CVD equipment

A device and fixture technology, applied in the field of chemical vapor deposition equipment, can solve the problems of easy installation deviation and long installation time of grounding belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

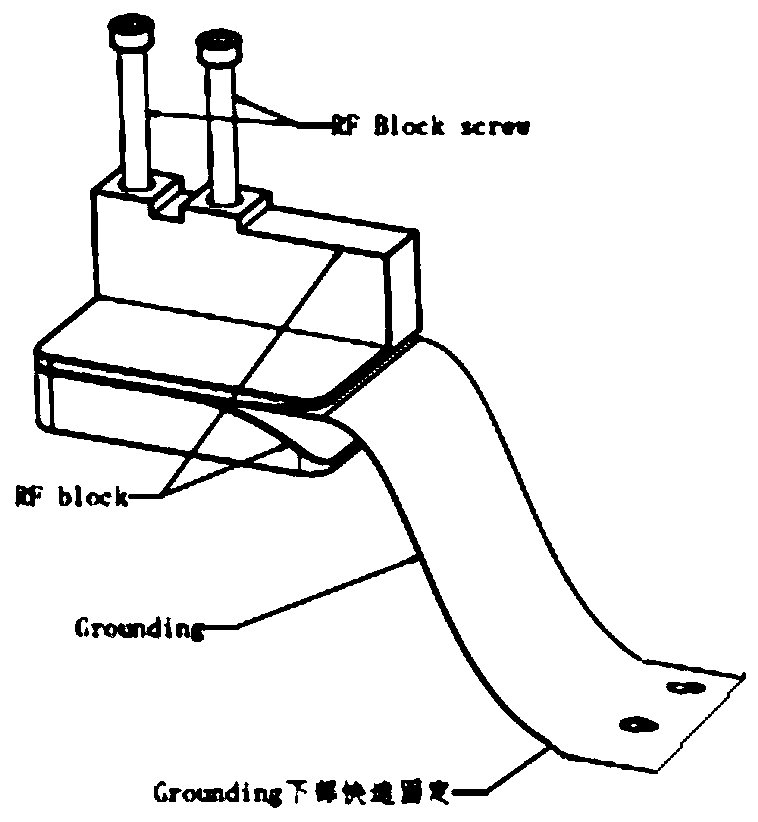

[0033] The inventors have found that the existing grounding straps are designed and installed as figure 1 As shown, the fixing pin (RF Block screw) passes through the base, and then passes through the RF Block with the grounding strap in the middle to fix one end of the grounding strap on the base, and the other end of the grounding strap passes through the grounding strap through screws, etc. The through hole at the other end is fixed at the bottom of the chamber of the deposition equipment; the installation time of the grounding belt is long, and it is prone to deviation during installation. The service life of the grounding belt is shortened, and the utilization rate of the equipment is reduced.

[0034] An embodiment of the present invention provides a CVD device, including a base, a ground belt, and a fixing device.

[0035] The grounding strap is connected between the base and the grounding terminal at the bottom of the device to eliminate static electricity. At least o...

Embodiment 2

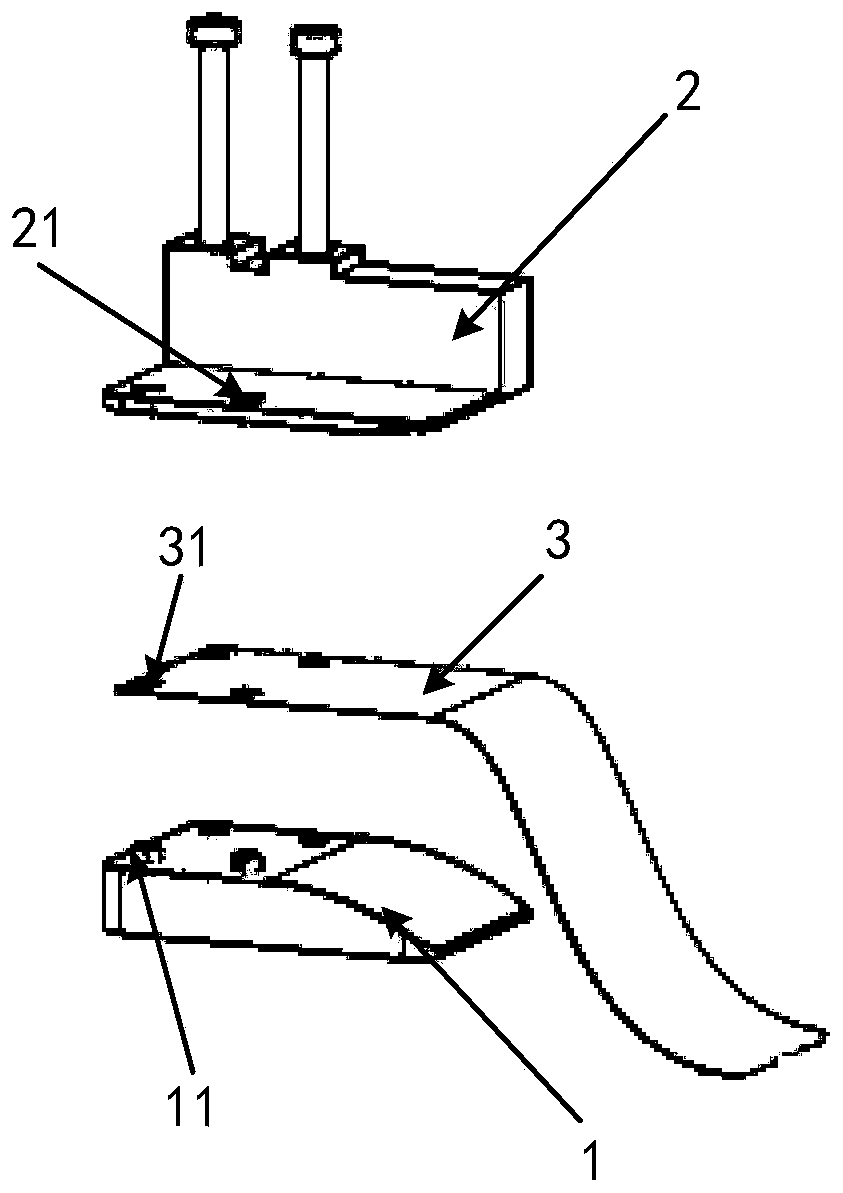

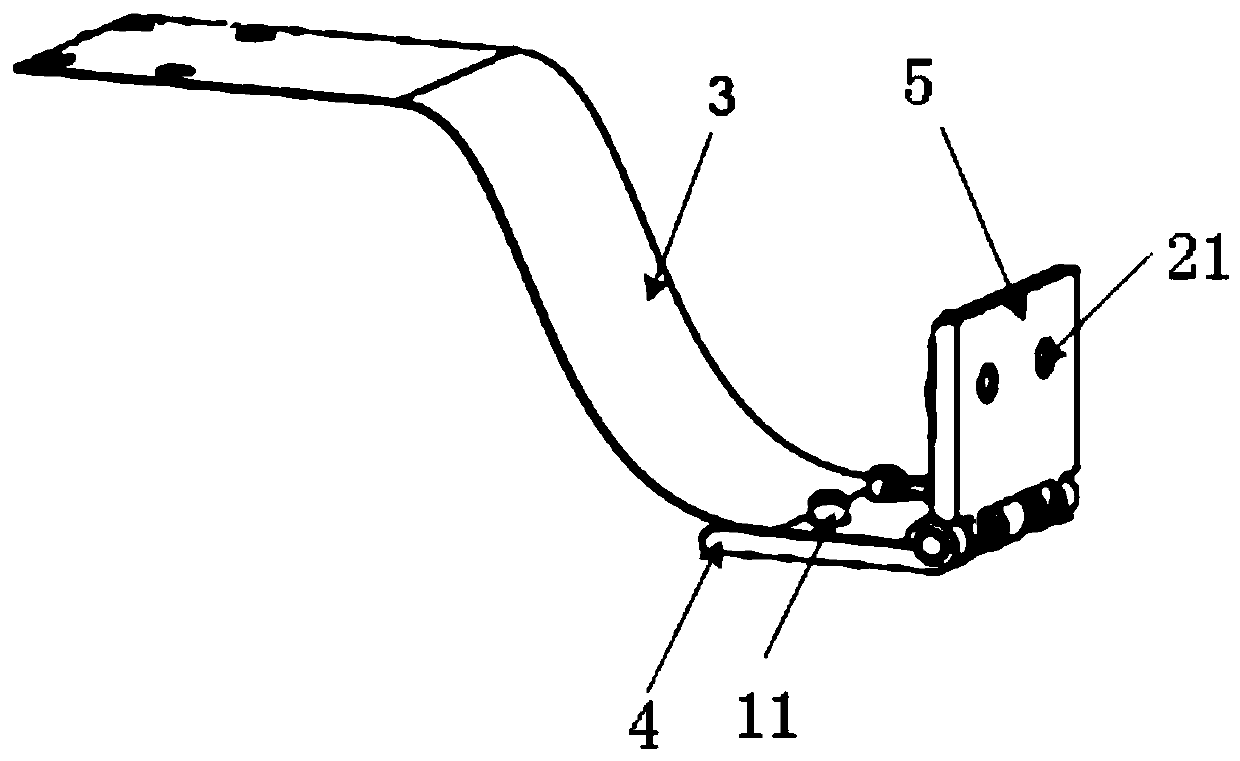

[0053] The embodiment of the present invention provides a preferred implementation of the fixing device in the CVD equipment provided in the above embodiments, wherein the first clamp 1 and the second clamp 2 are hinged through a hinge shaft, so that the fixing device has the The clamping position where the first clamp 1 and the second clamp 2 are attached, and the open position where the first clamp 1 and the second clamp 2 are opened, when the fixing device is in the clamping position, The positioning column 11 passes through the positioning hole 21 to fix the end of the grounding strap 3 . The first clamp 1 and the second clamp 2 are hingedly connected to form a hinge structure, such as image 3 and Figure 4 , including a first hinge 4 and a second hinge 5, wherein the first hinge 4 serves as the first clamp 1, and the second hinge 5 serves as the second clamp 2.

[0054] There are at least two positioning columns 11 on the first hinge 4; the second hinge 5 is hinged wit...

Embodiment 3

[0069] This embodiment also provides a CVD equipment, such as Figure 4 As shown, it includes: the fixing device in the above-mentioned embodiment 1 fixed on the base of the CVD equipment, and the fixing device in the above-mentioned embodiment 2 fixed on the bottom ground end of the CVD equipment. The fixing device can effectively control the direction of the grounding belt when it is installed, and it is not easy to produce deviation during installation, which avoids the uneven force on both sides of the grounding belt caused by the installation offset of the grounding belt, thus causing the problem of breaking the grounding belt; It can ensure the linearity of the installation direction of the grounding belt, prevent the grounding belt from breaking during use, and prolong the service life of the grounding belt.

[0070] Of course, as an alternative embodiment, both ends of the grounding strap can use the fixing device in embodiment 1 or the fixing device in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com