Long roll slitting equipment for woven fabric production

A kind of equipment and long roll technology, which is applied in the field of long roll slitting equipment for weaving production, can solve the problems of no separate roll collection, uneven fabric, etc., and achieve the effect of improving work efficiency and facilitating collection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

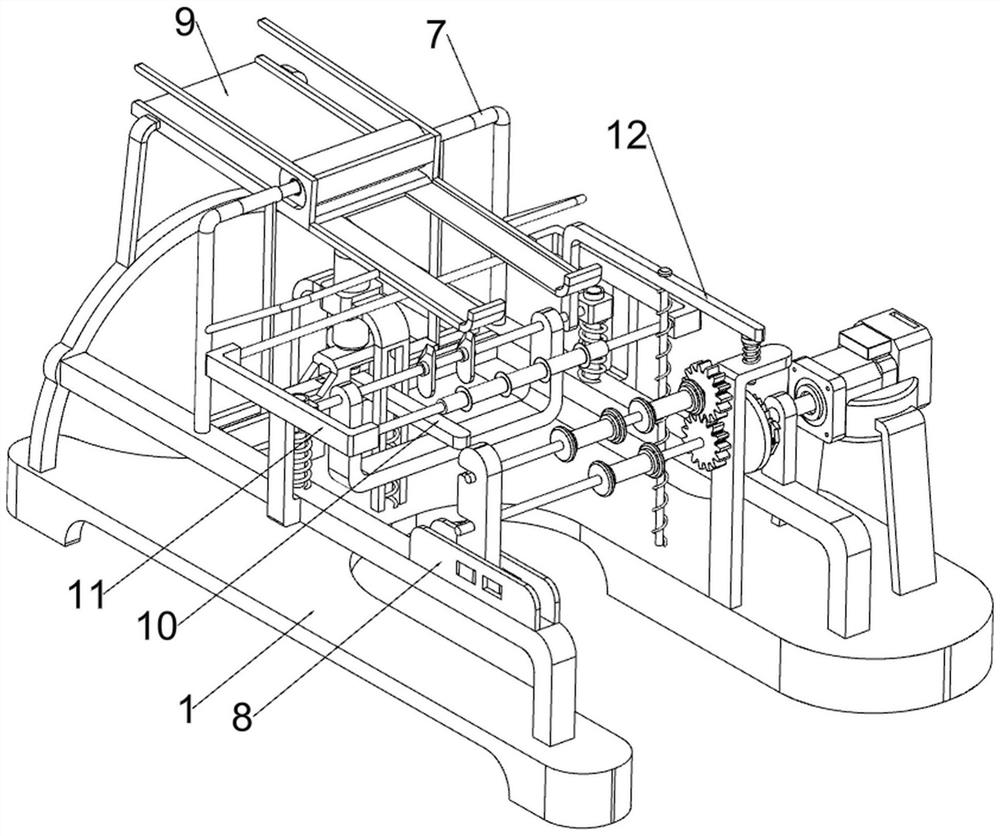

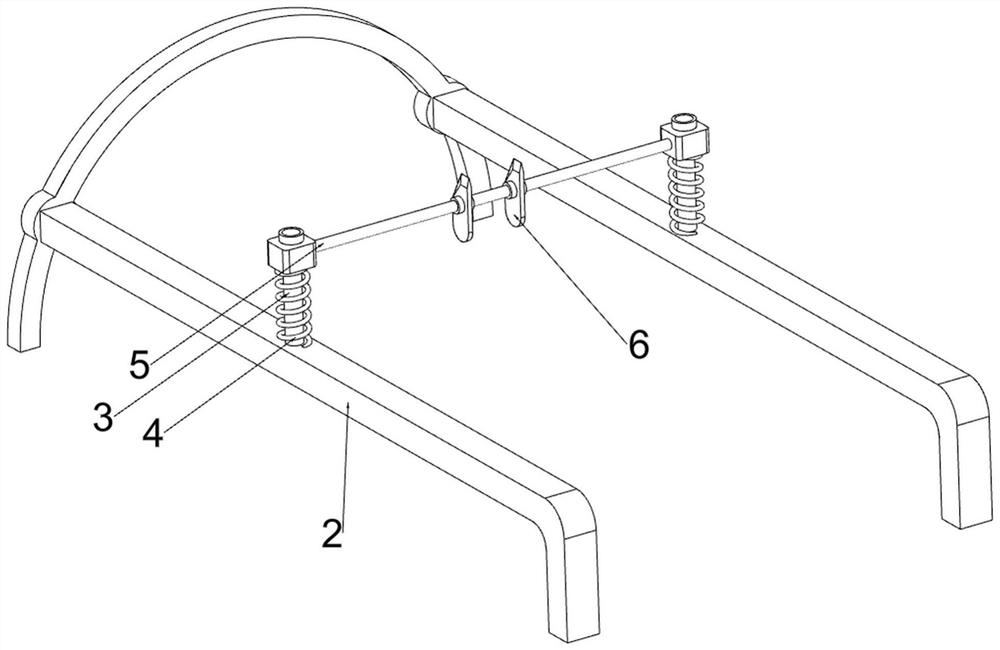

[0076] A long roll cutting equipment for weaving production, such as Figure 1-2 As shown, it includes a base 1, a first support frame 2, a first guide rod 3, a first spring 4, a connecting rod 5, a cutting blade 6, a clamping mechanism 7 and a rotating mechanism 8, and the top of the base 1 is provided with a first support Frame 2, first support frame 2 top front and rear symmetrical sliding type is provided with first guide rod 3, is all provided with first spring 4 between first guide rod 3 and first support frame 2, first guide rod 3 top A connecting rod 5 is arranged between them, and two cutting blades 6 are arranged on the connecting rod 5 , a locking mechanism 7 is arranged on the left side of the top of the base 1 , and a rotating mechanism 8 is arranged on the right side of the top of the base 1 .

[0077] The staff starts the clamping mechanism 7 to work, and places the long roll of fabric in the clamping mechanism 7. After the clamping mechanism 7 clamps the long r...

Embodiment 2

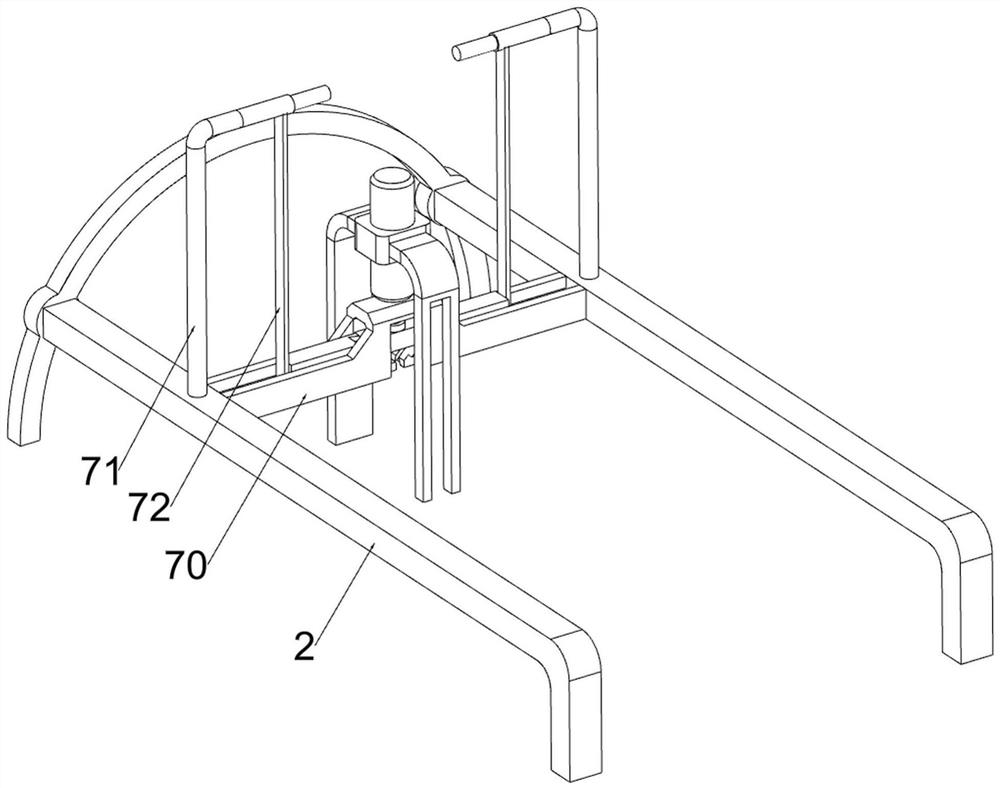

[0079] On the basis of Example 1, such as Figure 3-6 As shown, the clamping mechanism 7 includes a slide rail 70, a first support rod 71, a first connecting plate 72, a second spring 73, a third spring 74, a second support frame 75, a cylinder 76 and a mortise and tenon block 77. The inside of a support frame 2 is provided with slide rails 70, and the first support frame 2 is symmetrically provided with first support rods 71 on the front and rear sides of the top. A connection plate 72, a second spring 73 is provided between the slide rail 70 and the first connection plate 72 on the same side, a third spring 74 is provided between the first support rod 71 and the first connection plate 72, and the base 1 A second support frame 75 is provided on the left side of the top, and a cylinder 76 is provided inside the second support frame 75. Mortise and tenon blocks 77 are provided on the first connecting plate 72, and the tenon and tenon blocks 77 are slidingly connected with the...

Embodiment 3

[0083] On the basis of Example 2, such as Figure 7-10 As shown, it also includes a blanking mechanism 9, the blanking mechanism 9 includes a blanking basket 90, a fourth support plate 91, a material collecting plate 92 and a second support rod 93, and the left side of the top of the first support frame 2 is provided with two A fourth support plate 91, a blanking basket 90 is provided between the tops of the two fourth support plates 91, a second support bar 93 is provided on the first support bar 71, and a set is provided between the tops of the second support bar 93 Sheet 92.

[0084] Also comprise pressing mechanism 10, and pressing mechanism 10 comprises lower pressing plate 100, the second connecting plate 101 and the 4th spring 102, and the right side of cylinder 76 expansion rod bottoms is provided with lower pressing plate 100, and connecting rod 5 is provided with the second pressing plate 100. A fourth spring 102 is provided between the connecting plate 101 , the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com