Assembling and conduction detecting integrated device for ignition coil

A technology of conduction detection and ignition coil, applied in assembly machines, continuity testing, metal processing, etc., can solve the problems of missed inspection, time-consuming and labor-intensive, high labor cost, etc., to avoid missed inspection, good detection effect and low labor cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

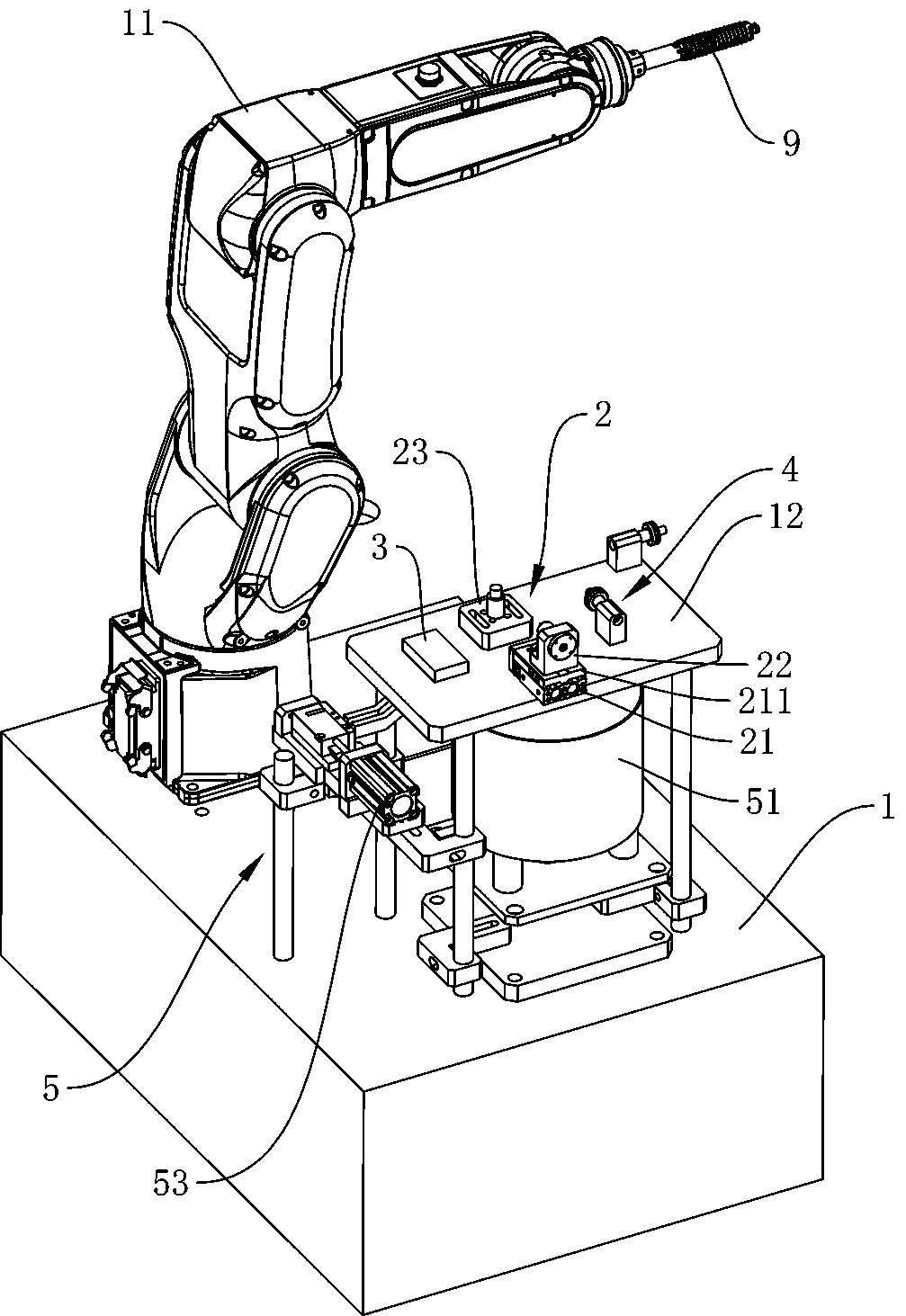

[0034] An integrated device for assembly and conduction detection of ignition coils, such as figure 1 As shown, a workbench 1 is included. A manipulator 11, a feeding mechanism 5 and a support 12 are arranged on the workbench 1. An assembly structure 2, a detection module 3 and a bending mechanism 4 are arranged on the support 12. During the processing, first pass The bending mechanism 4 can bend the winding wire wound outside the high-voltage wire package 9, and the feeding mechanism 5 will sequentially send out the high-pressure nozzle 91 that needs to be assembled on the front end of the high-voltage wire package 9 and pre-install it on the high-voltage wire package 9, and then carry out the process through the assembly structure 2. assembly, and conduct a continuity test at the same time.

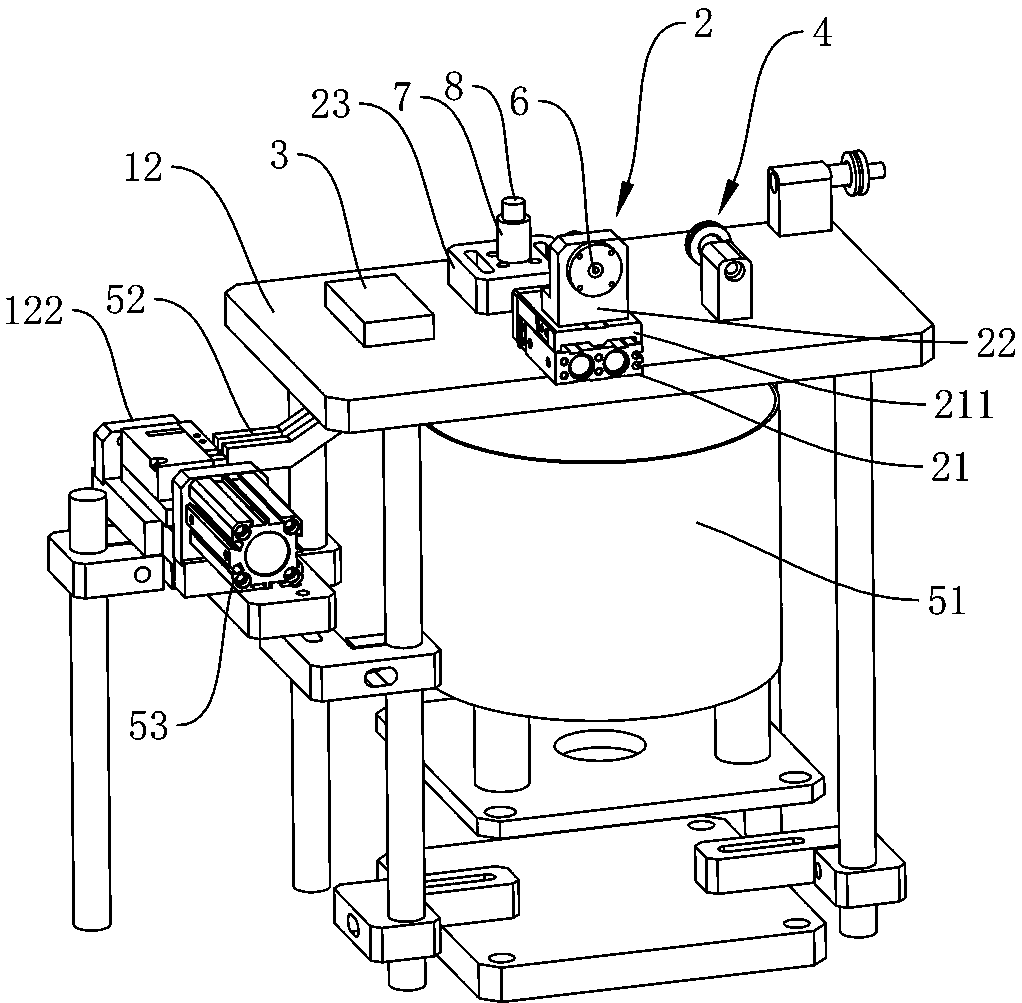

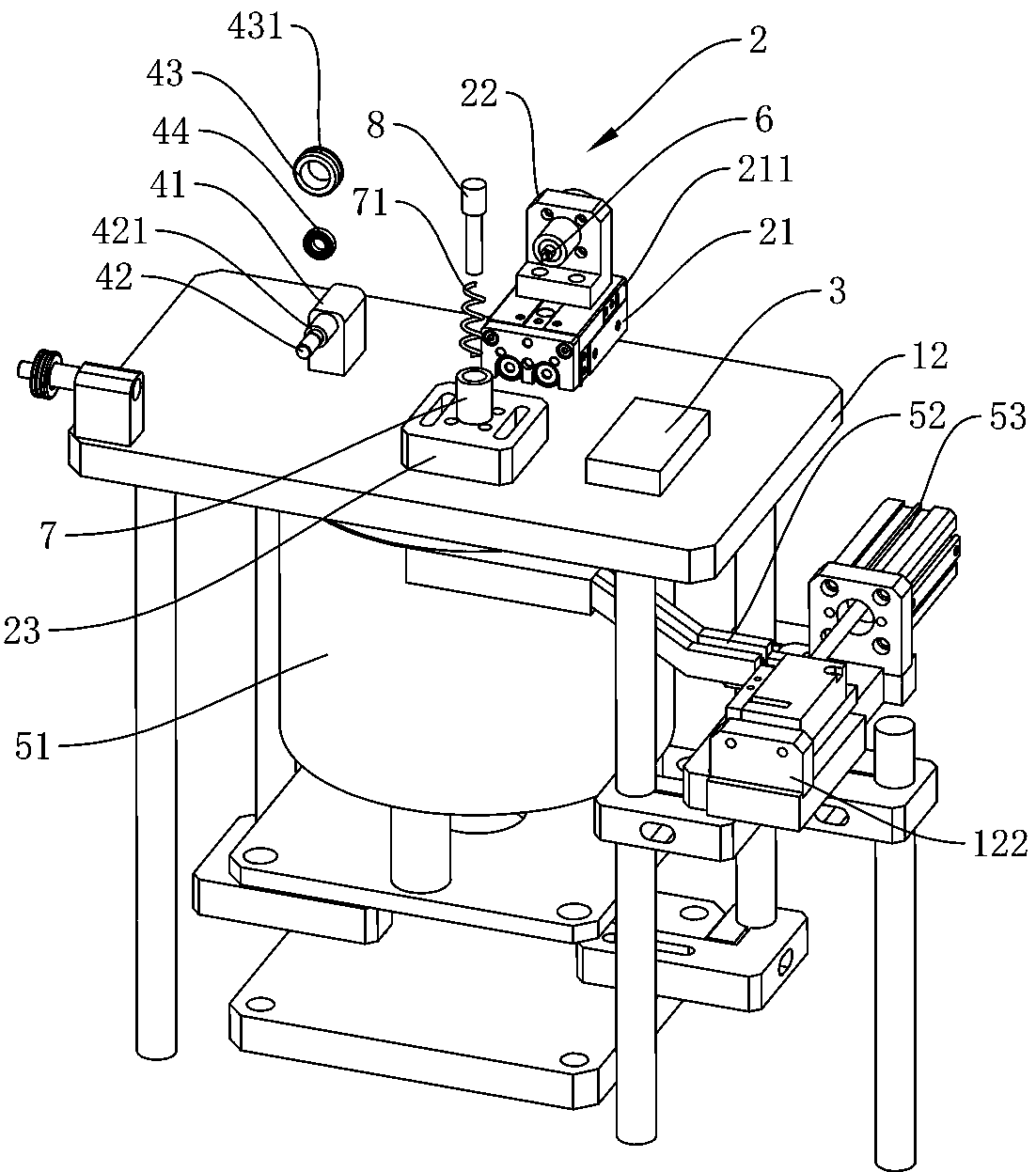

[0035] Such as figure 2 with image 3 As shown, the bending mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com