Shelling and collecting device for coconut pulp spheres in germinated coconuts

A collection device and shell breaking technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of different extraction and processing, and the inability to achieve effective extraction of coconut treasure, so as to achieve the effect of improving the knocking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

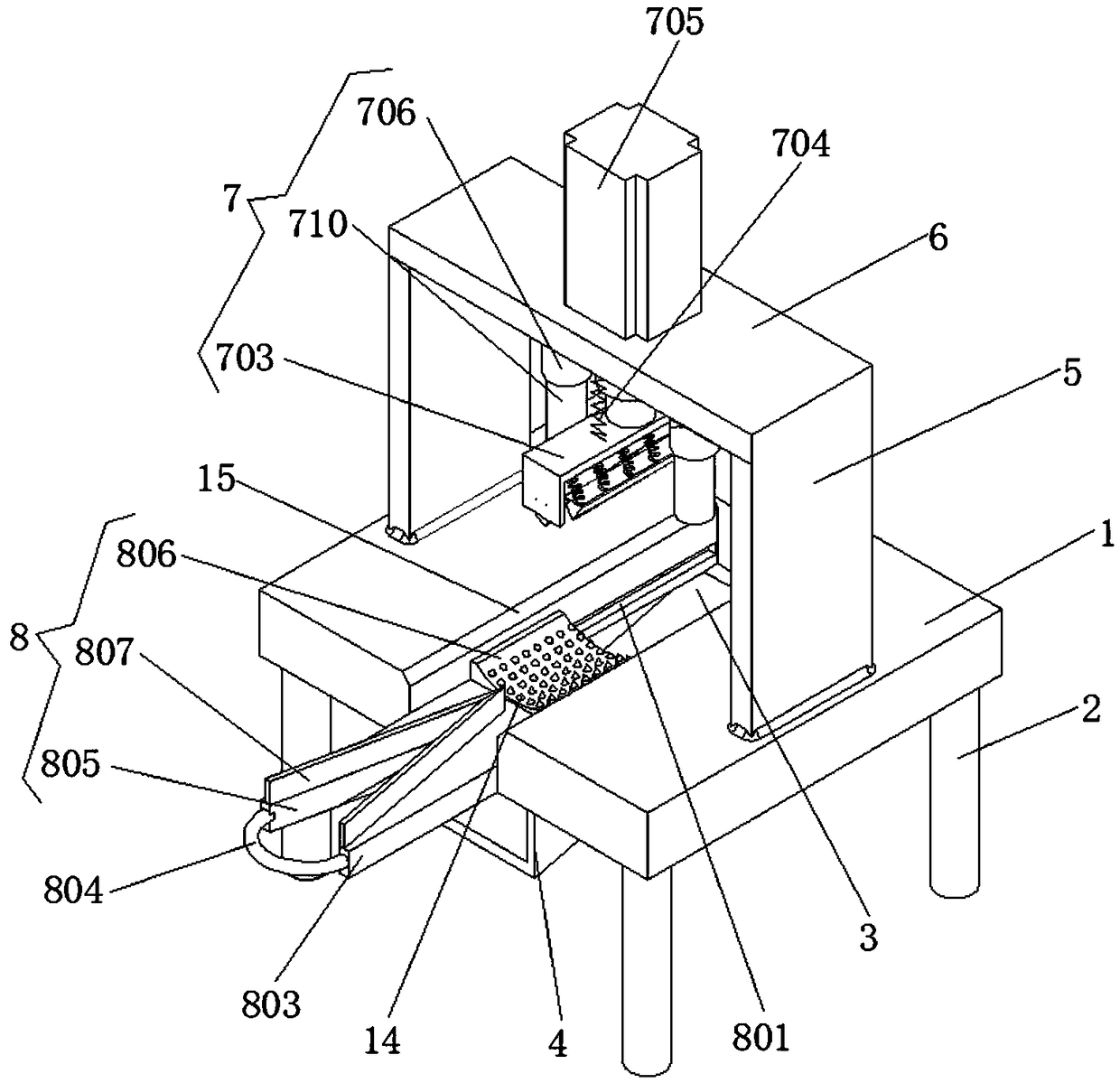

[0031] see Figure 1-5 , a technical solution: a broken shell collection device for germinated coconuts, including a workbench 1, the four corners of the lower surface of the workbench 1 are welded with outriggers 2, and the four outriggers 2 are welded by reinforcing rods , the middle part of the workbench 1 is provided with a bar-shaped hole 3, the bar-shaped hole 3 is opened inwardly from the front of the workbench 1, the bar-shaped hole 3 has an opening on the front of the workbench 1, and the lower surface of the workbench 1 corresponds to the bar-shaped hole 3 The position is fixed and connected with a material guide plate 4, the end of the material guide plate 4 close to the front of the workbench 1 is inclined downward, and the end of the material guide 4 away from the front of the workbench 1 is welded to the rear side of the strip hole 3 on the lower surface of the workbench 1, The left and right sides of the material guide plate 4 are welded on the lower surface of ...

Embodiment 2

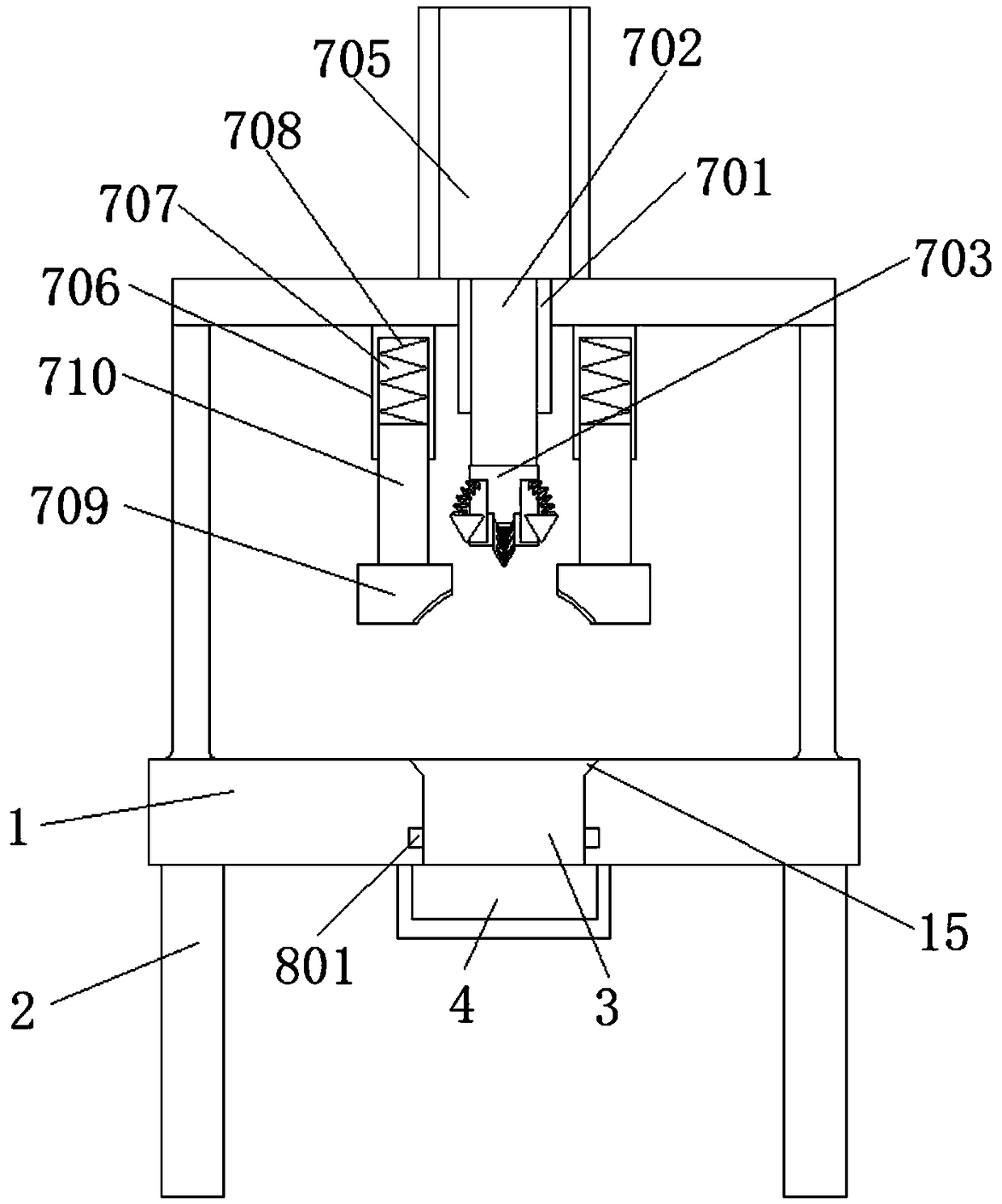

[0033] On the basis of Embodiment 1, the shell breaking mechanism 7 includes a guide tube 701, a movable rod 702, a shell breaking knife 703, a support spring 704, a telescopic motor 705, a positioning rod 706, a spring groove 707, a positioning spring 708 and a positioning plate 709, The top of the guide tube 701 is fixedly sleeved in the hole provided in the middle part of the top plate 6, and the inside of the guide tube 701 is plugged with a movable rod 702. In the middle, the front and rear ends of the upper surface of the shell breaking knife 703 are movably connected with the lower surface of the top plate 6 by a support spring 704, and the position of the upper surface of the top plate 6 corresponding to the guide tube 701 is fixedly installed with a telescopic motor 705 by bolts and a motor bracket. The top of 702 extends out of the guide tube 701 and is fixedly connected with the output shaft of the telescopic motor 705. The lower surface of the top plate 6 and the le...

Embodiment 3

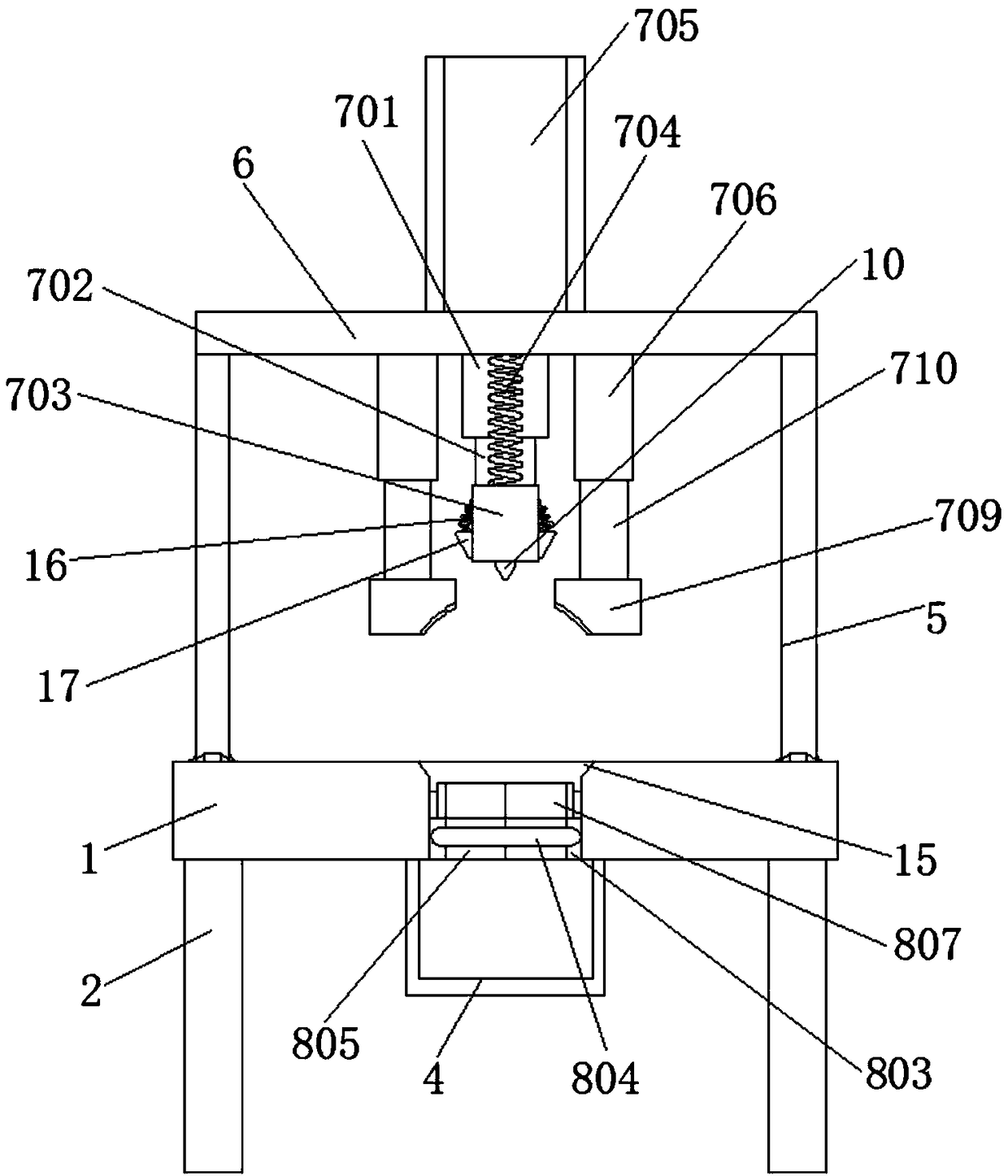

[0035]On the basis of Embodiment 2, the bottom end of the shell breaking knife 703 is in a concave arc shape, and the middle part of the lower surface of the shell breaking knife 703 is provided with a clamping groove 9, and a cutting knife 10 is clamped in the clamping groove 9 for cutting. The bottom section of knife 10 is in the shape of an isosceles trapezoid, and the width range of the bottom of cutting knife 10 is one to three millimeters, and the bottom end of the left and right sides of shell breaking knife 703 and the junction of shell breaking knife 703 lower surface are all provided with strip grooves 11. The upper wall of the bar-shaped groove 11 is movably connected to the knocking block 17 through the connecting spring 16, and the end of the knocking block 17 close to the snap-in groove is hinged between the front and rear side walls of the bar-shaped groove 11, and the knocking block 17 The setting can use the expansion and contraction of the telescopic motor 705...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com