Thread machining blade

A technology for threading and inserting, applied in the field of indexable threading inserts, can solve the problems of difficult breaking of chips, easy hitting on the insert, reducing production efficiency, etc. The effect of breaking and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

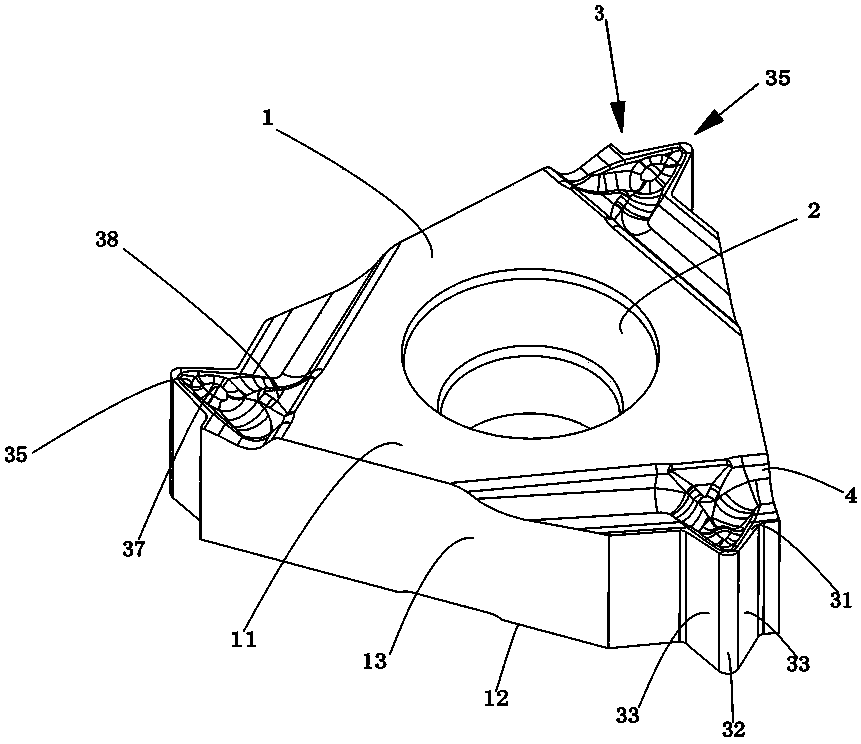

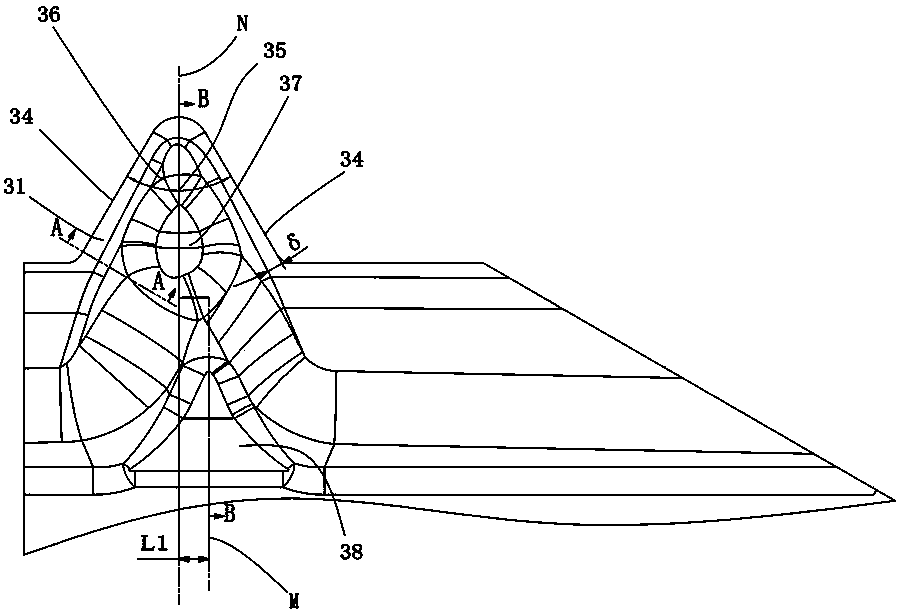

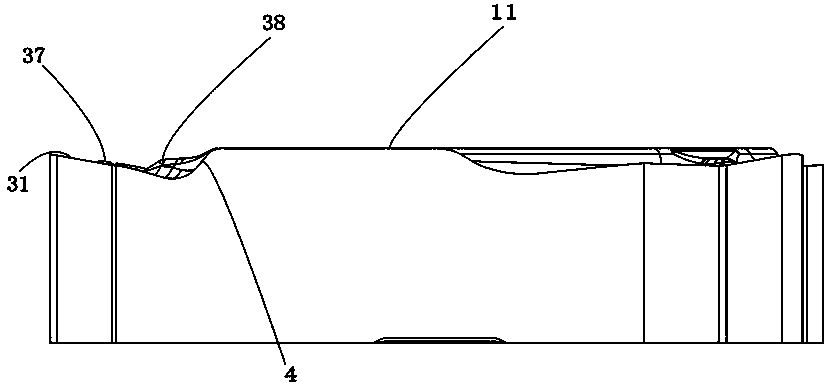

[0022] Figure 1 to Figure 5 Shown is a thread processing blade embodiment of the present invention, the thread processing blade includes a blade body 1, the blade body 1 is surrounded by an upper surface 11, a lower surface 12 and a side surface 13, and the blade body 1 is provided with a blade center hole 2 And the cutting edge portion 3, the cutting edge portion 3 is surrounded by a rake face 31, a rake face 32 and two bevel side faces 33, and the two bevel facets 33 intersect with the rake face 31 to form two side cutting edges 34, the angle between the two side cutting edges 34 is the cutting edge angle 35, the rake face 31 is connected with the upper surface 11 of the blade body 1 through a connecting curved surface 4, and the rake face 31 is provided with a cutting edge angle 35 The chip guide groove 36 is distributed symmetrically on the bisector of the angle N, protruding outward from the inside of the chip guide groove 36 to form a spherical chip breaking boss 37 hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com