Method for preparing needle point of atomic force microscope

An atomic force microscope and needle tip technology, applied in scanning probe microscopy, scanning probe technology, measuring devices, etc., can solve the problems of easy loss, delay of experiment progress, interruption of experiment process, etc., so as to speed up the experiment process and improve sharpness degree, method, effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

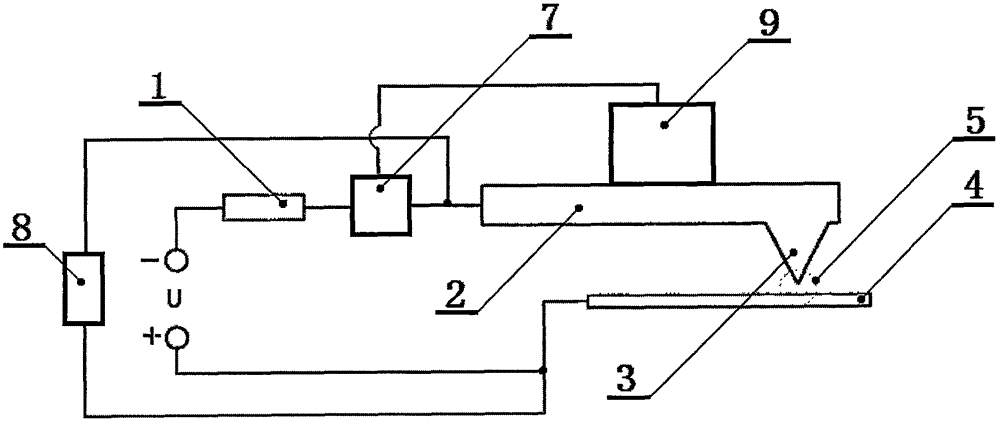

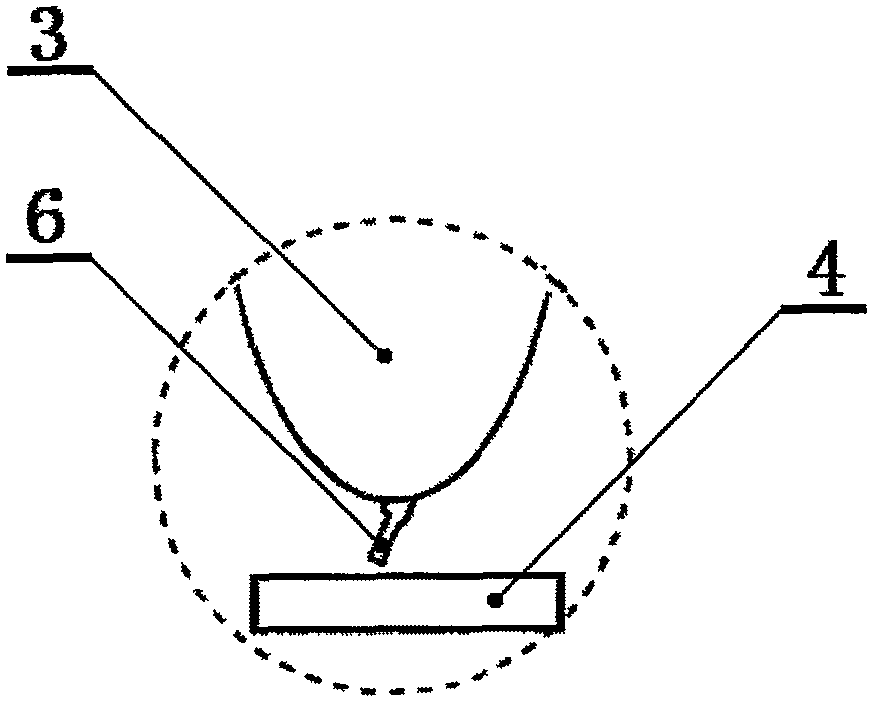

[0025] Such as figure 1It is a schematic diagram of the present invention, and the device for realizing the method mainly includes a resistor 1, a cantilever 2, a needle tip 3, a sample 4, a gap between the sample and the needle tip 5, a thorn 6, a current feedback system 7, a photoelectric feedback system 8, Piezoelectric driver 9, power supply U, wherein the positive pole of the power supply U is connected to the sample 4, the negative pole is connected to the resistor 1 in turn, the current feedback system 7, the cantilever 2 and the needle point 3, the needle point 3 is fixed below the cantilever 2, and the sample 4 includes The first specific sample and the second specific sample are located below the needle point 3; with the power supply U, the resistor 1, the current feedback system 7, the cantilever 2, the needle point 3, the gap between the sample and the needle point 5 and the sample 4 composed of a current feedback loop, when the current feedback system 7 is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com