Manufacturing method of bucket teeth for excavating

A technology of tooth tips and sharp teeth, which is applied in the field of preparation of bucket teeth for excavation, can solve the problems of low wear resistance and low strength, and achieve the effects of enhancing firmness, improving sharpness, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

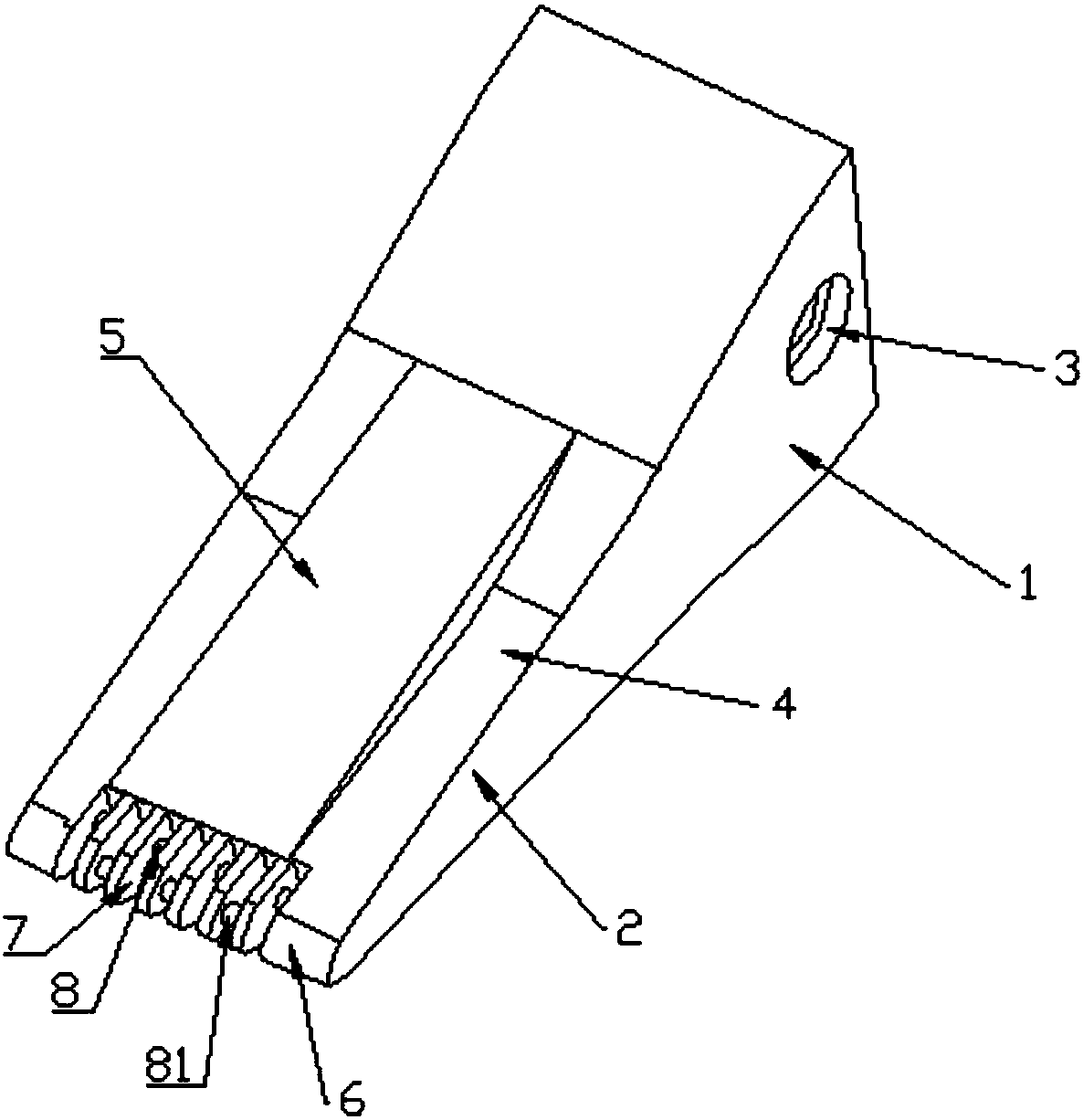

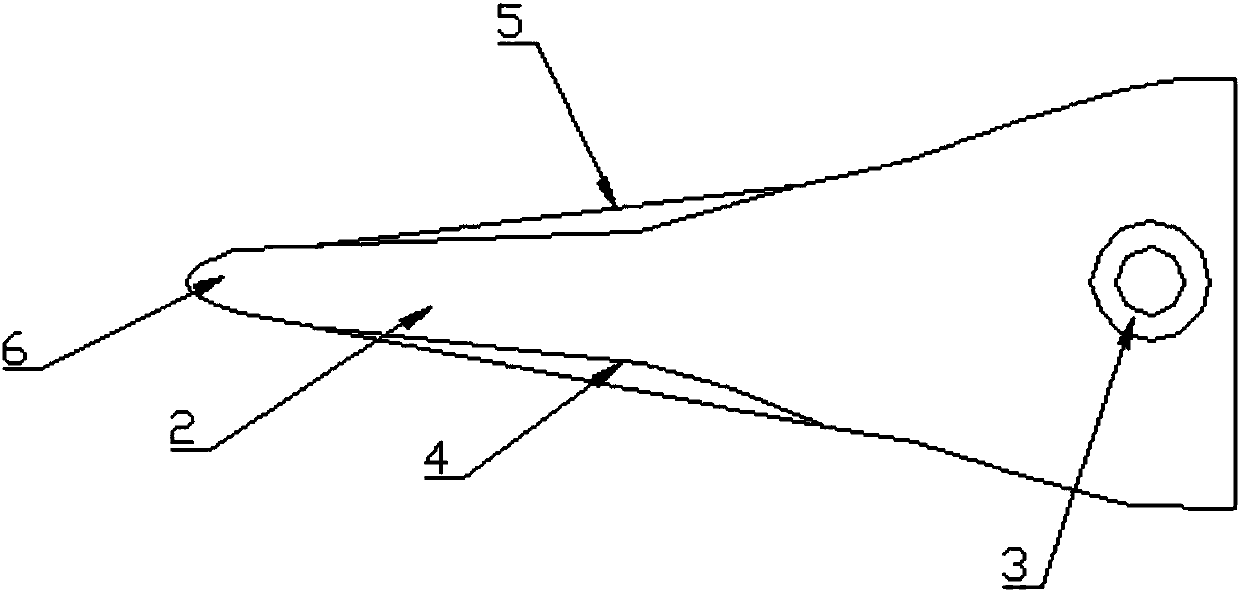

[0016] Such as figure 1 As shown, a method for preparing bucket teeth for excavation, including a connecting seat 1 and a tooth tip 2, the left and right side walls of the connecting seat 1 away from the tooth tip 2 are provided with counterbore holes 3, and the tooth tip 2 Concave surfaces 4 are provided on both sides of the upper and lower end surfaces. The concave surfaces 4 extend from the connection between the connecting base 1 and the tooth tip 2 to the front edge of the tooth tip 2. The middle of the two concave surfaces 4 is inclined downward. The reinforcement part, the free end of the tooth tip 2 is provided with tines 7 separated at equal intervals, and a first rib 8 and a second rib 81 are arranged between adjacent tines 7, the said The first ribs 8 and the second ribs 81 are alternately arranged.

[0017] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com