Novel process for cooling of pyrogenic process zinc smelting

A new process, zinc smelting technology, applied in the field of non-ferrous metal preparation, can solve the problems of low washing efficiency, poor product quality, low furnace negative pressure, etc. Direct yield, the effect of improving product quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

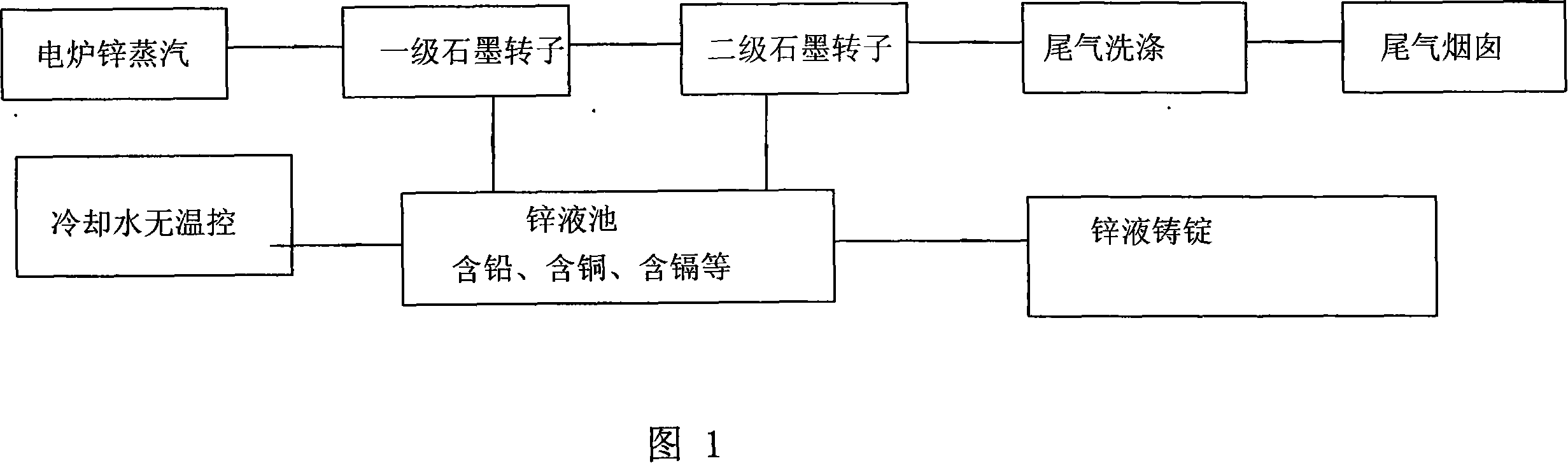

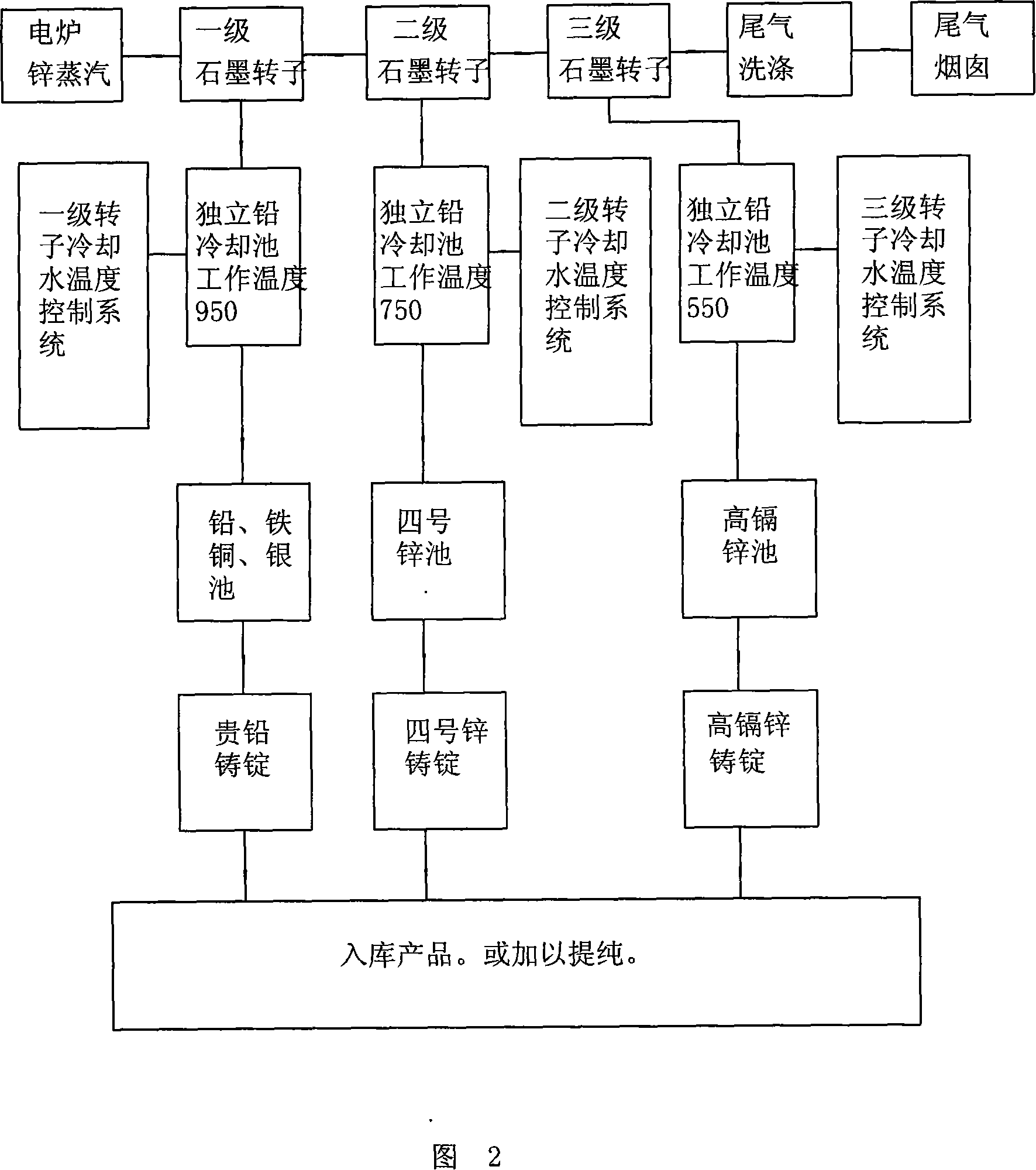

[0018] The electric furnace zinc smelting or vertical tank zinc smelting steam passes through the first-stage graphite rotor with an independent cooling pool, the second-stage graphite rotor with an independent cooling pool, and the third-stage graphite rotor with an independent cooling pool. The first-stage cooling medium used is Lead, the second level is zinc, and the third level can be either zinc or cadmium. The working temperature of each cooling pool is determined according to the condensation temperature of the recovered metal. For example, the working temperature of the primary cooling pool is determined according to the condensation point of lead, iron, copper, and silver. Generally, it is controlled at about 950°C. Finally, precious lead castings can be obtained. Ingots; the working temperature of the secondary cooling pool is determined by the condensation temperature of zinc, generally controlled at about 770 ° C, and finally No. 1 or No. 2 zinc ingots can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com