Centrifugal pump with cutting devices

A technology with cutting, centrifugal pumps, applied in the direction of components, pumps, pump elements, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

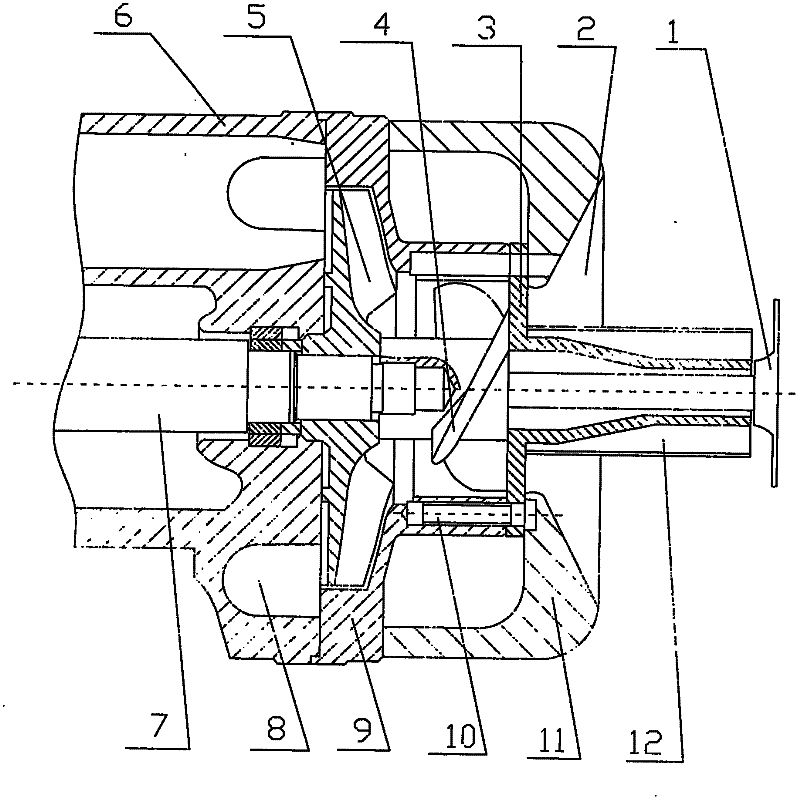

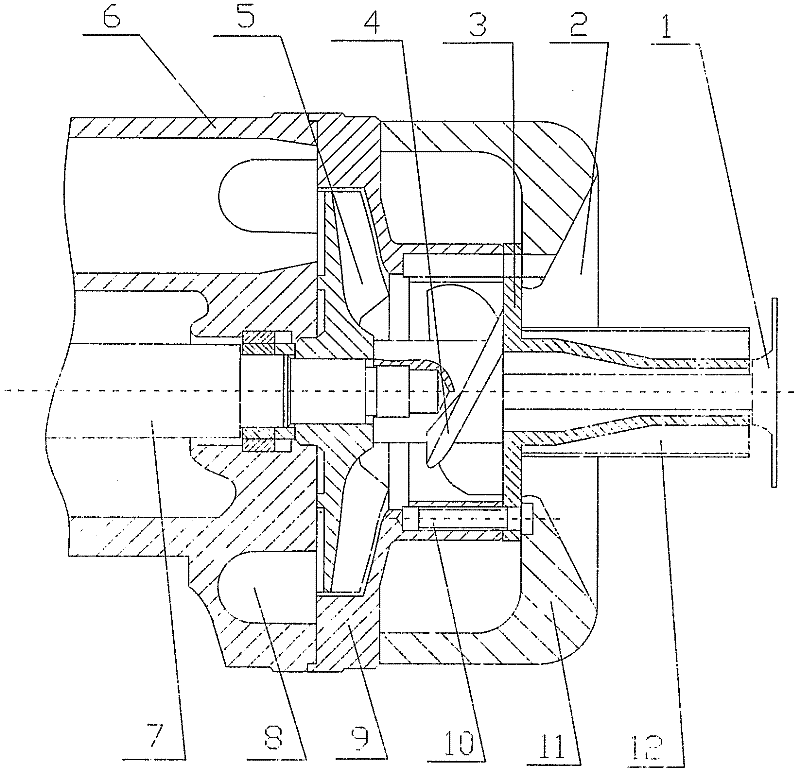

[0009] In order to make the technical means, innovative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings.

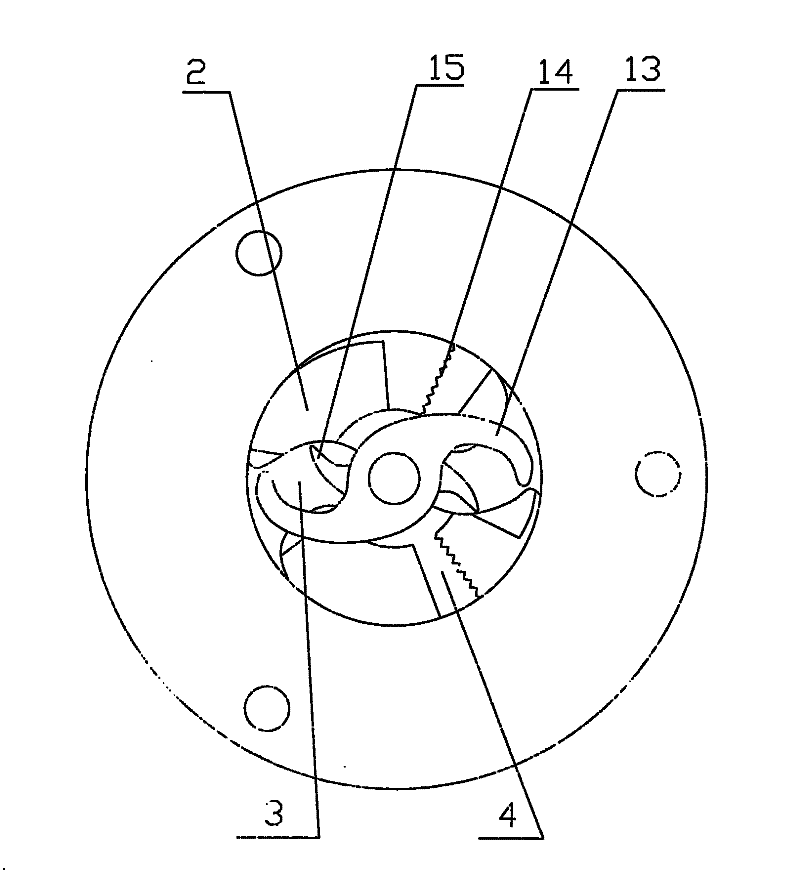

[0010] The centrifugal pump of the present invention adopts a triple cutting structure. This structure is used to crush the sundries in the sewage, improve the degree of non-blocking, and then improve the performance of the centrifugal pump. The cutting knife at the front end, the cutting impeller and the main impeller all rotate with the pump shaft. The cutting knife adopts two S-shaped shapes, and the cutting edge on the cutting impeller adopts three saw-toothed shapes.

[0011] Structure description

[0012] Such as figure 1 As shown, the centrifugal pump consists of a cutter (1), an inlet (2), a fixed cutter (3), a cutter impeller (4), a main impeller (5), a pump casing (6), a pump shaft (7), an outlet (8 ), main impeller front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com