Shockproof rotor

A rotor and rotor body technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of shortened rotation life, easy to grow, easy to loosen, etc., to reduce inertial momentum, use The effect of long life and not easy to drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

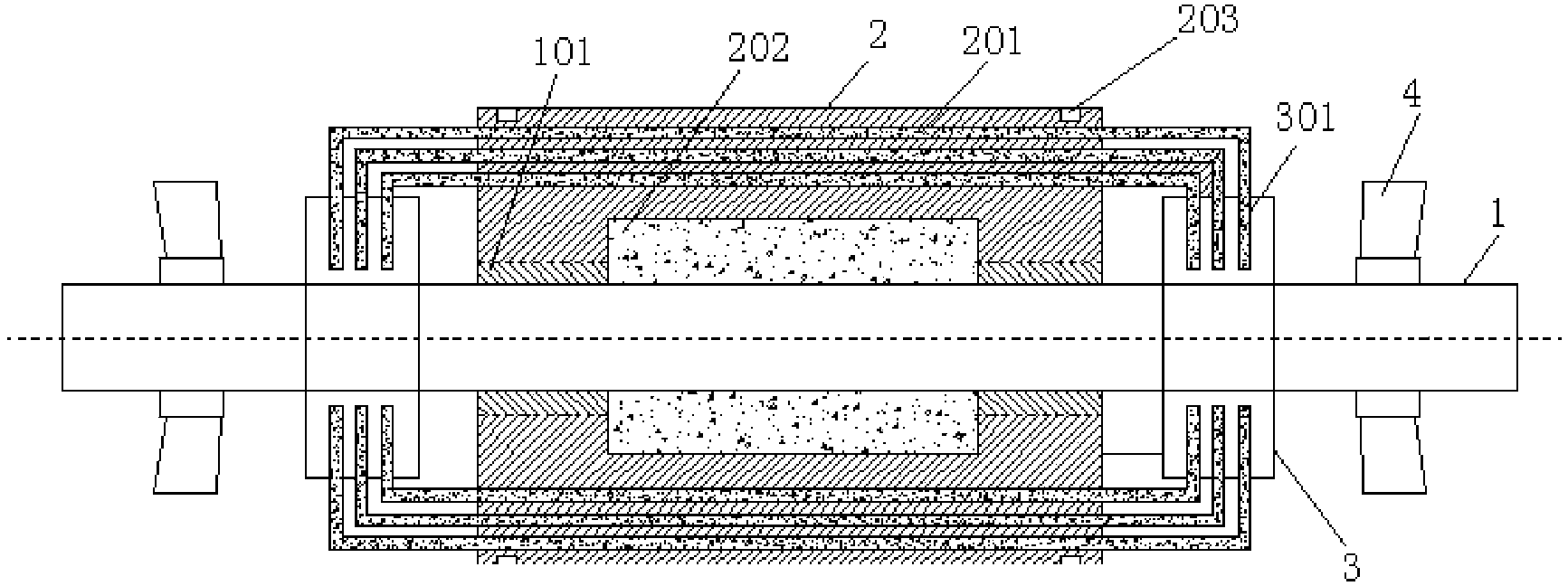

[0012] Referring to the accompanying drawings, an anti-vibration rotor includes a rotating shaft 1, a rotor body 2 and a permanent magnet 3. The rotating shaft 1 is fixedly connected to the rotor body 2. The rotor body 2 is provided with a plurality of permanent magnet placement slots 201. The positions on both sides of the rotor body 2 are The rotating shaft is provided with a fixed disk 3, and the fixed disk is provided with a plurality of permanent magnet fixing slots 301. The permanent magnet 3 is elongated, with two fixed parts extending outward, and the elongated part is embedded in the rotor body and placed In the slot, the fixed part is arranged in the slot of the fixed disc, so that the structural shape is equivalent to firmly fixing the permanent magnet and the rotor body together, and positioning the permanent magnet horizontally and vertically. The middle of the rotor body 2 is hollow , the hollow part is filled with foam 202, and the rotor body and the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com