Full-automatic storage battery protective mesh mounting equipment

A technology for installing equipment and protective nets, which is applied in the field of automatic battery protective netting installation equipment, which can solve the problems of low installation efficiency, large labor force, and inability to accurately align the installation, and achieve the effect of wide application range and high cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

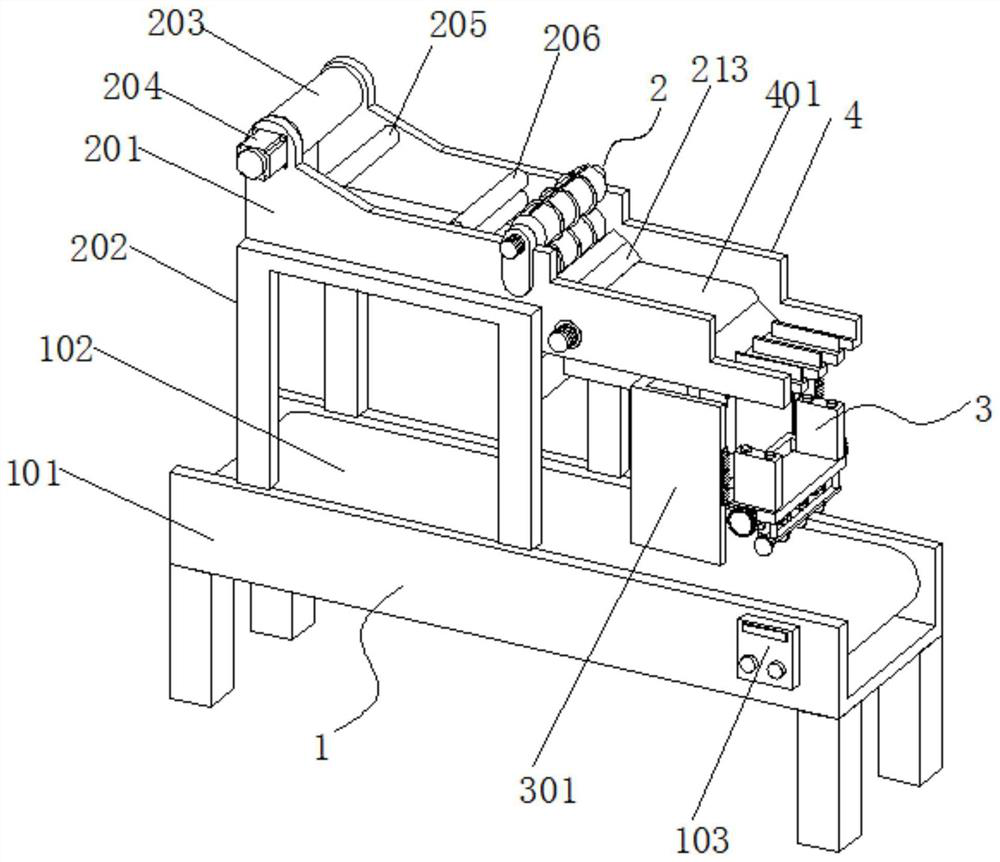

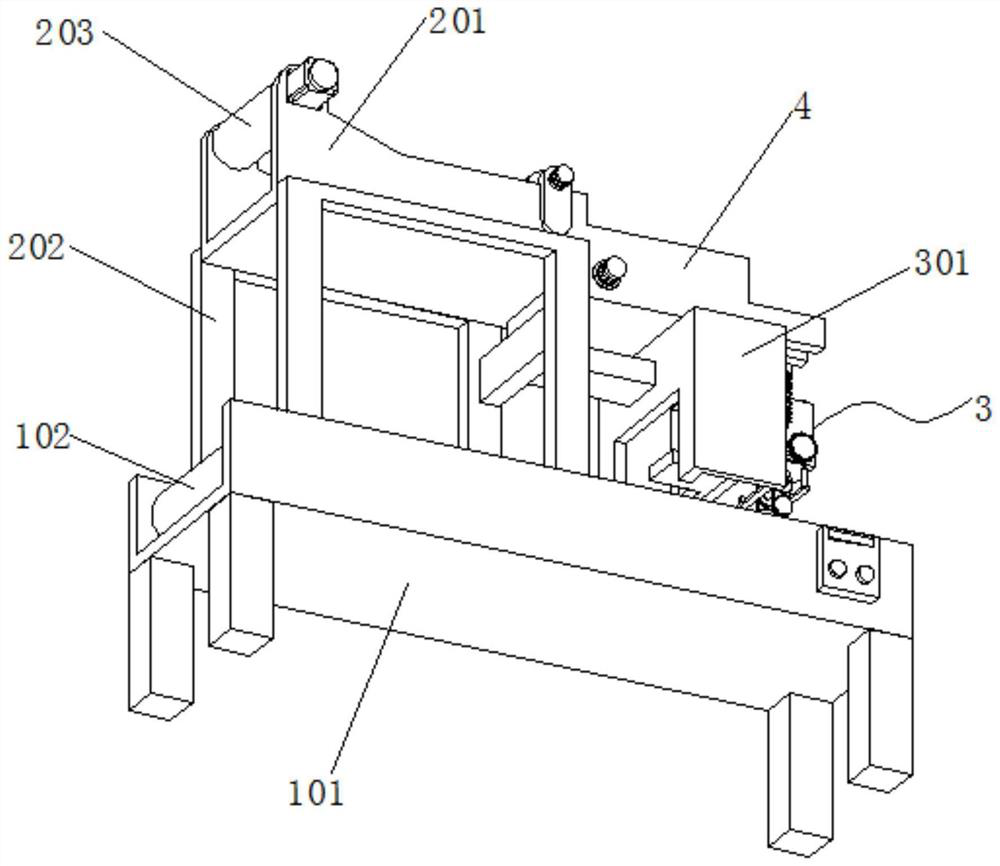

[0038] This embodiment 1 introduces a fully automatic battery protection mesh installation equipment, refer to the attached figure 1 And attached figure 2 , and its main structure includes a storage battery transmission mechanism 1, a protection mesh roll cutting mechanism 2 and a protection mesh installation mechanism 3. Let's describe them one by one.

[0039] Wherein, storage battery conveying mechanism 1 refers to attached figure 1 And attached figure 2 , which includes a bottom conveying frame 101, a first conveyor belt 102 is arranged in the bottom conveying frame 101, and a control panel 103 is arranged on the front of the bottom conveying frame 101. The batteries to be installed are transported by the first conveyor belt 102 .

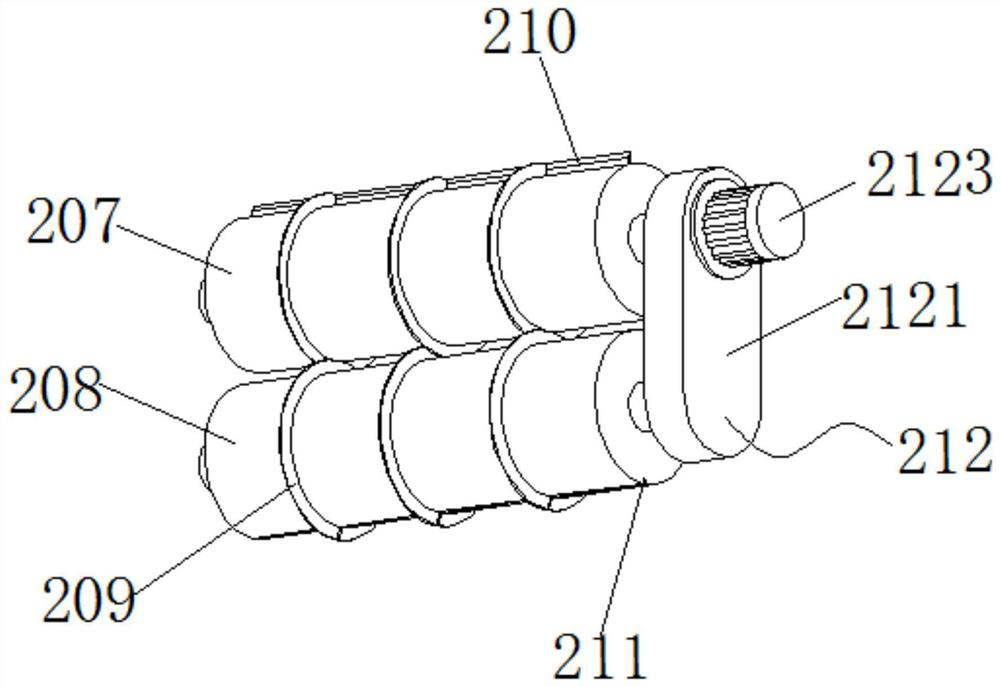

[0040] Among them, the protective net roll cutting mechanism 2 refers to the attached figure 1 , attached image 3 , attached Figure 4 And attached Figure 5 , which includes a slitting frame 201 arranged above the transmission frame...

Embodiment 2

[0047] This embodiment 2 introduces a fully automatic storage battery protection mesh installation device improved on the basis of the embodiment 1, which mainly focuses on the protection mesh bonding device 311 for specific description. Attached below Figure 8 And attached Figure 9 Describe in detail.

[0048] First of all, the similarities between this embodiment 2 and embodiment 1 will not be described again. The difference is that the protective mesh bonding device 311 in this embodiment 2 includes a number of rotating plates evenly arranged on the lower surface of the rotating plate 306. Seat 3111, the lower end of rotating seat 3111 is provided with bonding rubber wheel 3112, and the outer surface of bonding rubber wheel 3112 is coated with bonding glue, and the glue adhered on the surface of bonding rubber wheel 3112 by it can The slit protective mesh on the upper surface of the strip-shaped notch 402 is bonded and taken.

[0049] Further, in this embodiment 2, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com