Patents

Literature

65results about How to "Less prone to drift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

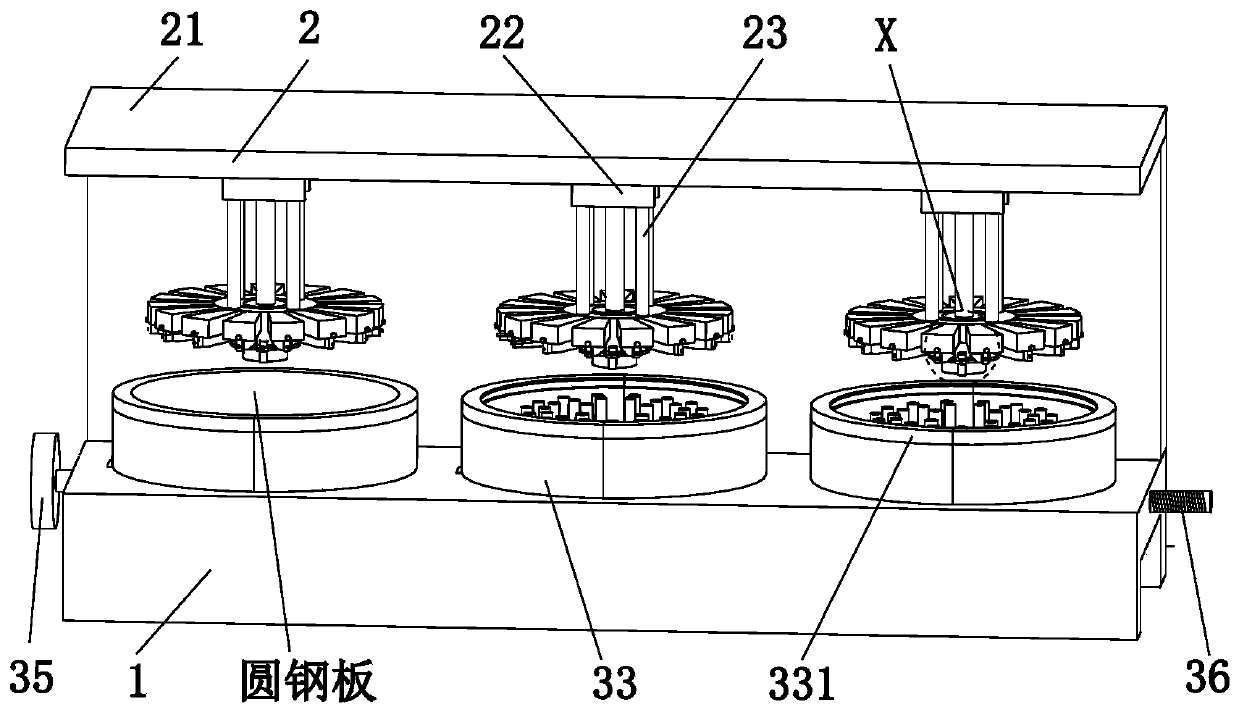

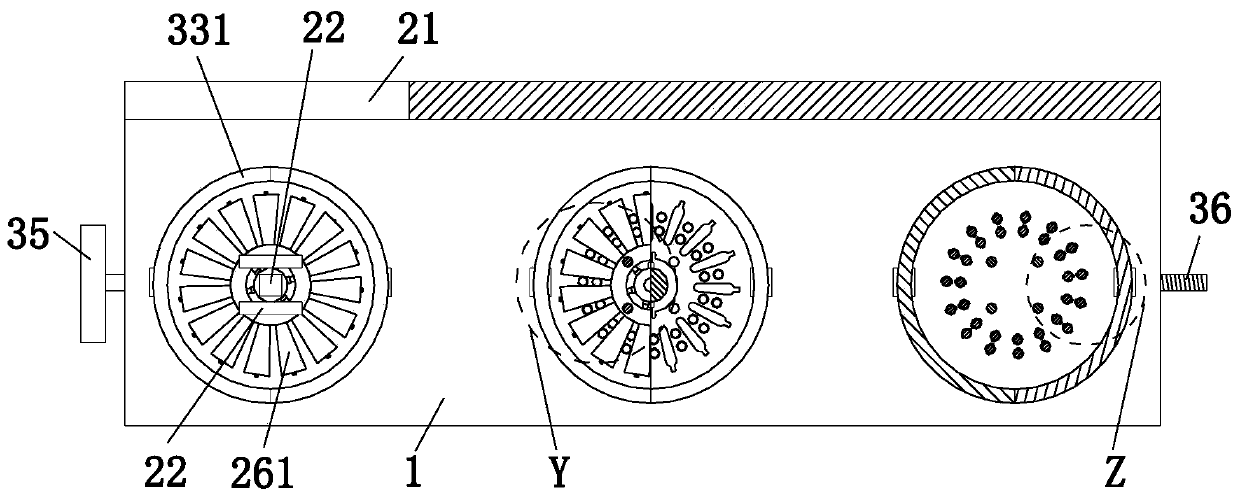

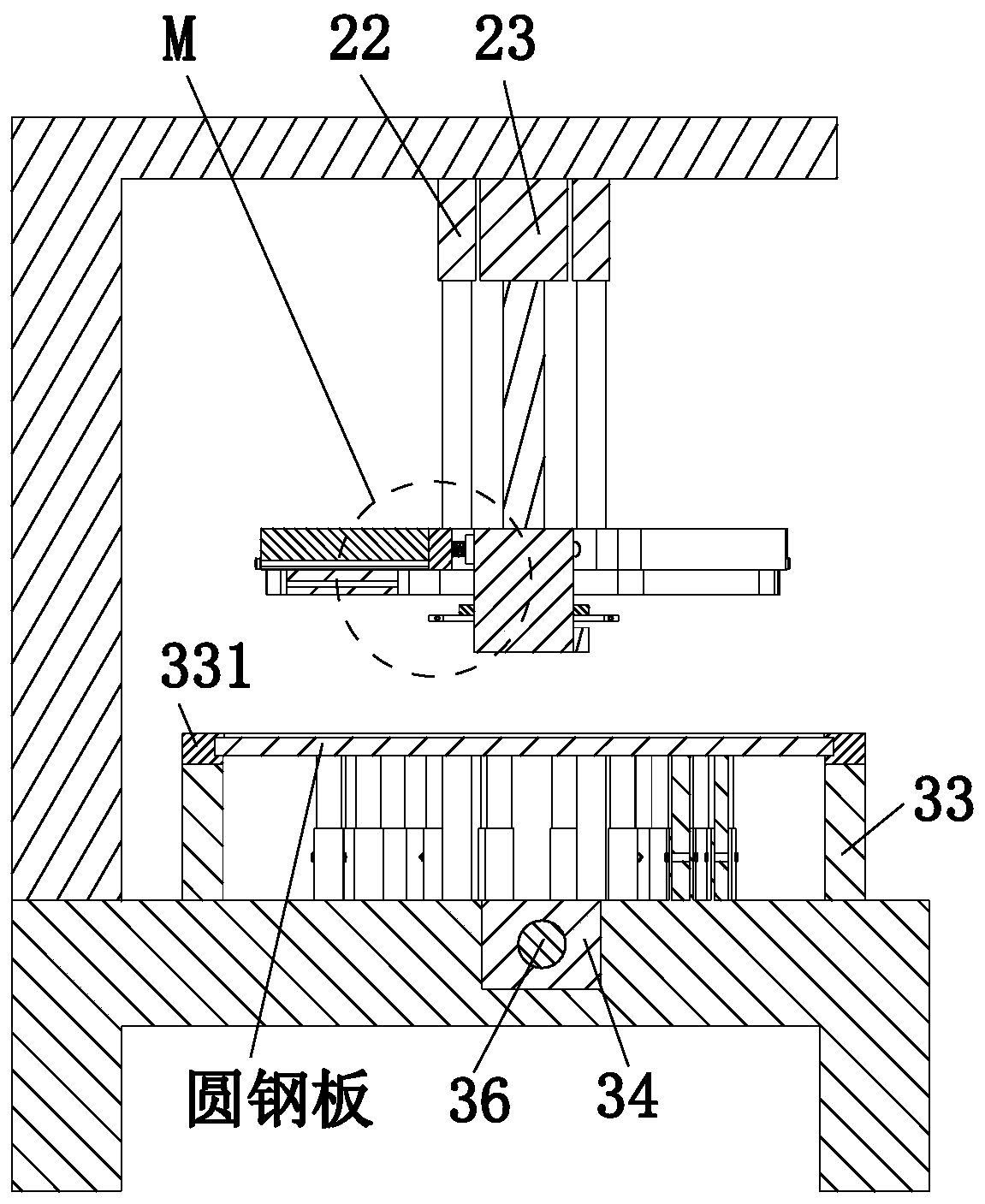

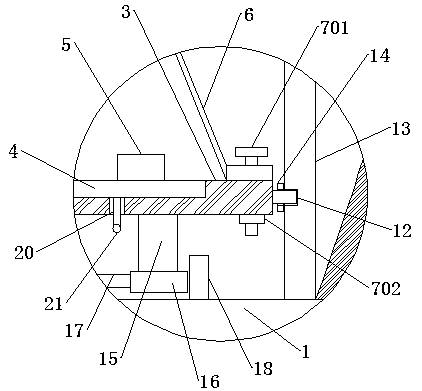

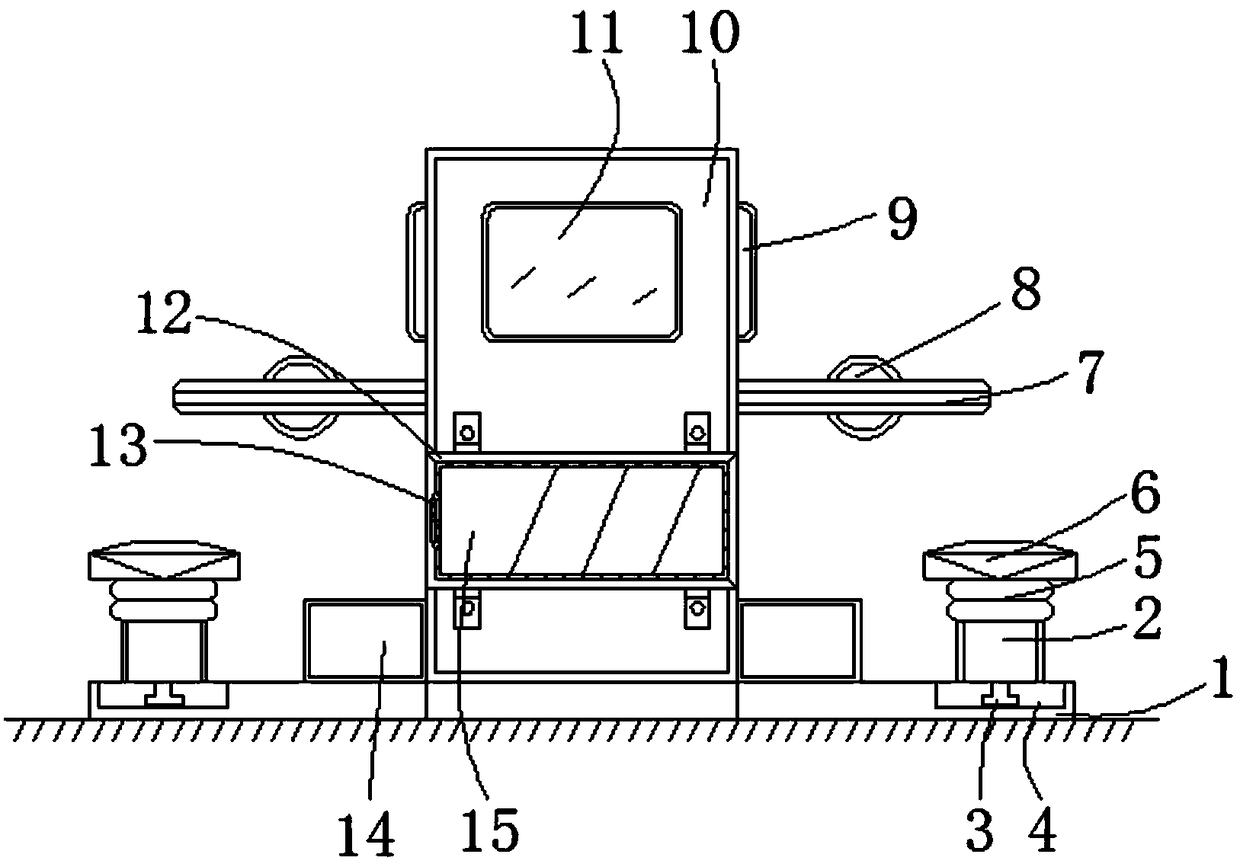

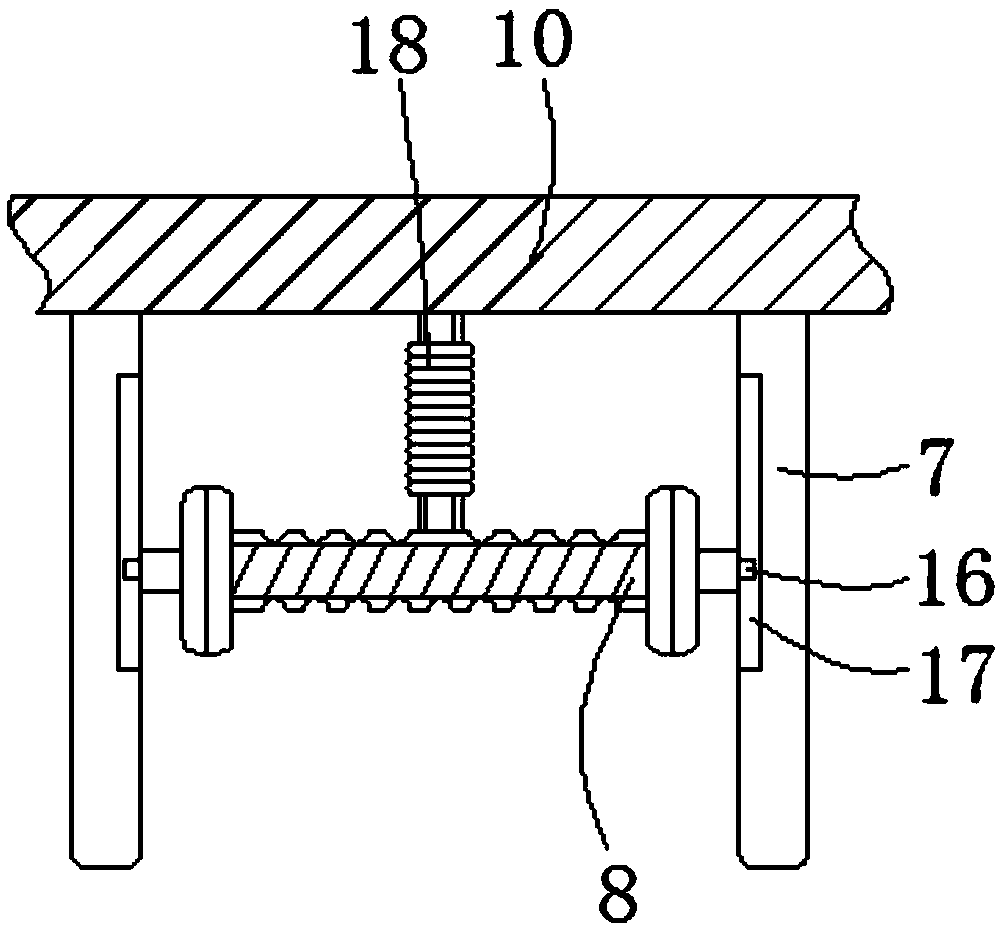

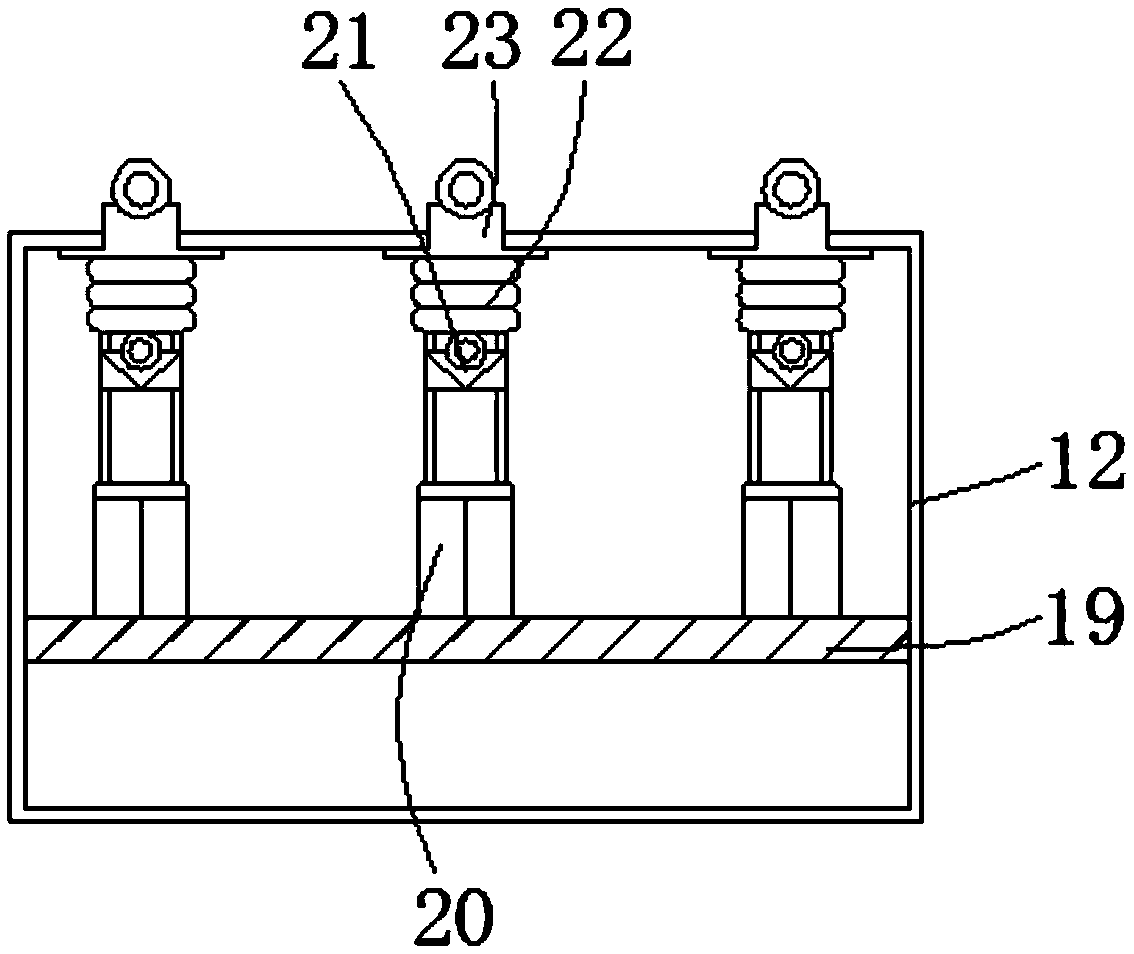

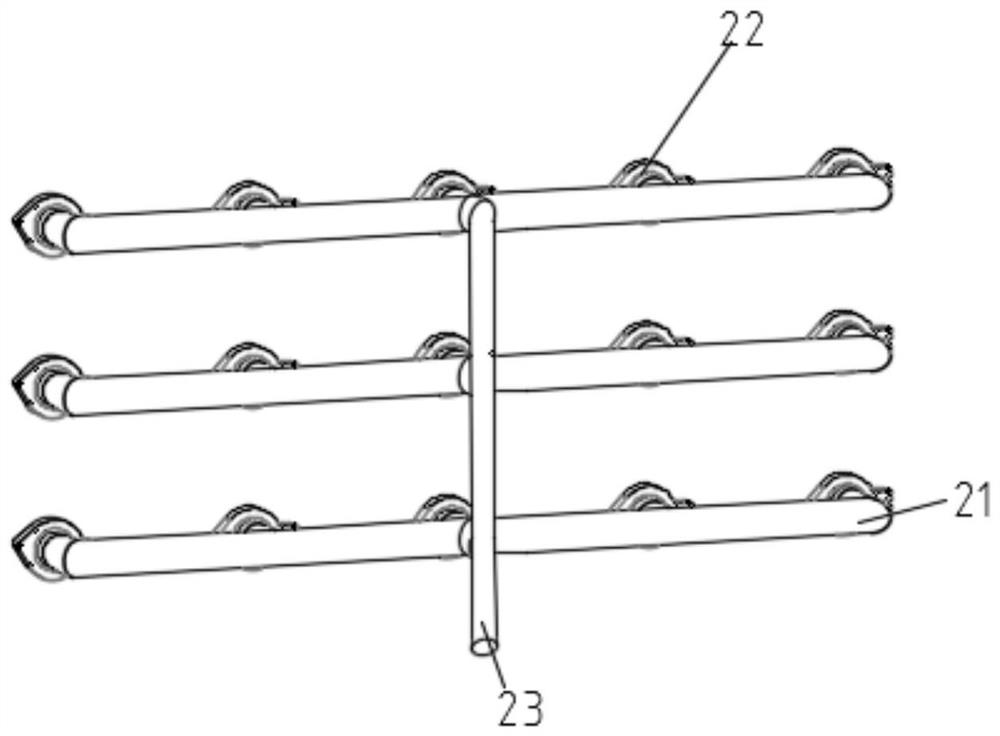

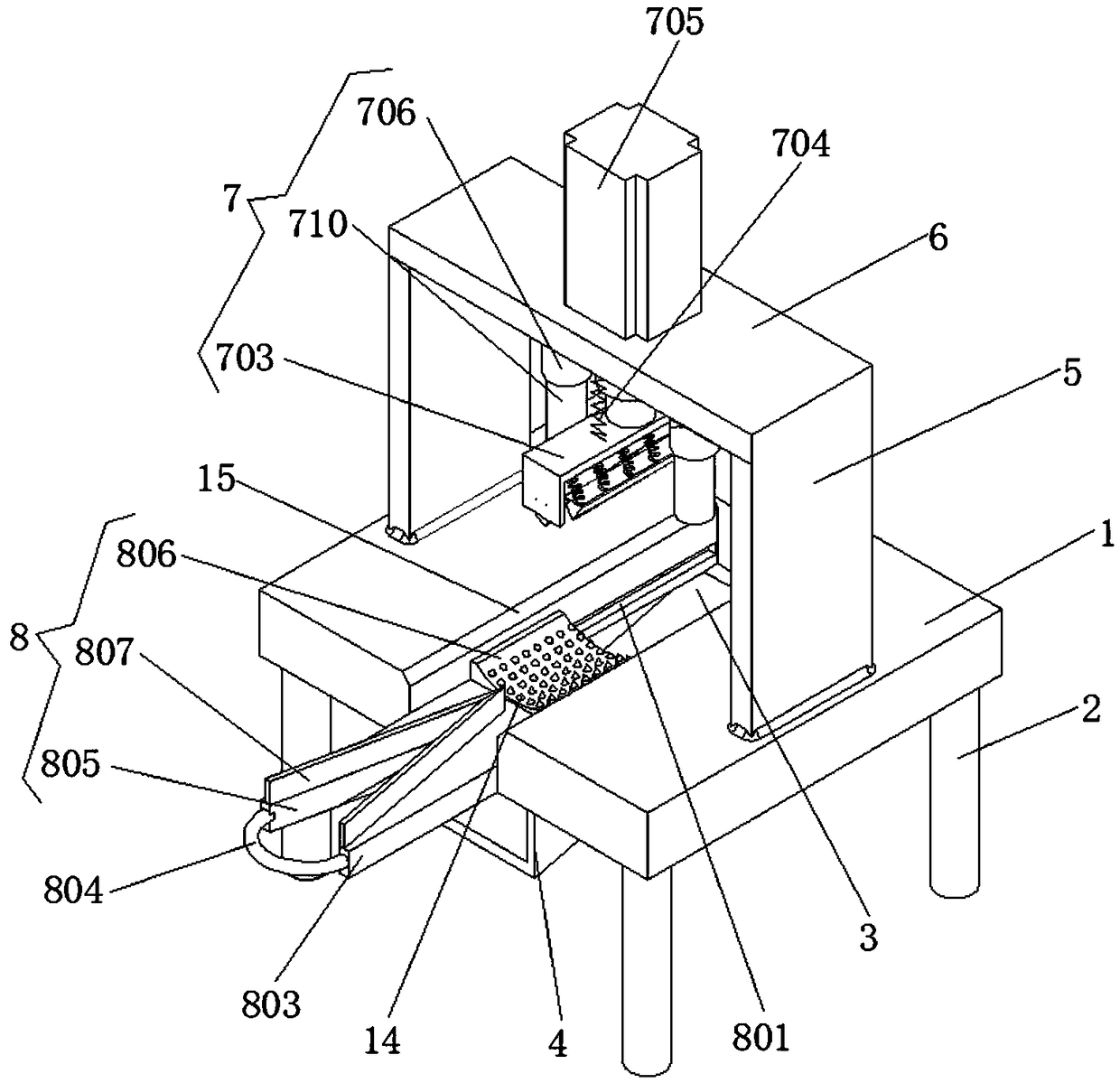

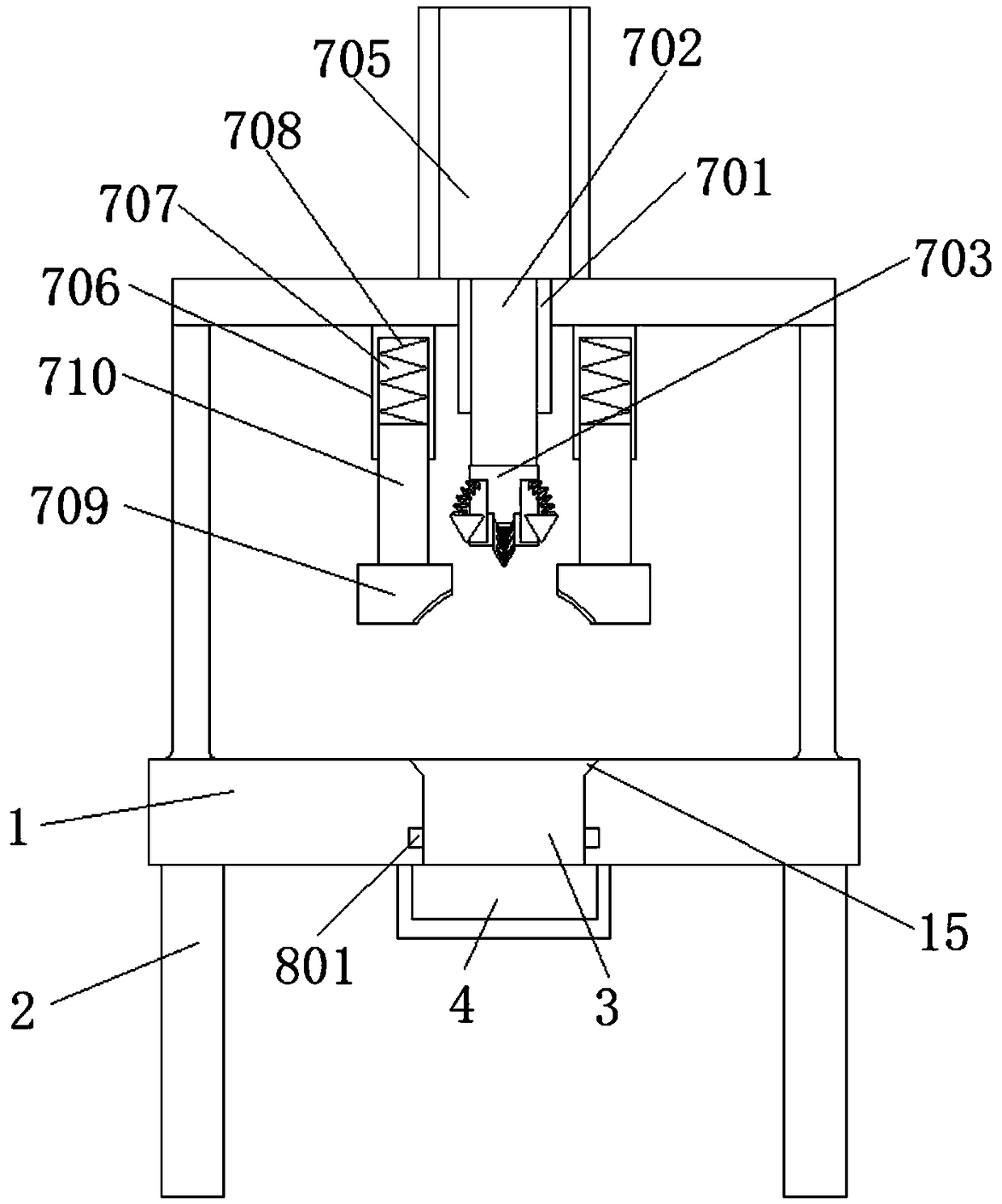

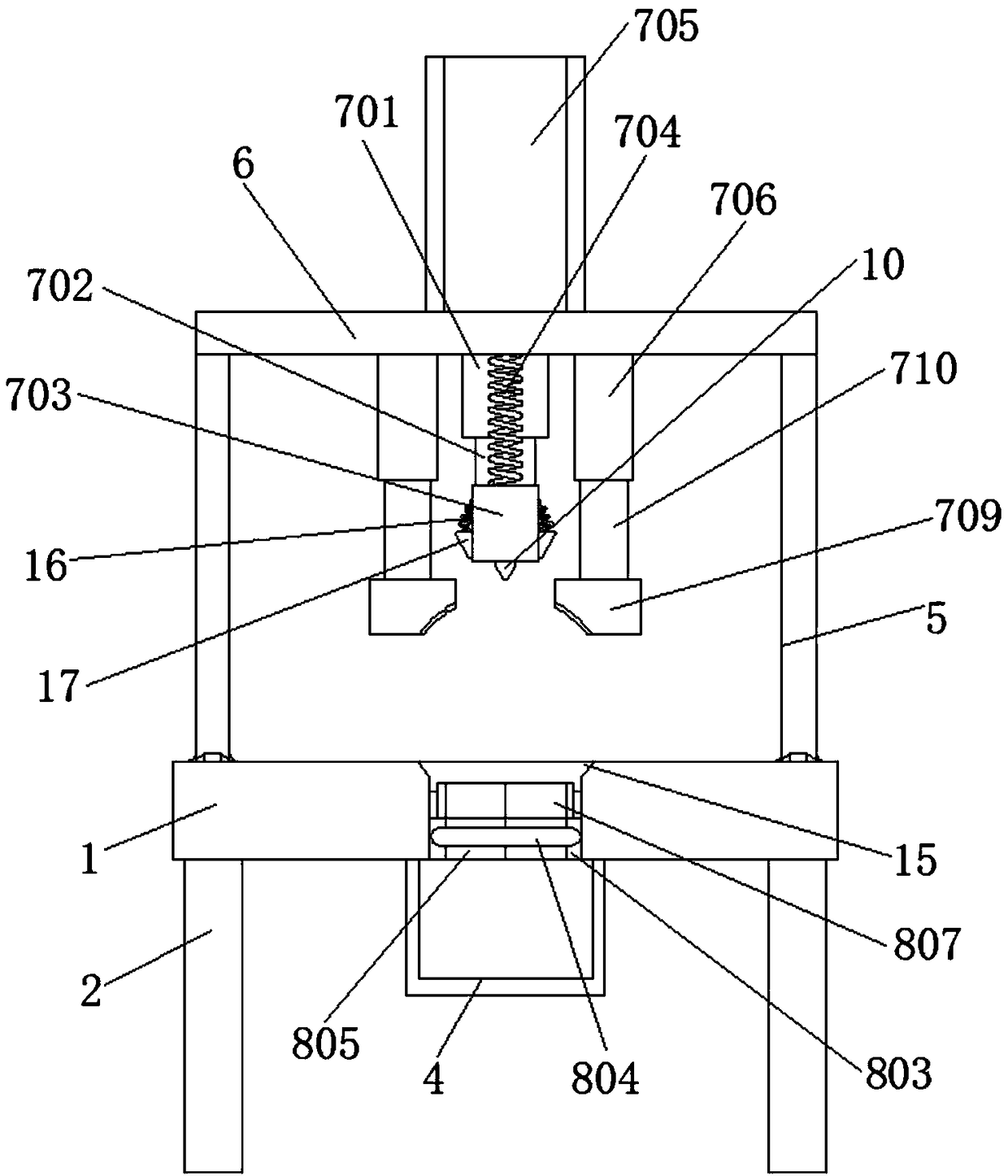

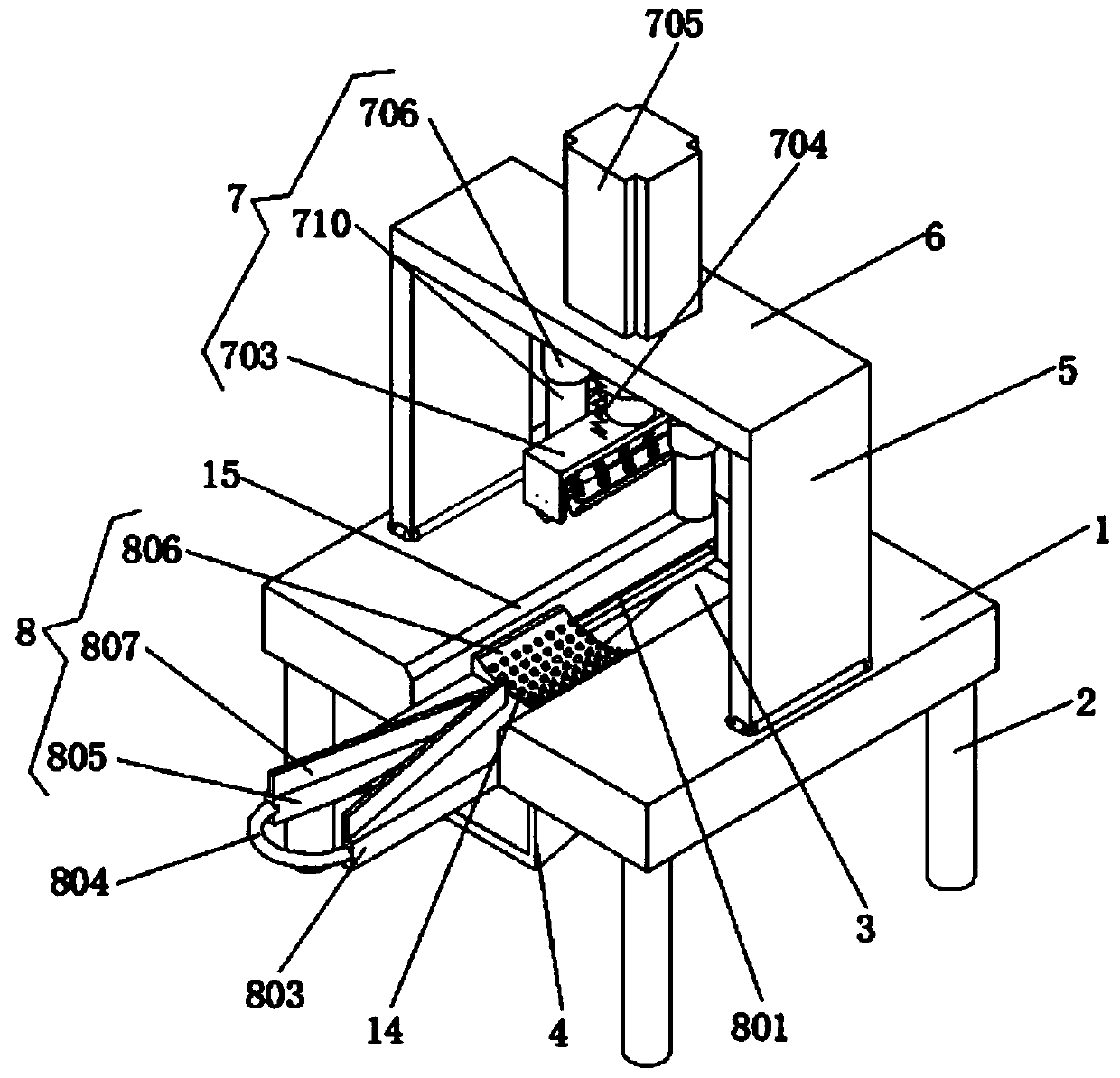

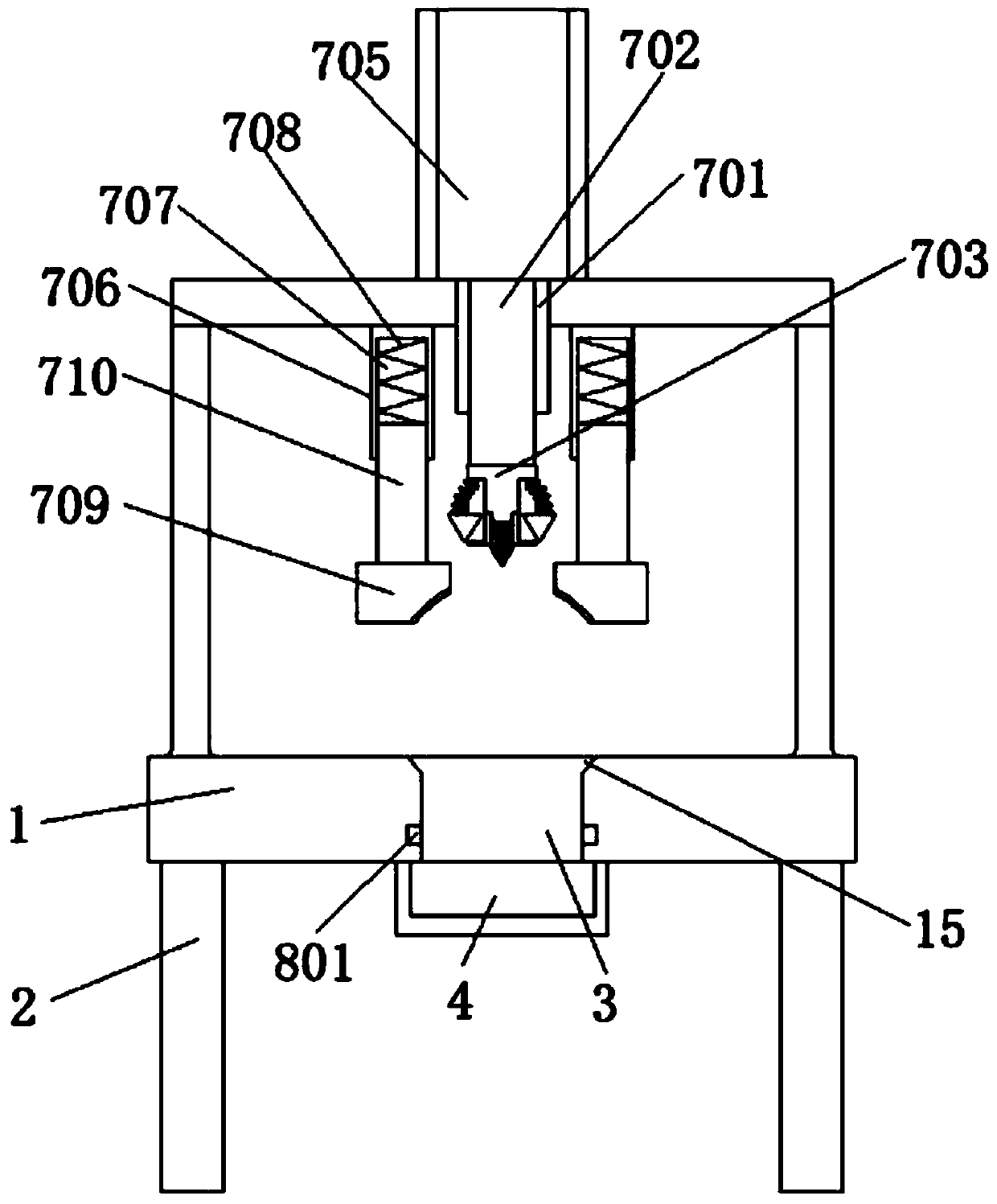

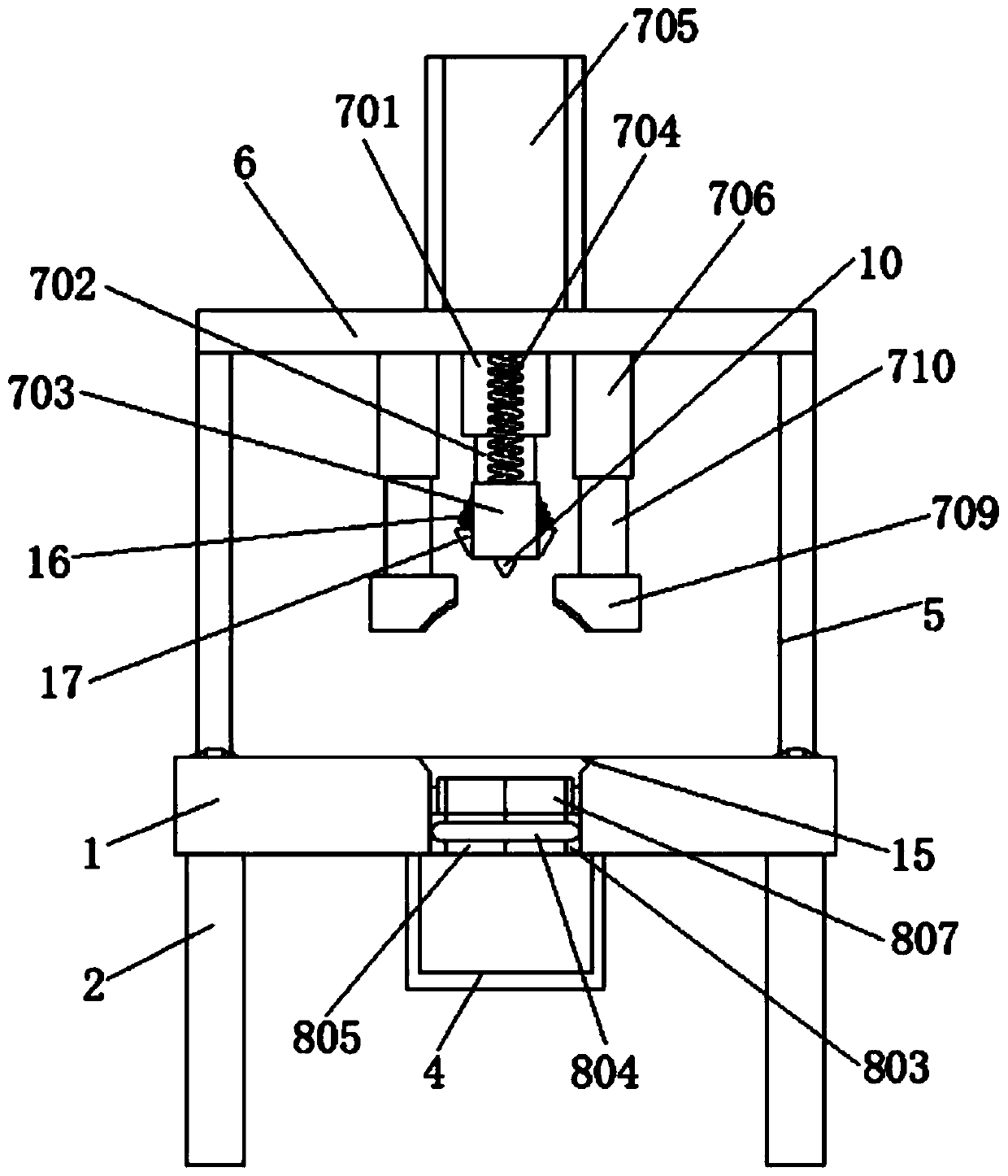

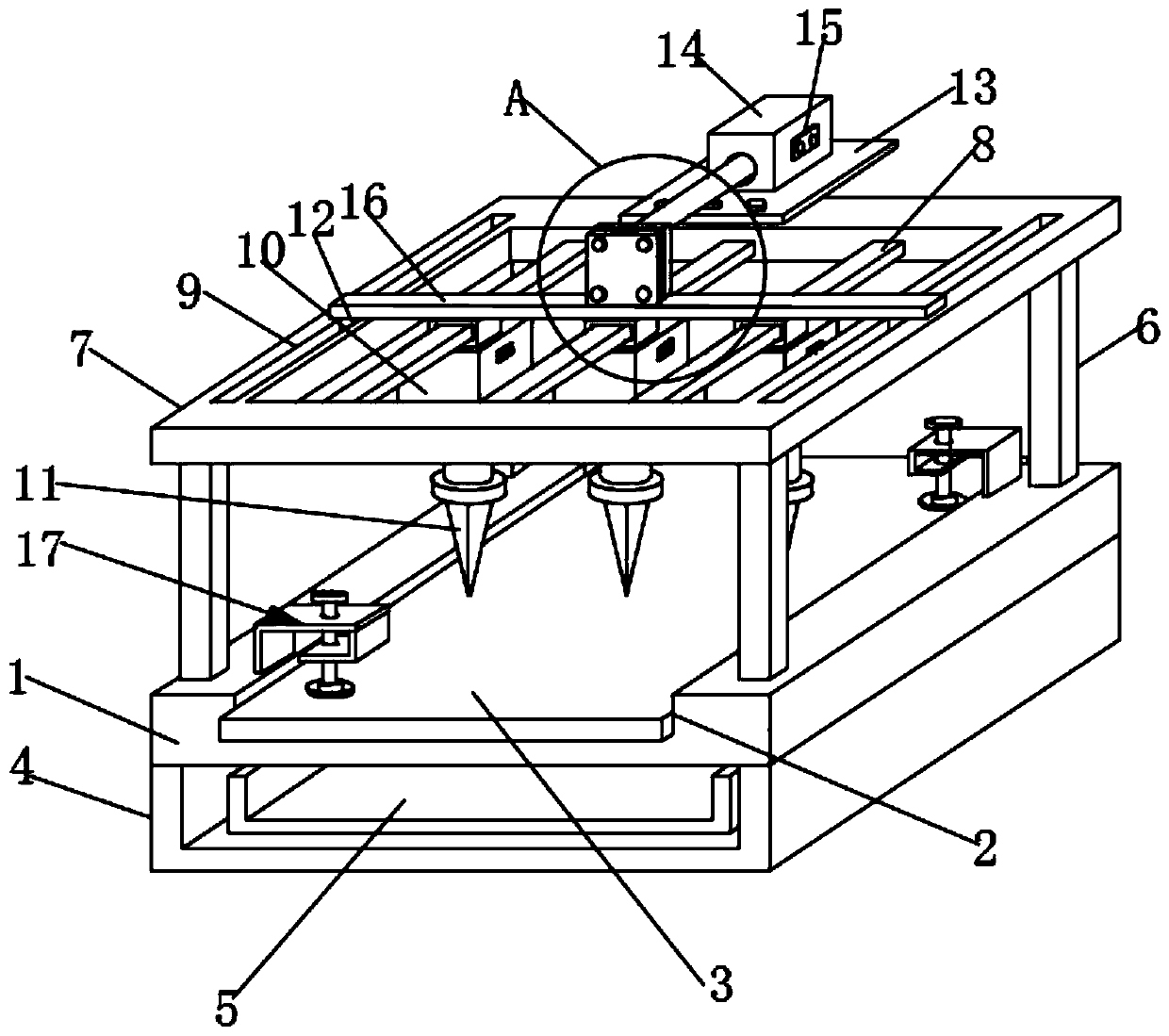

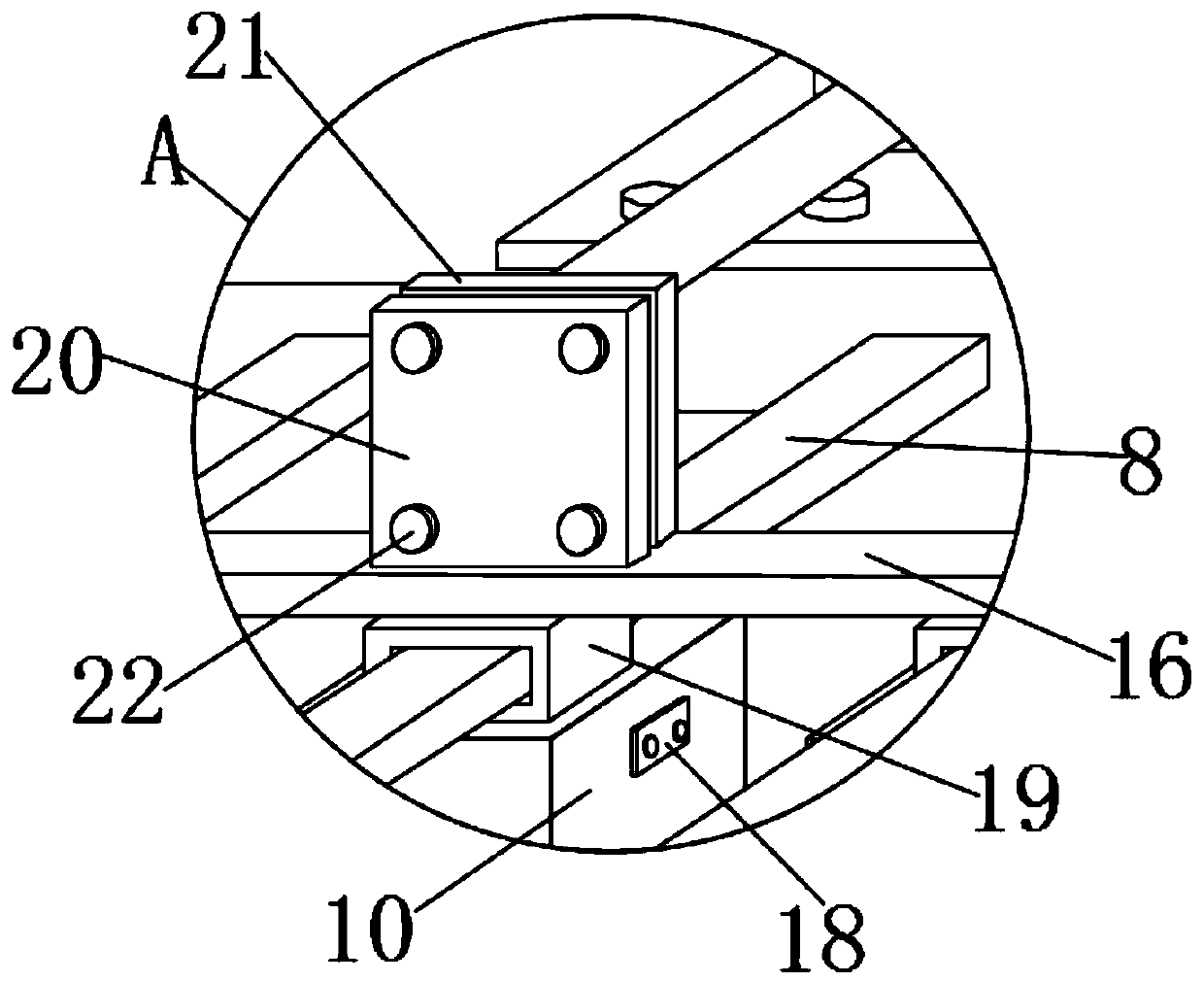

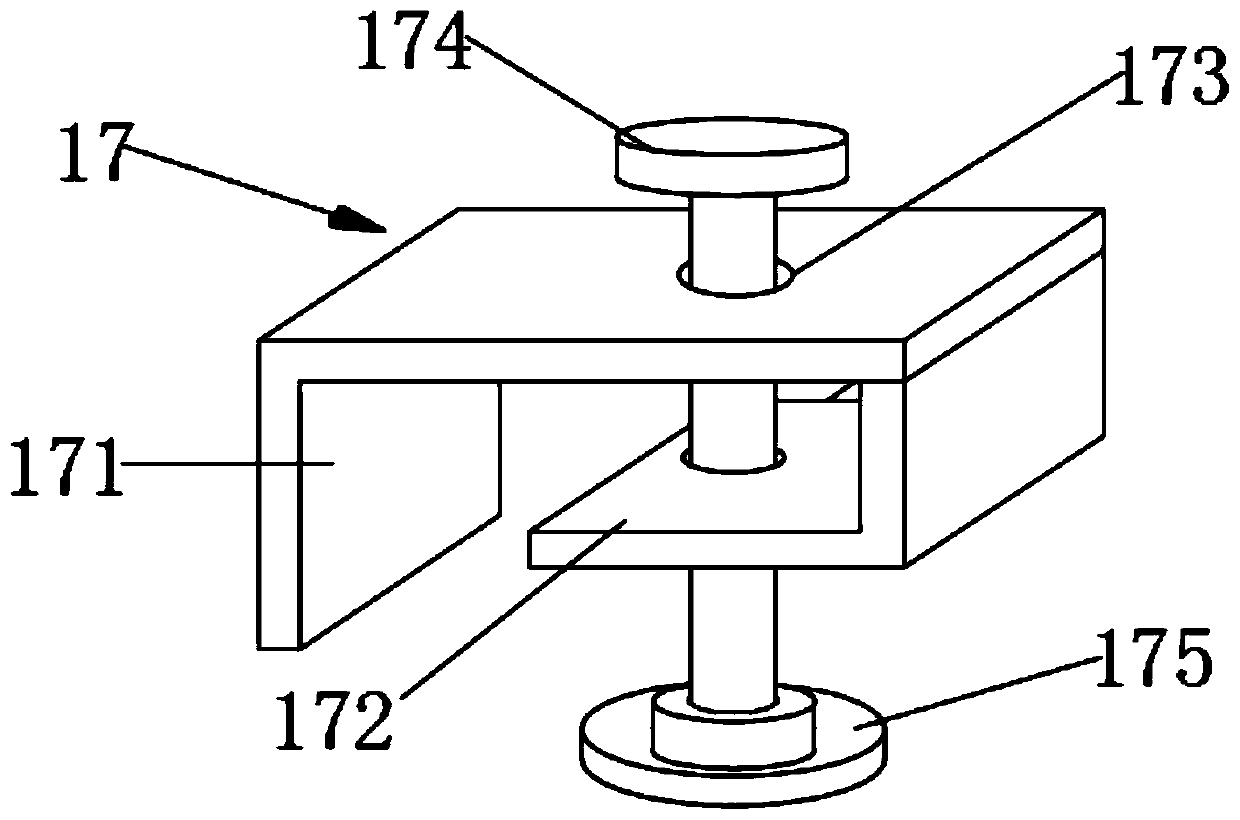

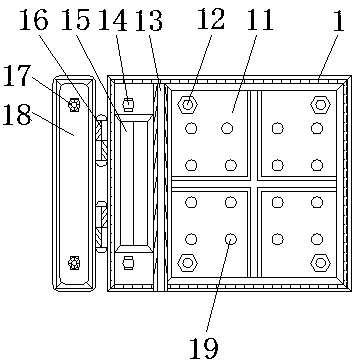

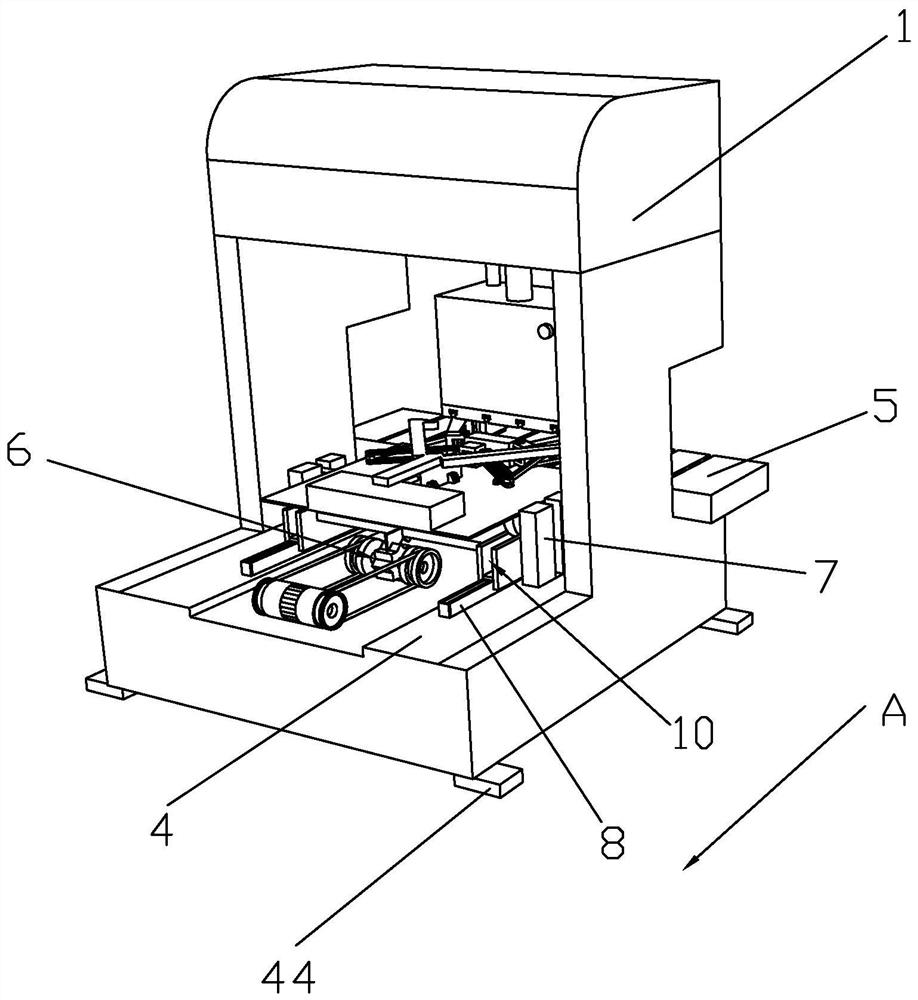

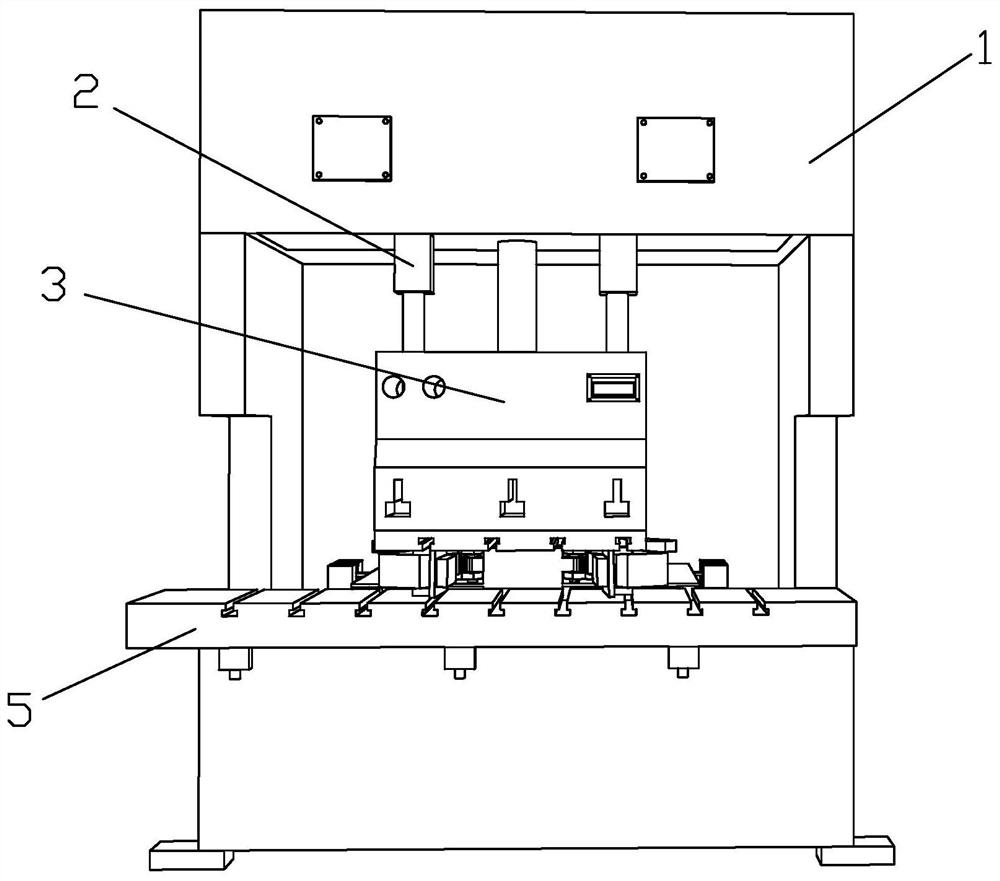

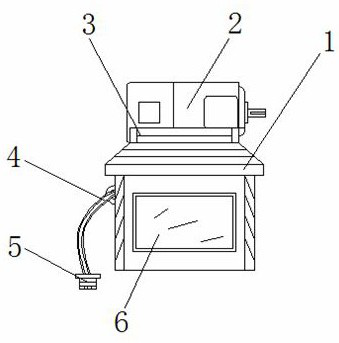

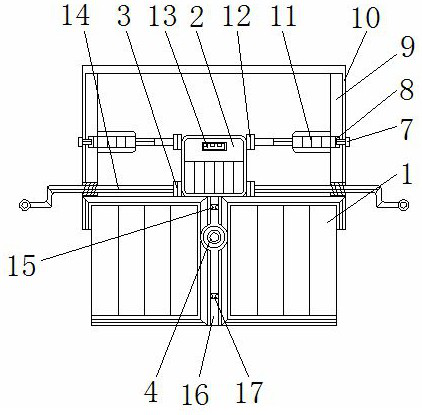

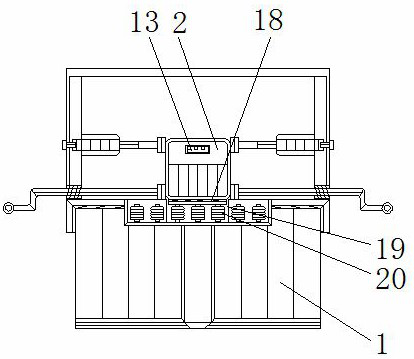

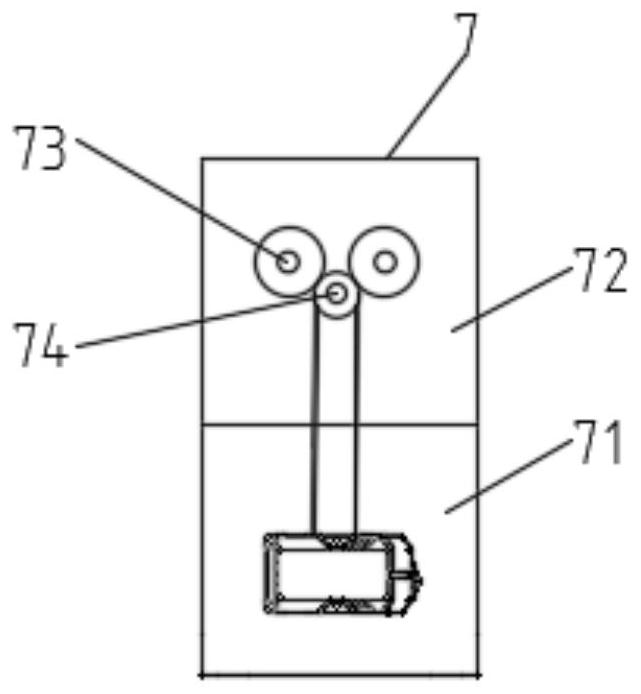

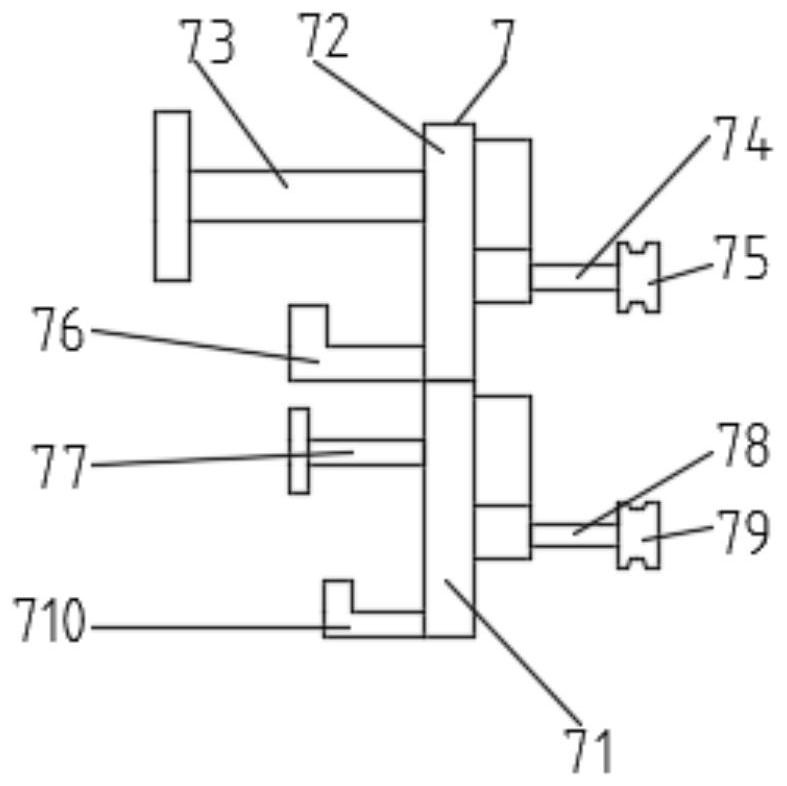

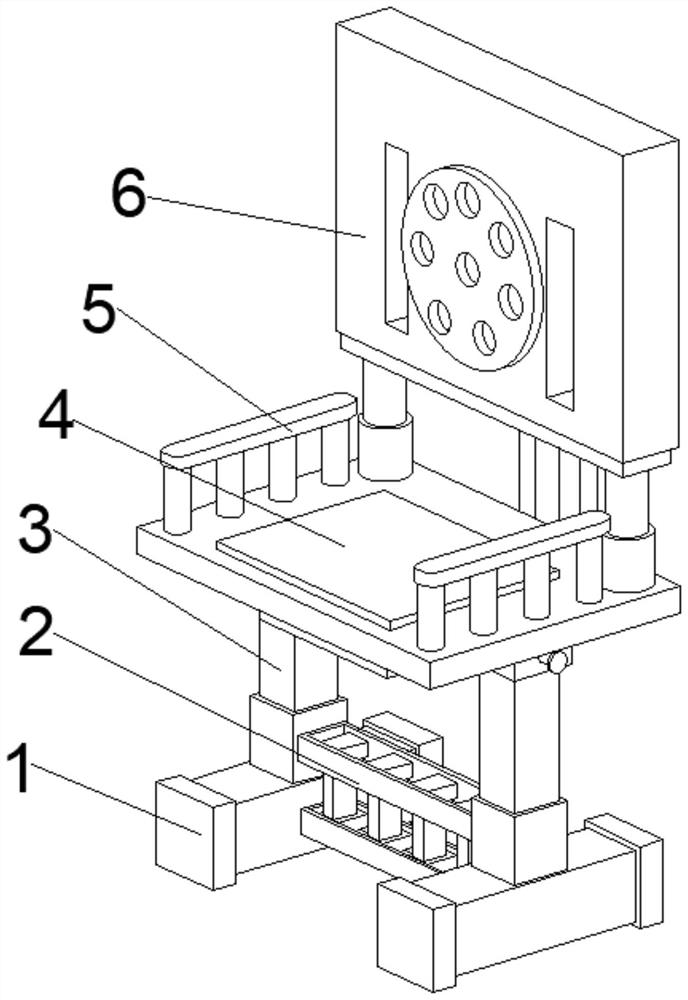

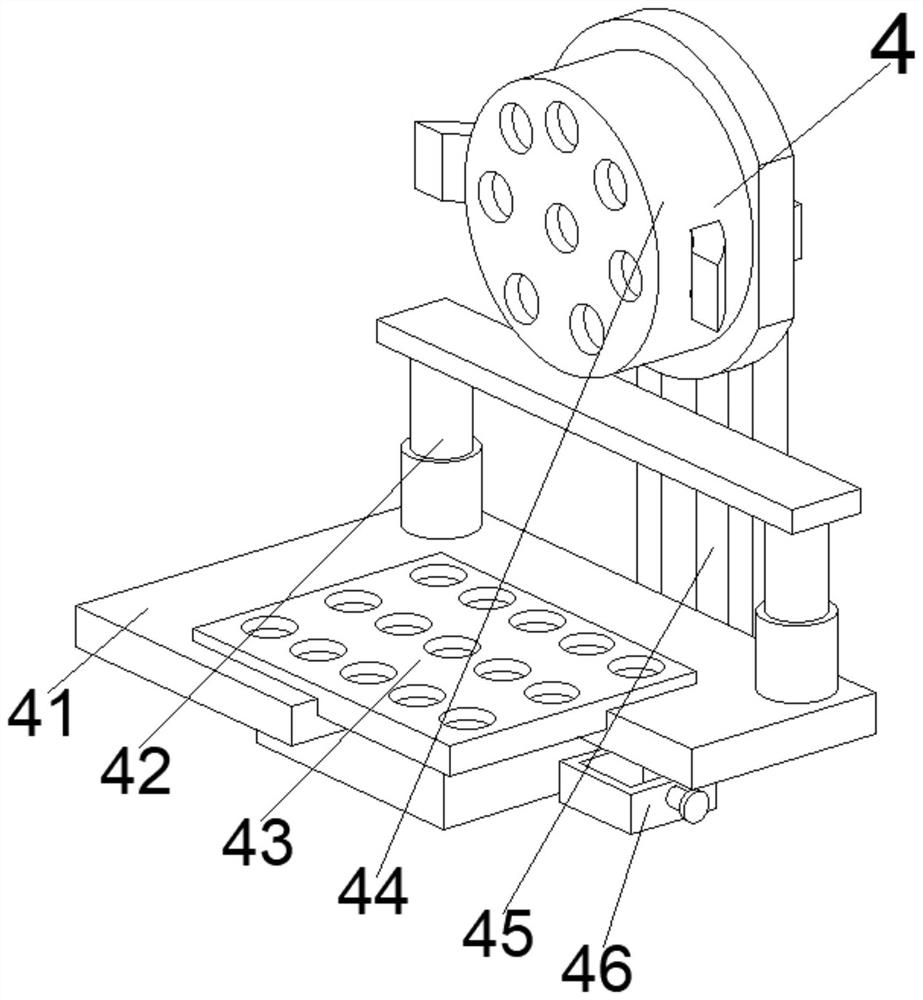

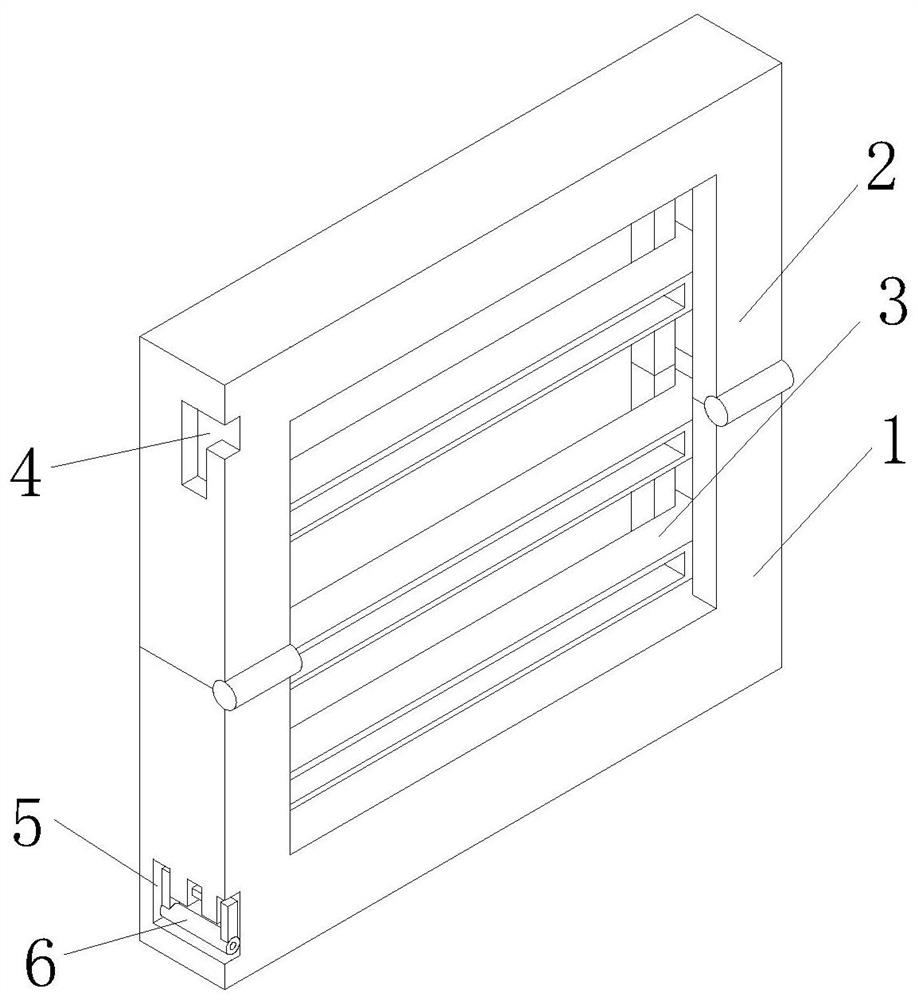

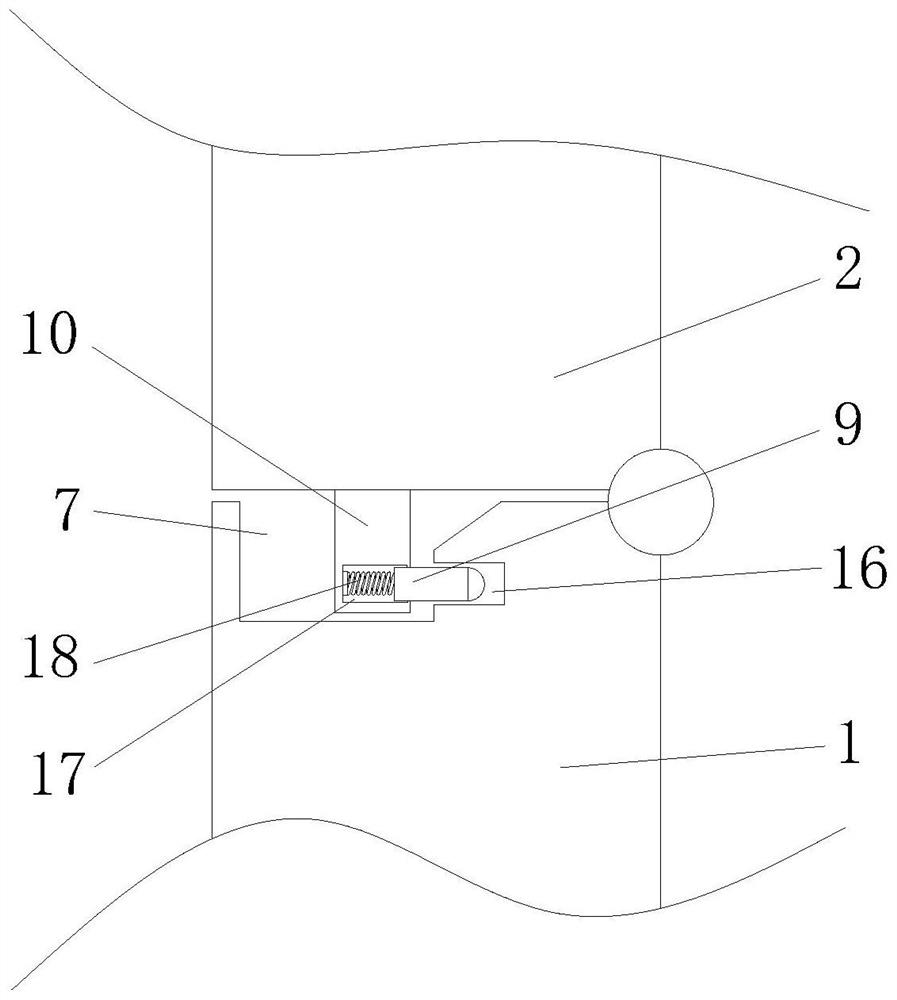

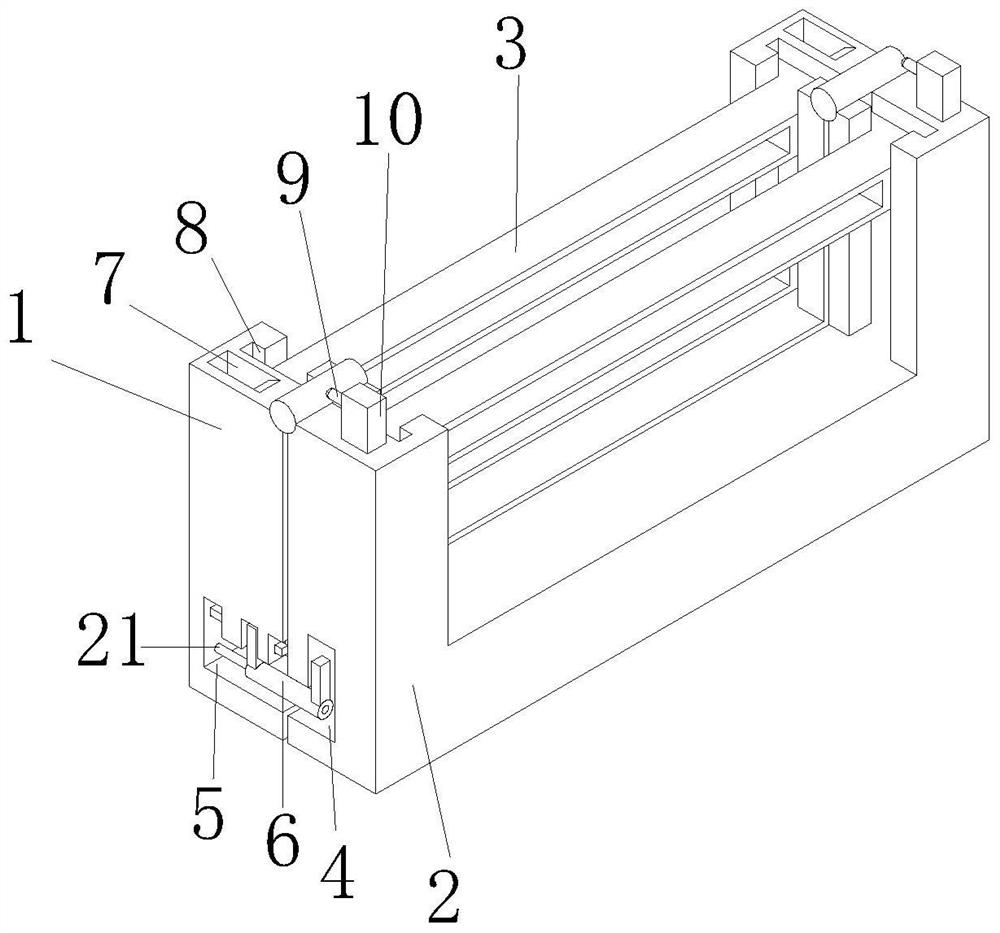

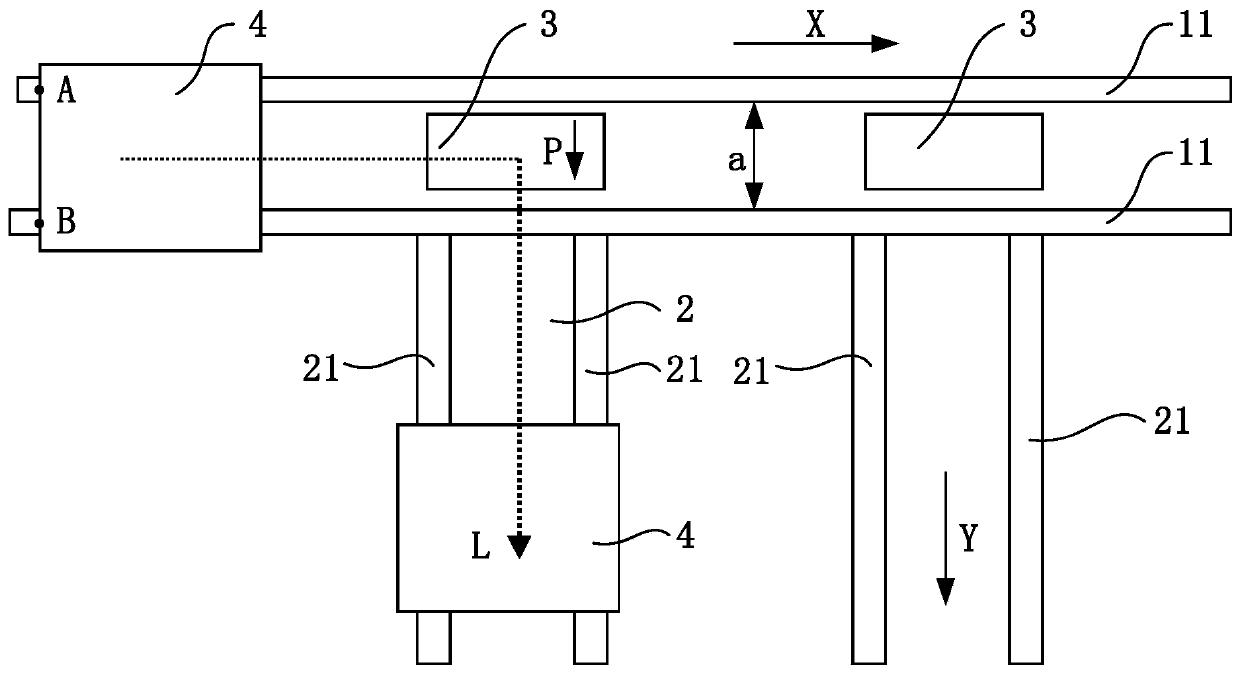

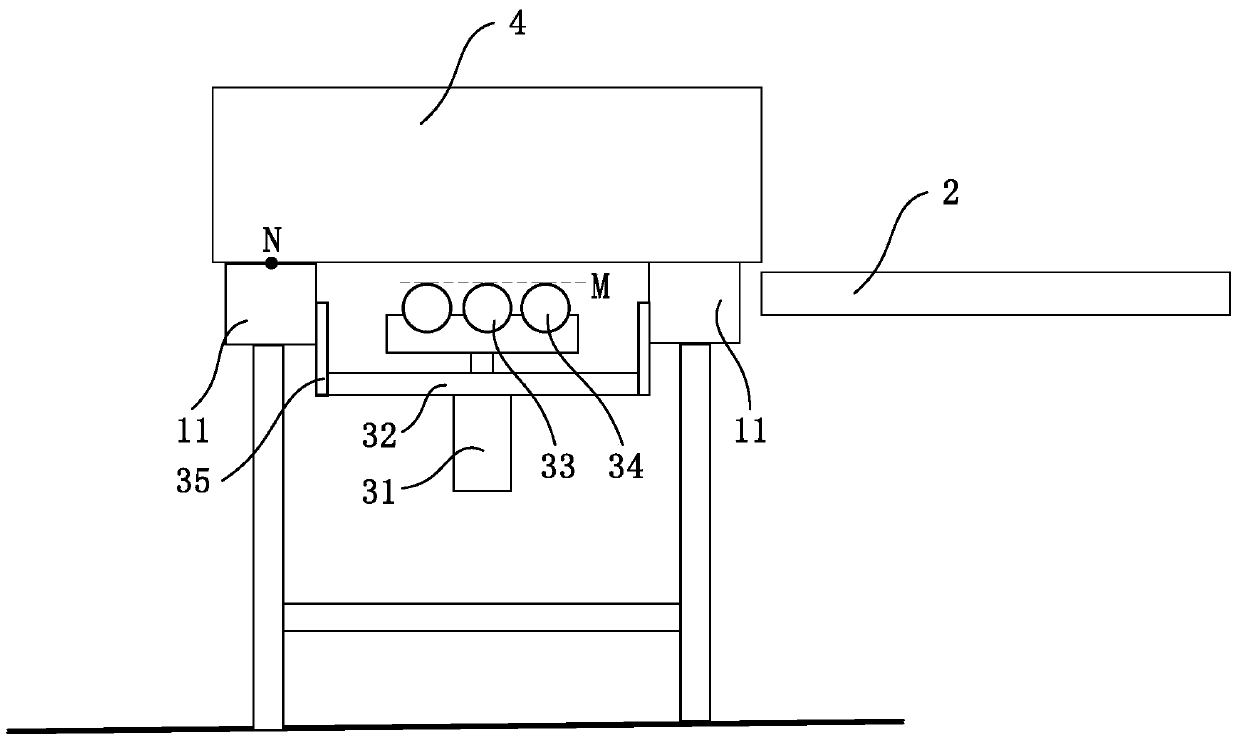

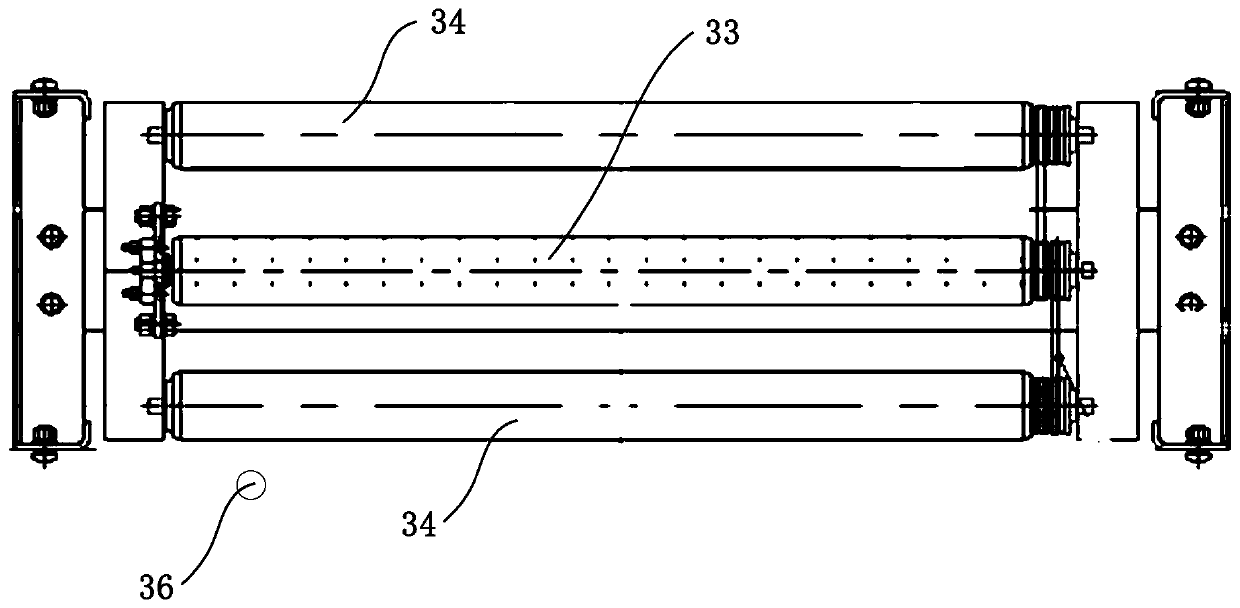

Motor stator punching machining machine

ActiveCN110773626AHigh precisionImprove the stabilityManufacturing stator/rotor bodiesPunchingElectric machine

The invention relates to a motor stator punching machining machine. The machine comprises a workbench, a punching device and clamping devices, wherein the punching device is mounted at the upper end of the workbench, the clamping devices are arranged below the punching device, the clamping devices are connected with the workbench in a slide fit mode, and the clamping devices is arranged at equal distance from left to right. According to the motor stator punching machining machine, a multi-stage adjustable design concept is adopted for motor stator punching machining, the stability degree of round steel plate machining is improved, the accuracy of punching points is guaranteed, then the precision of the motor stator punching machining is improved, and meanwhile, a motor stator with the required number of slots can be machined according to requirements due to the fact that spacing of edge punching blocks and stretching and retracting of a second jacking support column are both controllable.

Owner:湖北宝达机电有限公司

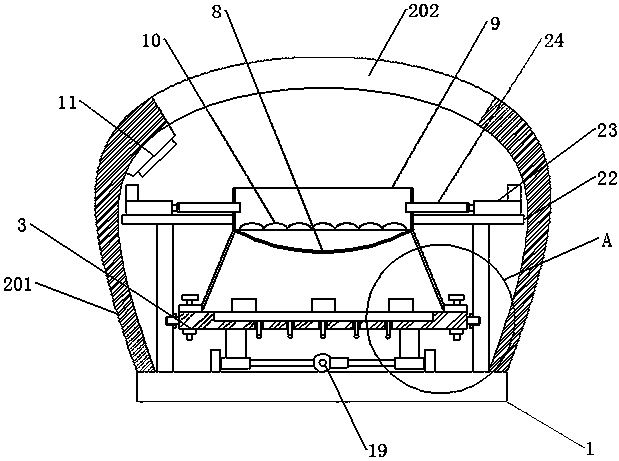

LED automobile lamp

PendingCN109185826AEasy to openIncreased flexibility of useVehicle headlampsElectric circuit arrangementsTraffic accidentEngineering

The invention discloses an LED automobile lamp and belongs to the field of automobile parts. The LED automobile lamp comprises a main control module and a mounting substrate. A power module is connected to the main control module. A lamphousing is fixedly connected to one end of the mounting substrate. A heat conduction seat is arranged inside the lamp housing. An embedded groove is formed in theend, away from the mounting substrate, of the heat conduction seat. An LED lamp mounting plate is connected in the embedded groove. Three LED lamp sources are connected to the LED lamp mounting plate,wherein the three LED lamp sources are distributed uniformly. A luminance adjustment circuit is connected between the LED lamp sources and the main control module. A light gathering housing is connected to the end, close to the LED lamp sources, of the heat conduction seat. Assembling holes are formed in the light gathering housing and the heat conduction seat, wherein the assembling holes of thelight gathering housing correspond to those of the heat conduction seat. By means of the LED automobile lamp, a driver can start a high beam pertinently according to the practical environment condition conveniently; furthermore, the luminance, angel and illuminating range of the high beam can be adjusted properly; use flexibility of the high beam is improved prominently; the probability that a traffic accident is reduced; and energy conservation and environment protection are achieved.

Owner:广州鸿志汽车配件有限公司

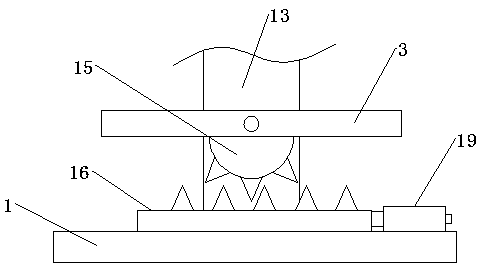

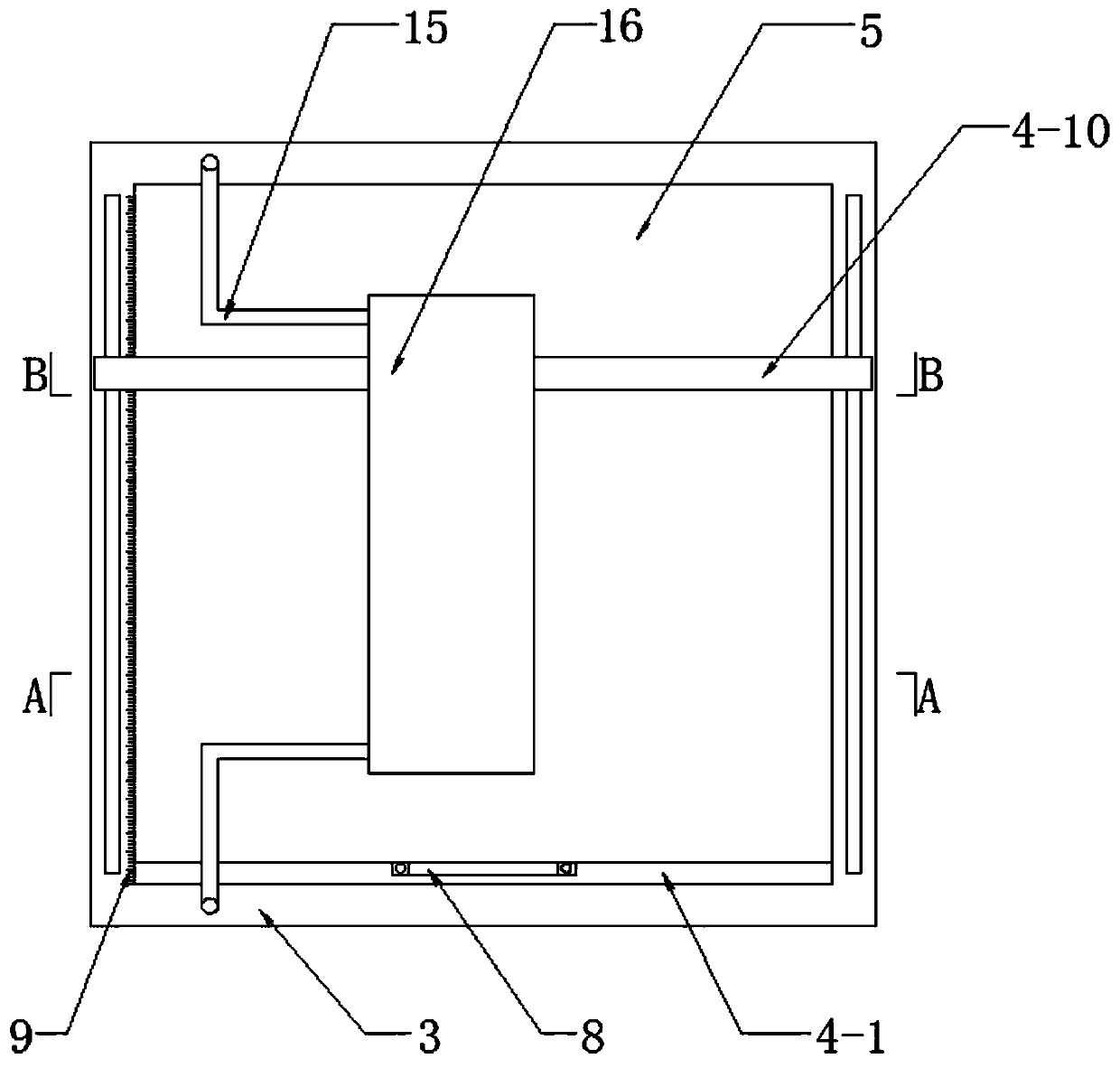

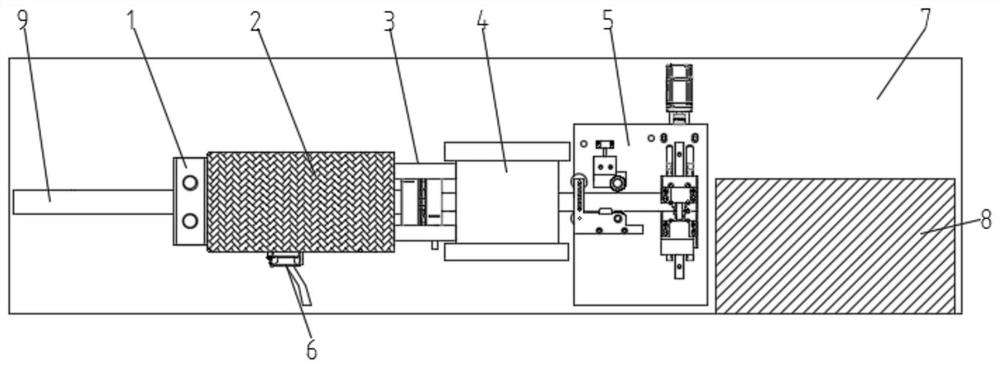

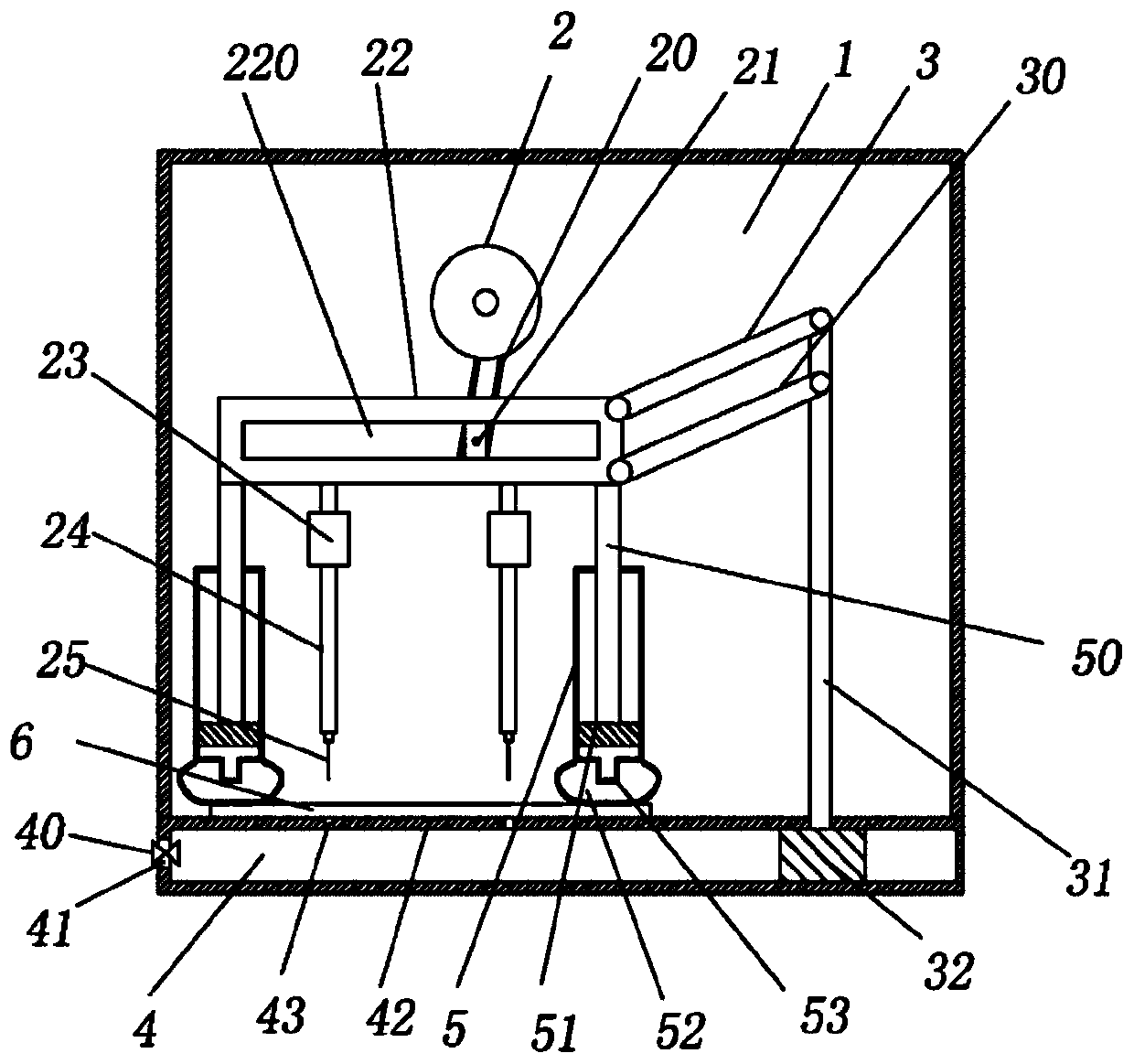

Circuit board machining device

InactiveCN107825519AEasy to operateSimple punching structureMetal working apparatusManufacturing technologyElectric machinery

The invention belongs to the technical field of electronic device manufacturing, and particularly relates to a circuit board machining device. The circuit board machining device comprises a machine frame, a piercing mechanism and a dedusting mechanism. The piercing mechanism comprises a motor, a rotary wheel, a slide block, a moving frame, supporting blocks, slide rods and drill bits; the moving frame is provided with a slide groove which is slidably connected with the slide block; and supporting blocks are fixed to the machine frame and provided with through holes. The dedusting mechanism comprises a main swing rod, a straight rod, a dedusting piston and a dedusting chamber; an air inlet provided with an air intake check valve is formed in the dedusting chamber; and a supporting table forstoring a substrate is arranged at the top of the dedusting chamber and provided with piercing holes which are aligned with the drill bits. According to the technical scheme, cutting powder in innerholes of the substrate can be effectively removed, and the inner holes are prevented from being blocked.

Owner:重庆市志益鑫电子科技有限公司

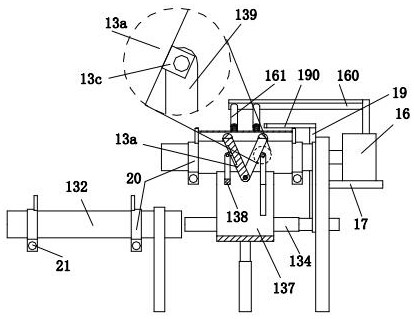

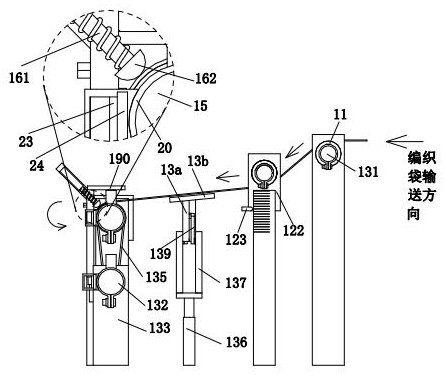

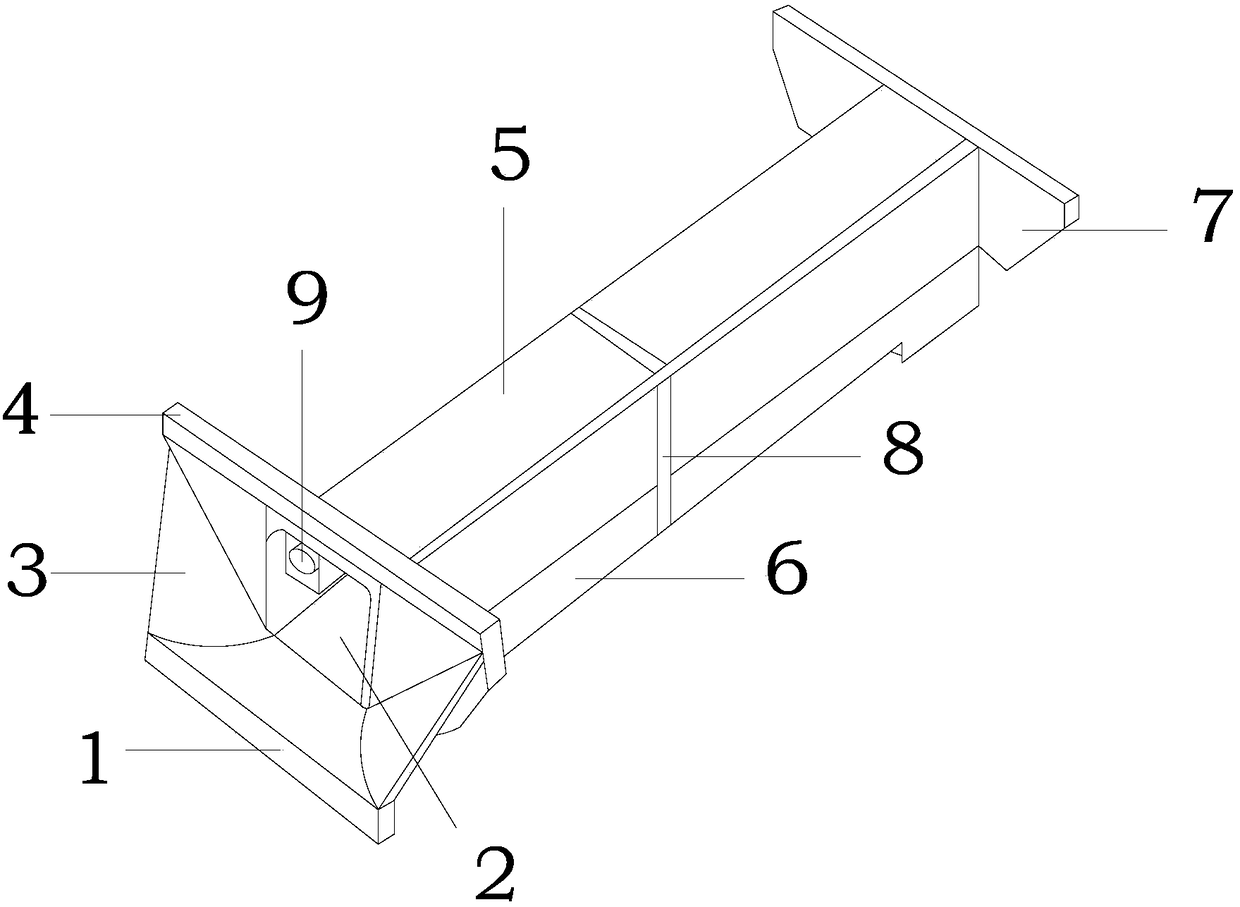

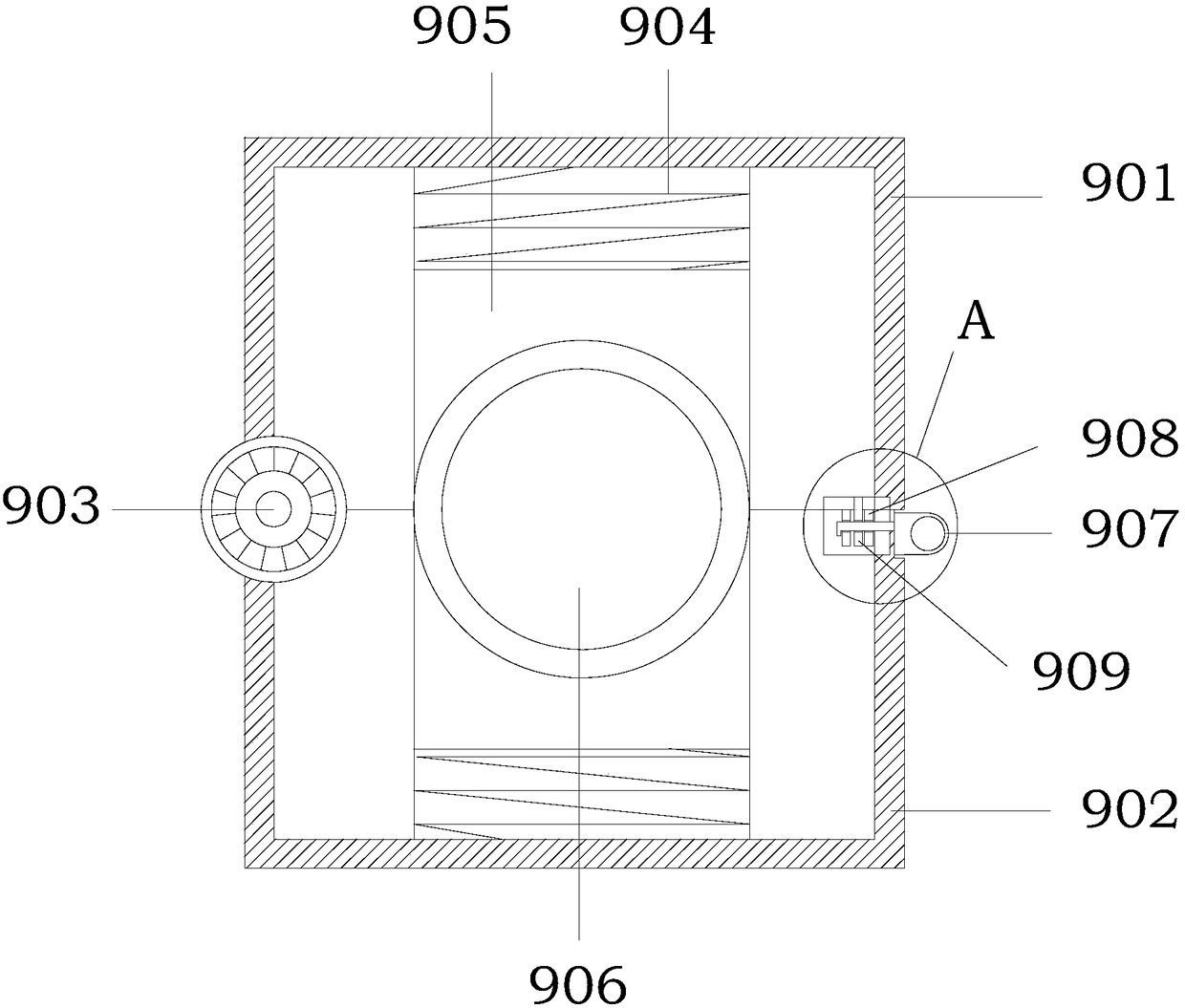

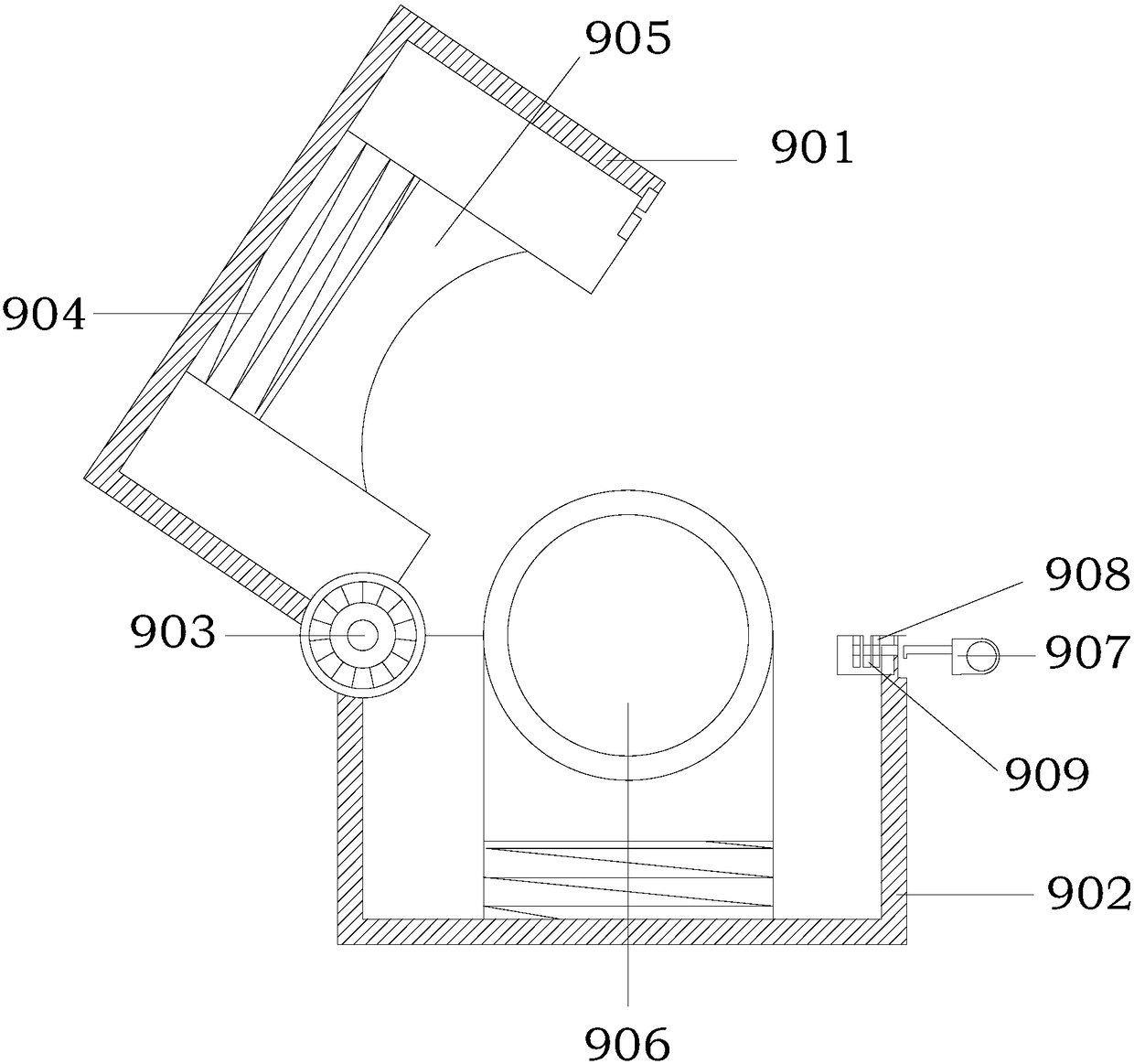

Winding device for plastic woven bag production

ActiveCN113277349AImprove the efficiency of winding workIncrease diversityWebs handlingTotal thicknessMechanical engineering

The invention relates to the field of plastic woven bag production, in particular to a winding device for plastic woven bag production. The device comprises a winding mechanism and a fixing mechanism, wherein the winding mechanism is installed on the ground, and the fixing mechanism is arranged on the left side of the winding mechanism. Winding for plastic woven bag product is performed based on a design concept of two working lines, the whole device can depend on a same transmission source to form two woven bag winding working lines, then the efficiency of the whole woven bag winding working is greatly improved, the arranged winding mechanism can accurately adjust the forming total thickness of a woven bag roll according to the forming requirement, and then the forming diversity of the device is improved. A vertical plate and an extension plate are matched to limit the winding of a woven bag so as to ensure that the overall length of the woven bag roll is equal to the length of a roll core all the time, and the total height of the extension plate and the vertical plate can be adjusted through a fourth electric sliding block so as to adapt to the forming of the woven bag rolls with different total thicknesses.

Owner:新沂市信达塑业有限公司

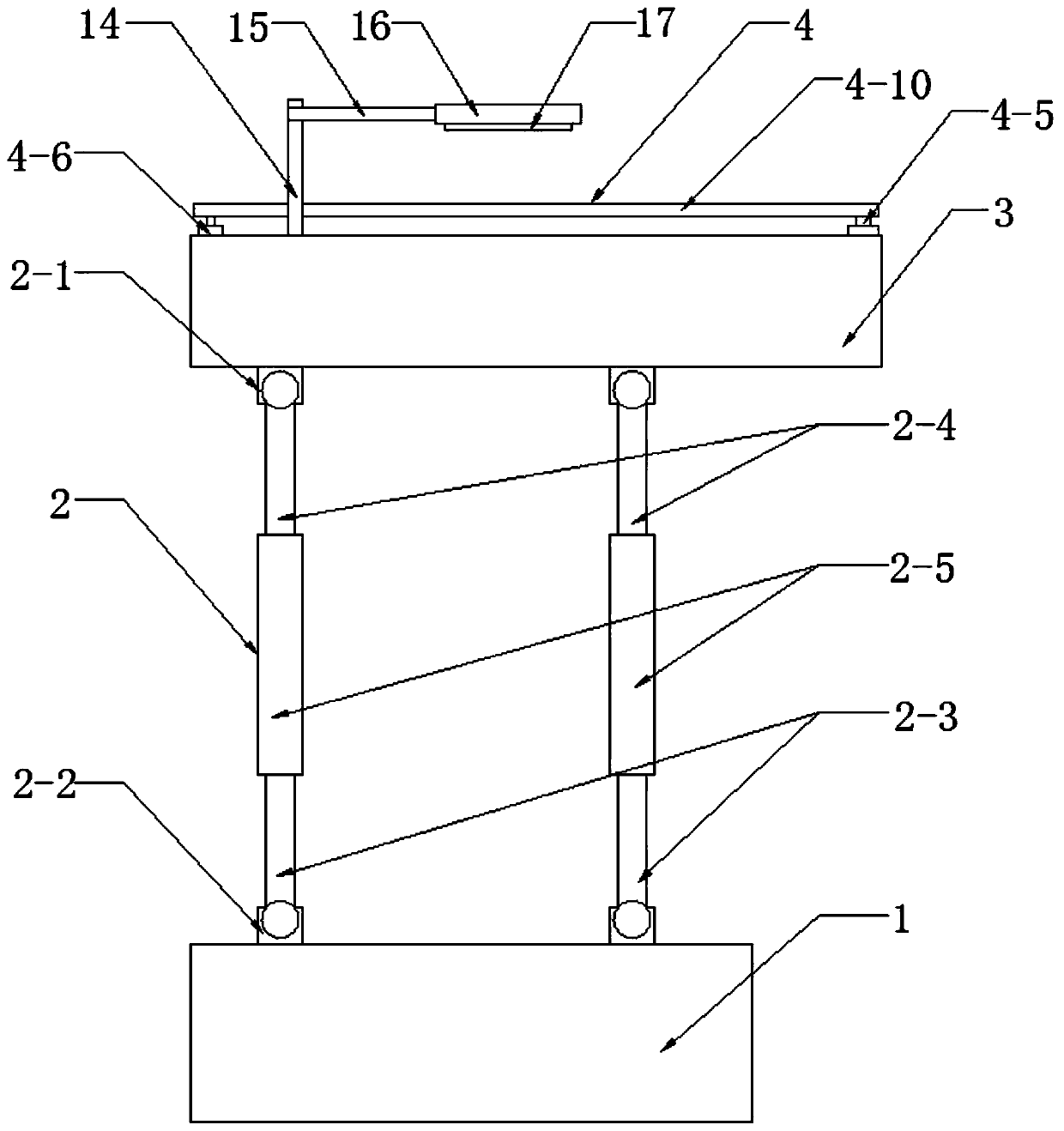

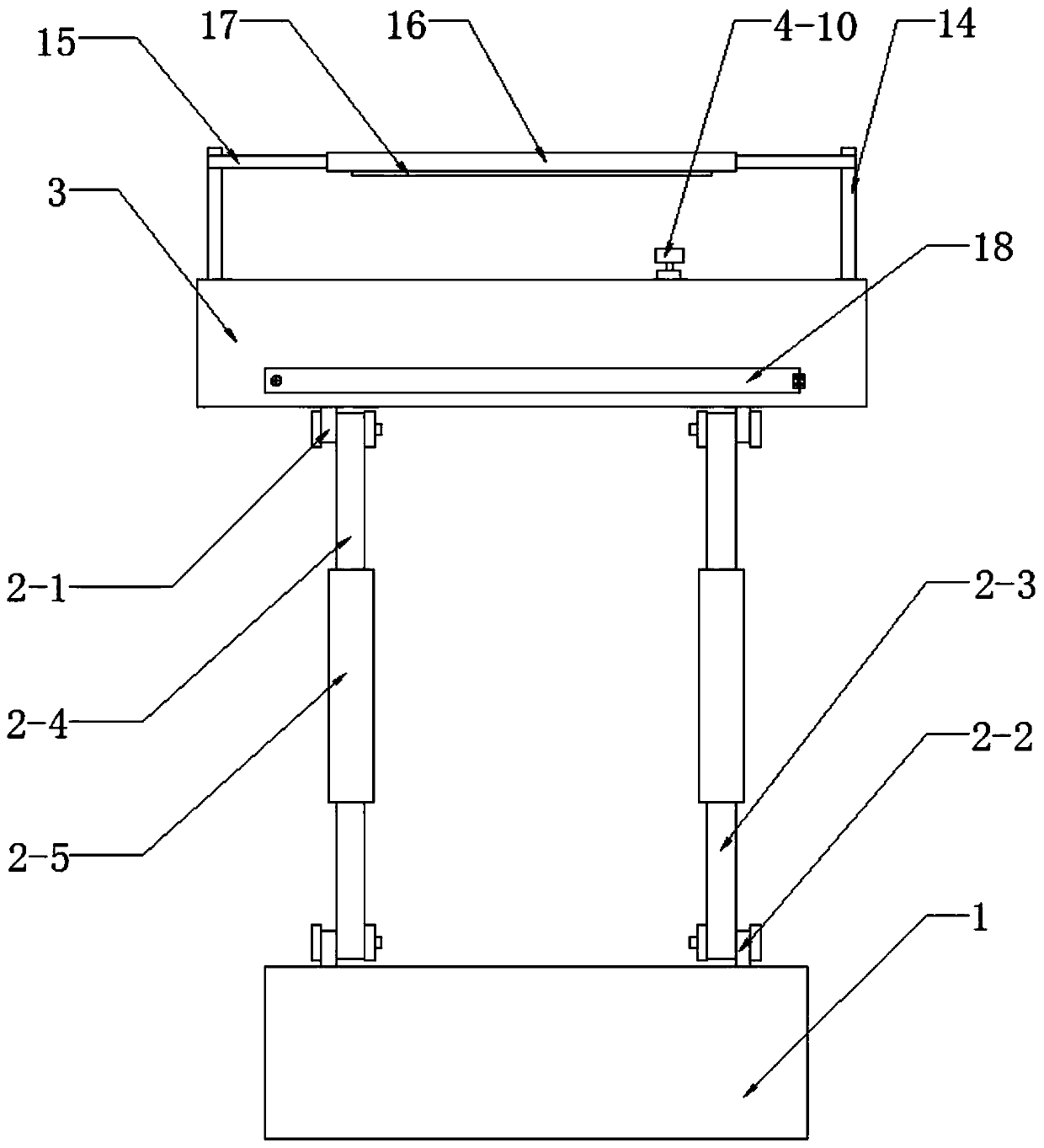

Plane design drawing device

InactiveCN111546810ALess prone to driftWill not affect the drawing effectDrawing boardsThreaded pipeEngineering

The invention provides a plane design drawing device and relates to the technical field of drawing equipment. The plane design drawing device comprises a base, supporting mechanisms, a drawing board and a pressing mechanism. The supporting mechanisms are arranged at the four corners of the upper surface of the base. Connecting parts II of the supporting mechanisms are slidably arranged in slidinggrooves in the lower surface of the drawing board. Each supporting mechanism further comprises a connecting part I, a screw rod I, a screw rod II and an internally threaded pipe. The upper side of thedrawing board is provided with a groove. The pressing mechanism is arranged in the groove. The pressing mechanism is composed of a pressing plate I, springs I, a pressing plate II, connecting rods, pull rods, sliding blocks, springs II, limiting plates, baffles and a holding rod. When a user conducts drawing through the drawing board, the two sides of a paper sheet are fixed to the drawing board,and the paper sheet is not prone to deviation without affecting the drawing effect. Moreover, the angle of the drawing board can be adjusted as required to meet the use demands of different users. The plane design drawing device has the advantages of being reasonable in arrangement, low in manufacturing cost and the like.

Owner:衡水职业技术学院

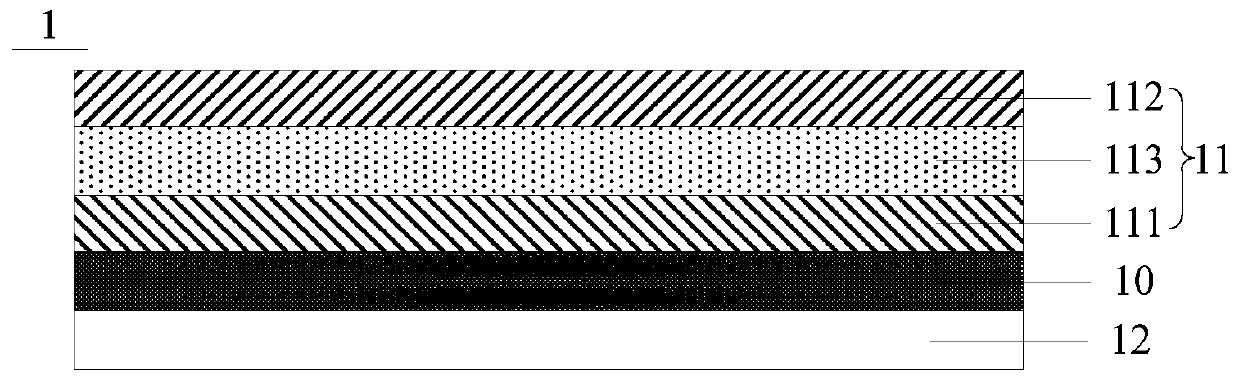

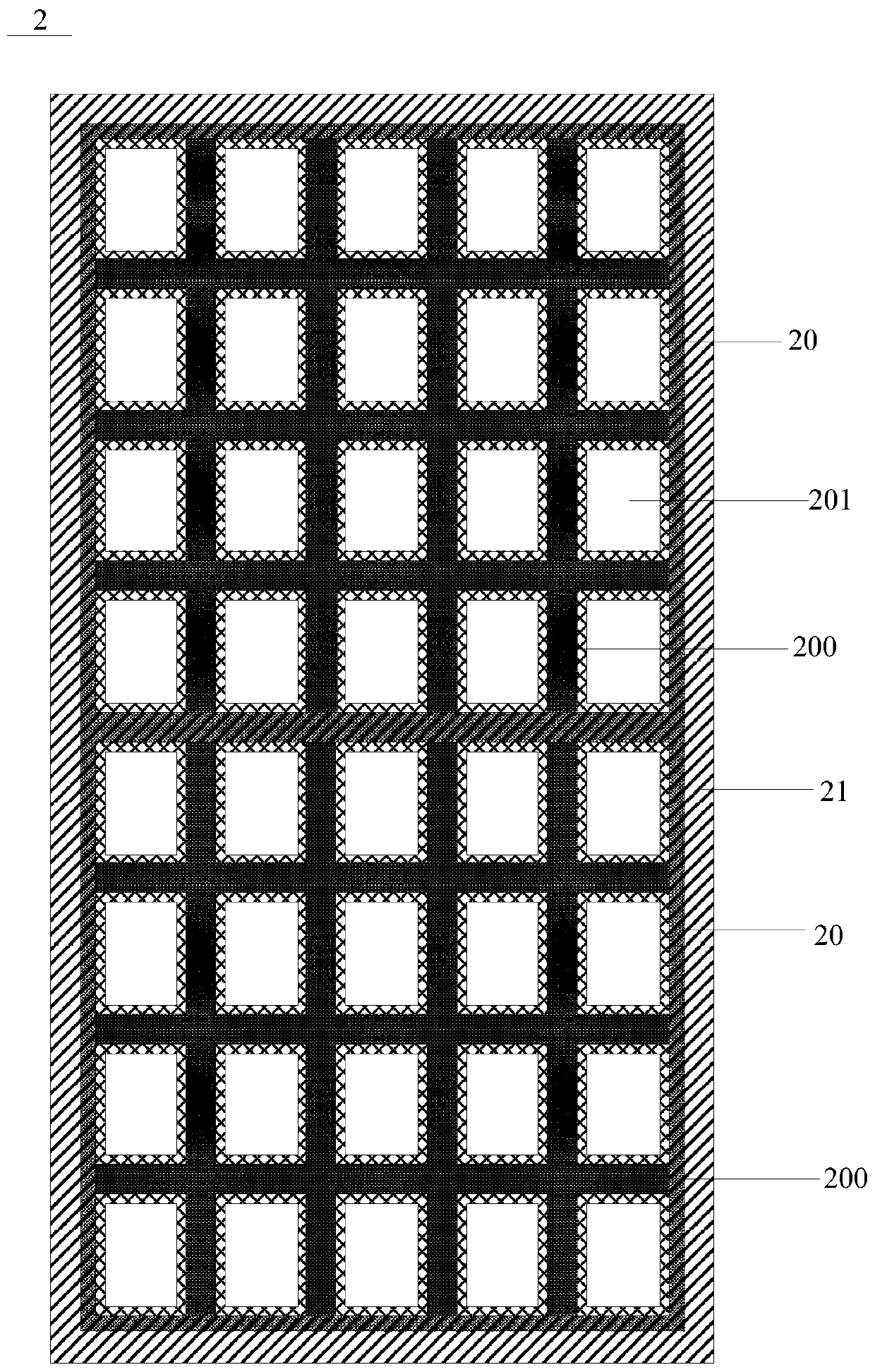

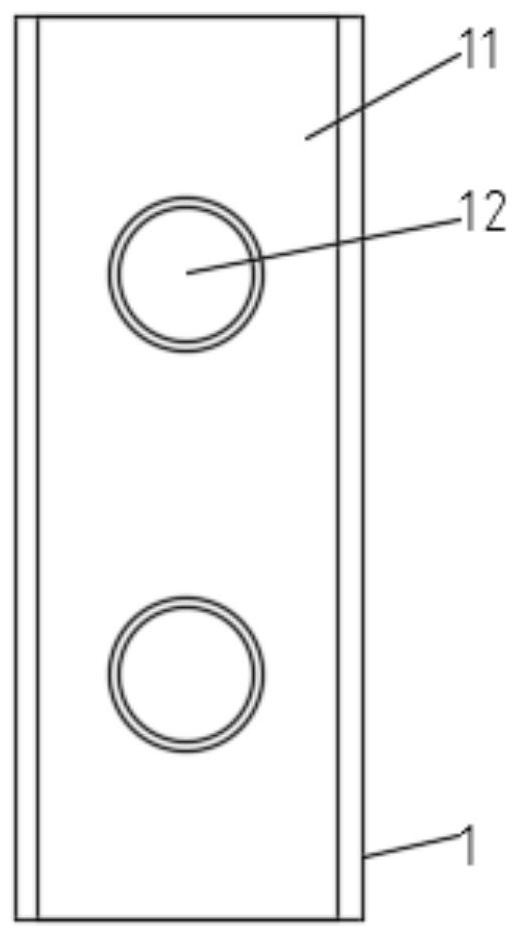

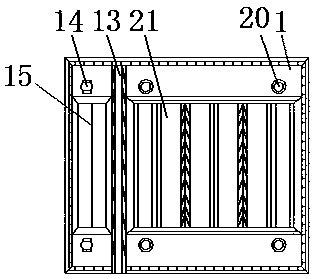

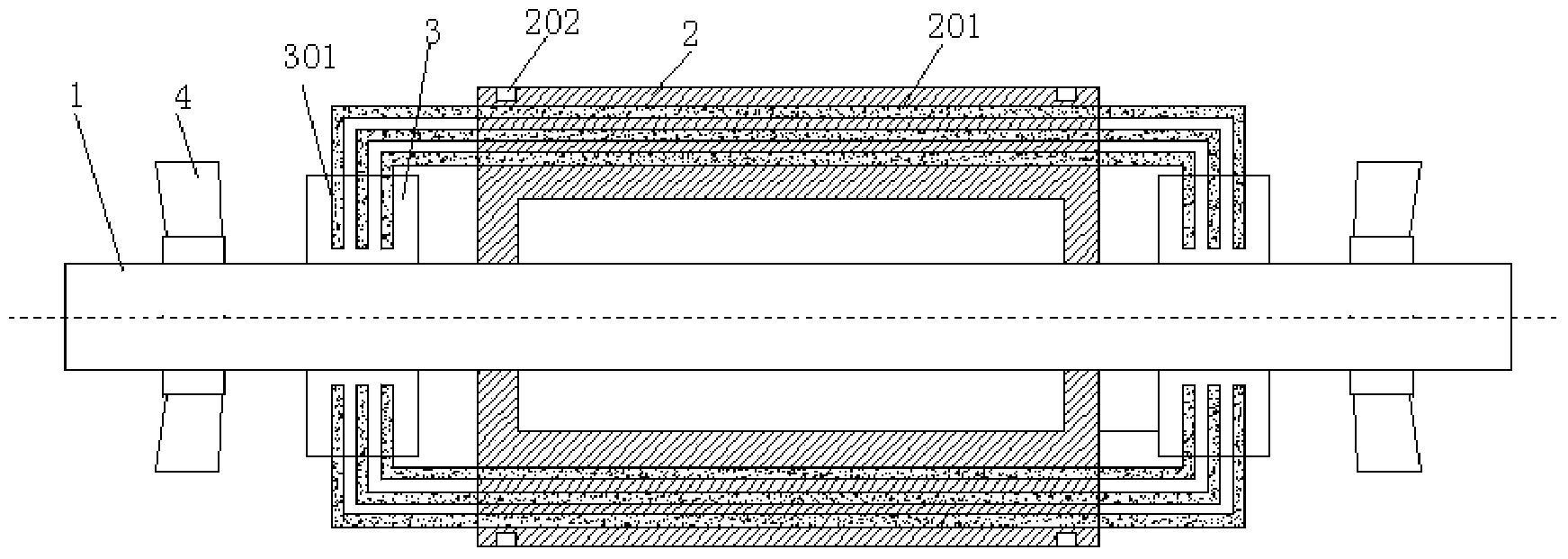

Masks, manufacturing method of masks, open mask plate, application method of open mask plate, and thin film deposition equipment

ActiveCN110331377ALess prone to driftImprove the deposition effectVacuum evaporation coatingSolid-state devicesEngineeringPellicle membrane

The invention provides masks, a manufacturing method of the masks, an open mask plate, an application method of the open mask plate, and thin film deposition equipment, and relates to the technical field of mask plates. The film layer overall deposition effect can be improved. Each mask comprises a plurality of openings. In the thickness direction of each mask, a first groove in a ring shape is formed in the position, located at the edge of each opening, on one side of the mask; and in the thickness direction of each mask, second grooves are formed in the positions, close to the edge of each opening, on the other side of the mask.

Owner:BOE TECH GRP CO LTD +1

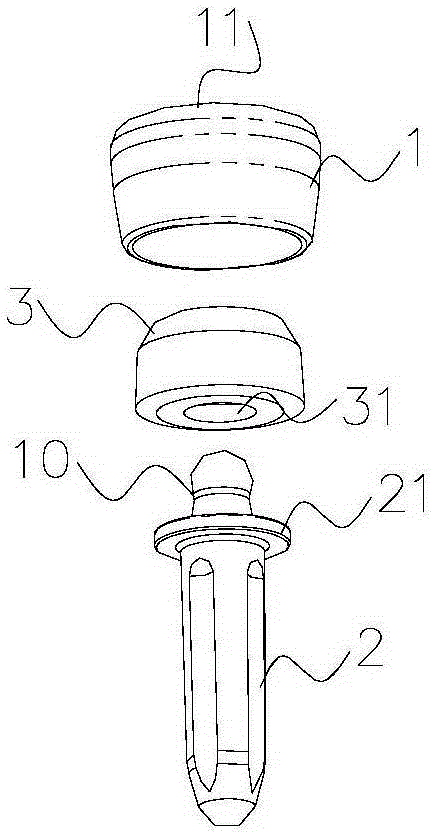

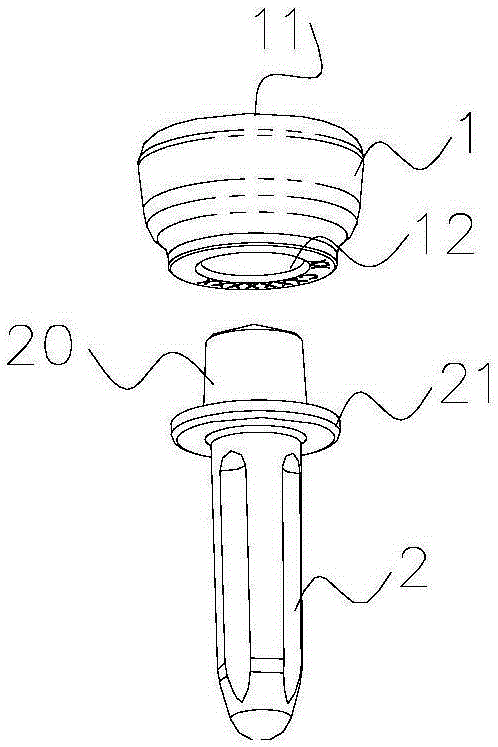

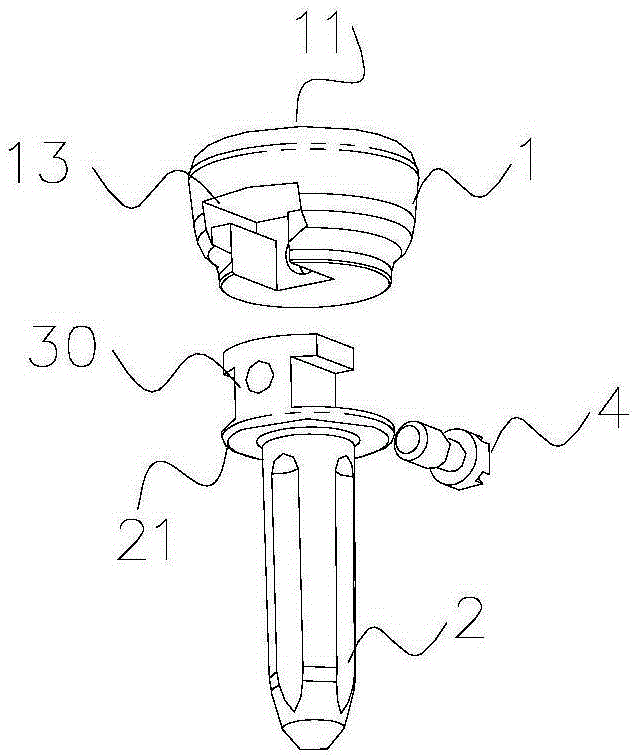

Capitulum radius replacement prosthesis

ActiveCN105193522AIn line with the characteristics of daily behavior sportsImprove stabilityAnkle jointsJoint implantsArticular surfacesHuman anatomy

The invention provides a capitulum radius replacement prosthesis. The capitulum radius replacement prosthesis comprises a capitulum radius and a radius broach, wherein the capitulum radius is in the shape of a circular truncated cone, the end face of the large-diameter end of the capitulum radius serves as the articular surface and is sunk inwards to form a spherical articular cavity, and the sphere center of the spherical articular cavity is located on the axis of the radius broach; a round connecting plane is arranged at the end of the radius broach, the diameter of the connecting plane is identical with that of the small-diameter end of the capitulum radius, and the small-diameter end of the capitulum radius is connected with the connecting plane of the radius broach through a connecting part in a matched mode. The capitulum radius replacement prosthesis accords with human anatomy and daily performance kinetic characteristics and has high stability and safety. Through the improvement of bone cement constituents, biocompatibility between the capitulum radius replacement prosthesis and bone substances is improved, complications such as deviation, looseness, infection and instability do not occur easily, service life is long, and different connecting parts can be adopted according to the conditions of patients to guarantee the optimal using effect of the capitulum radius replacement prosthesis.

Owner:北京威高亚华人工关节开发有限公司

Exercise rehabilitation instrument for exercising flexibility of double hands

InactiveCN109331395ALimiting force reductionKnowing the Limits of Exercise RehabMuscle exercising devicesEngineeringExercise flexibility

The invention discloses an exercise rehabilitation instrument for exercising the flexibility of double hands, and relates to the technical field of medical rehabilitation. The exercise rehabilitationinstrument comprises a bottom plate and a machine body. Bases are arranged at the left side and the right side of the top end of the bottom plate, the machine body is arranged in the middle of the topend of the bottom plate, the bottom plate is fixedly connected with the machine body, spring pieces are arranged at the top ends of the bases, first sliding blocks are mounted at the bottoms of the bases, and the first sliding blocks and the bases are fixedly connected. The exercise rehabilitation instrument for exercising the flexibility of the double hands has the advantages that through the arrangement of a first control panel, a second control panel, connecting rods and movable columns, the shape of the first control panel is matched with the shape of the second control panel, when a patient carries out rehabilitation exercise on the strength of the hands and the flexibility of the hands through the device, and under the effects of the first control panel and the second control panel,meanwhile, under the effect of sensors, the status of the patient during exercise can be displayed respectively.

Owner:SHANXI DATONG UNIV

High-strength insulating MPP power cable tube and preparation method thereof

PendingCN113583340AEfficient captureExcellent heat resistanceElectrical apparatusTubular articlesElastomerPolymer science

The invention discloses a high-strength insulating MPP power cable tube and a preparation method thereof. The high-strength insulating MPP power cable tube comprises the following components in parts by weight: 75-85 parts of isotactic polypropylene resin, 6-10 parts of elastomer rubber type CPE, 7-9 parts of block co-polypropylene, 24-26 parts of ultra-high molecular weight polyethylene resin, 3-5 parts of a flame retardant, 8-12 parts of a plasticizer, 1-3 parts of an antioxidant, 1-4 parts of a light stabilizer and 2-5 parts of a mixed auxiliary material. The preparation method comprises the steps of 1, weighing isotactic polypropylene resin, elastomer rubber type CPE, block co-polypropylene, ultra-high molecular weight polyethylene resin, a flame retardant, a plasticizer, an antioxidant, a light stabilizer and a mixed auxiliary material in parts by weight. The cable tube body prepared by the invention has high strength while having good insulativity, so that the cable tube body is ensured to have good wear resistance and longer service life during application.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

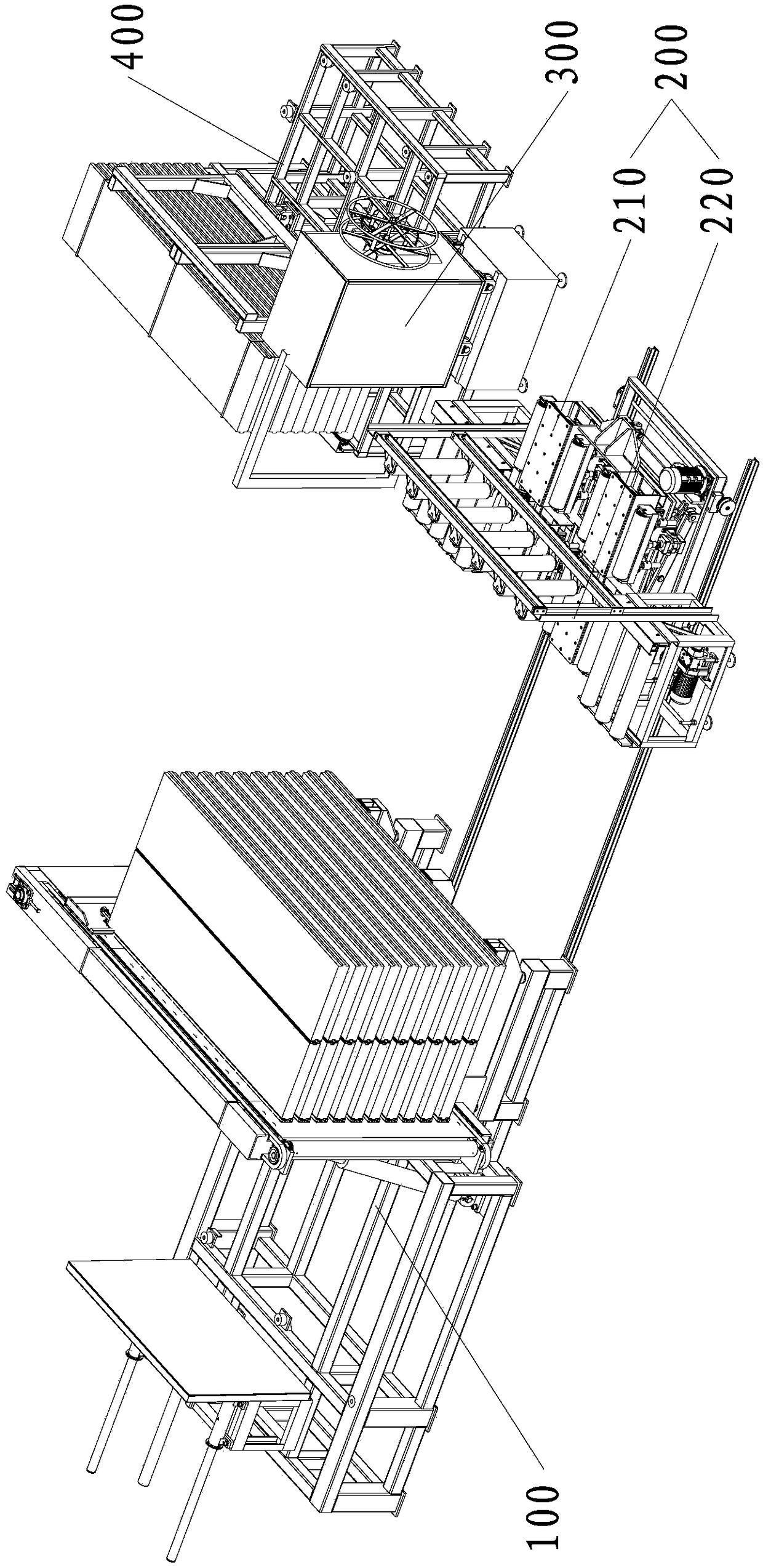

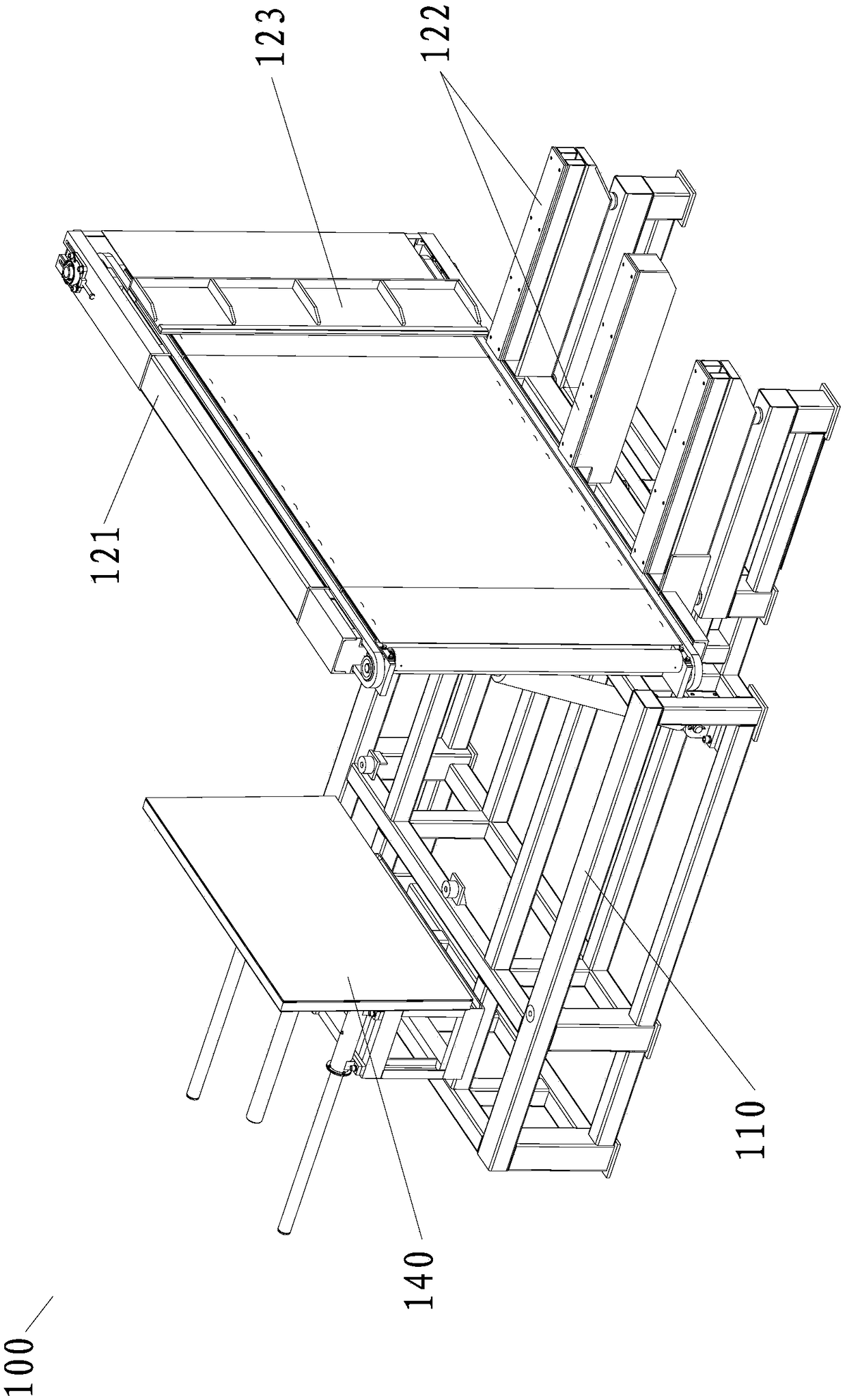

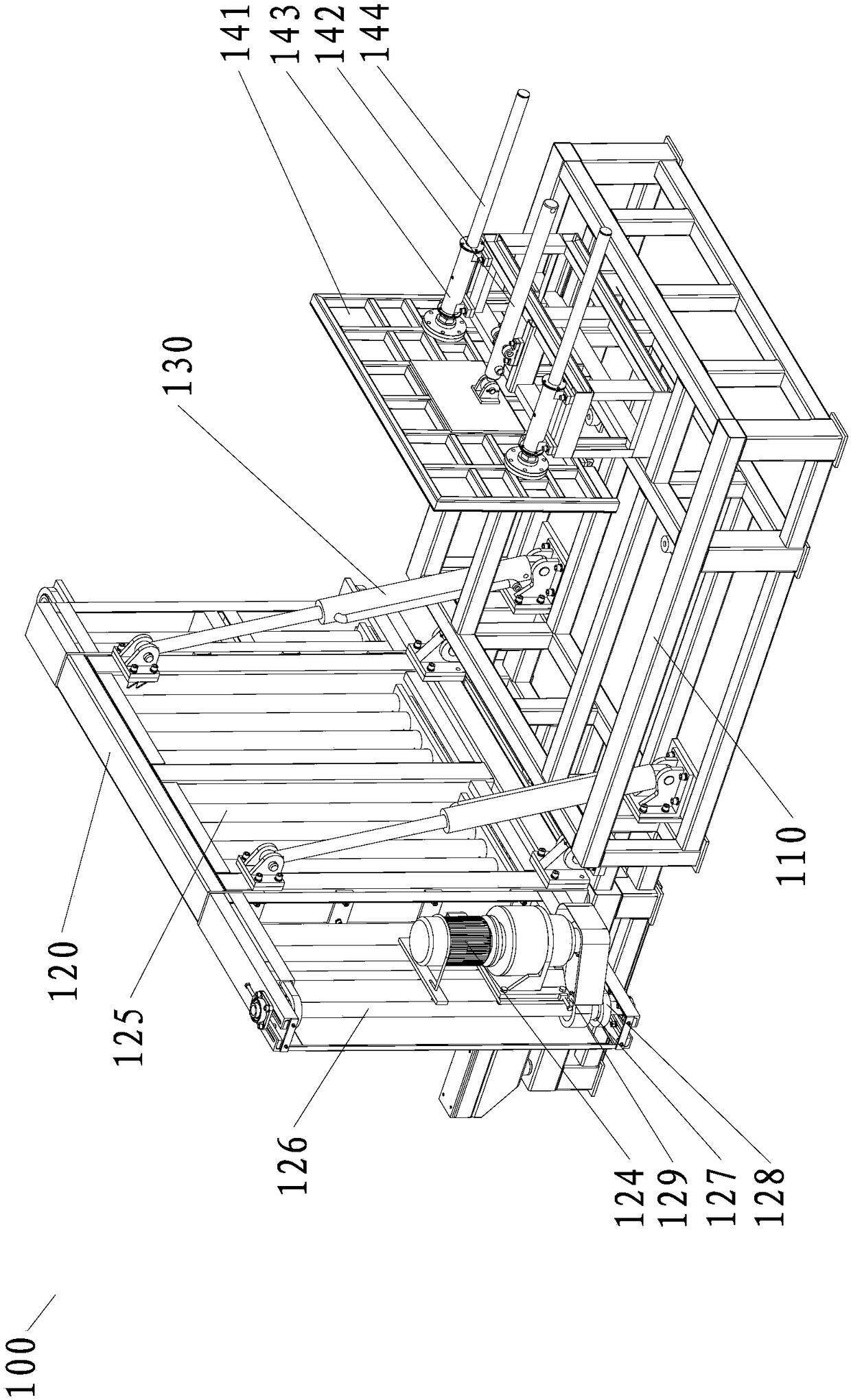

Wallboard production system

PendingCN109018946ALess prone to driftShorten turnaround timeDischarging arrangementCeramic shaping plantsMolding machineAssembly line

The invention provides a wallboard production system. The wallboard production system comprises a wallboard forming machine, and further comprises a wallboard demolding device, a wallboard pile splitting and conveying device, a wallboard packer and a wallboard overturning device which are sequentially connected; the wallboard demolding device and the wallboard forming machine are mutually connected; the wallboard packer is located between the wallboard pile splitting and conveying device and the wallboard overturning device; and the distance between a wallboard position adjusting device and the wallboard overturning device is shorter than the length of wallboards. The wallboard demolding device, the wallboard pile splitting and conveying device, the wallboard packer and the wallboard overturning device are sequentially connected to form an assembly line, the transfer cycle is effectively shortened, the production efficiency is high, meanwhile, the procedures of demolding, pile splitting and packing of the wallboards are completed without using a forklift, the position of the wallboard is not easy to shift, and the product quality is good.

Owner:QUNFENG INTELLIGENT MACHINERY

Shelling and collecting device for coconut pulp spheres in germinated coconuts

The invention belongs to the technical field of coconut processing, and discloses a shelling and collecting device for coconut pulp spheres in germinated coconuts. The shelling and collecting device for the coconut pulp spheres in the germinated coconuts comprises a workbench, supporting legs are welded to the four corners of the lower surface of the workbench and welded through reinforcing rods,and a strip-shaped hole is formed in the middle of the workbench from the front of the workbench to the interior, and provided with an opening in the front of the workbench; a material guide plate isfixedly connected to the portion, corresponding to the strip-shaped hole, of the lower surface of the workbench, the end, close to the front of the workbench, of the material guide plate inclines downwards, and the end, away from the front of the workbench, of the material guide plate is welded to the portion, at the rear side of the strip-shaped hole, of the lower surface of the workbench. According to the shelling and collecting device for the coconut pulp spheres in the germinated coconuts, through the arrangement of a shelling mechanism, the sphere-like coconuts can be quickly located, theshelling mechanism points to the centers of the coconuts for transverse shelling, the operation is different from punching operation by traditional coconut shelling equipment, and transverse punchinghelps to quickly discharge the coconut pulp spheres.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

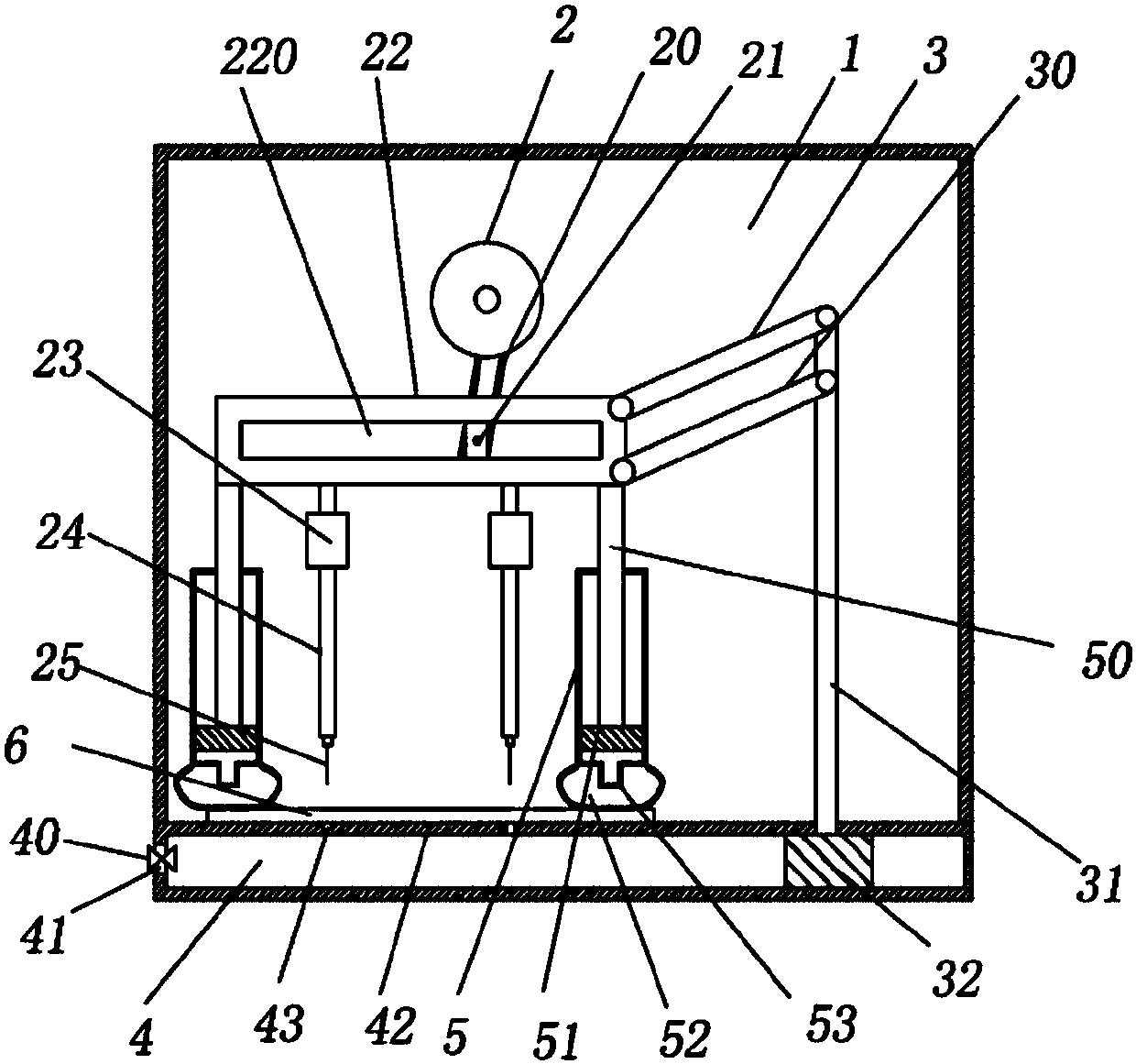

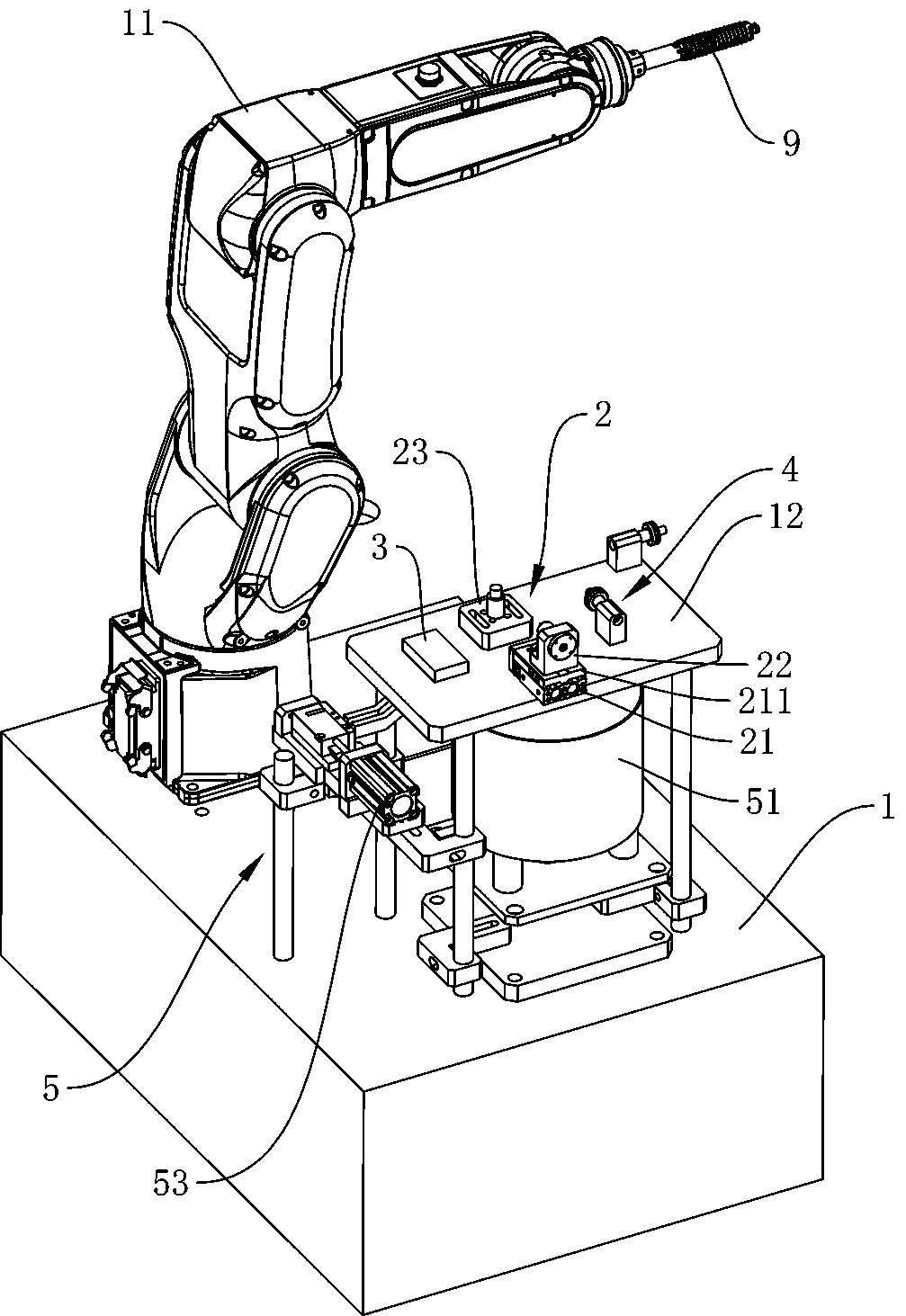

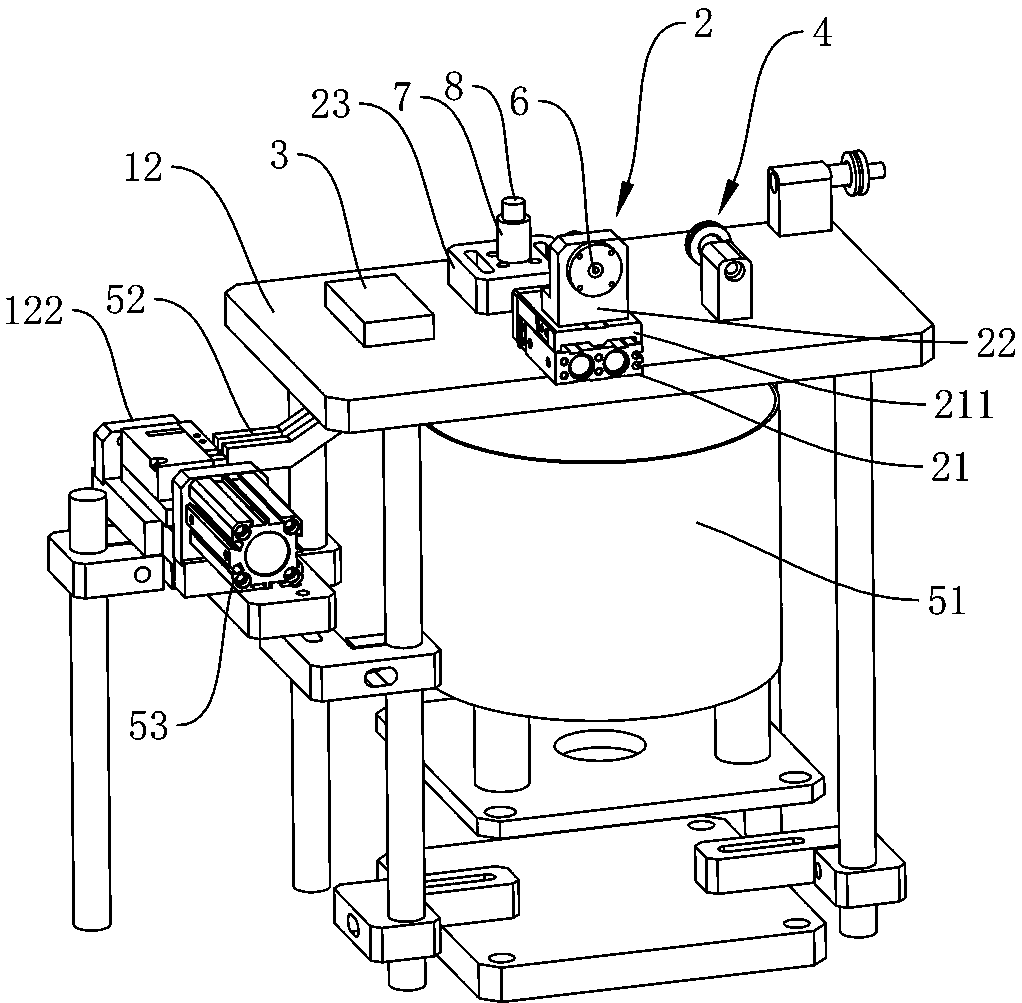

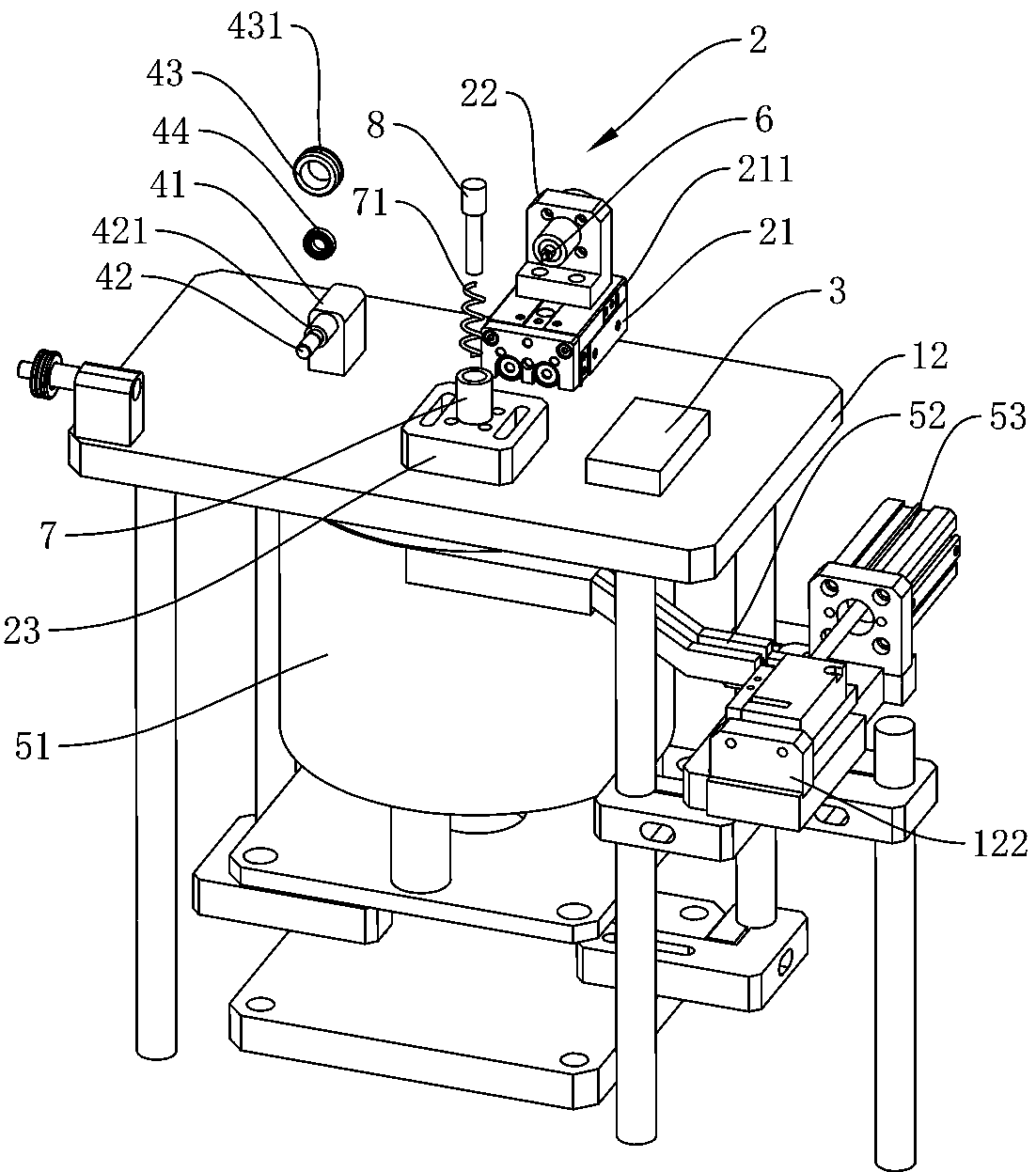

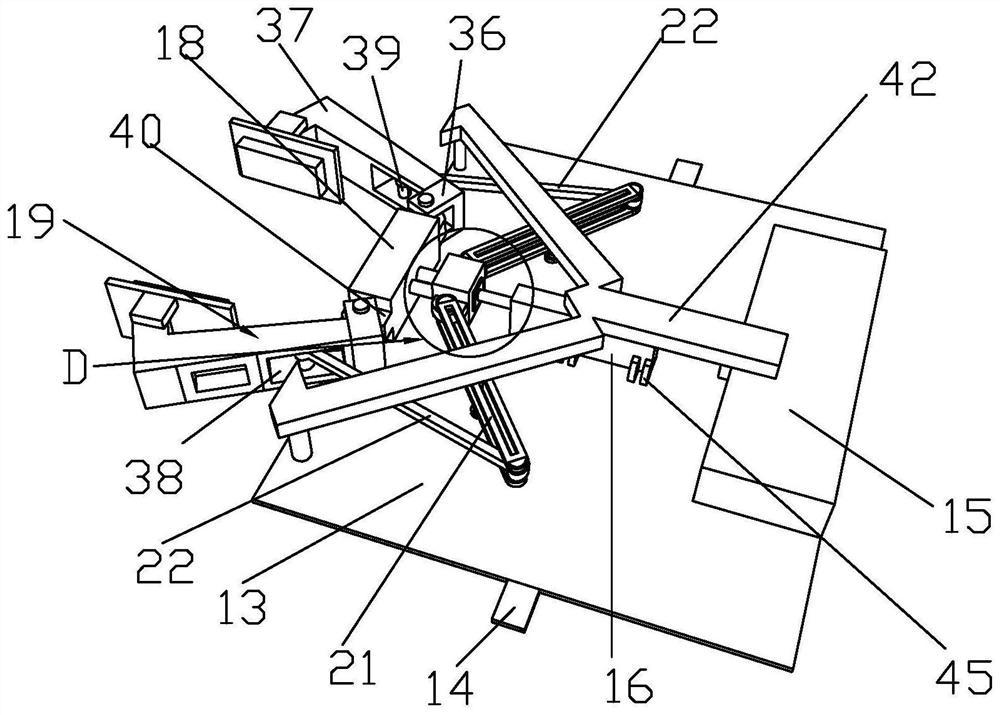

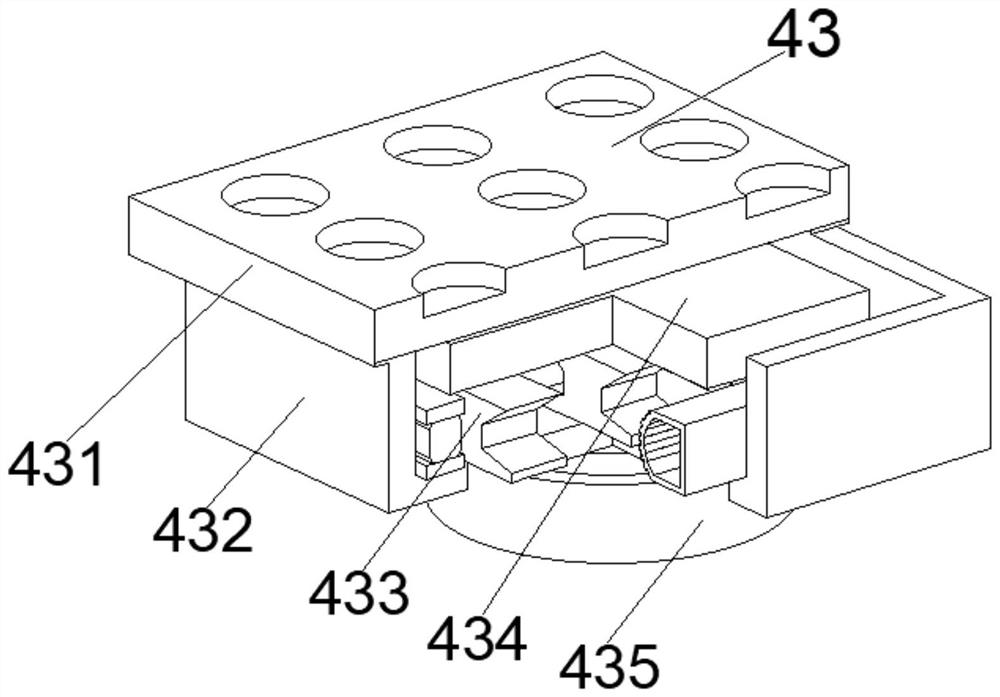

Assembling and conduction detecting integrated device for ignition coil

PendingCN110802402AReduce labor costsAvoid missing detectionAssembly machinesContinuity testingRobot handIgnition coil

The invention discloses an assembling and conduction detecting integrated device for an ignition coil. The integrated device comprises a workbench. A mechanical hand, a feeding mechanism and a supportare arranged on the workbench. An assembling structure and a detecting module are arranged on the support. The assembling structure comprises a thrust cylinder and an installing base. A first electrode is arranged on the installing base. A fixed base is further arranged on the support. An installing sleeve is arranged on the fixed base. A second electrode is movably arranged in the installing sleeve. One end of the second electrode extends out of the installing sleeve. The detecting module is electrically connected with the first electrode and the second electrode. The thrust cylinder drivesthe installing base to get close to or away from the fixed base. The assembling and conduction detecting integrated device has the advantages that through one step, the assembling of a high-voltage nozzle and the conduction detecting of a high-tension line package can be realized, time and labor are saved, the labor cost is low, detection omission can be avoided to a certain extent, the detectingeffect is good, and by means of a bending wheel rotationally connected to a connecting column, the damage to the high-tension line package in the bending process can be reduced.

Owner:宁波市柏诺斯电器有限公司

Broken shell collecting device and method for coconuts in germinated coconuts

InactiveCN111480859ARapid positioningEasy dischargeHuskingHullingStructural engineeringMechanical engineering

The invention belongs to the technical field of coconut processing, and discloses a broken shell collecting device for coconuts in germinated coconuts. The broken shell collecting device for the coconuts in the germinated coconuts comprises a workbench, and supporting legs are welded to the four corners of the lower surface of the workbench. The four supporting legs are welded through reinforcingrods; a strip-shaped hole is formed in the middle of the workbench. The strip-shaped hole is formed inwards from the front face of the workbench and provided with an opening in the front face of the workbench, a guide plate is fixedly connected to the position, corresponding to the strip-shaped hole, of the lower surface of the workbench, the end, close to the front face of the workbench, of the guide plate inclines downwards, and the end, away from the front face of the workbench, of the guide plate is welded to the rear side of the strip-shaped hole. According to the shell breaking and collecting device for the coconuts in the germinated coconuts, through the arrangement of the shell breaking mechanism, spheroidic coconuts can be rapidly positioned and point to the centers of the coconuts for transverse shell opening, the broken shell collecting device is different from hole opening operation of traditional coconut shell opening equipment, and rapid discharging of the coconuts is facilitated through transverse opening.

Owner:王朝红

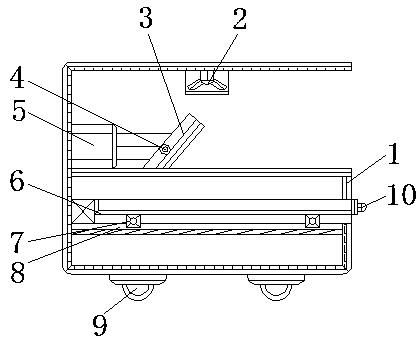

A positioning punching device for building aluminum formwork

InactiveCN109175081BReasonable structural designPrecise positioningShaping toolsPerforating toolsPunchingArchitectural engineering

The invention discloses a locating and punching device for a building aluminum formwork. The locating and punching device comprises a bearing plate. The lower end of the bearing plate is fixedly connected with a U-shaped bottom plate. The upper surface of the bearing plate is provided with an aluminum formwork containing groove. An aluminum formwork body is placed in the aluminum formwork containing groove. The two sides of the bearing plate are provided with two locating mechanisms. Stand columns are welded to the four corners of the upper end of the bearing plate. A rectangular frame plate is arranged on the upper portions of the four stand columns. Punching drills are welded to the output ends of first cylinders. A mounting plate is fixedly connected to the rear side of the upper end ofthe rectangular frame plate. A second cylinder is fixedly mounted on the mounting plate. The output end of a cylinder control switch I is fixedly connected with a connecting plate II. The connectingplate II is attached to a connecting plate I. The locating and punching device is good in locating effect during punching and can conduct fast adjustment according to the position to be punched, so that the punched position is not prone to deviation, and the punching efficiency is improved.

Owner:刘景春

Trimming equipment for non-woven fabric production

InactiveCN108570847ALess prone to driftIncrease flexibilitySevering textilesEngineeringNonwoven fabric

The invention relates to trimming equipment for non-woven fabric production. The trimming equipment comprises a main body, blades and a containing groove, wherein a ventilating fan is arranged on theinner wall on the top of the main body; a telescopic rod is arranged on the inner side of the main body; the blades are arranged at the right end of the telescopic rod, and a first bolt is arranged atthe inner sides of the blades in a penetrating way; a chute is fixed inside the main body; a slide block is arranged on the inner side of the chute; the containing groove is formed in the top of theslide block; a handle is fixed at the right end of the containing groove; rollers are movably arranged at the bottom of the main body; and a pressing plate is arranged on the inner side of the main body. The trimming equipment disclosed by the invention has the beneficial effects that due to the arrangement of the main body, the telescopic rod, the first bolt and the blades, the blades and the telescopic rod form a detachable structure by virtue of the first bolt, and when screwing operation is performed by the first bolt, the blades can be stabilized, so that the phenomenon that the blades are uneasy to offset when non-woven fabrics are trimmed by the device is avoided.

Owner:陈雪莲

Rain water tank culvert penetration underground pipeline protection device

InactiveCN108755754ALess prone to driftReduce shakingArtificial islandsGround-workUnderground pipelineWing wall

The invention discloses a rain water tank culvert penetration underground pipeline protection device. The rain water tank culvert penetration underground pipeline protection device structurally comprises a water isolation wall, a rainwater inlet, a pile slope, cap stone, a rain water tank culvert body, a sand-gravel cushion, a wing wall, a deformation seam and a pipeline protection device. The rain water tank culvert penetration underground pipeline protection device is structurally provided with the pipeline protection device, when an underground pipeline needs to be paved, a user rotates a fixing bolt to achieve extraction from a fixing hole and a locking hole, a device top cover is pushed to drive a direct gear to be lifted up, a stretchable spring and a limiting block are arranged so that swing of the underground pipeline can be reduced when vehicles pass through the underground pipeline, and pipelines with different sizes can be fixed and borne conveniently; and after paving is completed, the device top cover is closed to insert the fixing hole into the fixing hole, the fixing bolt is used for locking to complete fixation, the overall device is convenient, quick and effectiveto use, the defect that a rain water tank culvert cannot protect the underground pipeline in the proper art is overcome, the pipe fixing effect can be achieved, pipe excursion is not prone to being caused, and practicability is high.

Owner:江北建设有限公司

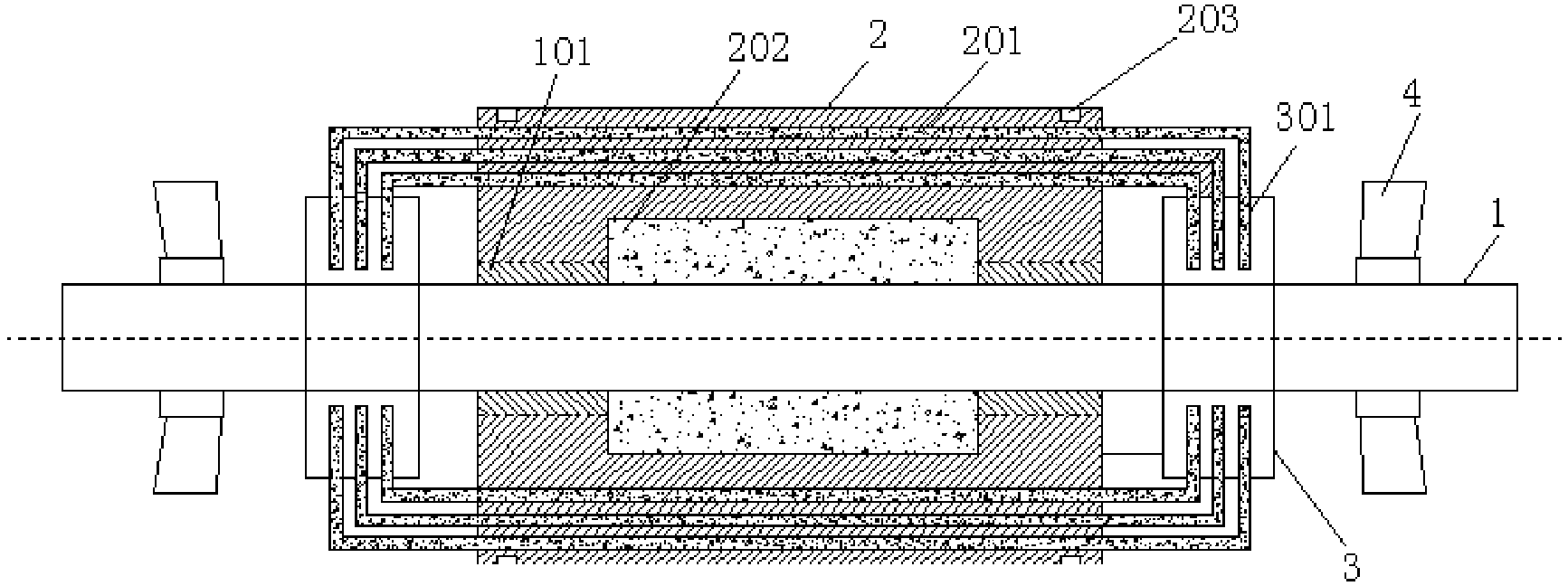

Shockproof rotor

The invention discloses a shockproof rotor. The shockproof rotor comprises a rotating shaft, a rotor body and permanent magnets; the rotating shaft is fixedly connected with the rotor body; the rotor body is provided with a plurality of permanent magnets accommodating grooves; the rotating shaft is provided with fixing disks located at two sides of the rotor body; the fixing disks are provided with a plurality of permanent magnet fixing clamping grooves; the permanent magnets are long-strip-shaped; two permanent magnets are provided with fixing portions which extend outwards and are arranged in the clamping grooves of the fixing disks and elongated portions which are embedded in the accommodating grooves of the rotor body; the interior of the middle of the rotor body is hollow; the hollow part of the rotor body is filled with flexible materials; the rotor body is fixedly connected with the rotating shaft through keyways; and a plurality of keyways are provided and are uniformly distributed along the circumference of the rotating shaft. According to the shockproof rotor of the invention, defects in the prior art can be eliminated, and the designed structure of the shockproof rotor is compact, and the permanent magnets are fixed firmly and do not tend to deviate, and the service lives of the permanent magnets are long; and the flexible materials in the rotor body and the rotor body are fixedly connected with the rotating shaft through the keyways, and therefore, the inertia force of the rotor body can be reduced.

Owner:TONGLING HEWU MACHINERY MFG

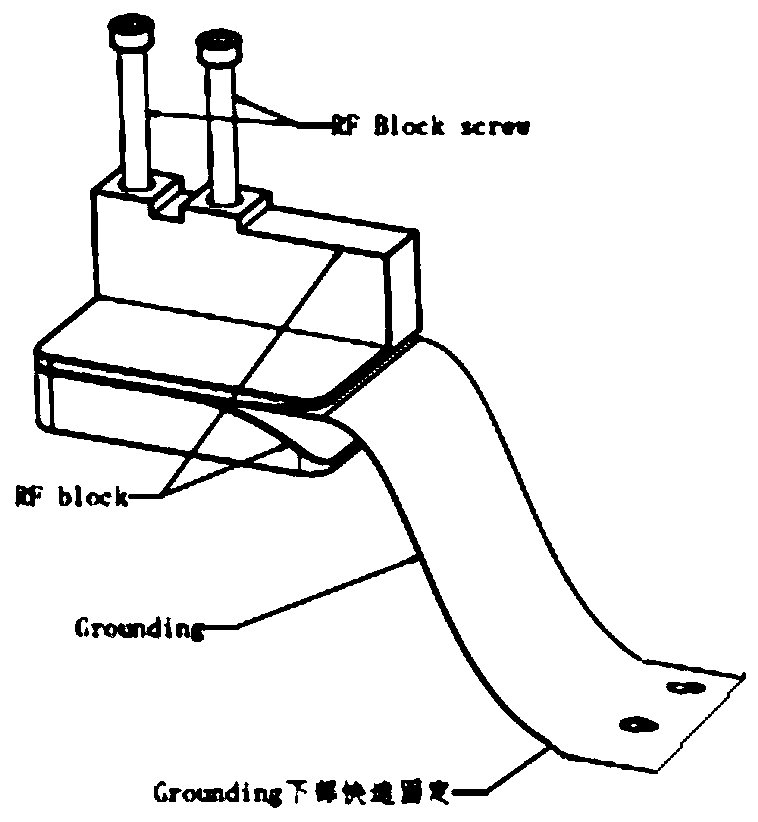

CVD equipment

InactiveCN110158053AEffective control of installation directionExtended service lifeChemical vapor deposition coatingMultiple conductors connectorEngineering

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Circuit board processing method

ActiveCN107889361BEasy to operateSimple drilling structurePrinted circuit manufactureManufacturing technologyEtching

The invention belongs to the technical field of electronic device manufacturing, and particularly relates to a circuit board processing method. The circuit board processing method comprises the following steps of A, material opening, in which a large copper plate is cut into a plurality of small copper plates; B, inner-layer film formation, in which a dry film is attached onto the copper plate andis exposed by ultraviolet ray; C, internal etching; the exposed copper plate is placed in an alkali solution; D, brownization, composition and plate pressing to obtain a substrate; and E, drilling, in which a drilling device is arranged to drill, wherein the drilling device comprises a rack, a drilling mechanism and a dust removal mechanism, the drilling mechanism comprise a motor, a rotation wheel, a sliding block, a mobile rack, a support block, a sliding rod and a drilling head, and the dust removal mechanism comprises a main oscillating rod, a straight rod, a dust removal piston and a dust removal chamber. With the circuit board processing method disclosed by the technical scheme, cutting powder in holes in the substrate can be effectively removed, and inner hole plugging is prevented.

Owner:重庆市志益鑫电子科技有限公司

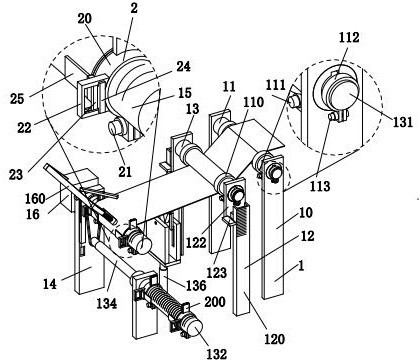

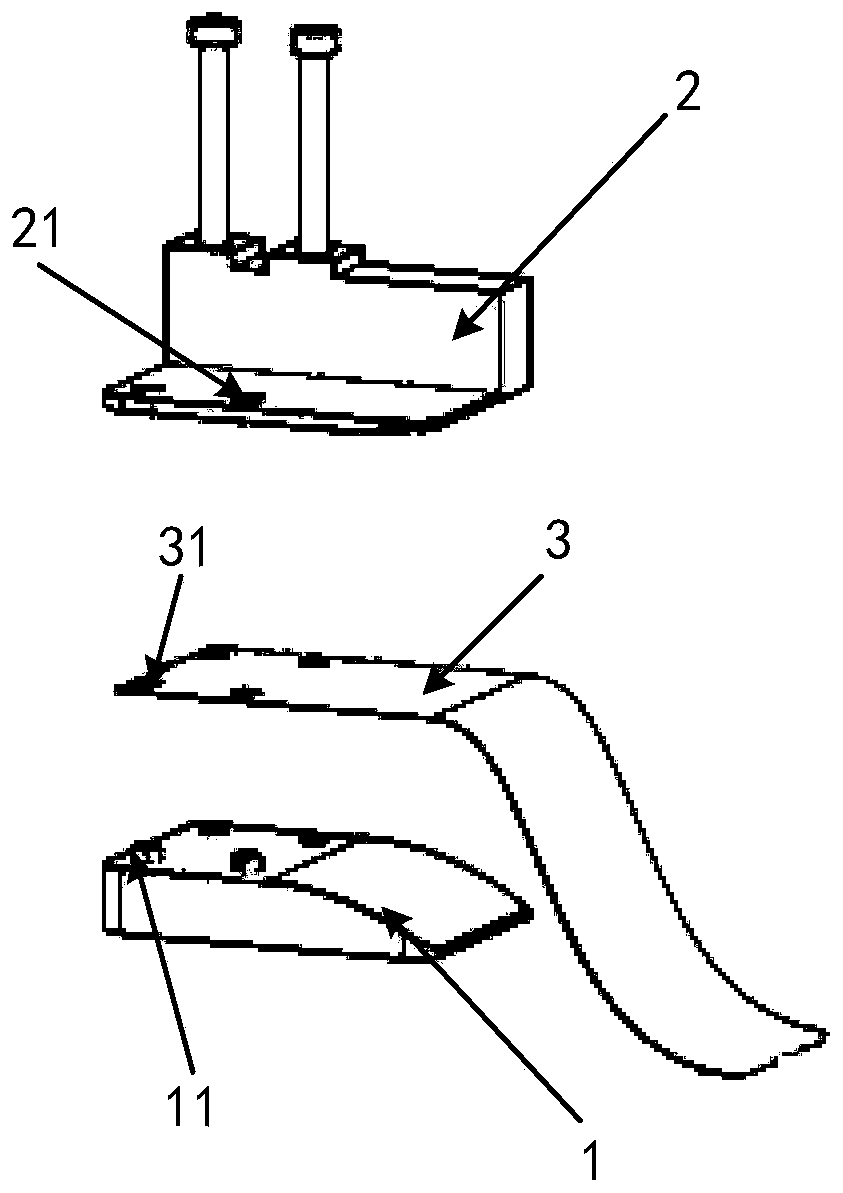

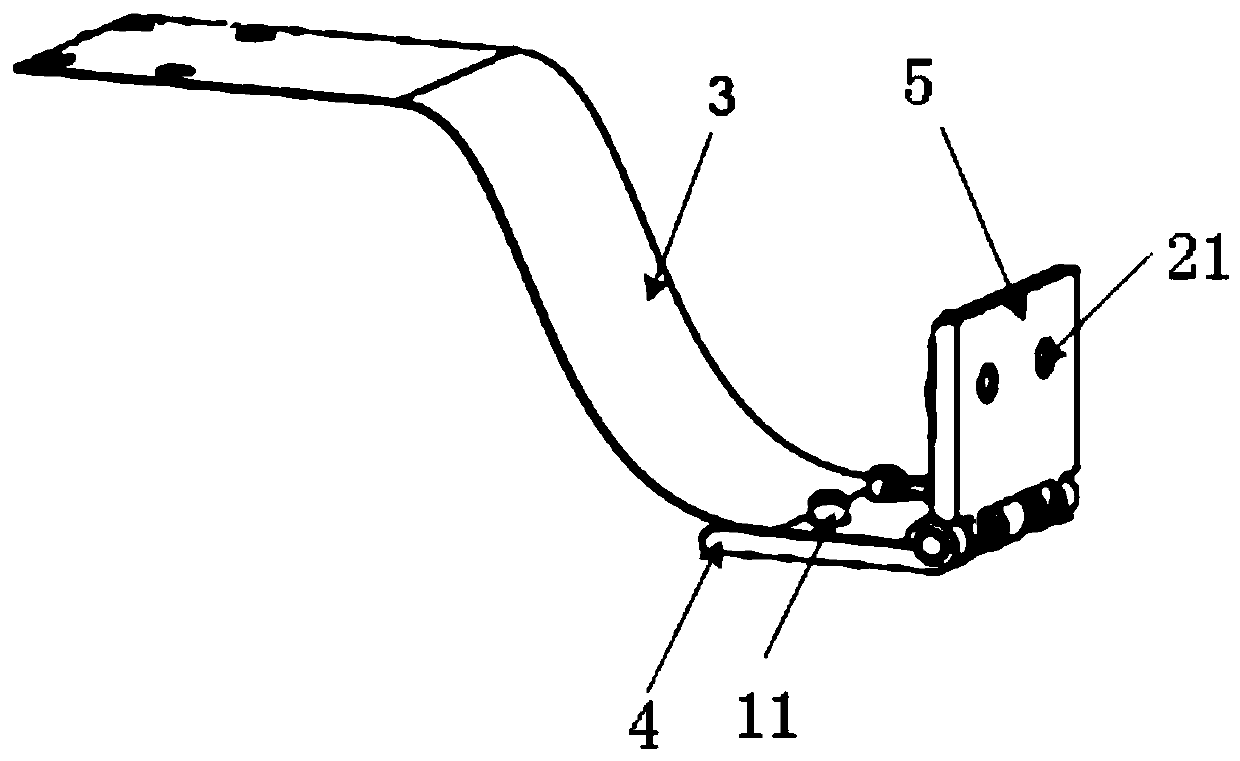

Open double crankshaft precision punching machine and its punching method

ActiveCN108995268BImprove securityReduce movementShaping toolsPress ramPunch pressElectric machinery

The invention discloses an open-type double-crankshaft precision overhead punch and a stamping method thereof. A working platform is provided with a transmission device, a limiting column and a sliding groove. The sliding groove is internally provided with a ball, the sliding groove is provided with a sliding device, the sliding device is provided with a first arc-shaped block, the first arc-shaped block is connected with a second arc-shaped block, and the second arc-shaped block is provided with an operation platform. The operation platform is provided with a position clamping block, the operation platform is provided with a motor and a first fixing block, the motor is provided with a push rod, the push rod is provided with a push block, the first fixing block is provided with a locatingdevice and a compression spring, the compression spring is provided with an elastic block, and the elastic block is provided with a first transmission rod. The first transmission rod is provided witha rotating groove, and the first transmission rod is provided with a second transmission rod. The stamping method comprises the following steps that a, previous preparation is performed; b, a stampingdie is fixed; c, stamping is performed; and d, stamping pieces are collected. According to the open-type double-crankshaft precision overhead punch and the stamping method, the stamping die is located by arranging the adjustable locating device, and the problems that the stamping die is prone to being displaced during stamping and uneven warping occurs during pressing are solved.

Owner:ZHEJIANG BOLUN HIGH PRECISION MACHINERY

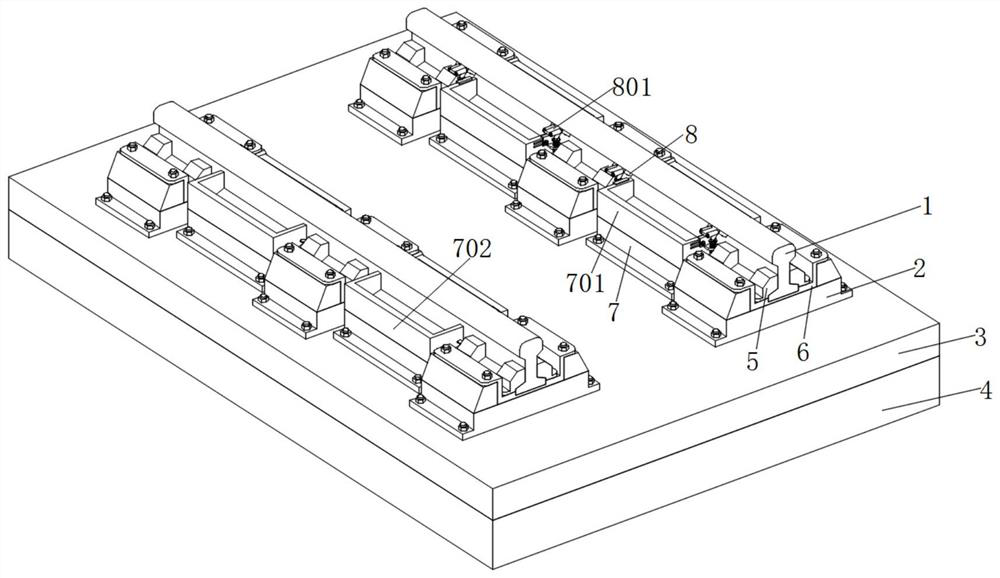

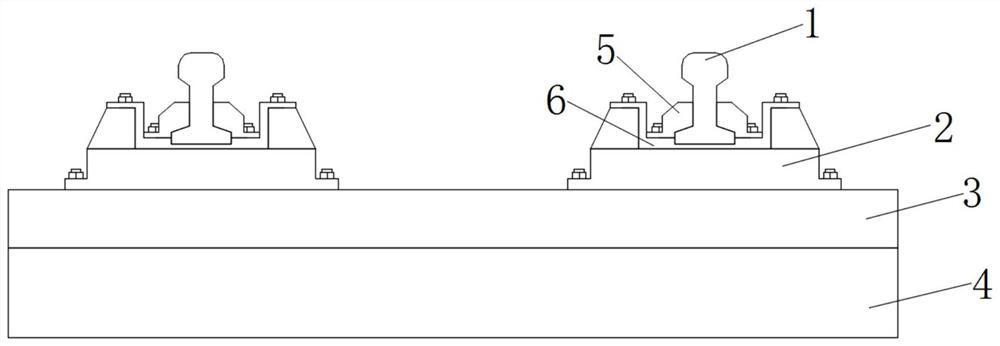

Anti-freezing track structure and track structure construction method thereof

ActiveCN114032712AImprove insulation effectImprove frost resistanceBallastwayNon-rotating vibration suppressionTrackwayStructural engineering

The invention discloses an anti-freezing track structure and a track structure construction method thereof. The anti-freezing track structure comprises a steel rail body, a base and a foundation bed, the base is fixed to the top of the foundation bed in a limited mode, sleeper bases are fixedly installed on the top of the base, a limiting frame is fixedly installed on the inner sides of the sleeper bases, and the steel rail body is limited to the top of the limiting frame; a fixing seat is fixedly installed on the base between the sleeper bases, a first heat preservation cover is fixedly installed on the fixing seat on the inner side of the steel rail body, and a second heat preservation cover is fixedly installed on the fixing seat on the outer side of the steel rail body. The anti-freezing effect of the steel rail body can be improved through mutual cooperation of the fixing set, the first heat preservation cover and the second heat preservation cover, the collision block can hit the inner side of the steel rail body through mutual cooperation of the collision block, a pressing block, a movable column, a movable frame, a rotating roller and a movable base, an ice layer is shaken off, and the convenience is effectively improved.

Owner:NANJING INST OF RAILWAY TECH

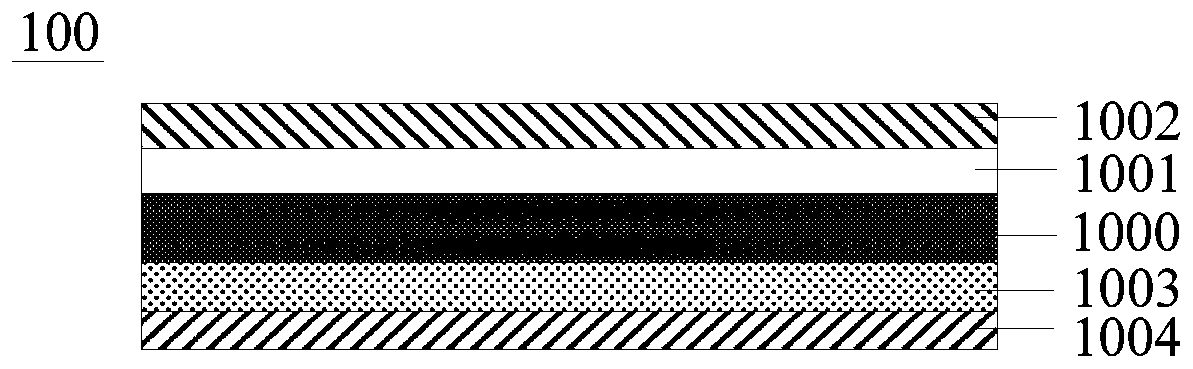

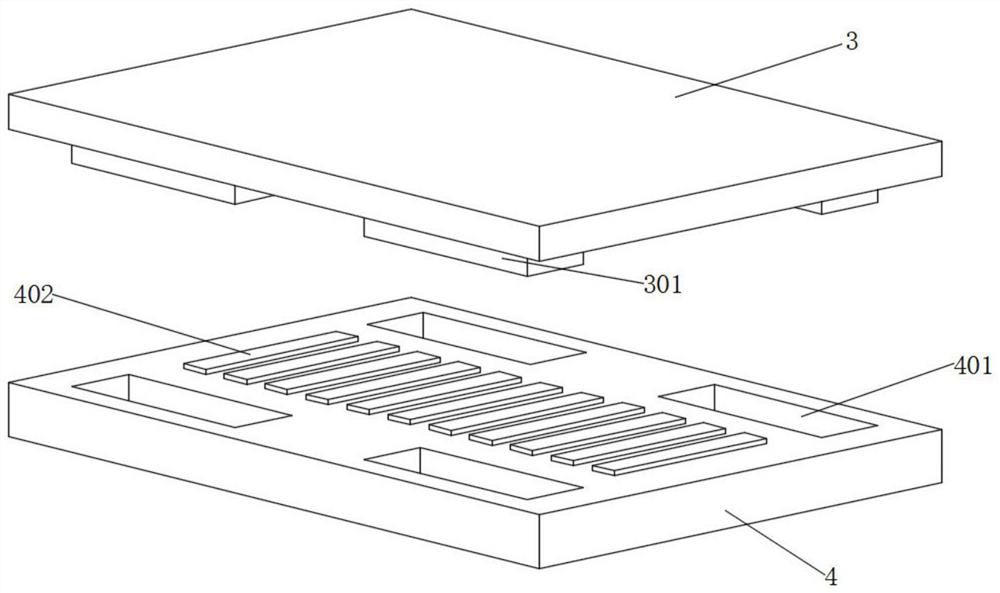

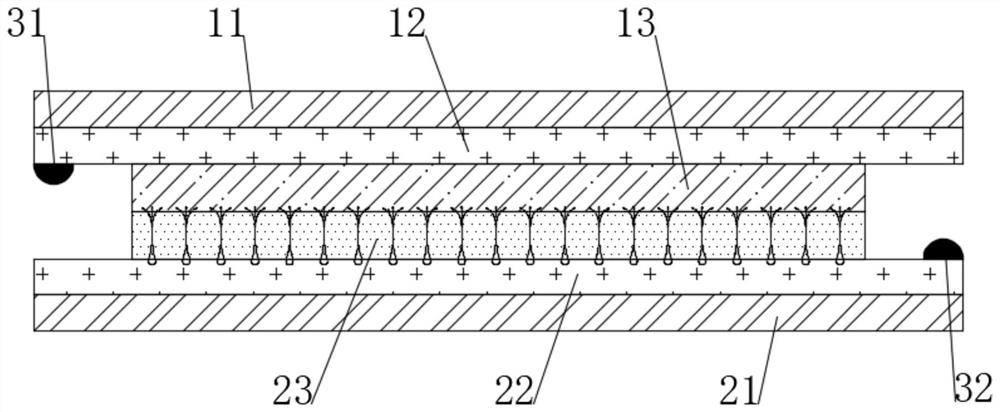

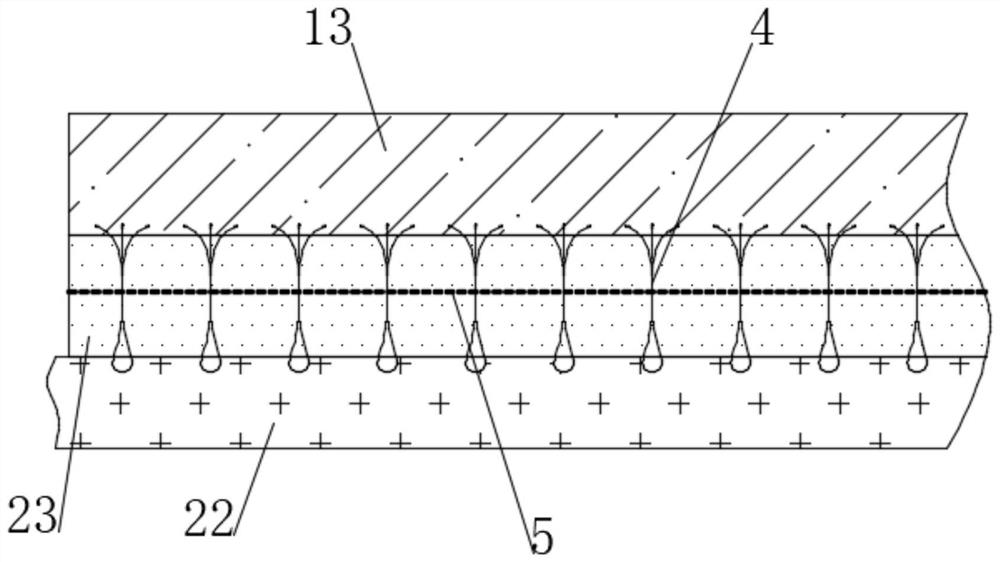

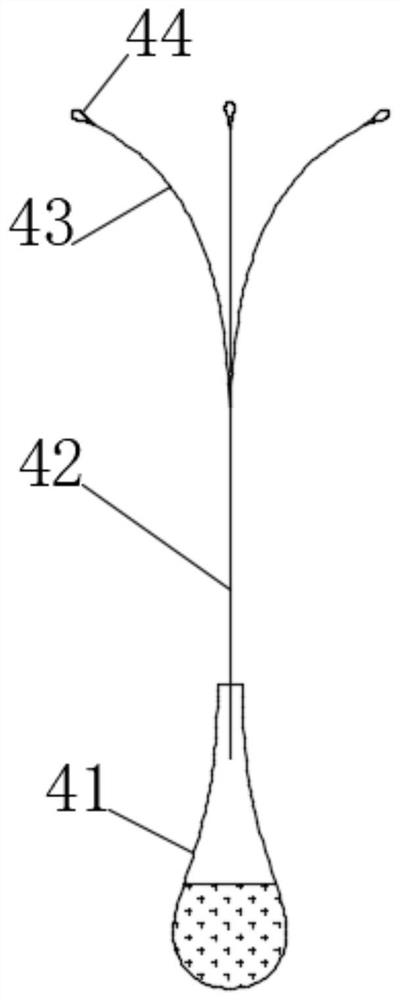

Intelligent color-changing film of nano-silver PET conductive film

ActiveCN111610680AEffective auxiliary dense fillingAvoid air voidsConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersLight guideEngineering

The invention discloses an intelligent color-changing film of a nano-silver PET conductive film, which belongs to the field of color changing films. According to the intelligent color-changing film ofthe nano-silver PET conductive film, a compensation light guide screen plate is embedded in a cementing layer; on one hand, the connection effect of the cementing layer on an upper diaphragm and a lower diaphragm can be effectively assisted; the situation that the stability of the color-changing film becomes poor due to the influence of the ambient temperature on the cementing layer is effectively avoided; moreover, the situation that the edge of the upper diaphragm and the edge of the lower diaphragm are raised or the upper diaphragm and the lower diaphragm fall off due to viscosity reduction of the cementing layer can be effectively prevented; on the other hand, the defect that the overall color changing effect of the color-changing film is poor due to poor light guide performance of the cementing layer can be effectively overcome; meanwhile, when the color-changing film is used, the powder uniformity of the transparent magnetic powder on a grid lining plate can be changed through the magnetic plate, then the color changing performance and the light transmission performance of different areas of the color-changing film can be adjusted according to needs; and compared with the prior art, the application range is wider.

Owner:上海亿乾实业有限公司

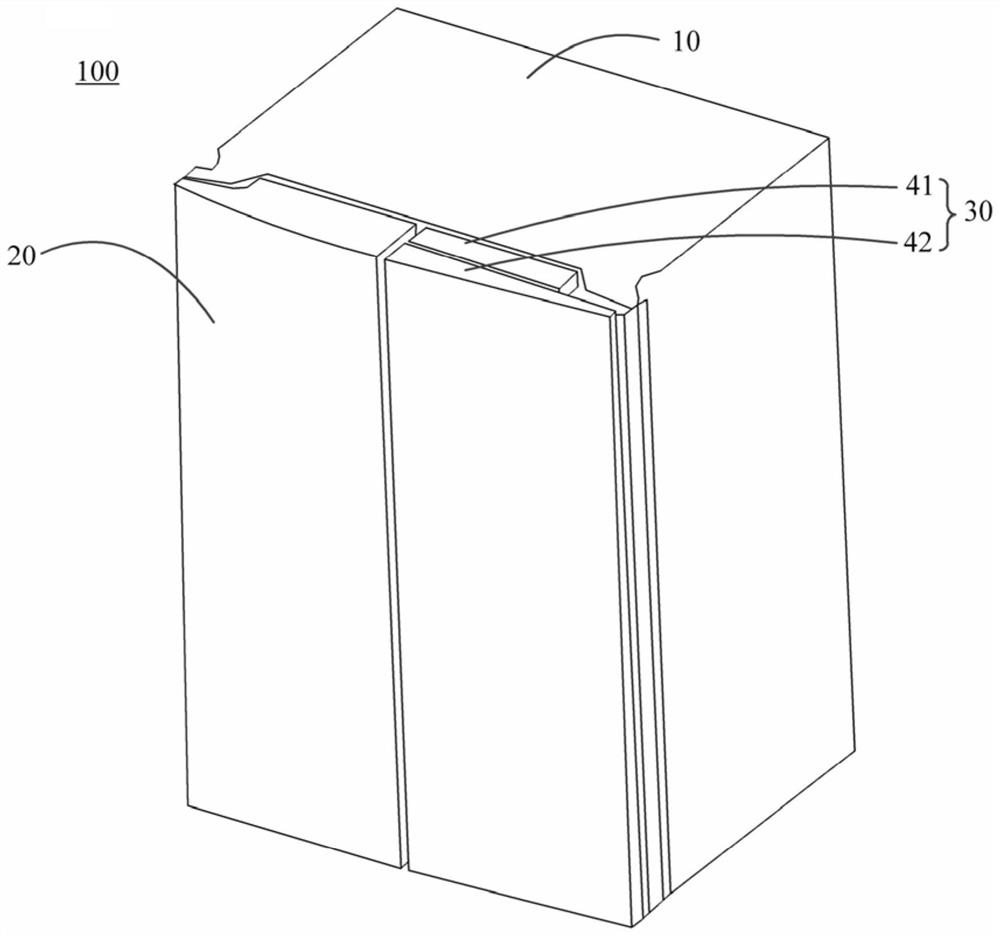

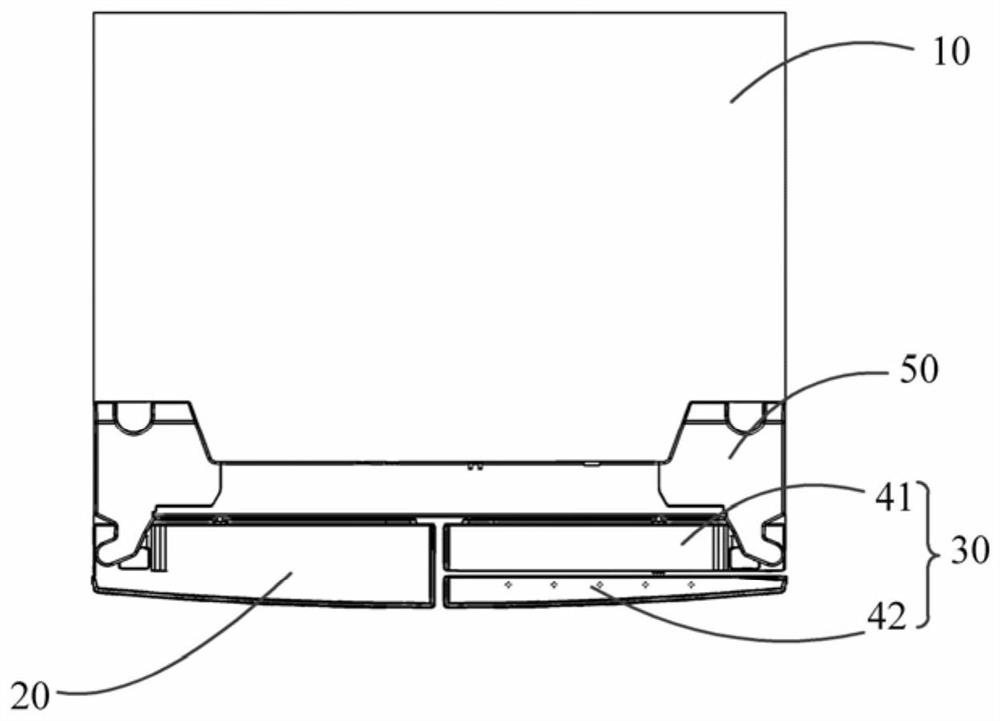

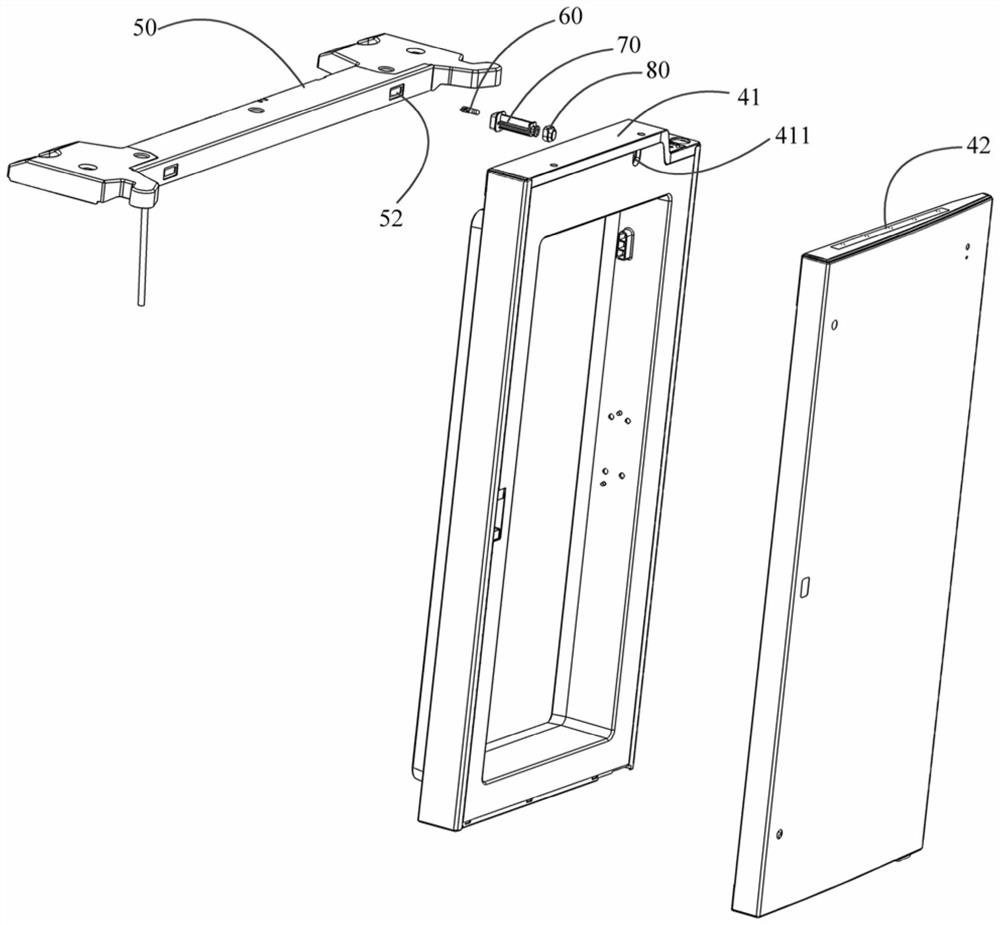

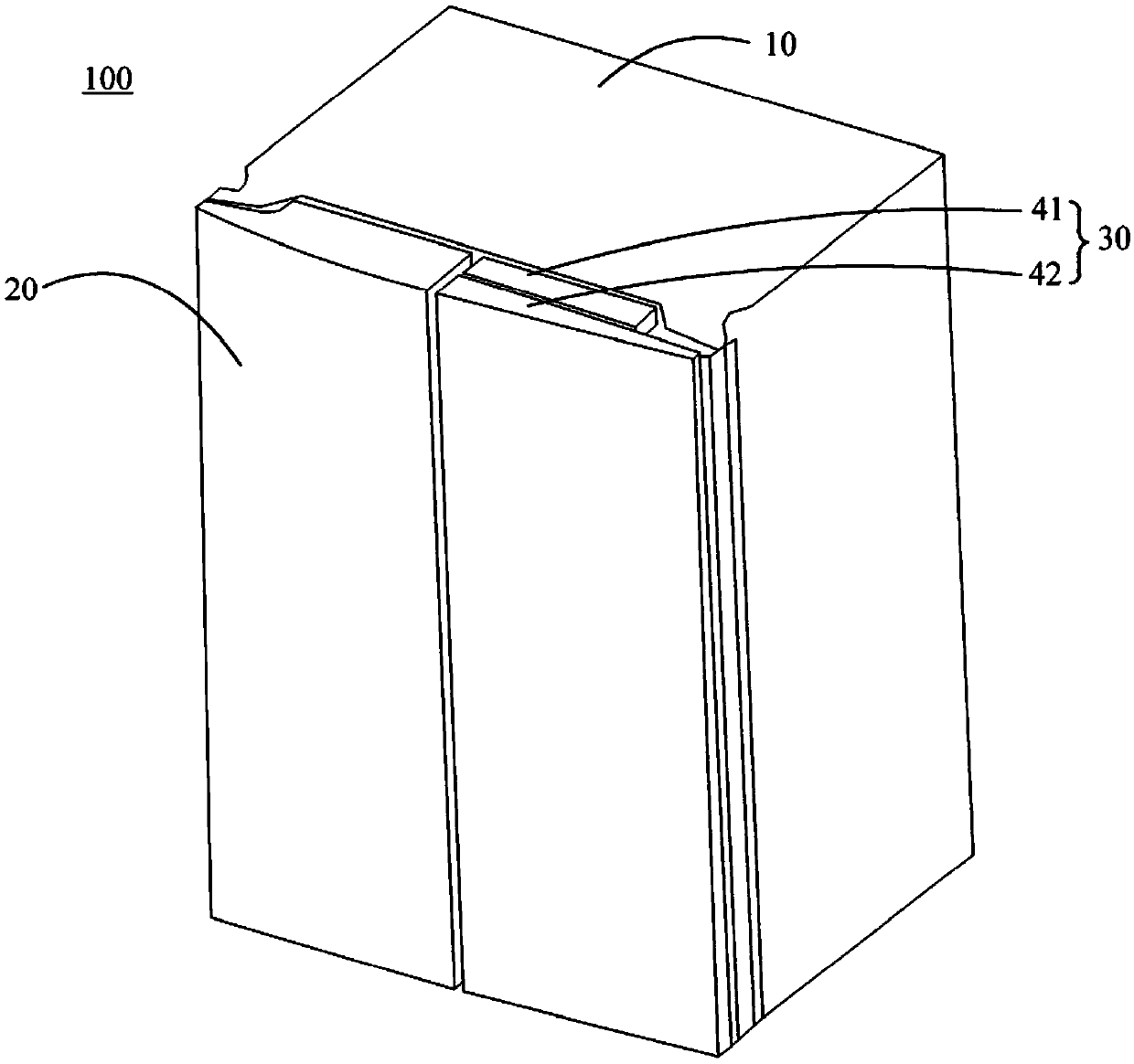

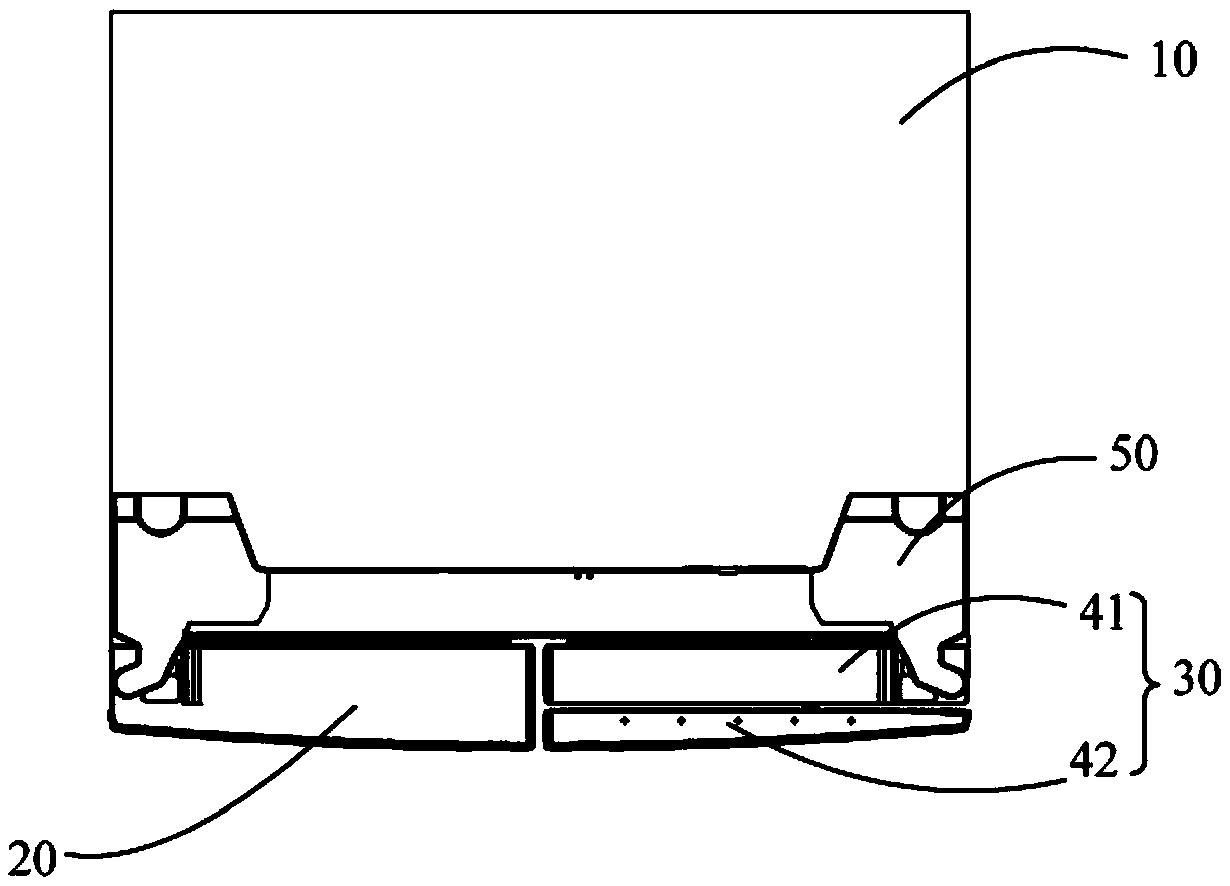

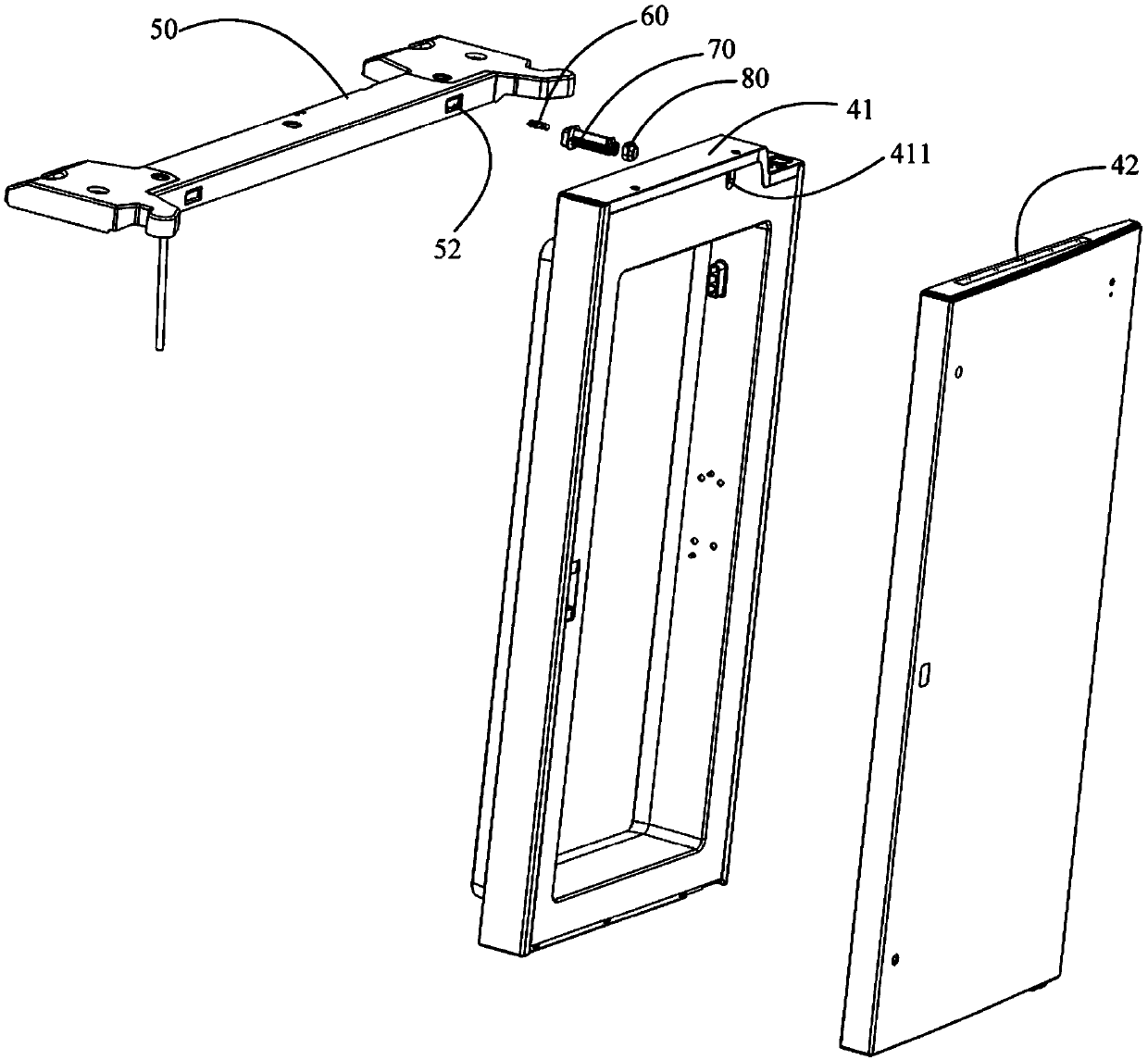

Refrigerator with double door structure

ActiveCN110873507BReduce controlSimplify control proceduresLighting and heating apparatusLighting arrangementIceboxStructural engineering

The present invention provides a refrigerator with a double-layer door structure, comprising: a box body defining a storage compartment inside; an inner layer door that is openably and closably connected to the box body, and opens at a position close to the edge of the box body; There are through holes; the outer door is openably and closably connected to the outside of the inner door, and the inner door and the outer door can be opened and closed independently or together; the lighting device is used to The lighting of the storage compartment; the lighting switch is arranged on the part of the box body in contact with the inner door, and its contact position is opposite to the through hole; the transition piece is integrally installed in the through hole Inside, the length of which is greater than the length of the through hole, so that the two ends can be interfered by the contacts of the outer door and the light switch respectively. The refrigerator with the double-layer door structure of the present invention uses a mechanical structure to close or break the light switch, has a simple structure, reduces switch control components, and simplifies the control program of the circuit.

Owner:CHONGQING HAIER REFRIGERATION ELECTRIC APPLIANCE CO LTD +2

A motor shock absorber with its own temperature measurement

InactiveCN109888968BEasy to useExtended service lifeThermometer applicationsSupports/enclosures/casingsElectric machinePhysics

The invention relates to a motor shock absorber with self-contained temperature measurement, which includes a support base, a connecting wire and a stopper. A support frame is arranged on the top of the support base, and a first chute is arranged on the inner side of the support frame. Bolts run through the outer wall of the support frame, a first sliding block is movably arranged inside the first chute, and a telescopic rod is connected to the inner wall of the first sliding block close to the central axis of the support seat. The beneficial effects of the present invention are: the present invention sets up the supporting base, the motor, the plug, the connection wire, the slot and the display screen, and the plug forms an integrated structure through welding and the connection wire. The slot is docked so that the device is in a connected state, and the motor is started to make the motor work normally. Through the function of the display screen, the temperature of the motor when it is working can be displayed in real time, so that the staff can use the motor correctly and extend the life of the motor. service life.

Owner:JIANGSU JUJIE ELECTROMECHANICAL CO LTD

Rotor

The invention discloses a rotor. The rotor comprises a rotation shaft, a rotor body and permanent magnets, wherein the rotation shaft is fixedly connected with the rotor body, the rotor body is provided with multiple permanent magnet displacing grooves, a fixing disc is arranged on the rotation shaft at two side positions of the rotor body, the fixing disc is provided with multiple permanent magnet fixing slots, the permanent magnets are long-strip structures, the two permanent magnets have fixed portions extending outwards, the long-strip portions are embedded in rotor body displacing grooves, and the fixed portions are arranged in the fixing disc slots. The rotor solves disadvantages in the prior art and has a compact design structure, the permanent magnets are fixed and secure, deviation is not liable to occur, and service life is long.

Owner:TONGLING HEWU MACHINERY MFG

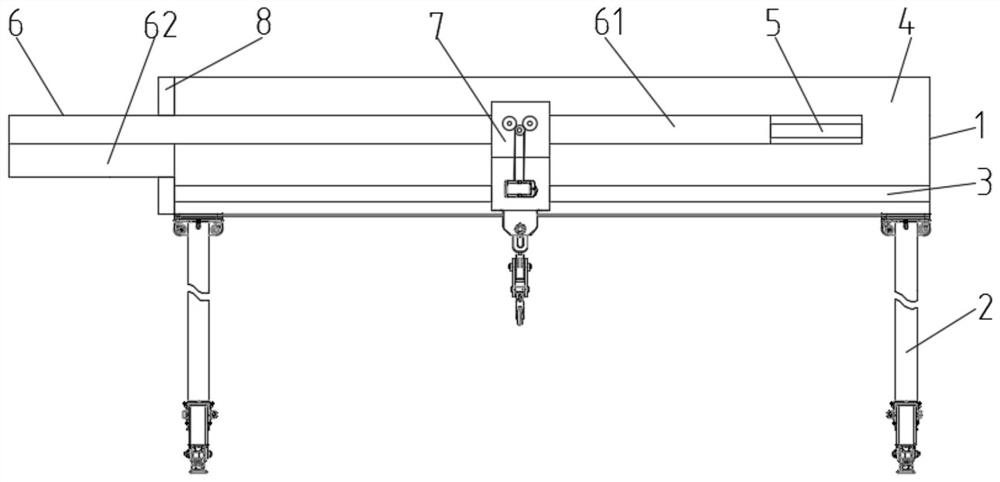

Double-hoist portal crane

PendingCN113816277AImprove delivery rangeLess prone to driftLoad-engaging girdersTrolley cranesClassical mechanicsEngineering

Owner:合肥市春华起重机械有限公司

Doze prevention seat for senior high school students

PendingCN114287761AImprove stabilityAvoid shaking from side to sideStoolsAdjustable chairsPhysical medicine and rehabilitationEngineering

The invention discloses a high school biologic anti-sleepiness seat which comprises an inner supporting frame, the bottom of the inner supporting frame is fixedly connected with a fixed base, the tops of the outer walls of the two sides of the inner supporting frame are fixedly connected with vertical bearing arms, and the tops of the vertical bearing arms are slidably connected with a mounting device. Lifting handles are slidably connected to the two sides of the top of the mounting device, and a seat backrest is fixedly connected to the top of the back face of the mounting device. According to the anti-sleepiness seat for the senior high school students, the situation that a user shakes left and right when sitting down due to looseness of the inner supporting frame is effectively avoided, then the service life of the inner supporting frame is prolonged, the locking frame can abut against components in contact with the inner supporting frame, and therefore the stopping position of the lifting height of the mounting plate is fixed, and the anti-sleepiness seat for the senior high school students is convenient to use. The problem that the mounting plate descends due to the pressure of a user is effectively avoided, and the convenience of adjusting the mounting plate to a proper sitting posture by the user is improved.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Refrigerator with double-layer door structure

ActiveCN110873507AReduce controlSimplify control proceduresLighting and heating apparatusLighting arrangementIceboxEngineering

Owner:CHONGQING HAIER REFRIGERATION ELECTRIC APPLIANCE CO LTD +2

A multifunctional frame for the installation of facing stone on walls

Owner:山东隆元建工集团有限公司

Object sorting system and method

The invention discloses an object sorting system and method and relates to the field of tobacco processing. The structure of the object sorting system is optimized. The object sorting system comprisesa first conveying device, second conveying devices and sorting devices. The first conveying device comprises two or more first conveying belts which are arranged in parallel. The adjacent first conveying belts are parallel to one another, and at least two of the first conveying belts are spaced. An angle is formed between the conveying direction of each second conveying device and the conveying direction of the first conveying device. The sorting devices are arranged in the gaps in a lifting mode, and the conveying direction of the sorting devices is consistent with the conveying direction ofthe second conveying devices. Specifically, each sorting device is configured as a surface to support objects. According to the object sorting system, the sorting device are in surface contact with cigarette boxes, and the conveying direction of the sorting devices is consistent with the conveying direction of the second conveying devices, so that the cigarette boxes are able to be effectively sorted.

Owner:LONGYAN CIGARETTE FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com