Reversible holes turning insert

A technology of inserts and inner holes, applied in turning equipment, tools for lathes, accessories of toolholders, etc., can solve the problems of limited inner hole finishing of workpieces, large cutting force, and uncontrollable or unpredictable chip flow. , to avoid interference and enhance sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with accompanying drawing:

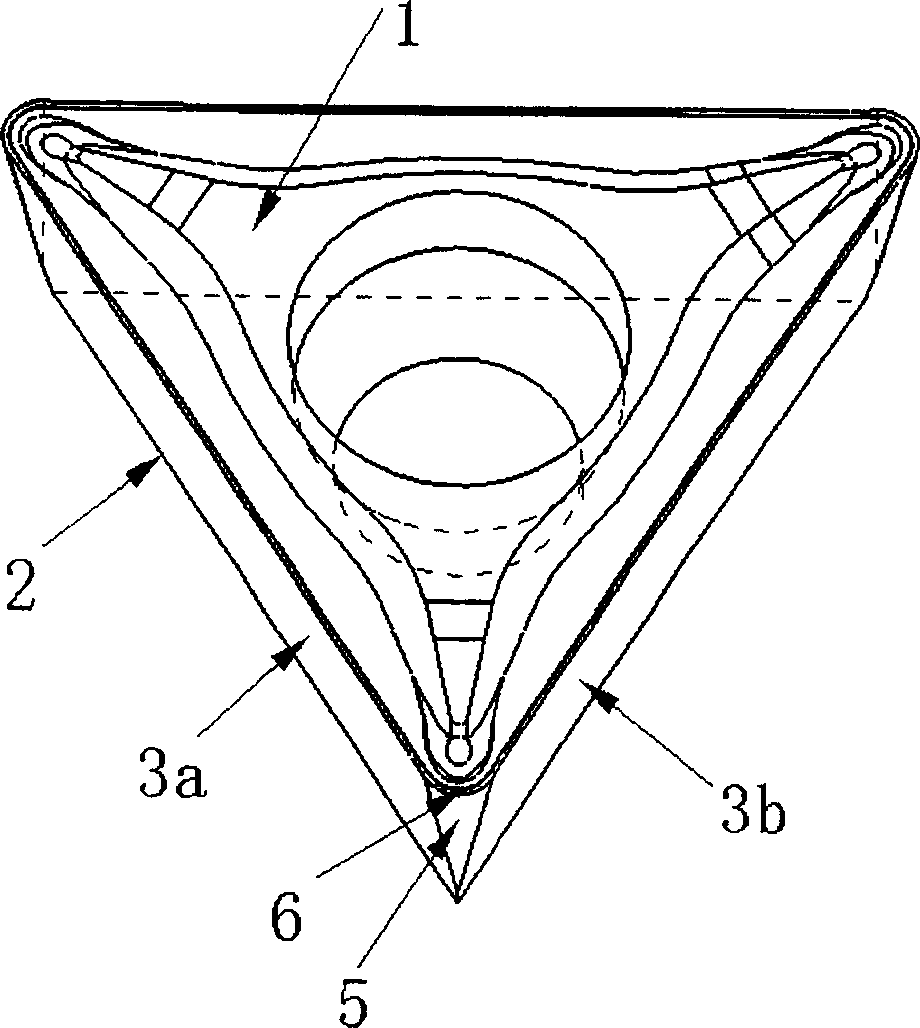

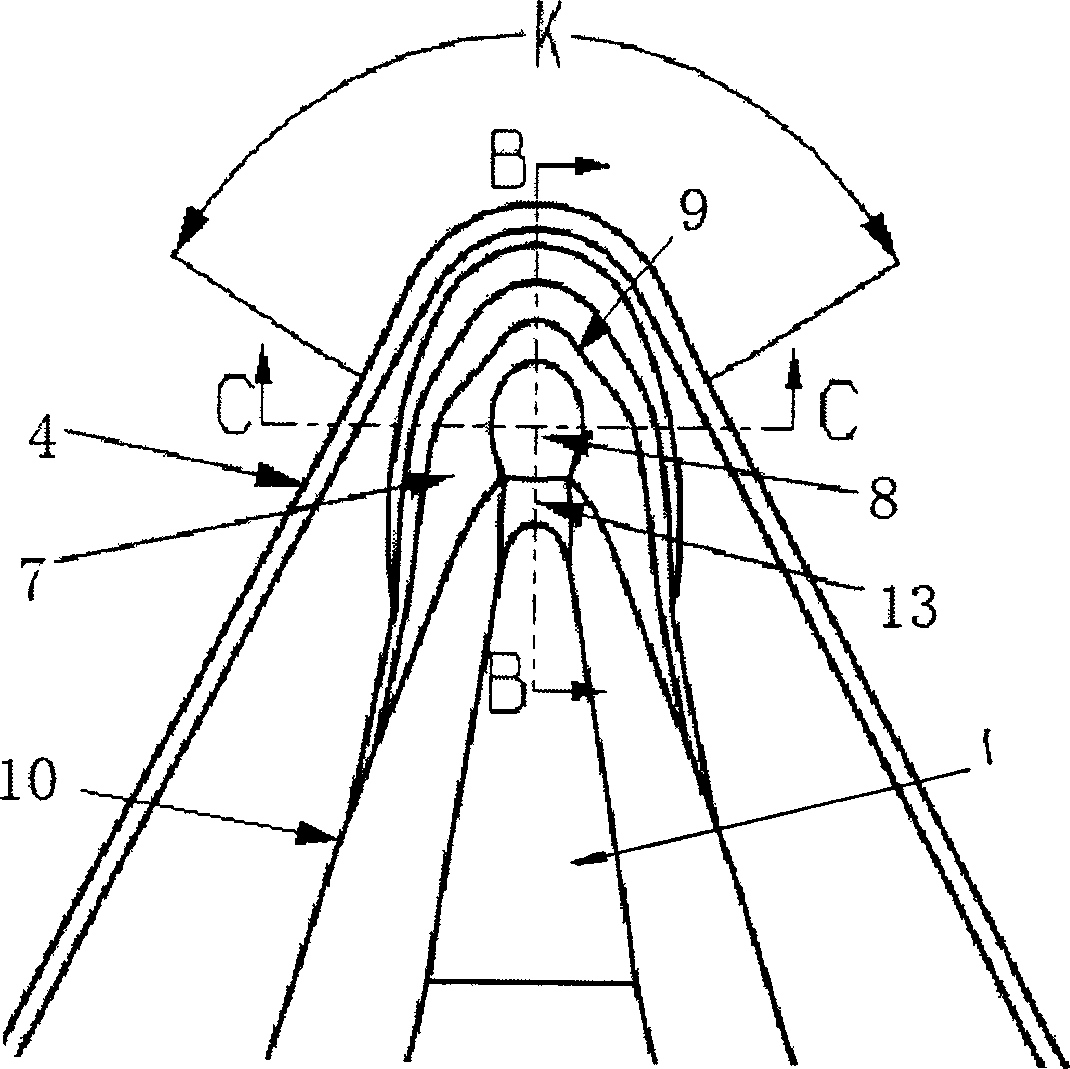

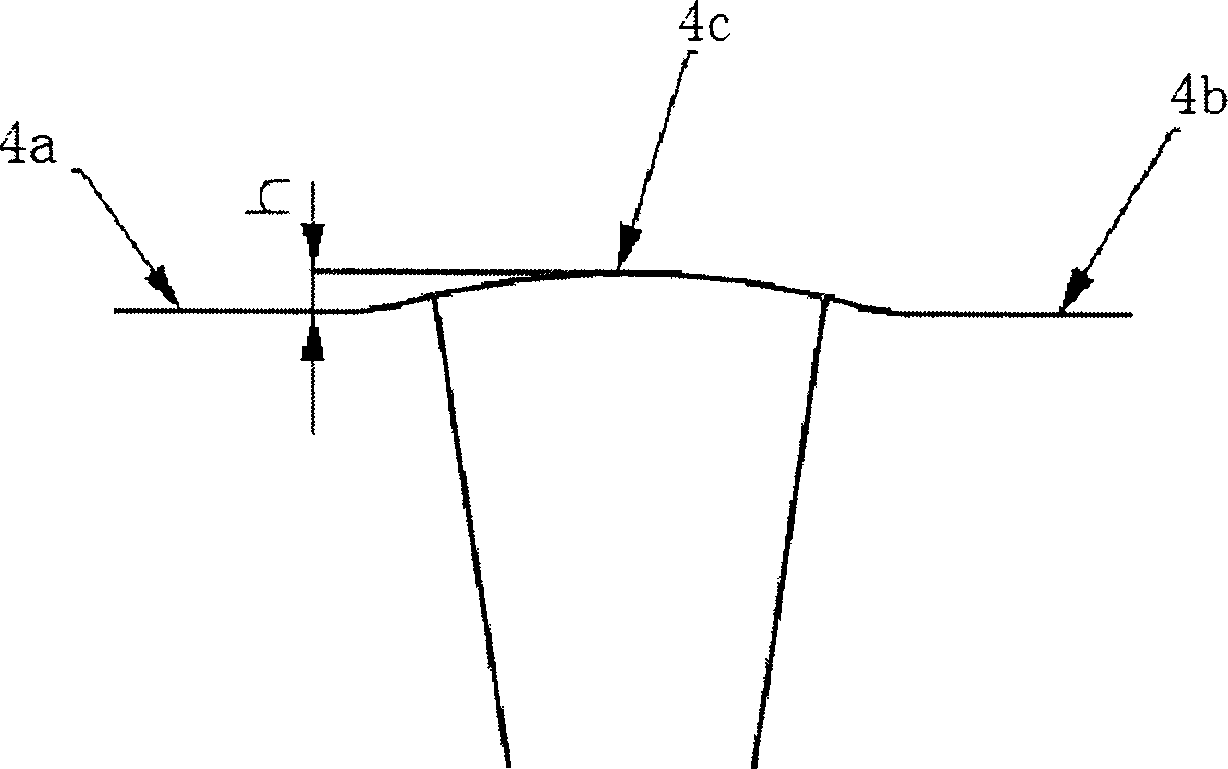

[0016] Such as Figure 1-Figure 6 As shown, the indexable inner hole turning insert of the present invention has a polygonal basic shape, such as a triangle, including opposite upper and lower surfaces 1, 2 and three groups of side walls 3 connecting the two, the side walls 3 and the upper surface 1 intersect to form the cutting edge 4 of the insert, where the upper surface 1 forms the rake face. The cutting edge 4 is distributed symmetrically with respect to the geometric bisector of the cutting edge angle 6, in the shape of a spatial helix, and the top edge 4c located on the geometric bisector of the cutting edge angle is at the highest position, and the maximum difference h between the symmetrical side edges 4a and 4b is 0.02 -0.2mm; Adjacent sidewalls 3a and 3b are connected by conical surface 5 to form a flank with a relief angle a of 5°-15°; upper surface 1, sidewal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com