Axial-force-controllable surgical bone drill using brazed PCBN (Polycrystalline Cubic Boron Nitride) superhard material drill bit

A super-hard material and axial force technology, applied in the field of medical devices, can solve the problems that the accuracy and accuracy of signal acquisition and processing are difficult to be guaranteed, the accuracy and accuracy of testing cannot meet the requirements, and the accuracy and accuracy cannot be guaranteed, etc. , to achieve the effect of taking away heat, ensuring strength and reducing drilling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

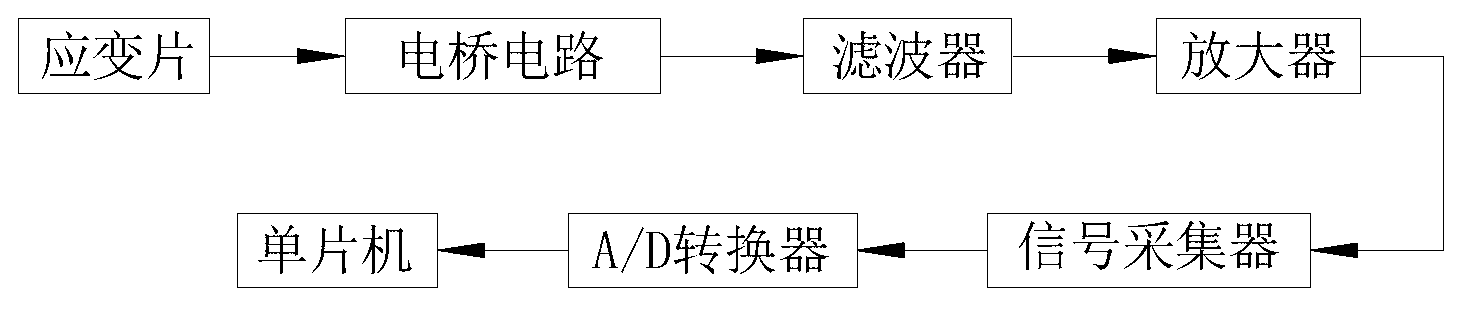

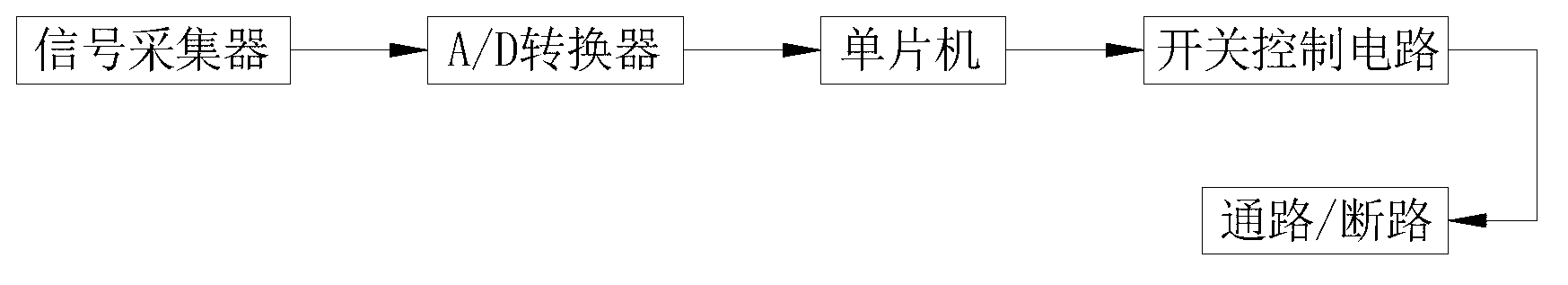

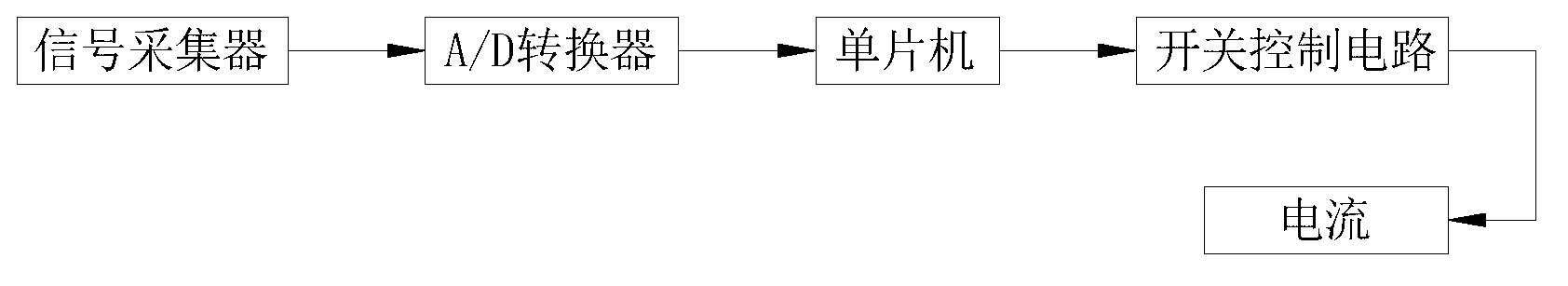

[0033] figure 1 The various components of the self-stop cooling electric drill for surgical bone drilling are shown, wherein the casing 4 is composed of symmetrical upper and lower halves, and is fixed by screws through threaded holes 31 . The DC power supply 1 is connected to the control switch 2 with wires, combined with figure 2 It can be seen that the control switch 2 is connected with the switch control circuit 38 in the intelligent integrated control system 7 with wires, and the switch control circuit 38 is connected with the DC motor 5 with wires. DC motor 5 is fixed on the DC motor base 29. The DC motor 5 and the driving gear shaft 3 are connected through concave-convex grooves. The driving gear shaft 3 is installed on the deep groove ball bearing I21 and the deep groove ball bearing II22 to realize positioning, and the two bearings are posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com