Aluminum foil roll slitting and stretching machine and matching aluminum foil roll processing method

A processing method and technology of aluminum foil rolls, applied in metal processing and other directions, can solve problems such as unstable product quality control, uneven rolling density of explosion-proof materials, and easy-to-break mesh materials, so as to achieve dense rolls and uniform sizes , the effect of high filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

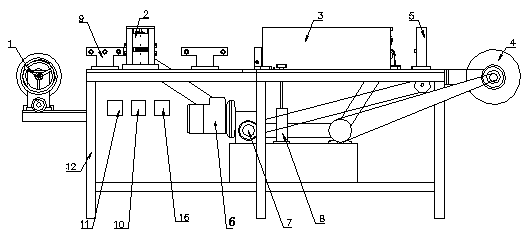

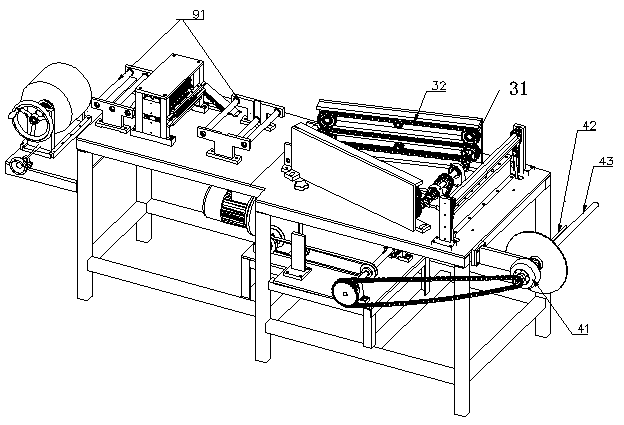

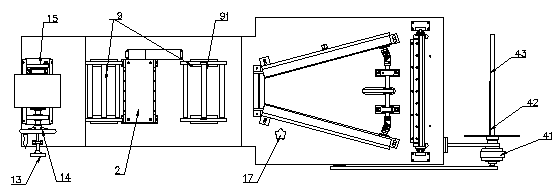

[0040] Embodiment: An aluminum foil roll slitting and stretching machine, see Figure 1 to Figure 5, the feeding device 1 is installed on one side of the frame, behind the feeding device 1 and on the frame is also installed a machine driven by the same power source. , slitting device 2, stretching net device 3 and material receiving device 4, respectively be provided with shaping device 9 between feeding device 1 and slitting device 2, between slitting device 2 and stretching net device 3, in stretching net device 3 A cutter device 5 is provided between the receiving device 4;

[0041] The slitting device 2 comprises a knife roll fixed mount 23, and a pair of fixed blocks and a pair of sliding blocks 25 are correspondingly arranged at the two ends of the knife roll fixed mount 23, the fixed block is corresponding to the two ends of the lower cutter roll 22, and the sliding block is connected to the upper cutting blade. The two ends of knife roll 21 are corresponding, and slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com