Indexable turning blade for high temperature alloy semifinishing under high-pressure cooling

A high-temperature alloy, semi-finishing technology, used in metal processing equipment, tools for lathes, cutting inserts, etc., can solve the problems of difficult to guarantee machining accuracy, poor machinability of materials, wear and tear of turning inserts, etc. quality, reducing cutting temperature, reducing the effect of tool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

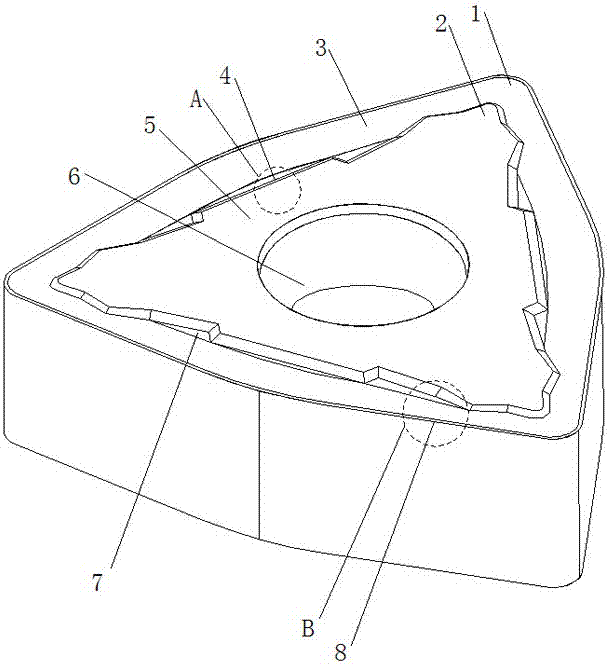

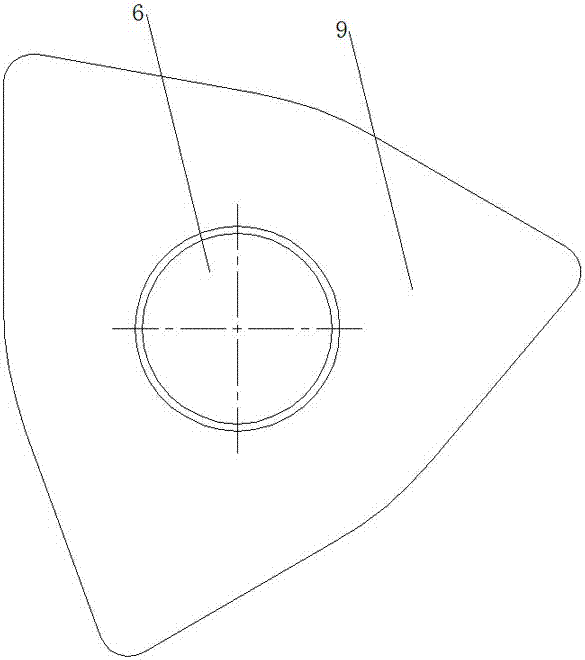

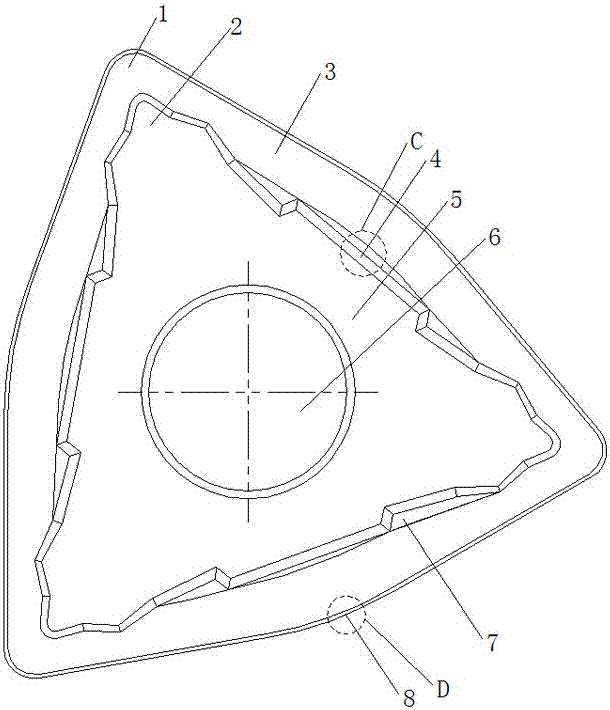

[0022] Specific implementation mode one: as Figure 1-Figure 7 As shown, this embodiment discloses an indexable turning insert for semi-finishing superalloys under high-pressure cooling, including a turning insert body, the outer contour of the horizontal section of the turning insert main body is hexagonal, and the hexagonal The geometric center of the car blade main body 5 is provided with a fastening screw hole 6, and the outer periphery of the hexagonal car blade main body 5 top surface is provided with a rake face 3, and the six corners of the hexagonal car blade main body 5 are formed by three 80 ° angle and three 160 ° angles are arranged alternately to form successively, three 80 ° angle places of hexagonal turning blade main body 5 are all provided with circular arc knife tip 1, and the six outer edges of hexagonal turning blade main body 5 top surfaces A negative chamfer cutting edge 8 is provided, and a protrusion 2 is provided near each of the circular arc tool tip...

specific Embodiment approach 2

[0025] Specific implementation mode two: as figure 1 , image 3 As shown, this embodiment is a further description of the first embodiment, and the shape of the protrusions 2 near each circular-arc knife tip 1 is tower-shaped.

[0026] Both the tower-shaped protrusion and the broken-line stepped chip breaker 4 need to ensure the proportional size and strength of the structure, and play a certain role in chip breaking and chip guiding, which can meet the chip space requirements of the chip slot 7 and play a role in chip removal. function, and store a certain amount of coolant at the same time, which can reduce the temperature of the turning blade during the cutting process.

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 1 , image 3 , Figure 5 , Figure 7 As shown, this embodiment is a further description of Embodiment 1. The combination of the rake face 3 and the negative chamfer cutting edge 8 forms a double rake angle design, and the rake angle of the turning insert is 10° , the angle of the negative chamfer is -15°, the width of the negative chamfer is 0.1mm, and the relief angle of the turning blade is 0°. It is also possible to form a suitable relief angle by combining with the high-pressure cooling turning tool holder, so that the turning Blades are more practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com