Automatic processing assembling device for screwdriver

A technology of automatic processing and assembly device, applied in positioning devices, metal processing, metal processing equipment, etc., can solve the problems of low concentricity between screwdriver shank and screwdriver handle, high product scrap rate, and achieve automatic assembly and high degree of automation. , the effect of increasing profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

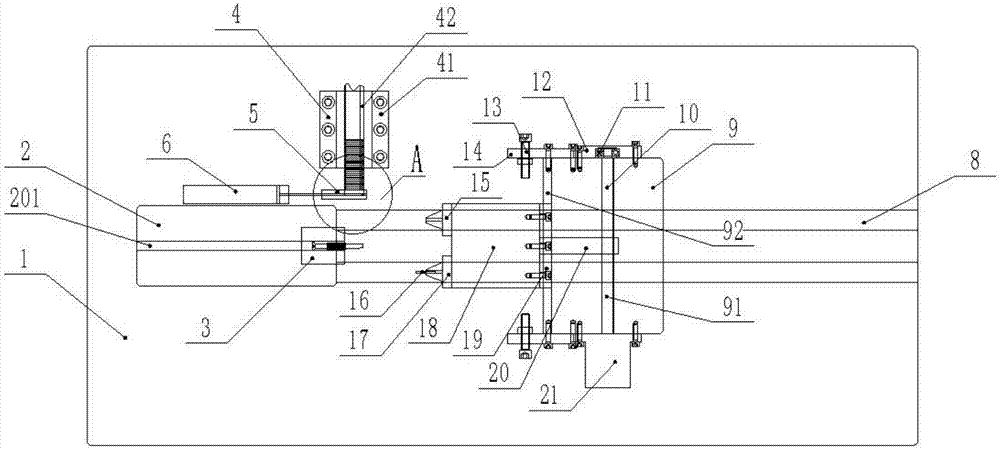

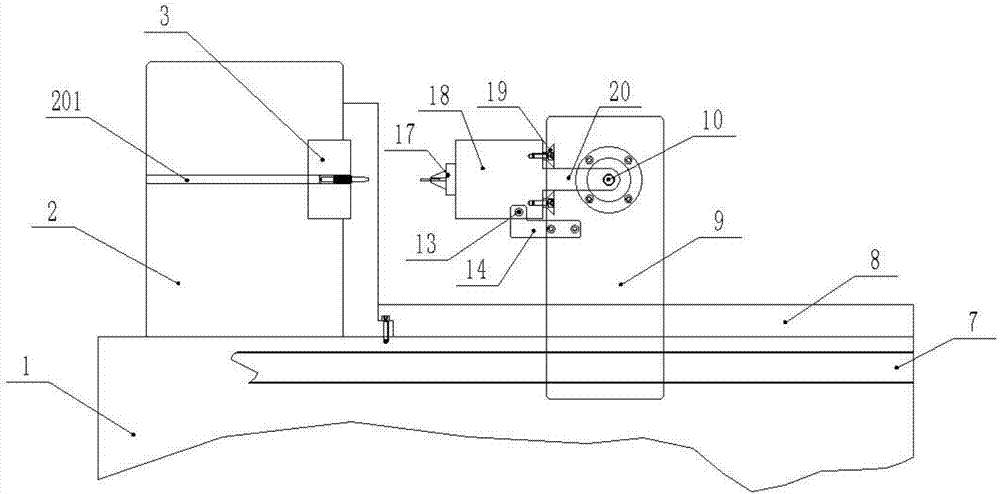

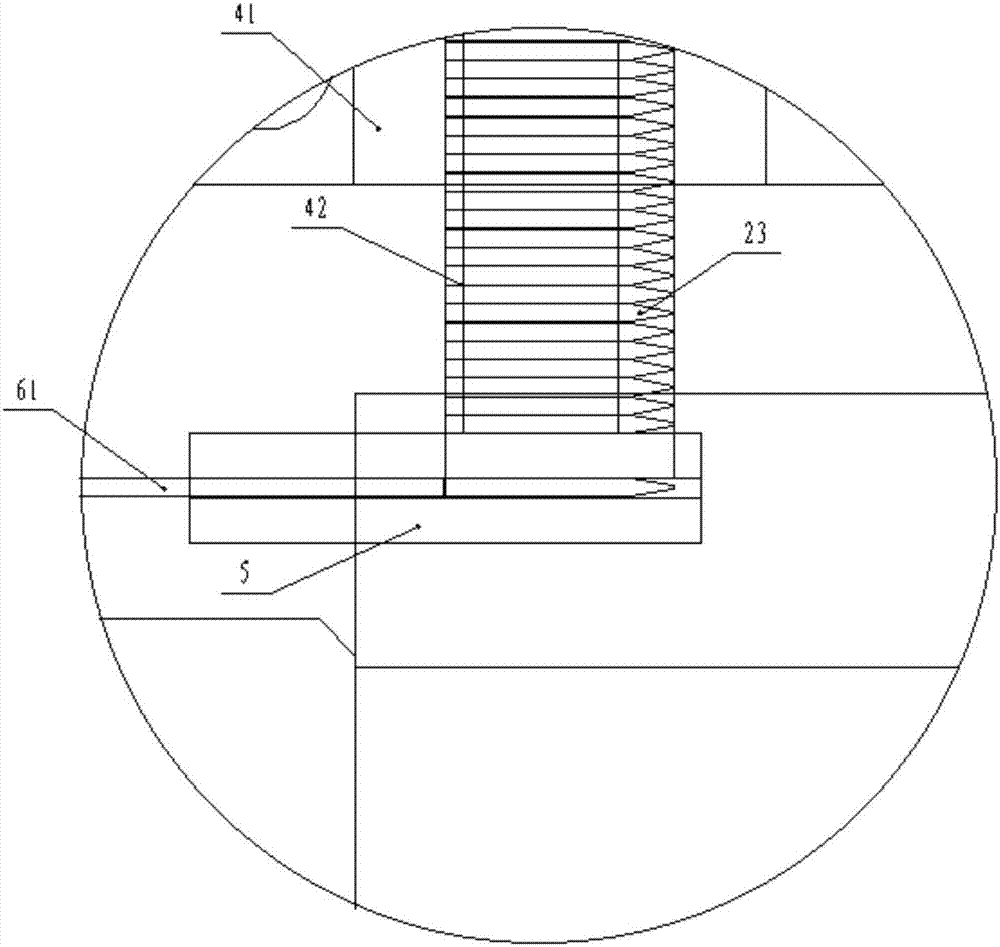

[0030] As shown in the figure, a screwdriver automatic processing and assembling device according to the embodiment of the present invention includes: figure 1 , figure 2 As shown, the machine base 1 is equipped with a power screw 7, and the slideway 8 is symmetrically installed on the working surface of the machine base 1; the machine head 2 is fixed on the left side and the top of the machine base 1, and a horizontal discharge material Pipe 201; the pneumatic chuck 3 is fixed on the right side of the machine head 2, and the pneumatic chuck 3 is flush with the discharge pipe 201; the pneumatic chuck 3 can rotate freely; 4 comprises the flat feeder 41 and the flat feed track 42 above it ( Figure 5 shown); the top of the horizontal feeding mechanism 4 is connected with a vibrating feeding tray; as image 3 As shown, the discharge block 5 is fixed between the machine head 2 and the flat delivery mechanism 4, as Figure 4 As shown, the material pushing track 51 and the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com