A production and winding device for plastic woven bags

A plastic woven bag and winding device technology, which is applied in thin material processing, strip winding, transportation and packaging, etc., can solve the problems of low work efficiency and low diversity of winding equipment, so as to improve efficiency, Effects of increasing variety and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention can also be implemented in various specific ways according to the content defined and covered by the claims.

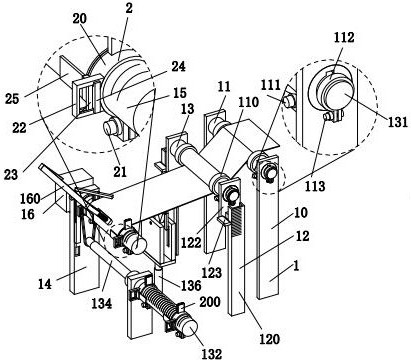

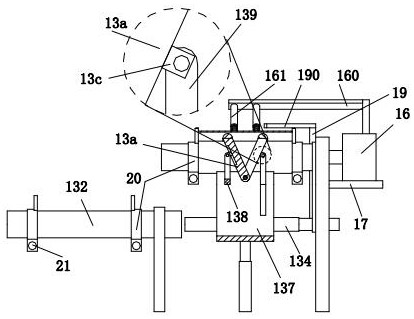

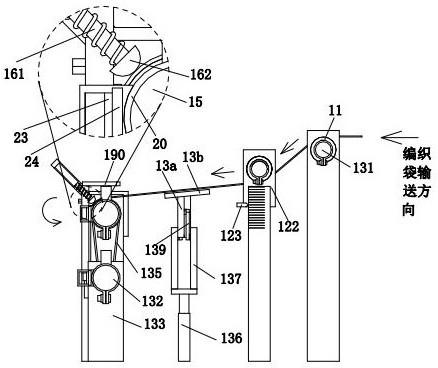

[0030] Such as Figure 1 to Figure 7 As shown, a rolling device for producing plastic woven bags includes a rolling mechanism 1 and a fixing mechanism 2. The rolling mechanism 1 is installed on the ground, and the fixing mechanism 2 is arranged on the left side of the winding mechanism 1.

[0031] The rewinding mechanism 1 includes a No. 1 vertical frame 10, a transmission roller 11, a No. 2 vertical frame 12, a conveying roller 13, a vertical frame 14, a winding roller 15, a motor 16, a frame 17, and a No. 1 electric slider 18 , connecting plate 19, limit plate 190 and indicator plate 191, the No. 1 vertical frame 10 is symmetrically installed on the ground front and back, and the upper end of the No. The No. 2 st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com