Paper roll slitting and winding device

A rewinding device and paper roll technology, applied in the direction of cardboard winding articles, etc., can solve the problems of cumbersome, time-consuming, labor-intensive, low work efficiency, etc. The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below:

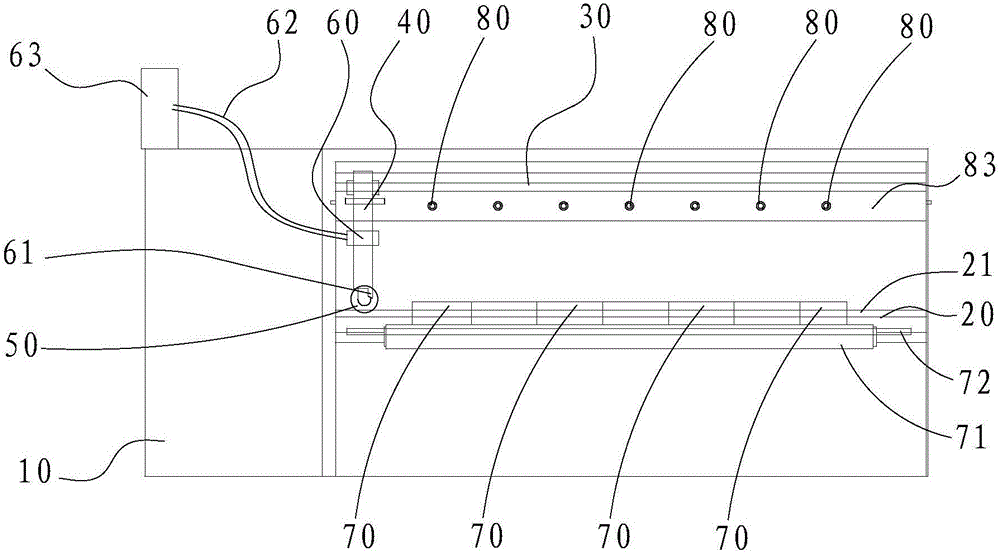

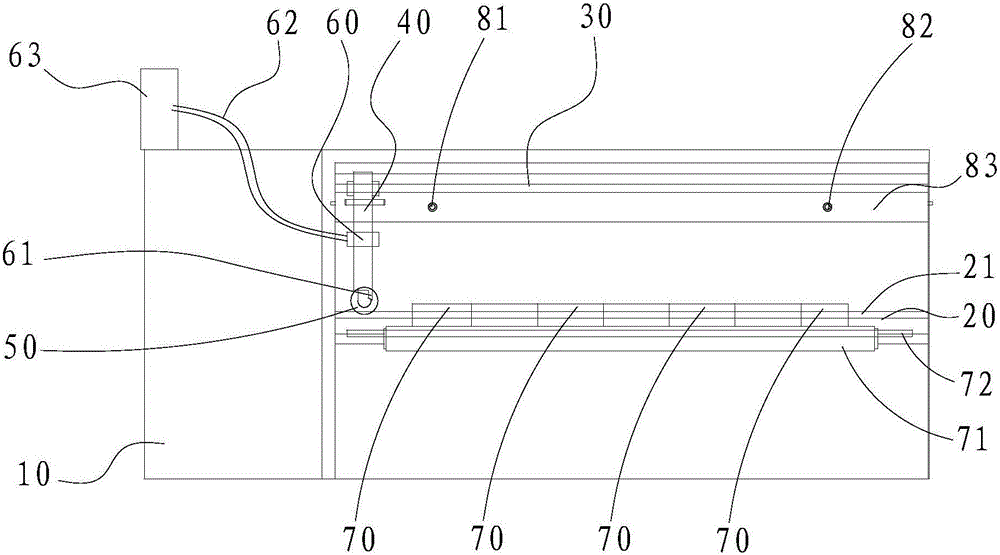

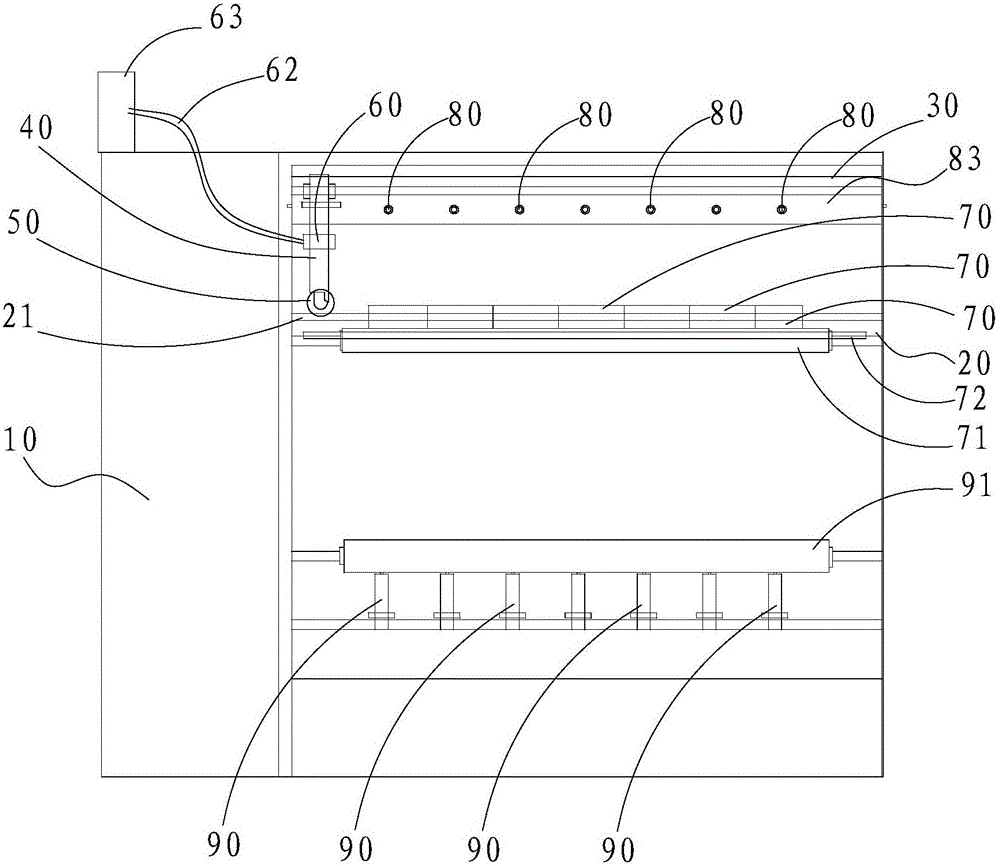

[0024] Such as figure 1 As shown, the paper roll slitting and winding device of the present invention includes an unwinding mechanism, a slitting mechanism, a winding mechanism 10, a cutting table 20, a sliding rail 30, a sliding member 40, a cutting member 50, and a glue spraying mechanism 60.

[0025] The unwinding mechanism is used for unwinding the paper roll. The slitting mechanism is used to slit the unwinded paper into more than two paper strips 70. The winding mechanism 10 is used to wind more than two paper strips 70 onto a reel 71. Wherein, the number of rolls 71 may be more than two, and more than two rolls 71 are sleeved on the rotating shaft 72 in series, and the two or more rolls 71 correspond to the two or more paper strips 70 one by one. During the winding process of the paper strip 70, driving the rotating shaft 72 to rotate can realize the winding of two or more paper strips 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com