Food cutter and manufacturing method thereof

A slitting knife and food technology, applied in metal processing, metal processing equipment, etc., can solve the problems of uneven slitting, large wear, easy sticking of knives, etc., and achieve good slitting effect, small wear, and not easy to become blunt Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

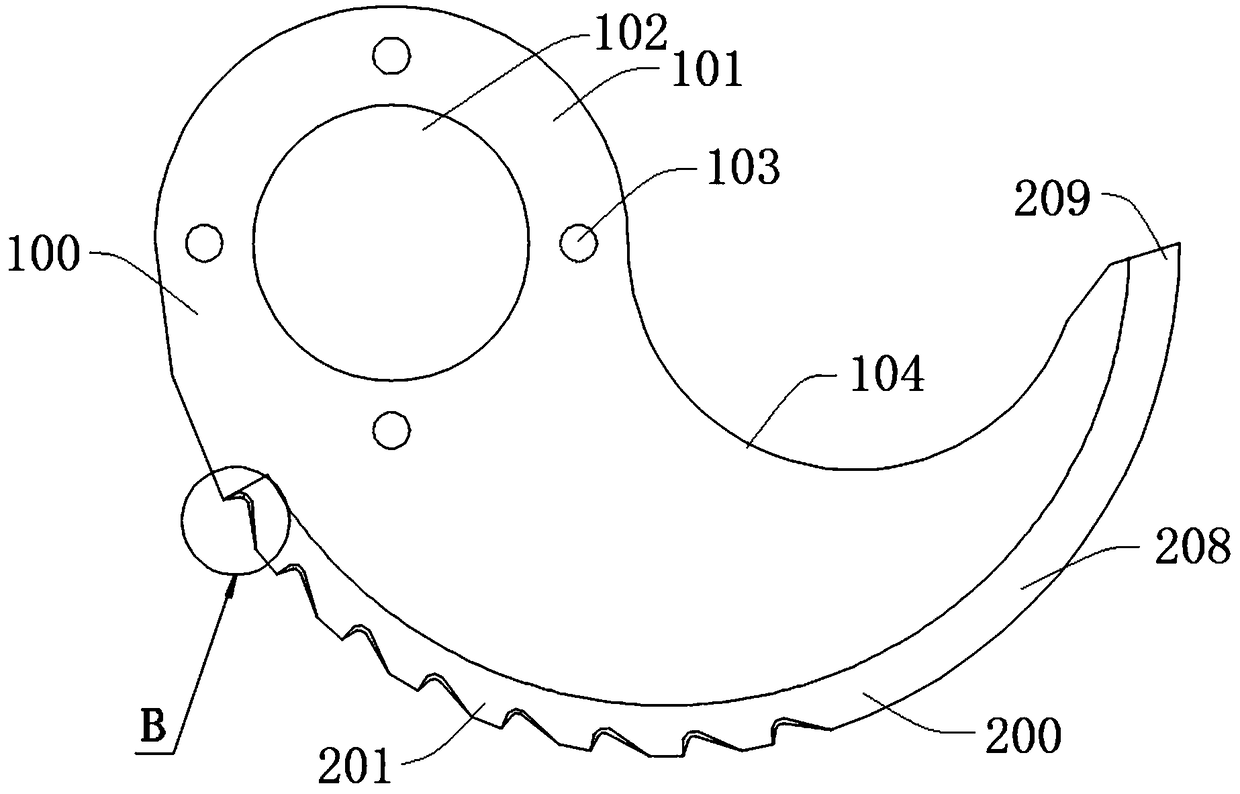

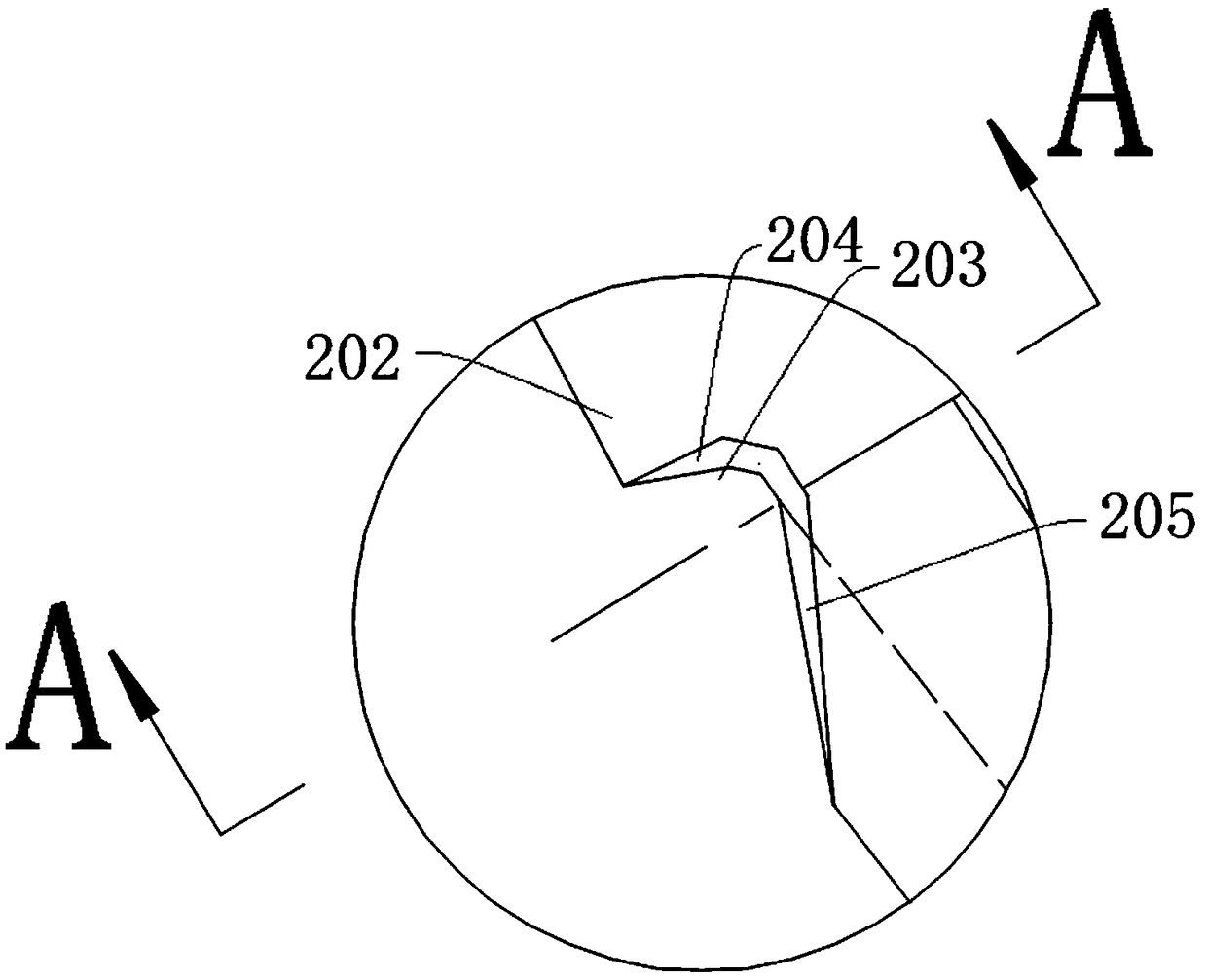

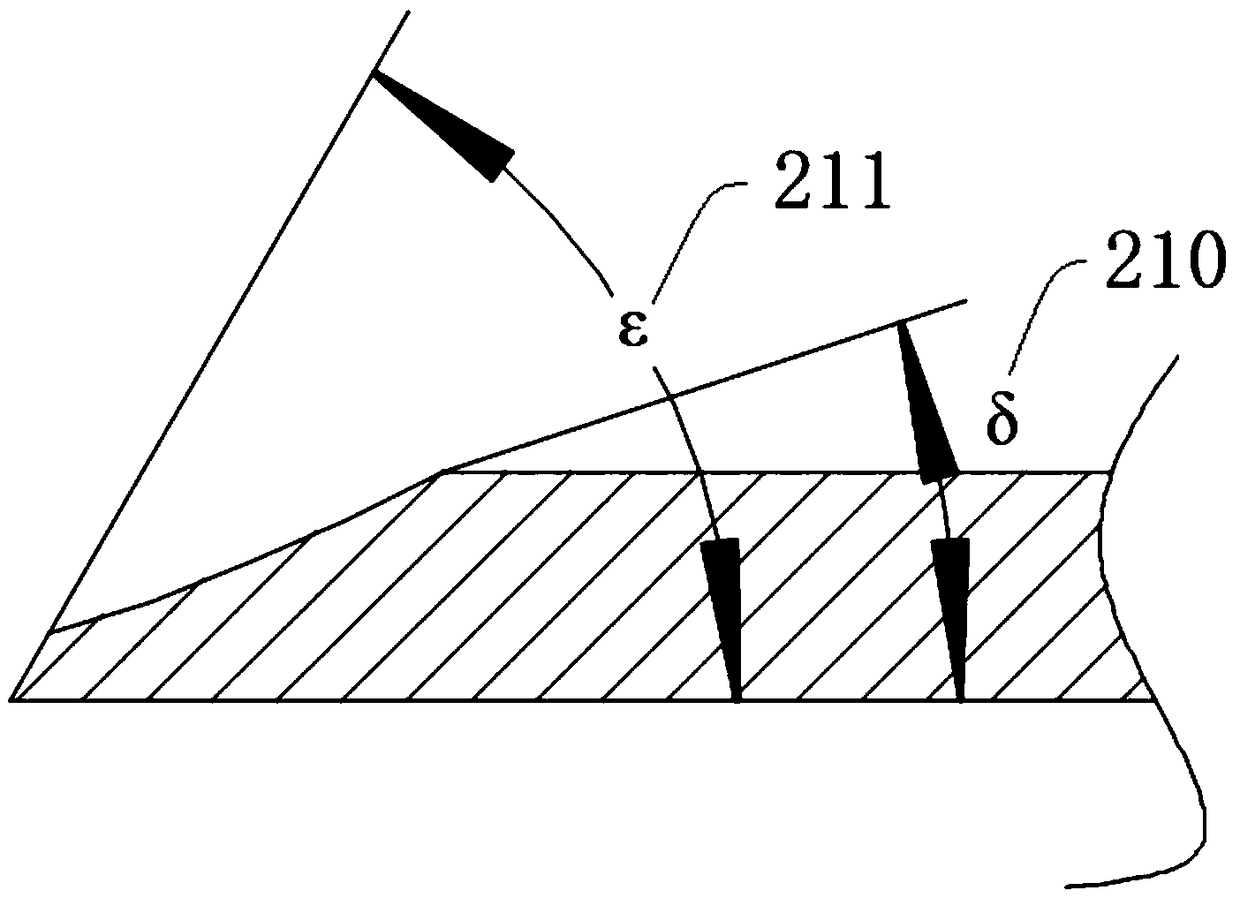

[0082] A food dividing knife in this embodiment includes a knife body 100 and a blade 200, and the knife body 100 and the blade 200 constitute a food dividing knife body.

[0083] The cutter body 100 includes a mounting portion 101, a knife back 104 and a first central angle α105, the mounting portion 101 is located at one end of the cutter body 100, the mounting portion 101 includes a mounting hole 102 and a fixing hole 103, the mounting hole 102 is located at the center of the mounting portion 101, and the fixing hole The number of 103 is more than two, and they are evenly arranged around the installation hole 102 in the circumferential direction. The knife back 104 is located on the opposite side of the food cutting knife body where the blade 200 is provided, and the knife back 104 is generally arc-shaped.

[0084] The included angle formed by the connection line between the center point of the mounting hole 102 and the blade tip 209 and the connection line between the apex...

Embodiment 2

[0107] A food dividing knife in this embodiment includes a knife body 100 and a blade 200, and the knife body 100 and the blade 200 constitute a food dividing knife body.

[0108] The cutter body 100 includes a mounting portion 101, a knife back 104 and a first central angle α105, the mounting portion 101 is located at one end of the cutter body 100, the mounting portion 101 includes a mounting hole 102 and a fixing hole 103, the mounting hole 102 is located at the center of the mounting portion 101, and the fixing hole The number of 103 is more than two, and they are evenly arranged around the installation hole 102 in the circumferential direction. The knife back 104 is located on the opposite side of the food cutting knife body where the blade 200 is provided, and the knife back 104 is generally arc-shaped.

[0109] The angle formed by the connection line between the center point of the mounting hole 102 and the tip of the blade 209 and the line between the apex of the first...

Embodiment 3

[0132] A food dividing knife in this embodiment includes a knife body 100 and a blade 200, and the knife body 100 and the blade 200 constitute a food dividing knife body.

[0133] The cutter body 100 includes a mounting portion 101, a knife back 104 and a first central angle α105, the mounting portion 101 is located at one end of the cutter body 100, the mounting portion 101 includes a mounting hole 102 and a fixing hole 103, the mounting hole 102 is located at the center of the mounting portion 101, and the fixing hole The number of 103 is more than two, and they are evenly arranged around the installation hole 102 in the circumferential direction. The knife back 104 is located on the opposite side of the food cutting knife body where the blade 200 is provided, and the knife back 104 is generally arc-shaped.

[0134] The included angle formed by the line connecting the center point of the mounting hole 102 and the tip of the blade 209 and the line connecting the apex of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com