Open double crankshaft precision punching machine and its punching method

A precision punching and double crankshaft technology, applied in the direction of stamping machines, presses, forming tools, etc., can solve the problems of stamping die displacement, uneven pressing and warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

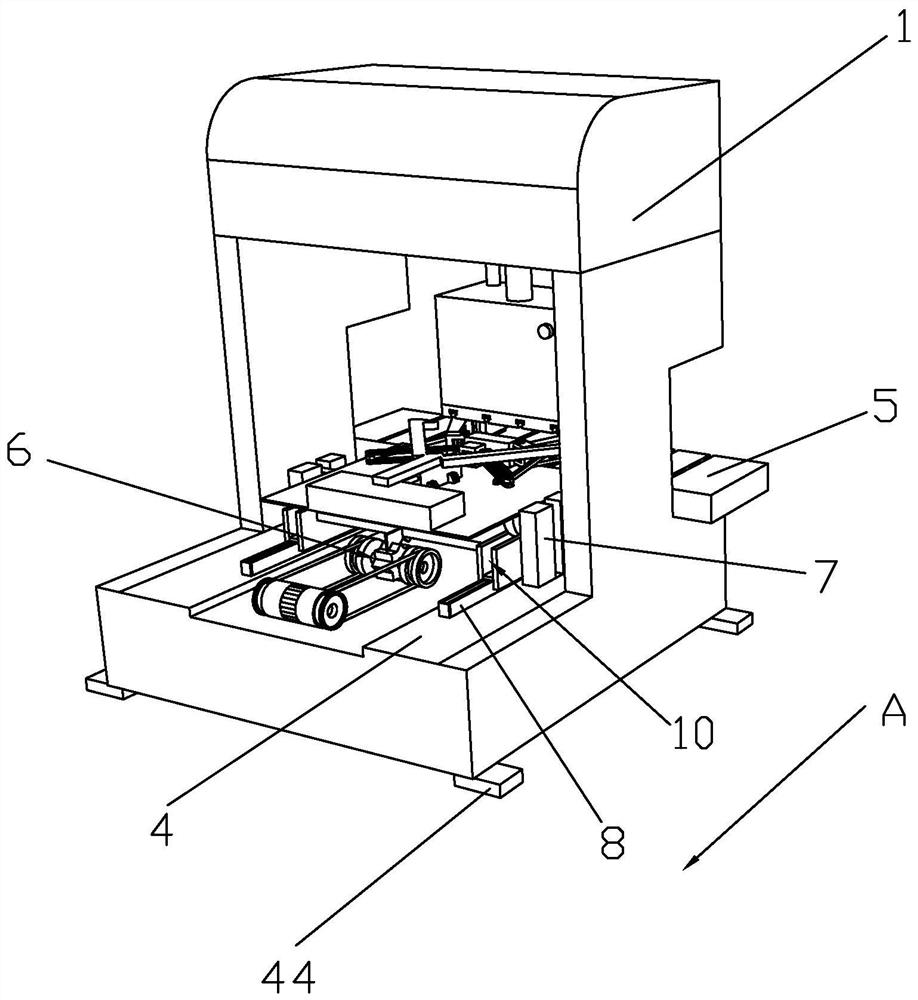

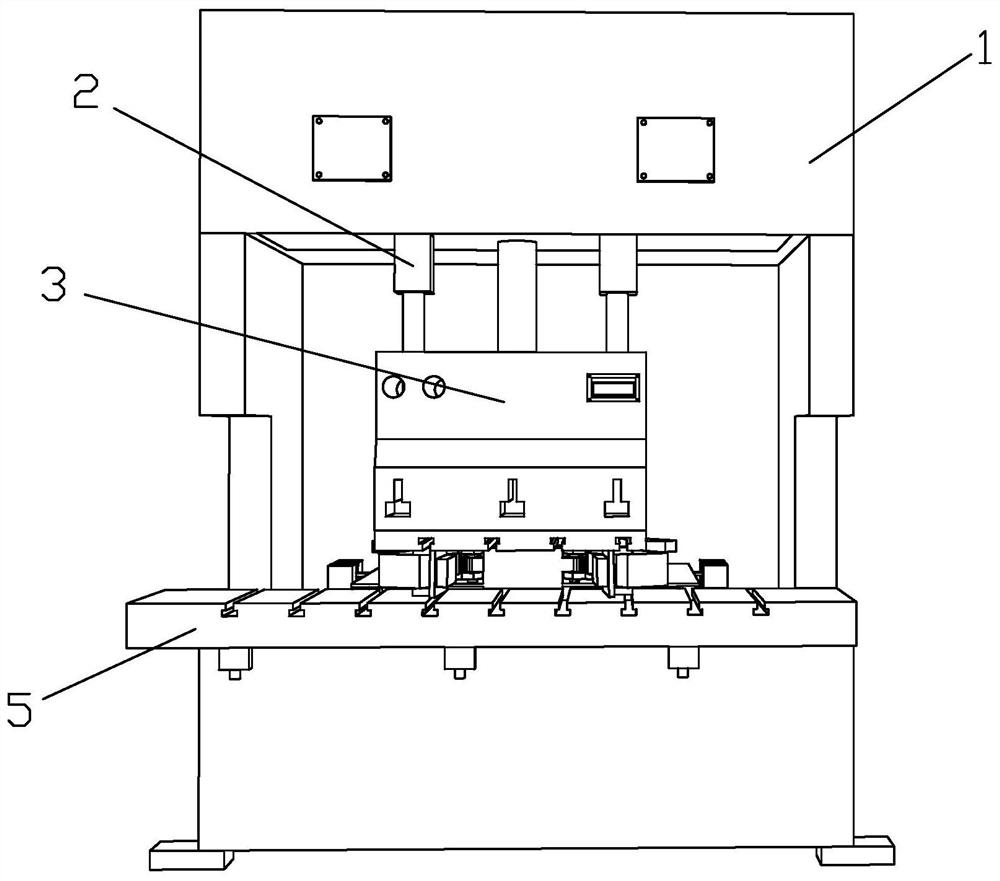

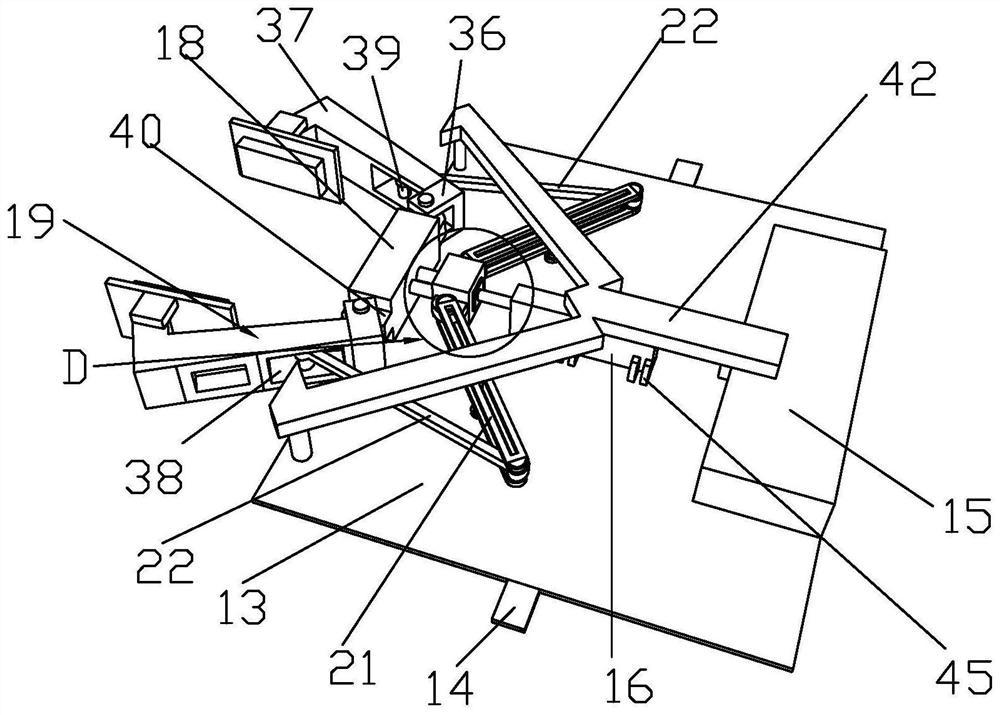

[0041] Such as Figure 1 to Figure 9 As shown, it is an open double-crank precision punching machine of the present invention, including a fuselage 1, a crankshaft 2, a slider device 3, a working platform 4 and a stamping platform 5, the fuselage 1 is connected to the crankshaft 2, and the slider device 3 is connected to the crankshaft 2 respectively. , the fuselage 1 is connected, a stamping platform 5 is provided under the slider device 3, a transmission device 6, a limit post 7 and a chute 8 are provided on the working platform 4, balls 9 are arranged inside the chute 8, and the balls 9 are evenly arranged , the chute 8 is provided with a sliding device 10, the transmission device 6 drives the sliding device 10 to move, the stamping is realized through the movement of the crankshaft 2 and the slider device 3, the stamping die is placed on the stamping platform 5, and the parts to be stamped are placed on the stamping On the mold, stamping is used to complete the shaping of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com