Pole roll slitting machine

A technology of slitting machine and pole roll, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, shearing devices, etc., to achieve the effect of improving slitting quality and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

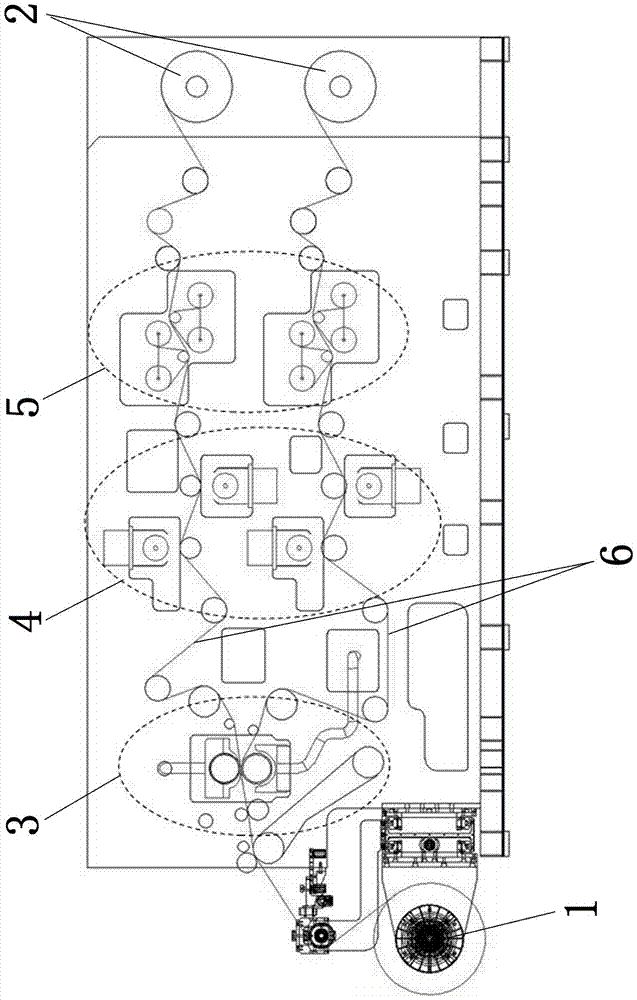

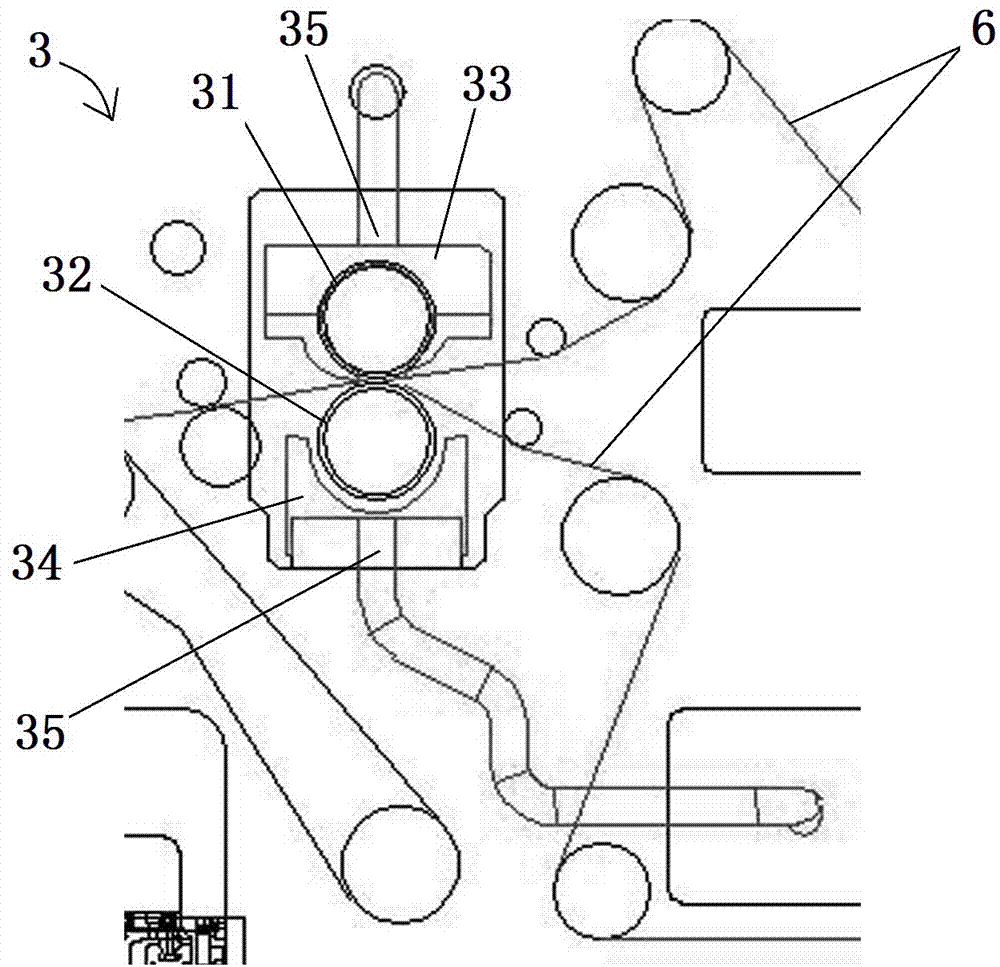

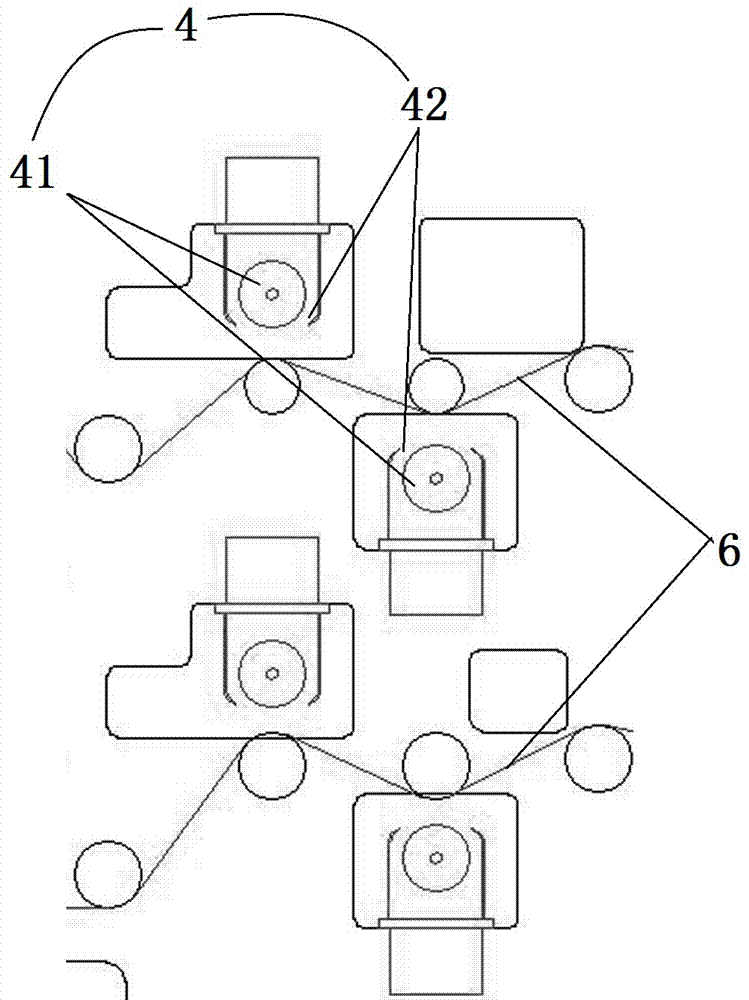

[0029] The specific embodiment of pole volume slitting machine of the present invention, as Figure 1 to Figure 4 As shown, including the body of the slitting machine, the body is provided with an unwinding mechanism 1 to unwind the pole roll, and the body is also provided with a slitting knife to perform slitting operations on the unwinded pole roll. The slitting knife includes an upper slitting knife 31 and a lower slitting knife 32. The tangent position of the upper and lower slitting knives is the slitting position, and the pole roll is divided into two at this slitting position. Rewinding is carried out through the rewinding mechanism 2 after passing through the dividing dust removal mechanism 3, the brush dust removal mechanism 4 and the wiping dust removal mechanism 5 respectively arranged on the body to complete the slitting work.

[0030] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com