Adjustable portal assembly for forklift

An adjustable, gantry technology, applied in the direction of lifting devices, etc., can solve the problem that the fork legs cannot be adjusted automatically, and achieve the effects of improving work stability, improving use efficiency and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

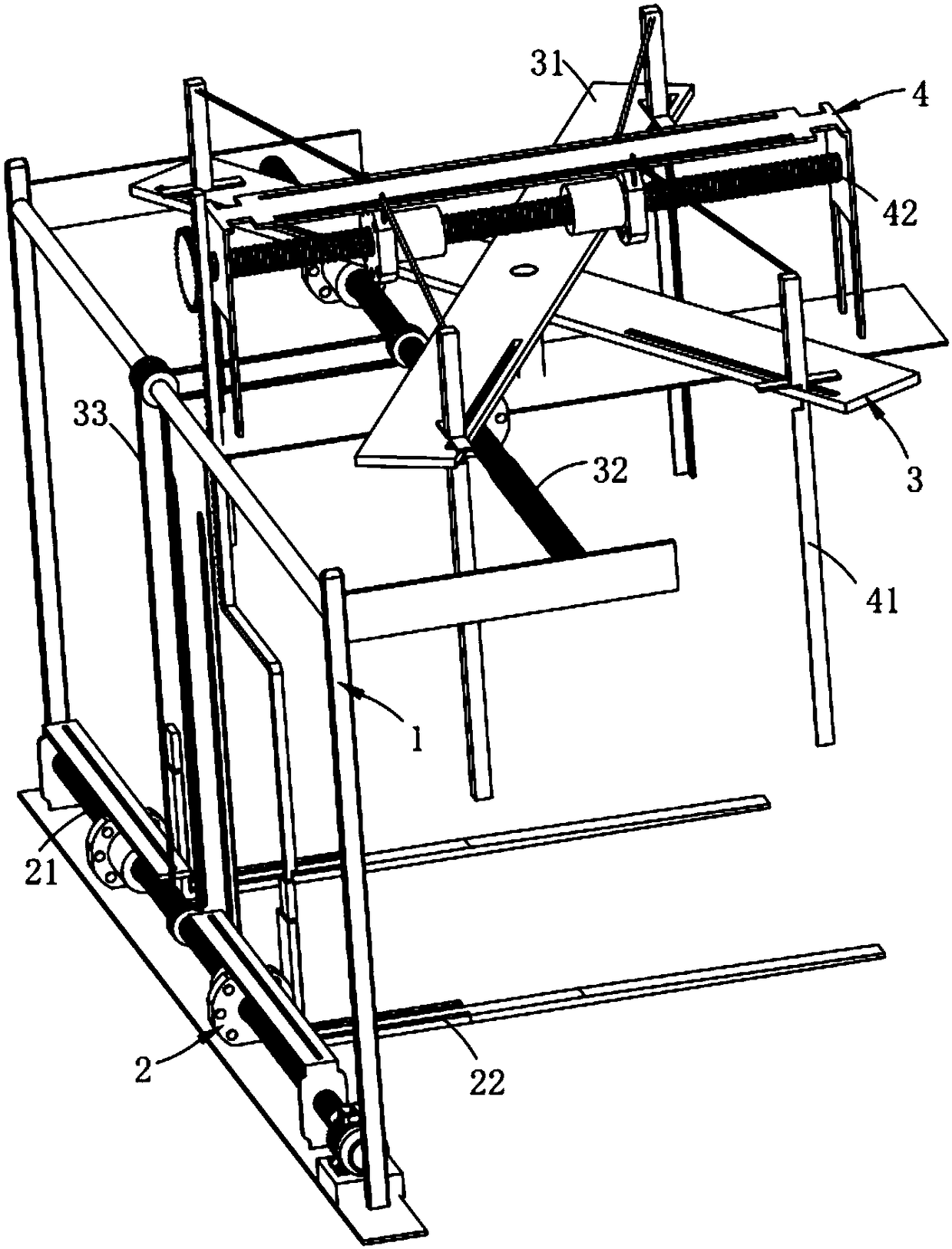

[0069] Such as figure 1 As shown, an adjustable mast assembly for a forklift, including a frame 1, also includes:

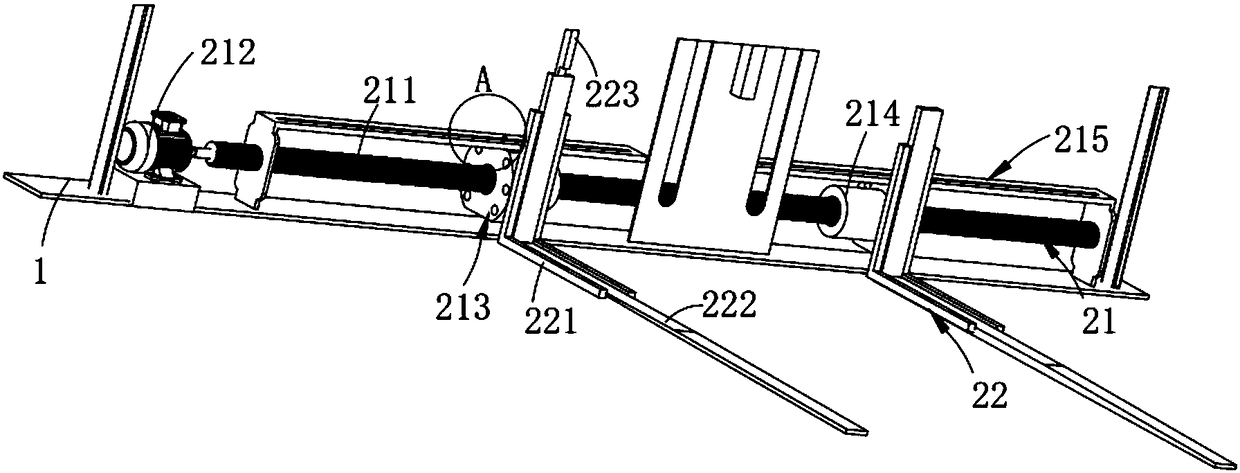

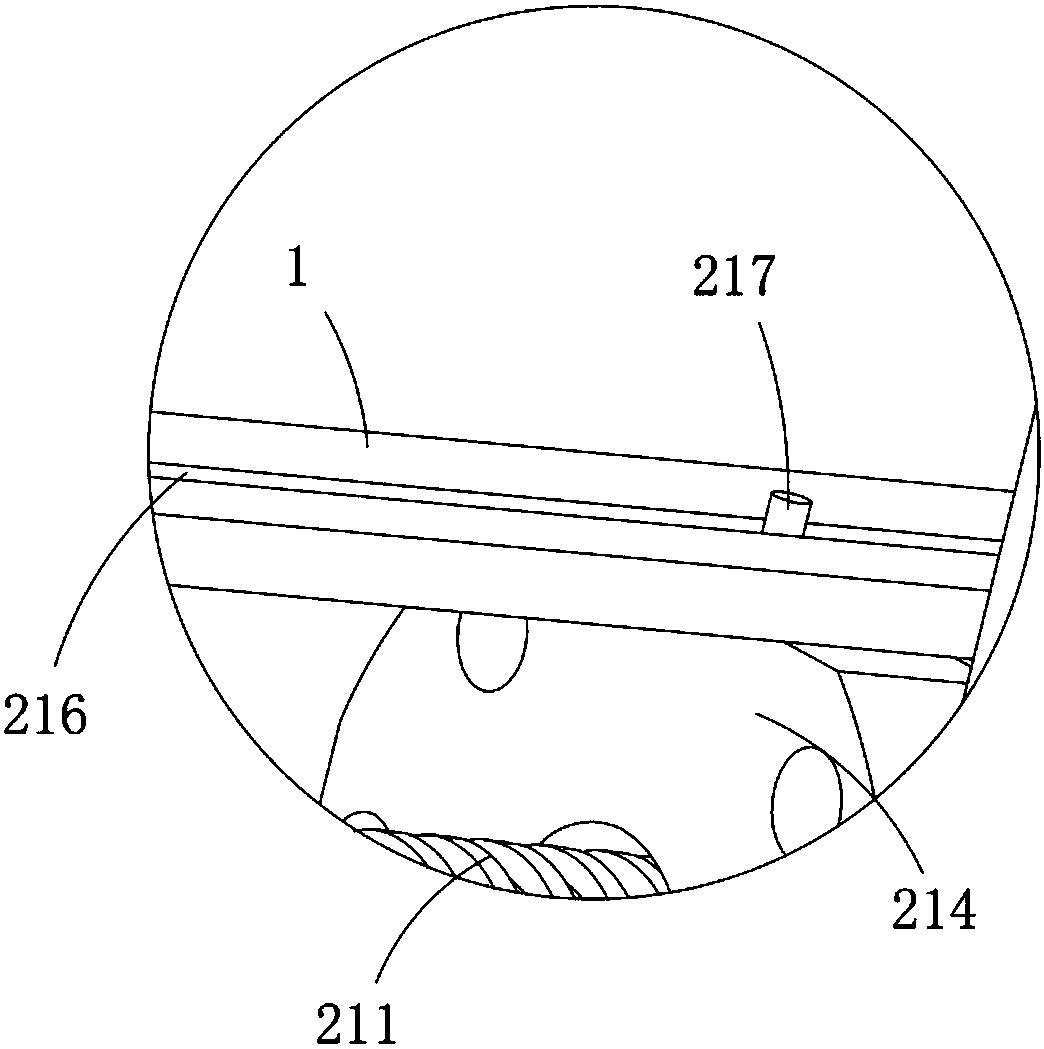

[0070] An adjustment mechanism 2, the adjustment frame 1 is installed on the frame 1, which includes a control assembly a21 arranged above the frame 1 and a lifting mechanism fixedly connected to the control assembly a21 and located on one side thereof component 22;

[0071] The scissors mechanism 3, the scissors mechanism 3 is located on the side of the adjustment mechanism 2 and arranged above the lifting assembly 22, which includes a cross assembly 31 synchronously driven with the lifting assembly 22, slidingly arranged on the cross A control assembly b32 on and below the assembly 31 and a transmission assembly 33 connected to the control assembly b32 at one end and connected to the control assembly a21 at the other end; and

[0072] The stabilizing mechanism 4, the stabilizing mechanism 4 is arranged above the scissor mechanism 3, which includes a tightenin...

Embodiment 2

[0119] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between this embodiment two and embodiment one is:

[0120] Further, the height difference between the rotating shaft a3243 and the rotating shaft b3253 is H1, the thickness difference between the first cross plate 313 and the second cross plate 314 is H2, the angle iron a413 and the The height difference between the angle iron b418 is H3, said H1=H2=H3.

[0121] In this embodiment, since the first crossing plate 313 and the second crossing plate 314 are set up and down, by setting H1=H2=H3, on the one hand, the lower ends of the angle iron a413 and the angle iron b418 are flush with each other while ensuring that they are respectively The connecting rod a415 and connecting rod b419 hinged at the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com