Object sorting system and method

A sorting system and object technology, applied in the field of tobacco processing, can solve problems such as easy skewing of cigarette boxes, hidden dangers of rear conveying equipment, high failure rate of cigarette boxes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

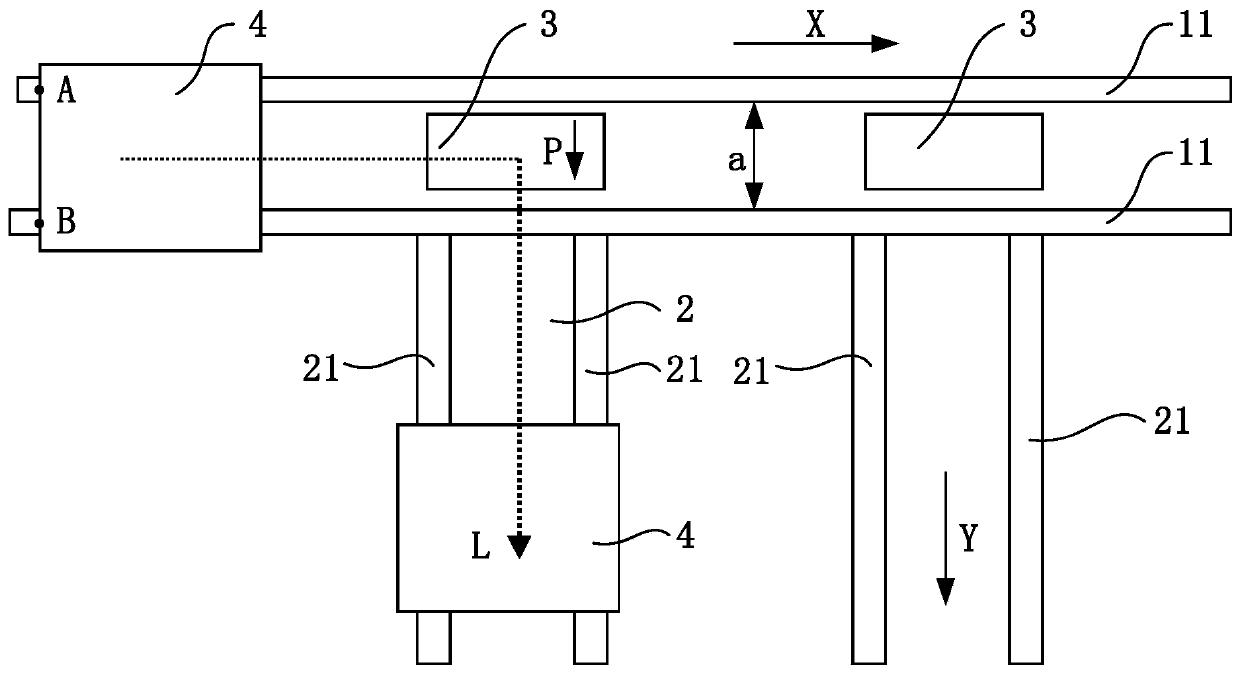

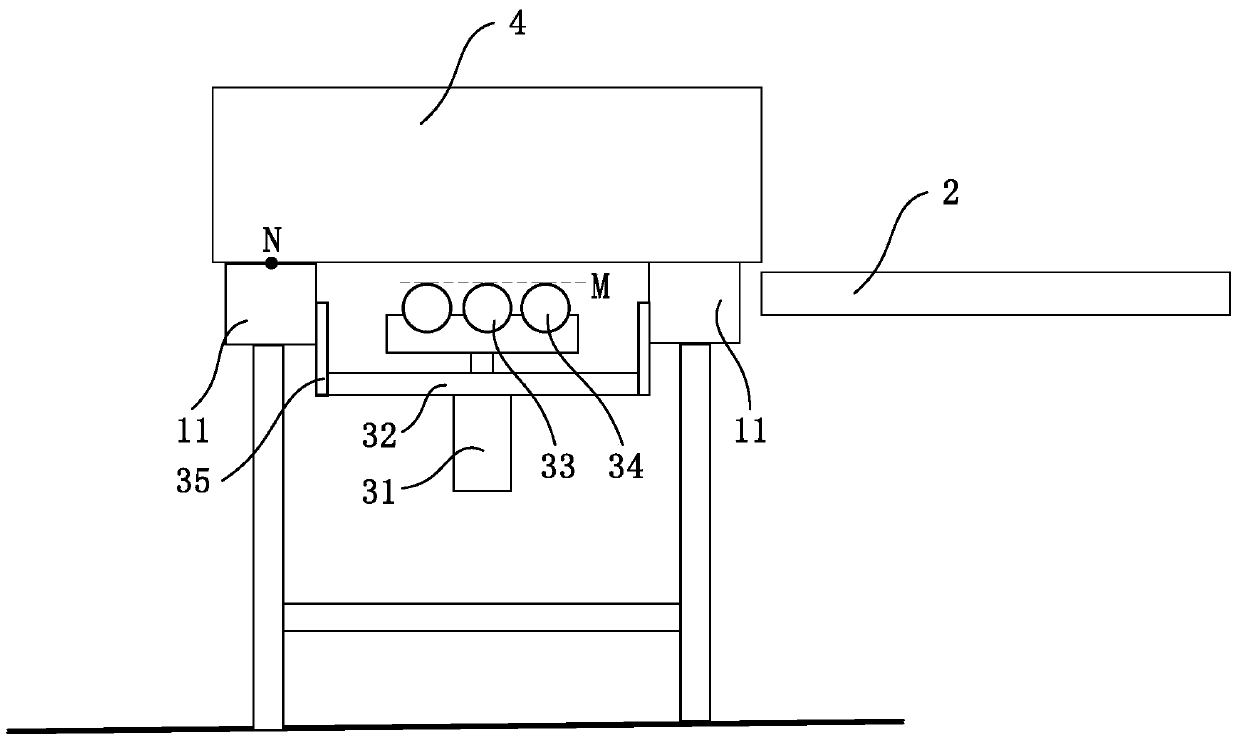

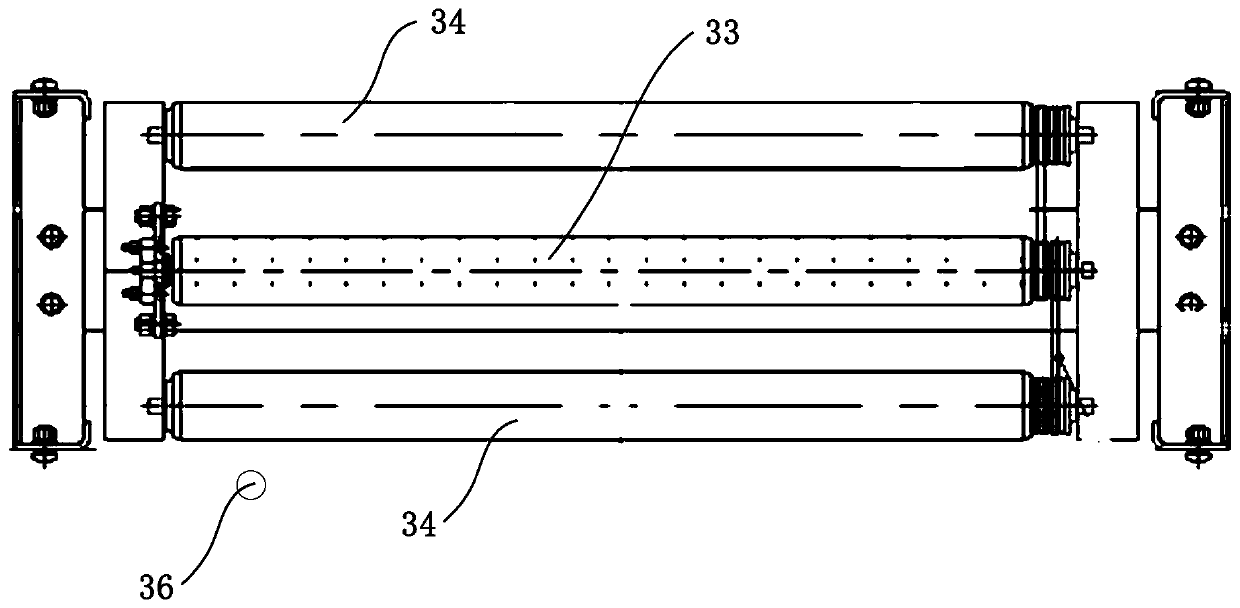

[0046] Combine below Figure 1 to Figure 5 The technical solution provided by the present invention is described in more detail.

[0047] see Figure 1 to Figure 4 , the present invention provides an object sorting system, including a first conveying device 1 , a second conveying device 2 and a sorting device 3 . The first conveying device 1 includes two or more first conveying belts 11 arranged side by side. Adjacent first conveyor belts 11 are arranged in parallel, and there is a gap a between at least two first conveyor belts 11 . The conveying direction Y of the second conveying device 2 is at an angle to the conveying direction X of the first conveying device 1 . The sorting device 3 is arranged in the gap a in a liftable manner. The conveying direction P of the sorting device 3 is consistent with the conveying direction Y of the second conveying device 2 . Among them, the sorting device 3 is configured as a surface support object 4 .

[0048] The object 4 is, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com