A kind of rapid assembly equipment for power distribution cabinet

A technology for assembling equipment and power distribution cabinets, which is applied in the field of rapid assembly equipment for power distribution cabinets, can solve the problems of connecting power supplies and electrode plates, and achieve the effects of ingenious structure, quick and convenient installation, and good molding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

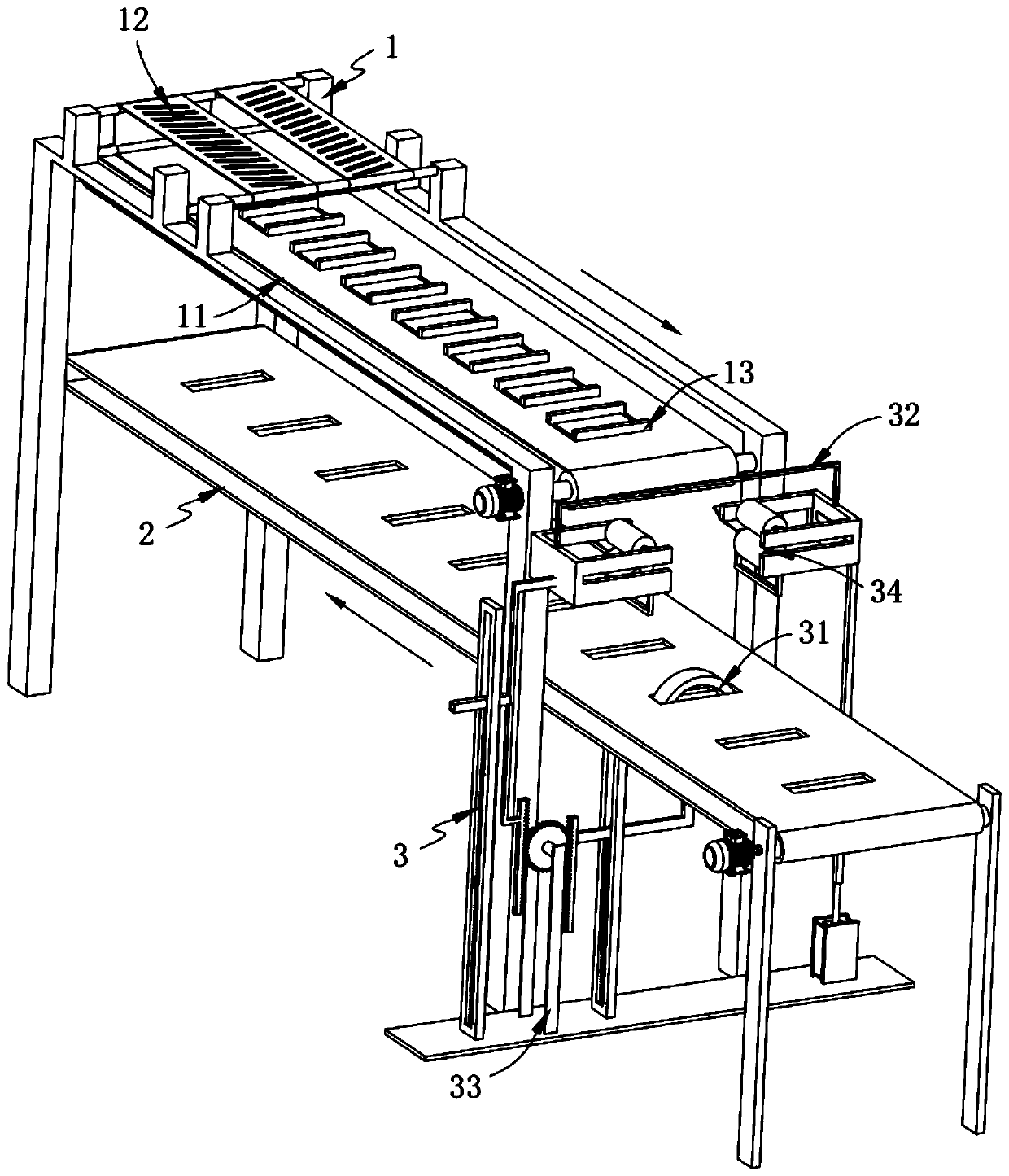

[0078] Such as figure 1 , Figure 11 As shown, a rapid assembly equipment for power distribution cabinets, including:

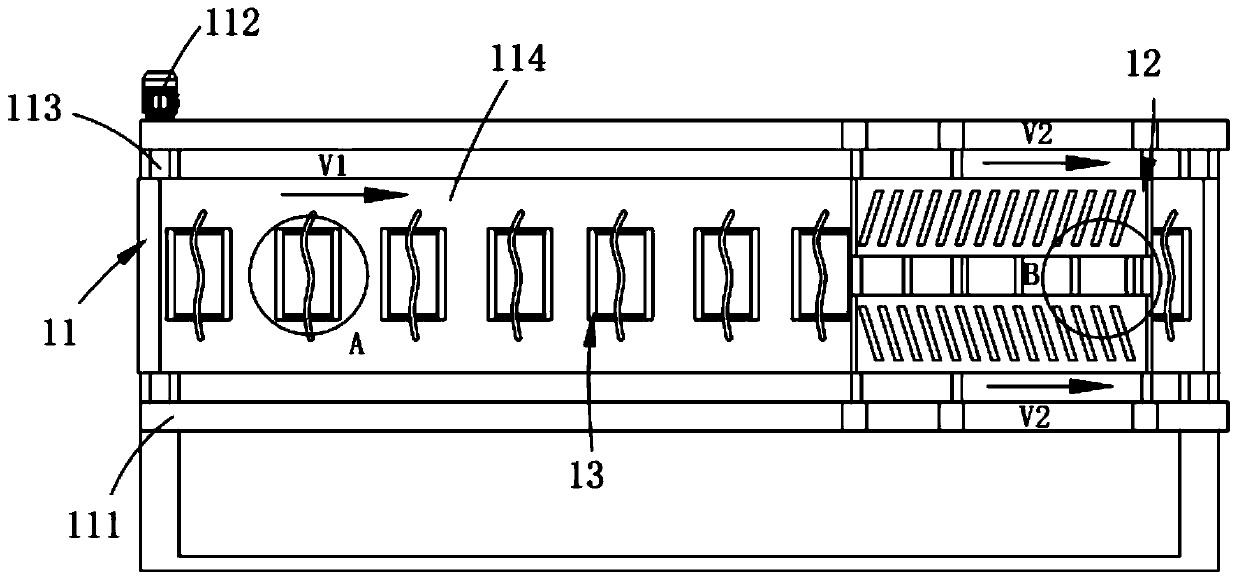

[0079] The zero-line loading mechanism 1, the zero-line loading mechanism 1 includes a forward conveying member 11, two groups of rollers arranged above the forward conveying member 11 and arranged symmetrically along the centerline of the width of the forward conveying member 11 The pressing member 12 and several groups of straightening members 13 are equidistantly arranged along the forward conveying member 11;

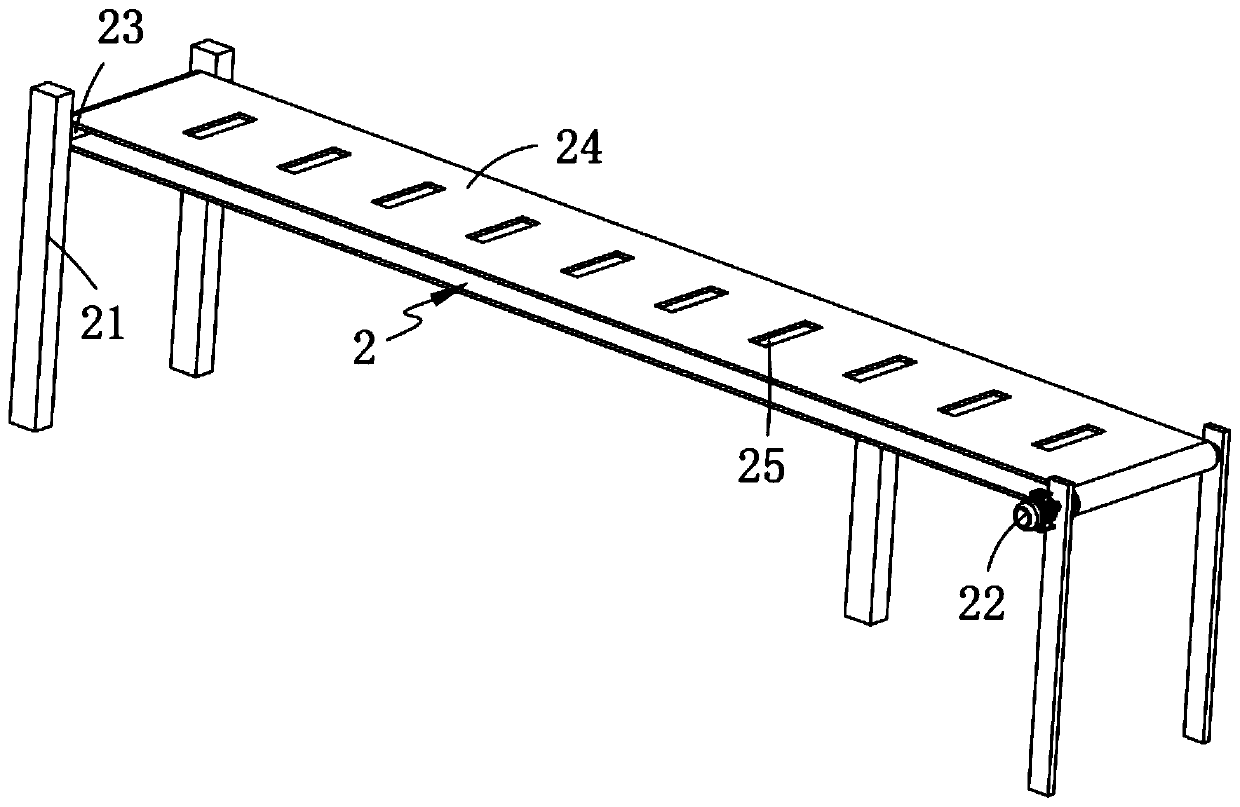

[0080] An electrode plate loading mechanism 2, the electrode plate loading mechanism 2 is set opposite to the conveying direction of the forward conveying member 11 and is located directly below the forward conveying member 11; and

[0081] A zero-line bending mechanism 3, the zero-line bending mechanism 3 includes a mold assembly 31 installed below the pole plate loading mechanism 2, located above the pole plate loading mechanism 2 and cooperati...

Embodiment 2

[0135] Such as Figure 9 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0136] further, such as Figure 9 As shown, the boxer assembly 34 includes:

[0137] A support rod 341, one end of the support rod 341 is fixedly connected to the rotation shaft a3262 and the other end is rotatably connected to the rotation shaft b3265;

[0138] The driving rod a342, the upper end of the driving rod a342 is fixedly arranged on the side wall of the roller a3263;

[0139] A waist groove 343, the waist groove 343 is opened at the lower end of the driving rod a342; and

[0140] The driving rod b344, one end of the driving rod b344 is fixedly arranged on the roller b3266 and the other end is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com