Circuit board processing method

A processing method and circuit board technology, which is applied to printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of cutting powder not being removed in time, cutting powder residue, substrate hole blockage, etc., and achieve better drilling effect Good, easy to operate, prevent the effect of inner hole clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

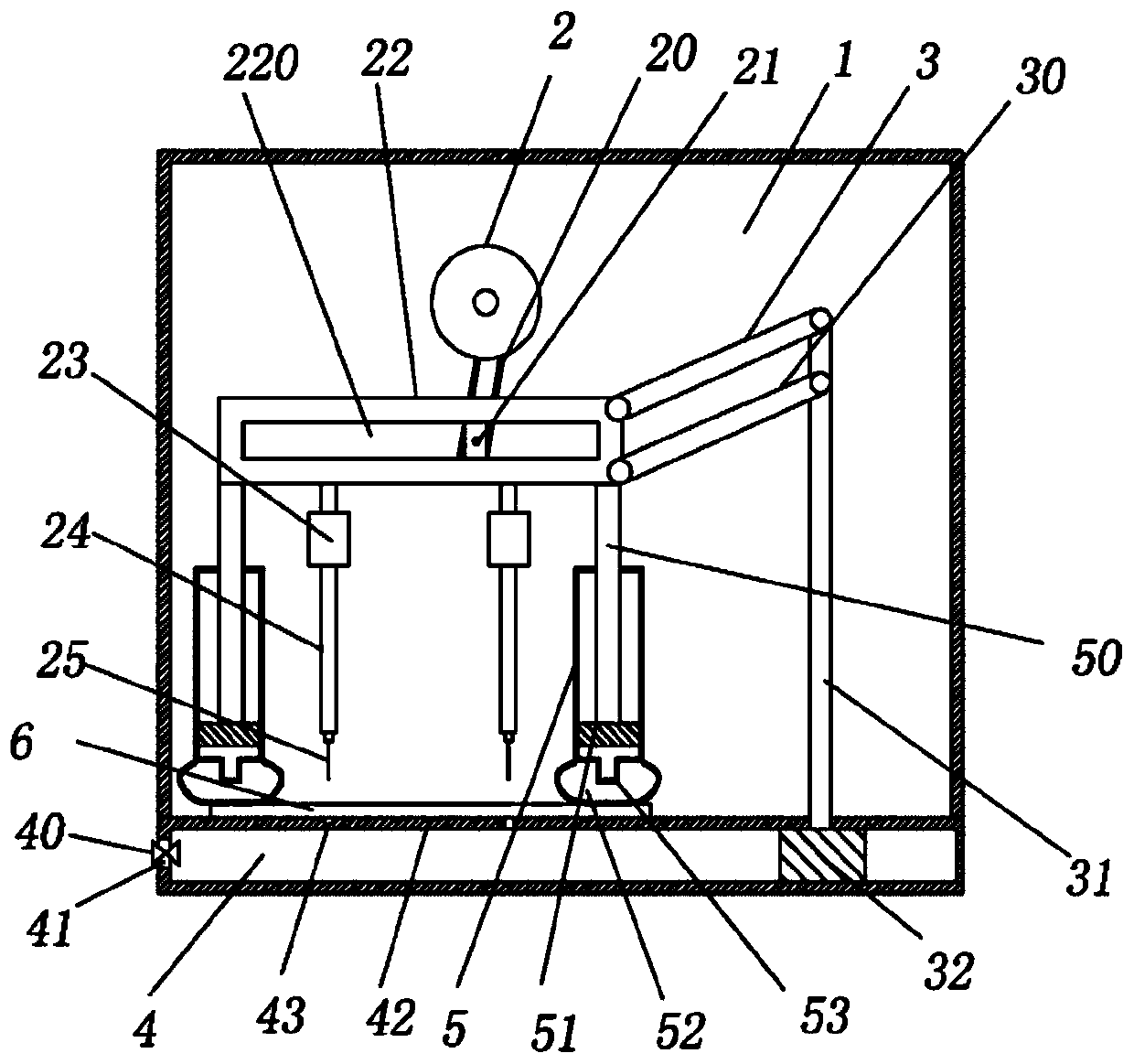

[0024] The reference signs in the accompanying drawings of the description include: frame 1, runner 2, extension rod 20, slider 21, moving frame 22, chute 220, support block 23, slide rod 24, drill bit 25, main swing rod 3, Auxiliary swing rod 30, straight rod 31, dust removal piston 32, dust removal chamber 4, air intake check valve 40, air inlet 41, support platform 42, punching hole 43, cylinder body 5, push-pull rod 50, air blowing piston 51, The airbag 52 , the gas injection port 53 , and the substrate 6 .

[0025] The embodiment is basically as attached figure 1 Shown: the circuit board processing method, comprises the following steps:

[0026] A. Cutting: Cut the large copper plate into several small copper plates;

[0027] B. Inner layer film: stick a dry film on the copper plate and expose it with ultraviolet rays;

[0028] C. Internal etching: put the exposed copper plate into the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com