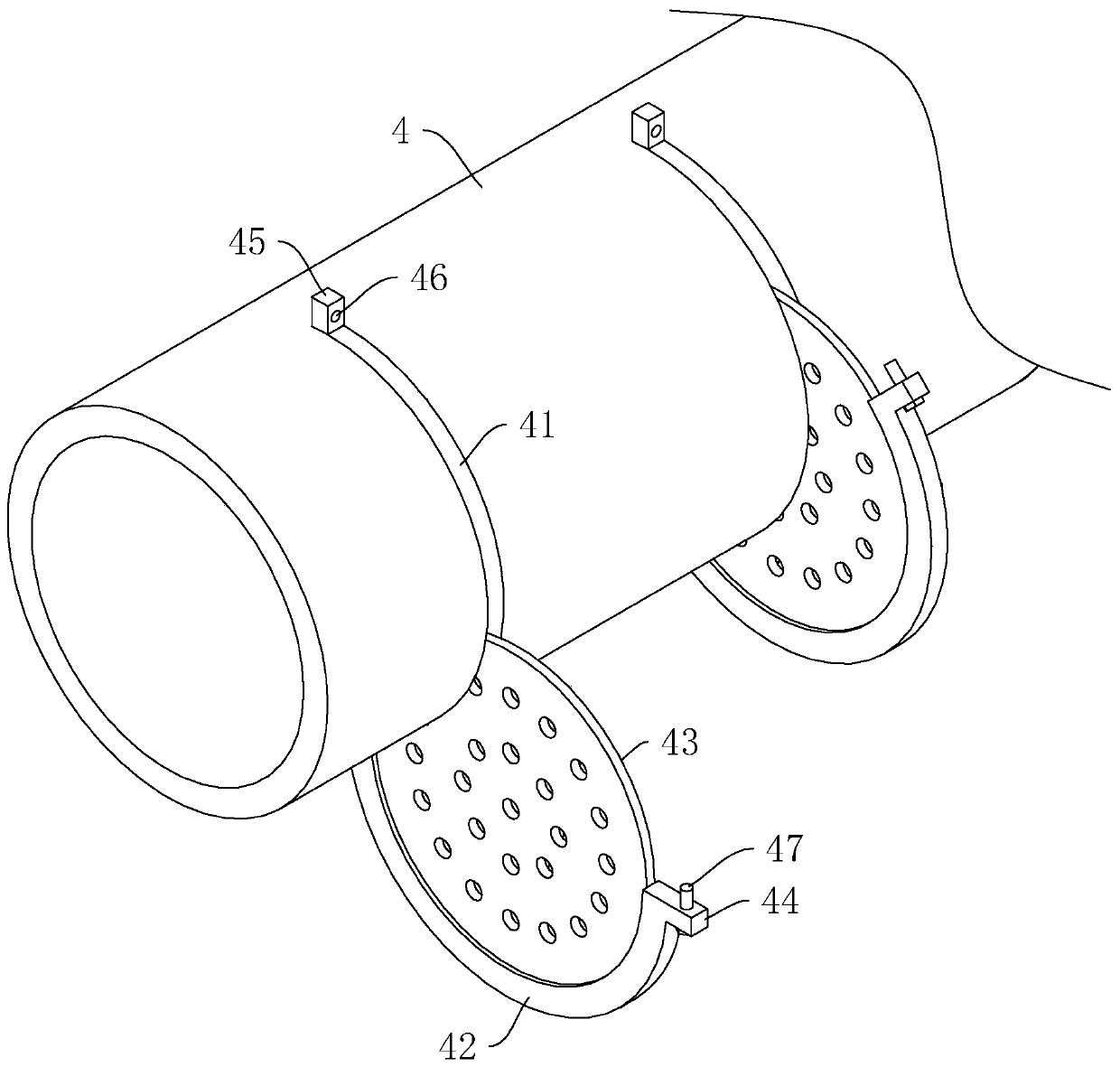

Submersible pump

InactiveCN109707632AAvoid sundries blocking the pump bodyIncrease sharpnessSpecific fluid pumpsPump componentsEngineeringShear force

The invention discloses a submersible pump and relates to the field of water pumps. The submersible pump comprises an electric motor and a pump body, wherein a water inlet hole is formed in the lowerend face of the pump body; an installation ring is disposed at the water inlet hole; a plurality of shear blocks are disposed on the inner wall circumferential bulge of the installation ring; a pump shaft is in rotatable connection in the pump body; the outer wall of the lower end of the pump shaft is sleeved with an installation sleeve; a pair of shear knives are disposed on the outer wall of theinstallation sleeve; and lower ends of the shear knives are pressed against upper end faces of the shear blocks. The submersible pump disclosed by the invention has the advantages and effects that the shear knives are rotated relative to upper end faces of the shear blocks when water flows into the pump body. In this way, distances between the shear knives and the shear blocks are gradually reduced and shear force at intersections of the shear knives and the shear blocks is gradually increased, so that sundries in water flows are cut into pieces at the intersections, the pump body is protected from sundry blocking and anti-blocking effects are realized.

Owner:越连机电有限公司

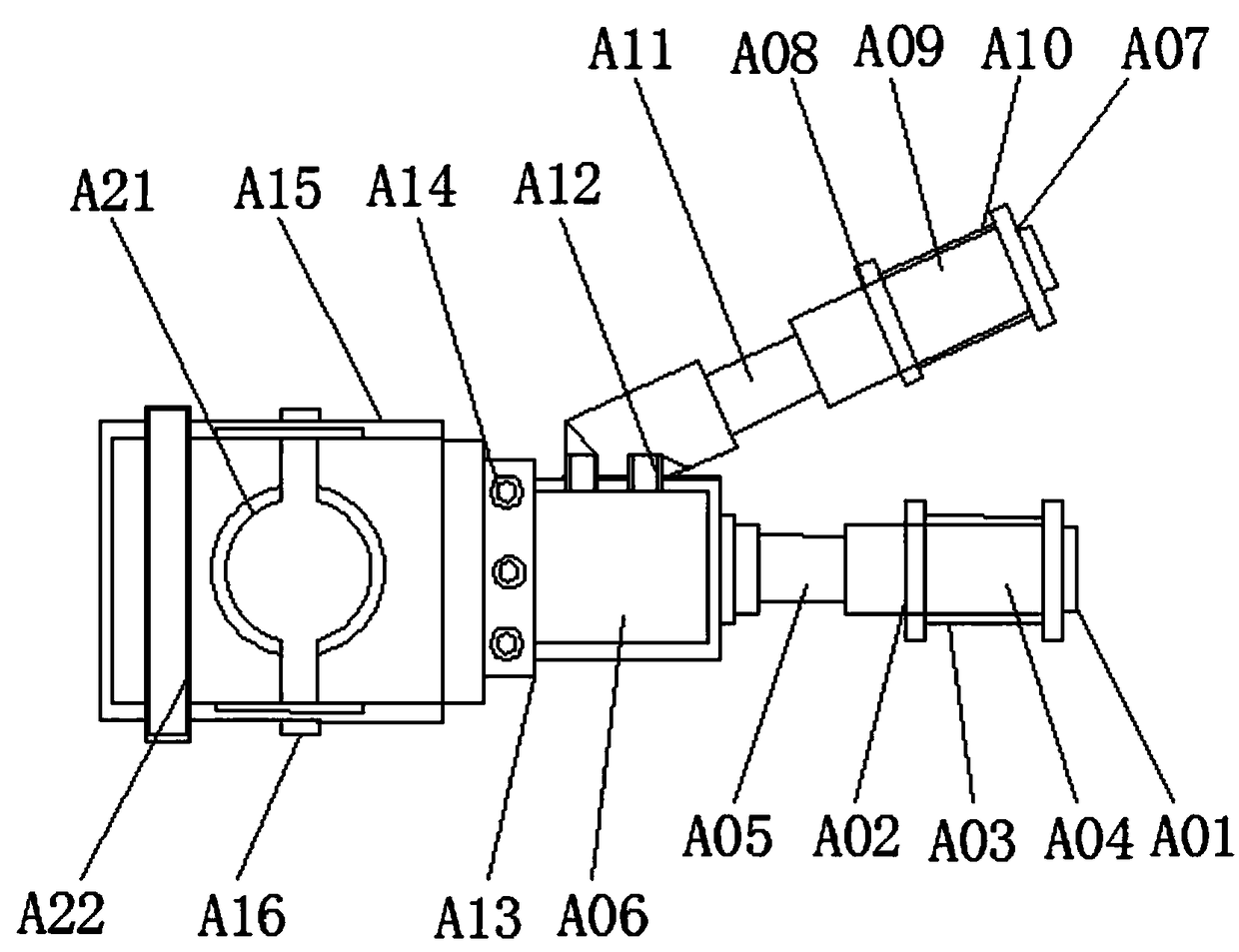

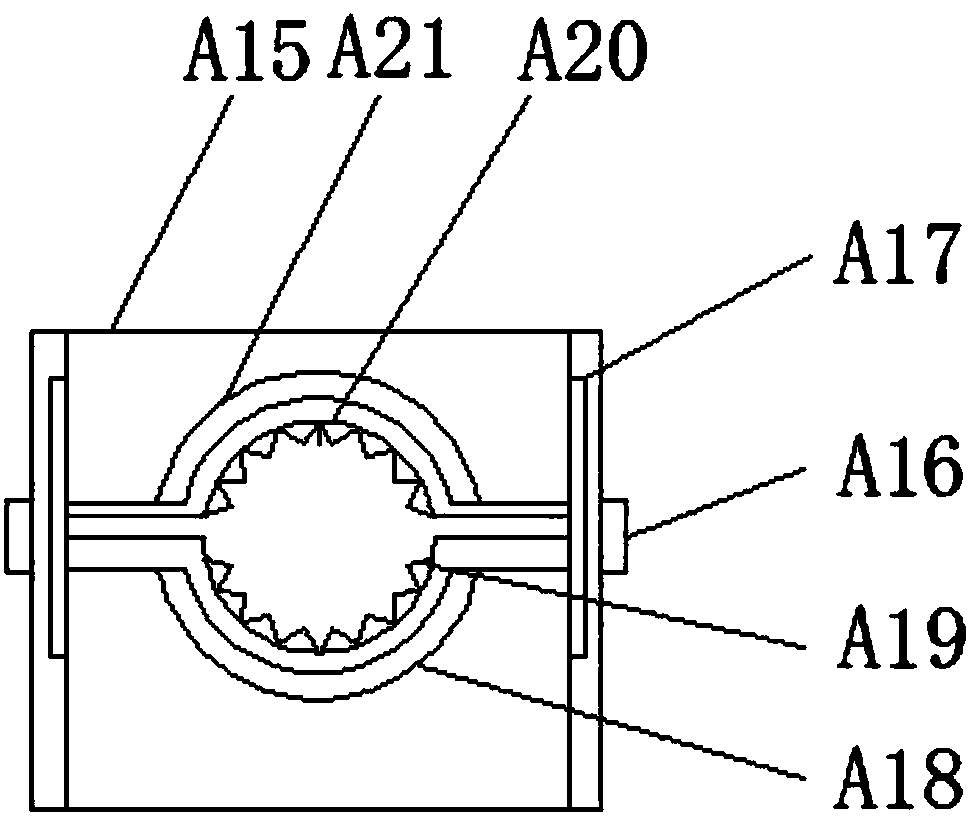

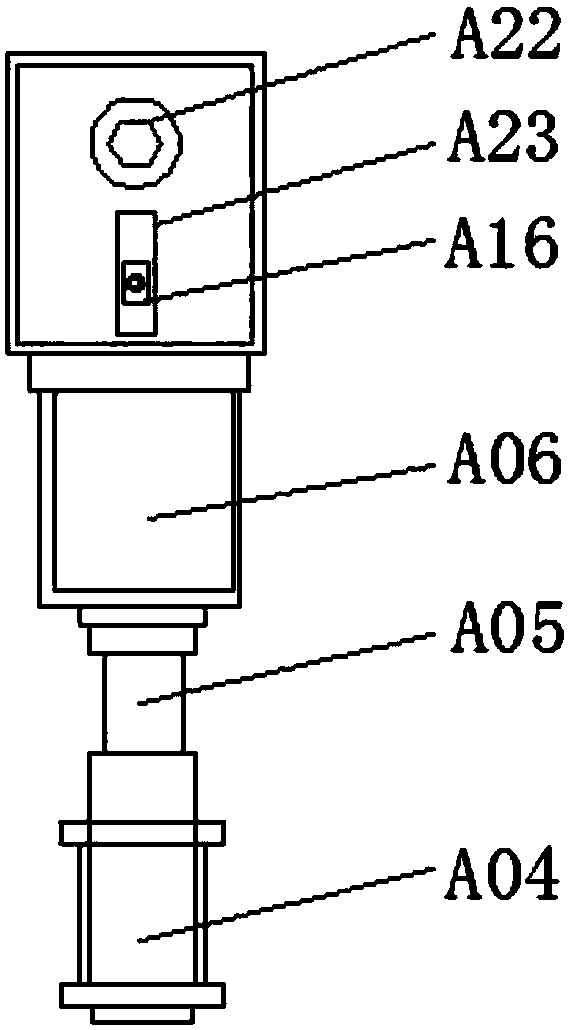

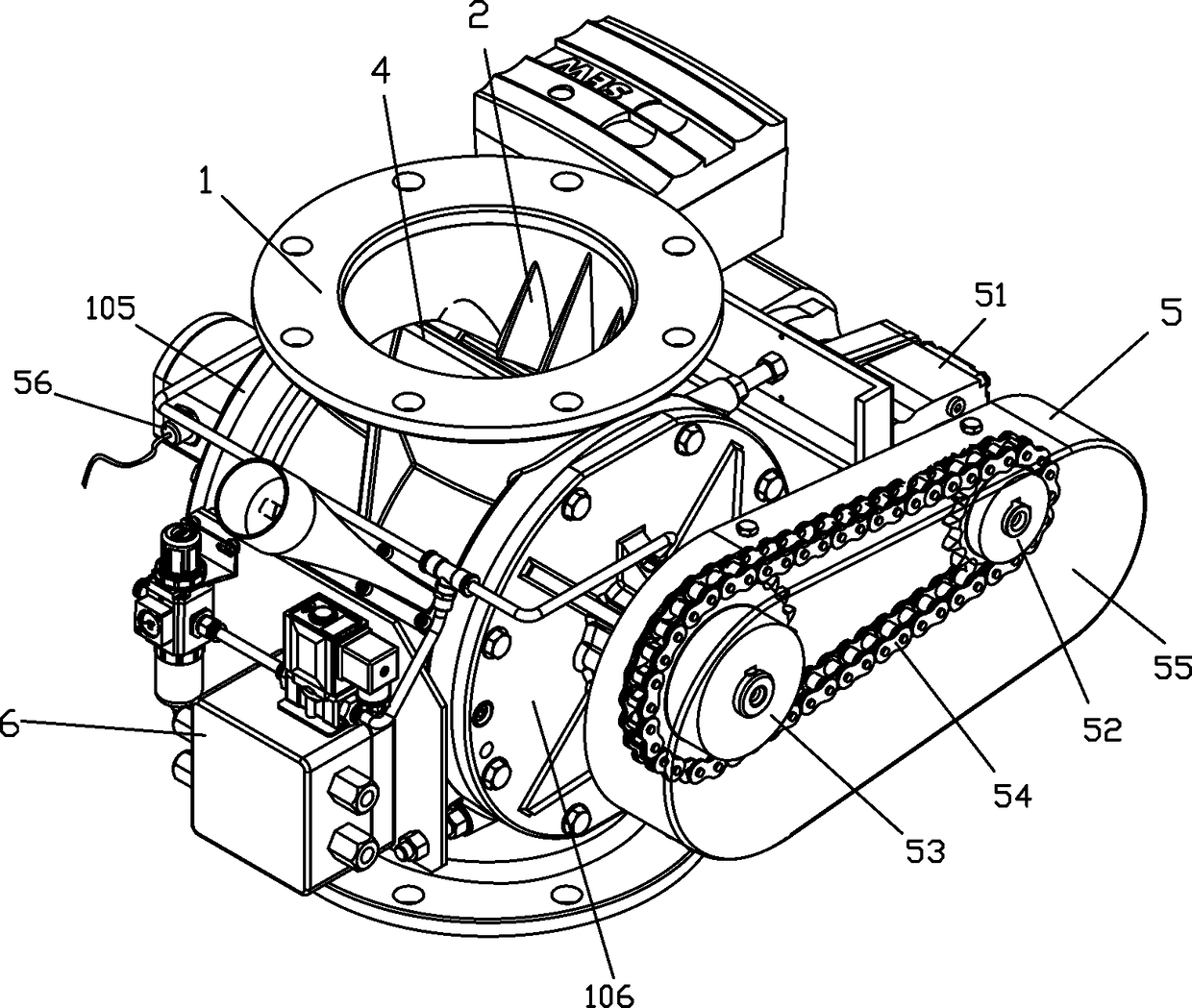

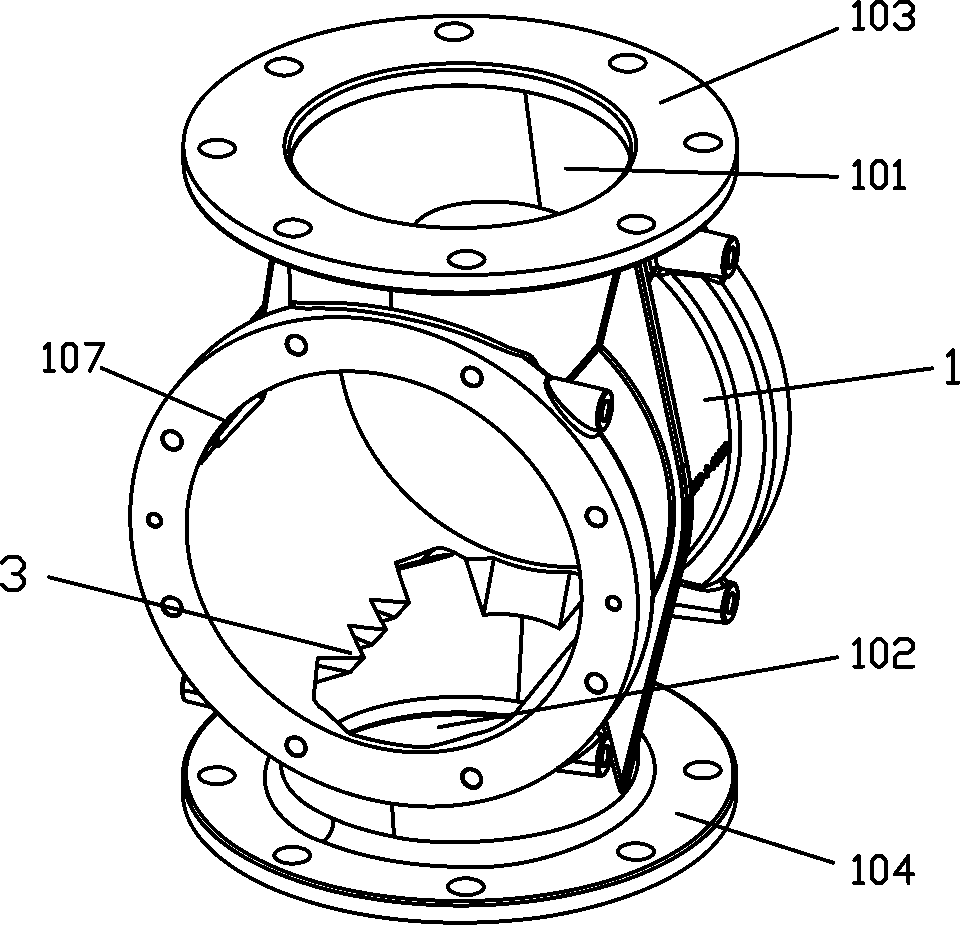

Particle material rotary valve

PendingCN109484861AContinuous and uniform fluidityContinuous uniform stateBulk conveyorsRotary valveReducer

The invention discloses a particle material rotary valve. The particle material rotary valve comprises a valve body, a rotor, a driving mechanism, a controller and a junction box, wherein the upper port of the valve body is a feeding port and the lower port of the valve body is a discharge port, each of a left port and a right port of the valve body is provided with an end plate, and a shaft holeis formed in the middle of each end plate; a plurality of material cutting teeth are arranged on one side of the inner wall of the feeding port side of the valve body in a protruding mode, an exhaustport is formed in the other side of the valve body, exhaust grooves are formed in the bottom surfaces of the material cutting teeth, and an exhaust channel connected to the exhaust port and the exhaust grooves is formed in the upper part of the inner wall of the valve body; the inner wall, on the same side of the exhaust port, of the discharge port of the valve body is provided with the material cutting teeth in the protruding mode; the rotor is in a star-shaped structure, and comprises a central shaft and a plurality of blades thereon; the driving mechanism comprises a motor, a speed reducer,a driving chain wheel, a driven chain wheel and a chain, a chain wheel protecting cover and a sensor, wherein the motor and the speed reducer are arranged on one side of the valve body, the driving chain wheel is arranged on a speed reducer output end and the driven chain wheel is arranged on the end part of one end of the rotor central shaft, the chain wheel protecting cover is arranged outsidethe driving chain wheel and the driven chain wheel in a covering mode, and the sensor is arranged on the outer side of the other end of the rotor center shaft; and the controller and the junction boxare arranged on the other side of the valve body, and the motor and the sensor are electrically connected to the interior of the junction box.

Owner:SHANGHAI BOLONG EQUIP TECH CO LTD

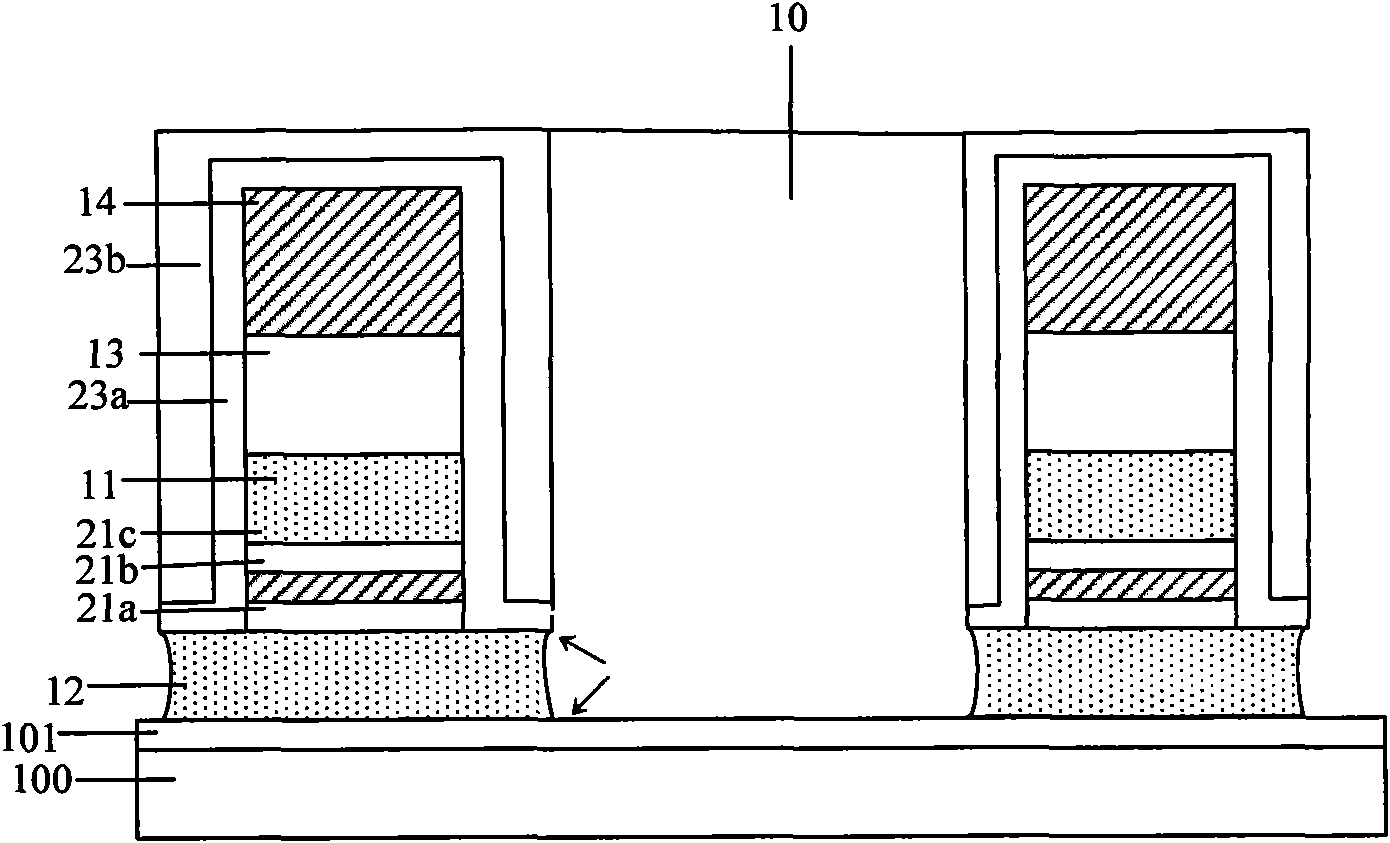

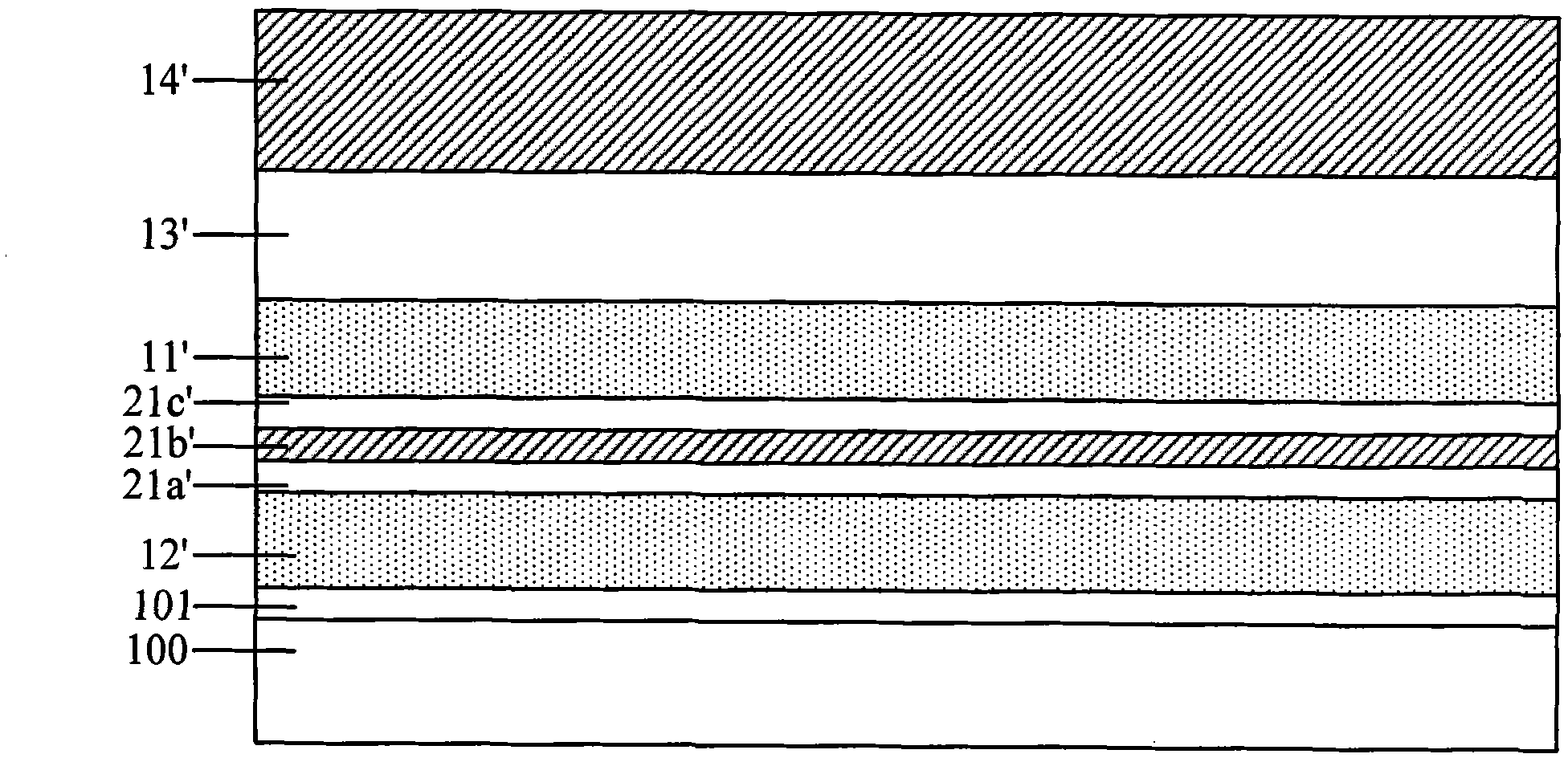

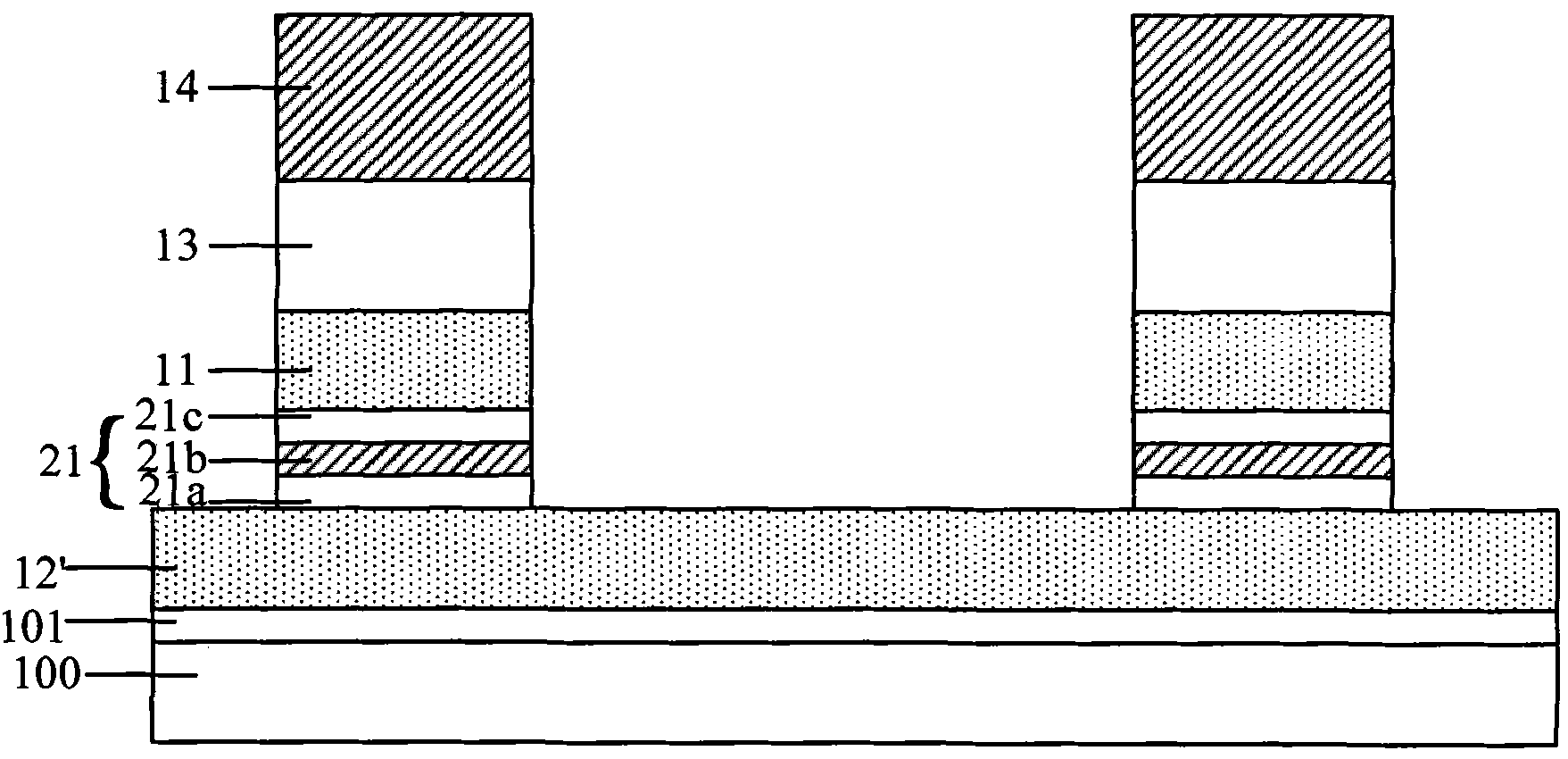

Method for manufacturing floating gate discharging sharp corner

InactiveCN101958240AReduce consumptionIncrease sharpnessSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringOxide

The invention discloses a method for manufacturing a floating gate discharging sharp corner, which at least comprises the following steps: oxidizing the side wall of a floating grate to form a side wall oxide layer; and removing the side wall oxide layer and part of the floating grate top corner oxide layer to form the floating grate discharging sharp corner. The floating gate discharging sharp corner manufactured by the invention has high sharpness and can improve the erasing speed of Flash data.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Thread cutting insert for thread turning processing and external thread component manufacturing method

InactiveCN107971587AGood effectLow costThread cutting toolsThread cutting machinesEdge strengthScrew thread

The present invention relates to a thread cutting insert for thread turning processing, and the cutting insert has a thread cutting edge formed on the outer peripheral surface of a shaft member by thread turning processing. A thread groove is bilaterally symmetrical in the section passing through the axis of the shaft member, and thus does not cause the reduction of machining surface accuracy, soas to reduce the cost of processing. The cutting edge is formed in a manner that the one side face of the cutting insert is used as the flank face, and the common flank face with the main flank angleof 0 is formed as the flank face, and the rake face is formed on the front and rear surfaces of the cutting insert. There are two cutting edges on one side of the face. In the thread turning process,interrupted cutting of minute portions is performed, and the cutting edge after one cutting operation is a machining surface away from the thread groove processed by the previous cutting. Therefore, without the main relief angle, the machining surface accuracy is not reduced. Therefore, the cutting insert is provided with the cutting edge on the front and back without the main relief angle, and the cutting edge strength is improved without reducing the accuracy of the machining surface, thereby reducing the cost of the machining.

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com