E-shaped inductance automatic processing device

An automatic processing and inductance technology, applied in the manufacture of inductance/transformer/magnet, circuits, electrical components, etc., can solve problems such as uneven shape, uneven bending of wires, manual straightening, etc., to achieve high linkage and improve product quality , to achieve the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

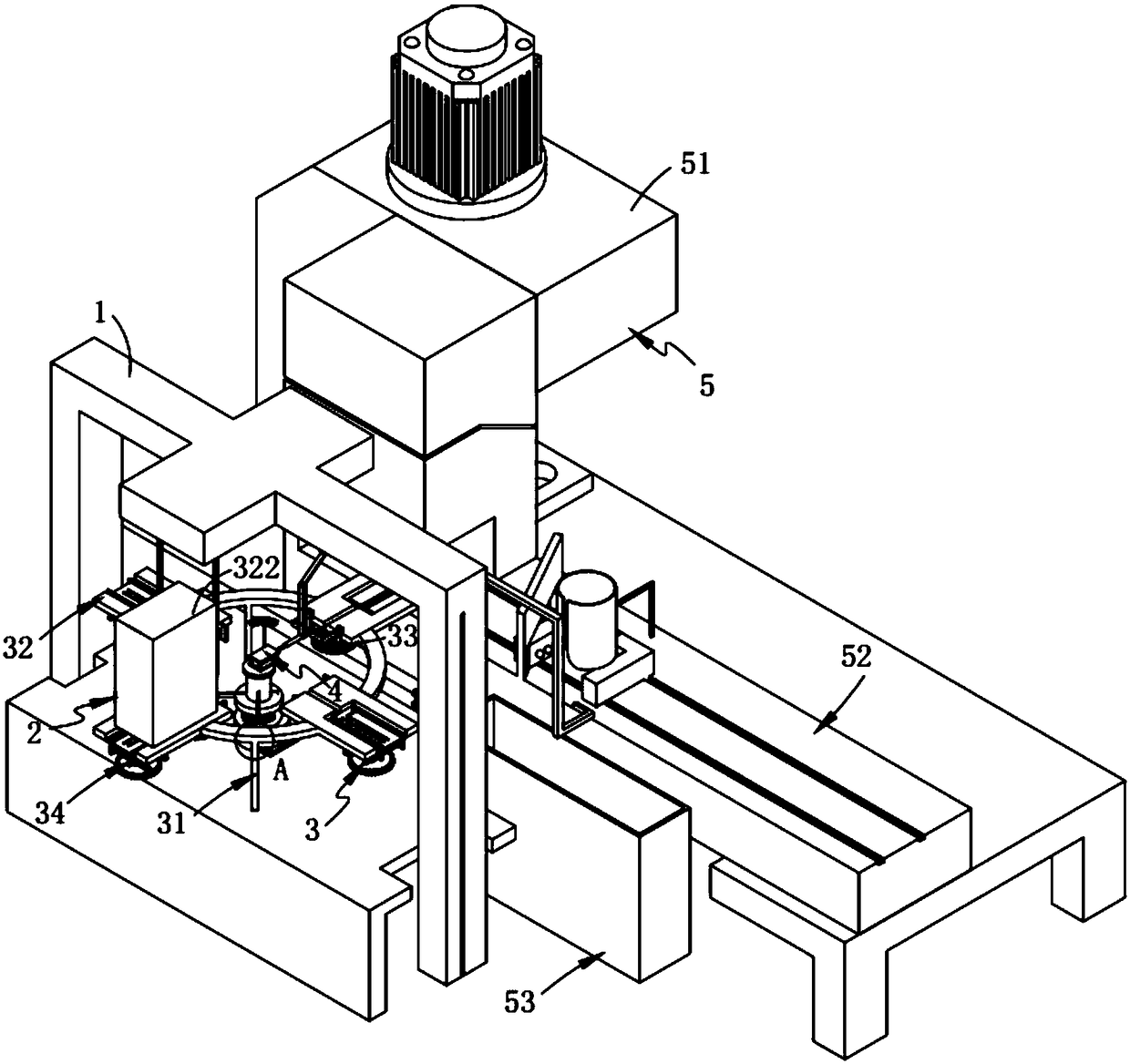

[0078] Such as figure 1 As shown, an E-shaped inductance automatic processing device includes:

[0079] Rack 1;

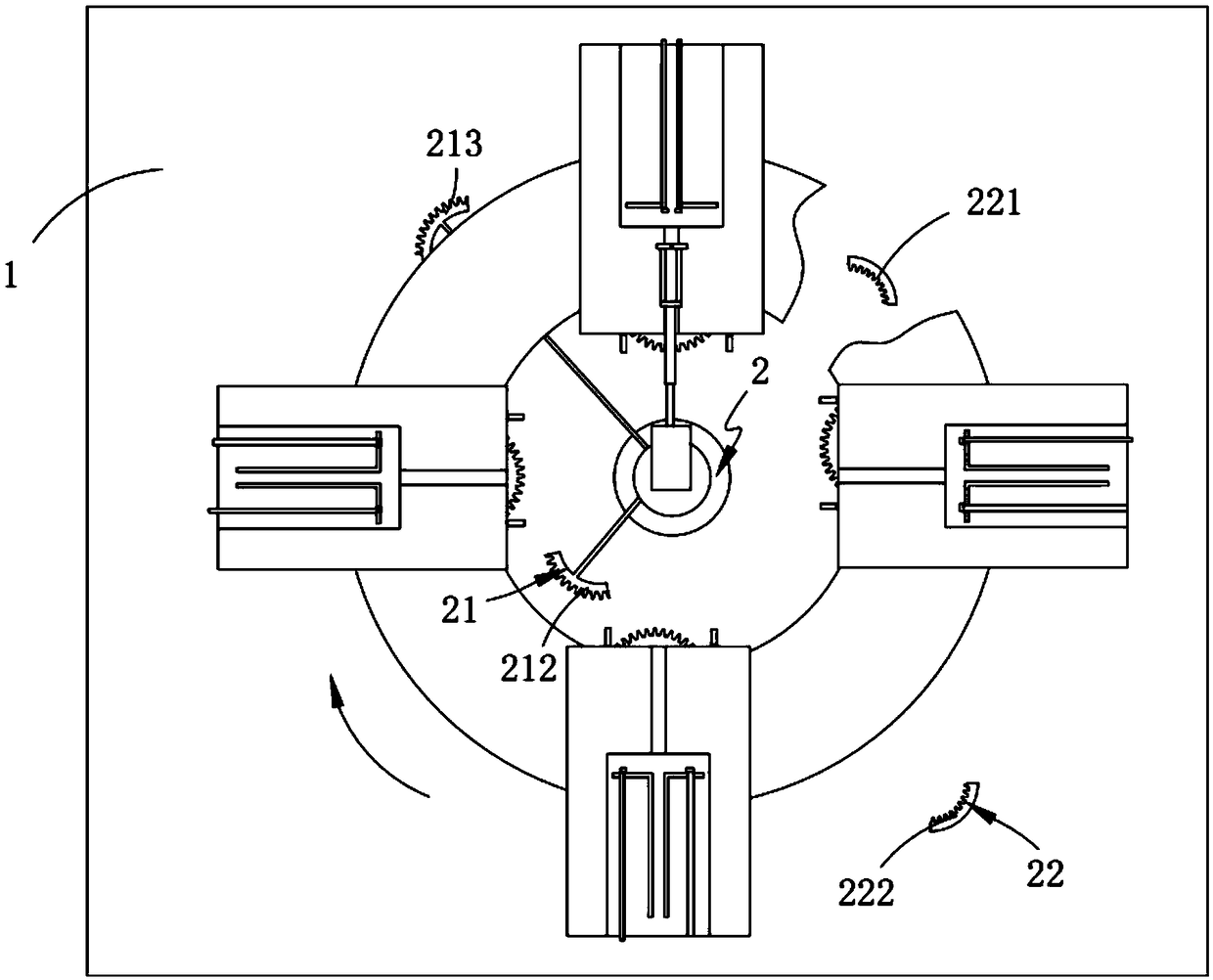

[0080] An adjustment mechanism 2, the adjustment mechanism 2 is fixedly arranged on the frame 1;

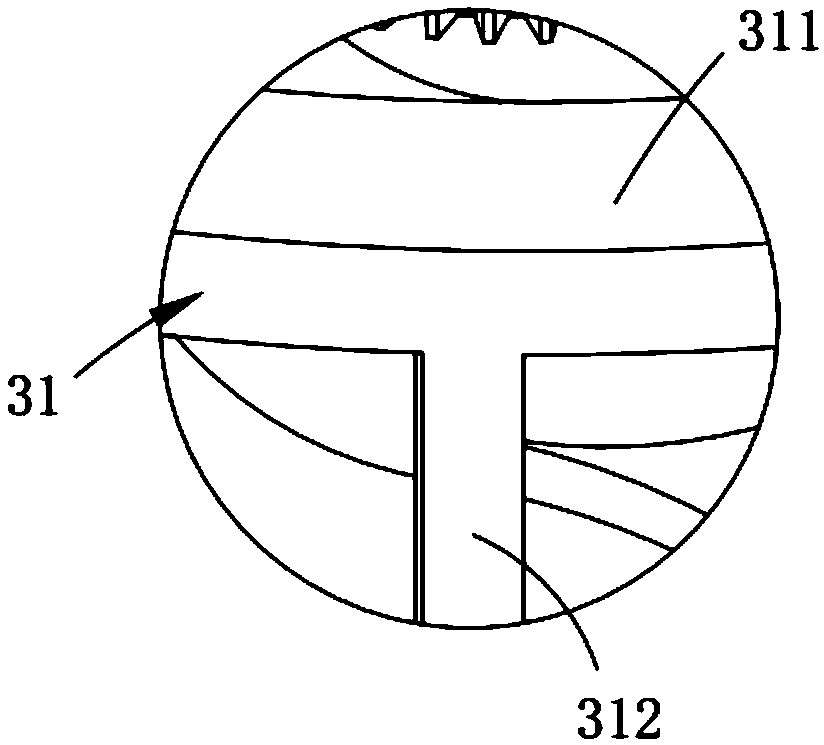

[0081] Clamping mechanism 3, the clamping mechanism 3 includes a revolving assembly 31, fixedly arranged on the revolving assembly 31 and four sets of feeding assemblies 32 arranged in a circular array, fixedly arranged at the bottom of the feeding assembly 32 and located at the The first positioning assembly 33 provided at the front end of the feeding assembly 32 and the second positioning assembly 34 located at the rear end of the feeding assembly 32;

[0082] a smoothing mechanism 4, the smoothing mechanism 4 is fixedly arranged on the adjustment mechanism 2 and cooperates with the second positioning assembly 34 for transmission; and

[0083] The coil delivery mechanism 5, the coil delivery mechanism 5 includes a crimping machine 51 arranged at the output end of...

Embodiment 2

[0135] Such as Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0136] Going a step further, as in Figure 12 As shown, the discharge assembly 53 includes:

[0137] A limiting plate 531, the limiting plate 531 is located at the output end of the uploading assembly 52 and is rotatably arranged on the uploading assembly 52, the limiting plate 531 is provided with a control slot 532, and the control slot 532 is connected to the uploading assembly 52. Said sliding part 522 matching setting;

[0138] The mounting frame 533, the mounting frame 533 is fixedly arranged on the frame platform 5211 and arranged linearly with the rotating shaft 535 of the limiting plate 531;

[0139] A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com