A kind of card washing equipment and cleaning method of TF card

A device and card loading technology, applied in the field of TF card washing equipment and its cleaning, can solve the problems of product surface scratches, difficult to clean, low efficiency, etc., to reduce water consumption and cost, increase the number of cleaning, improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

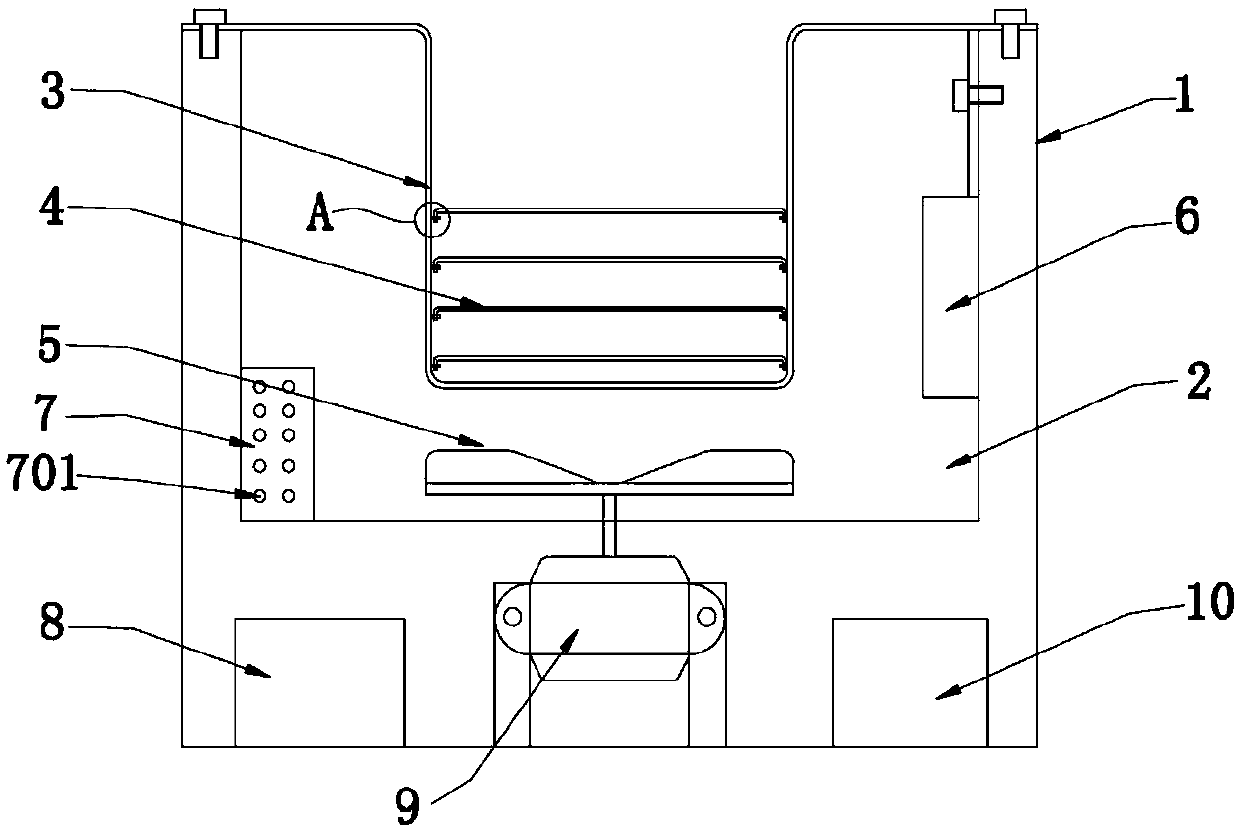

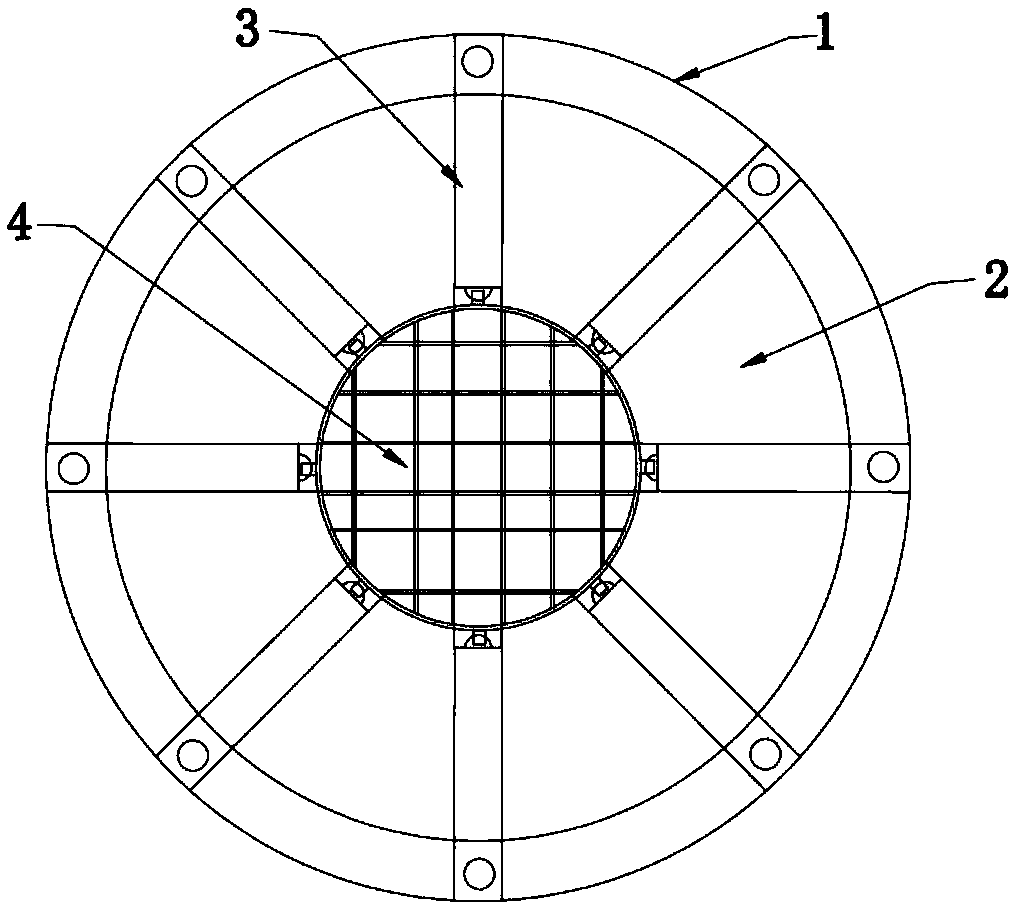

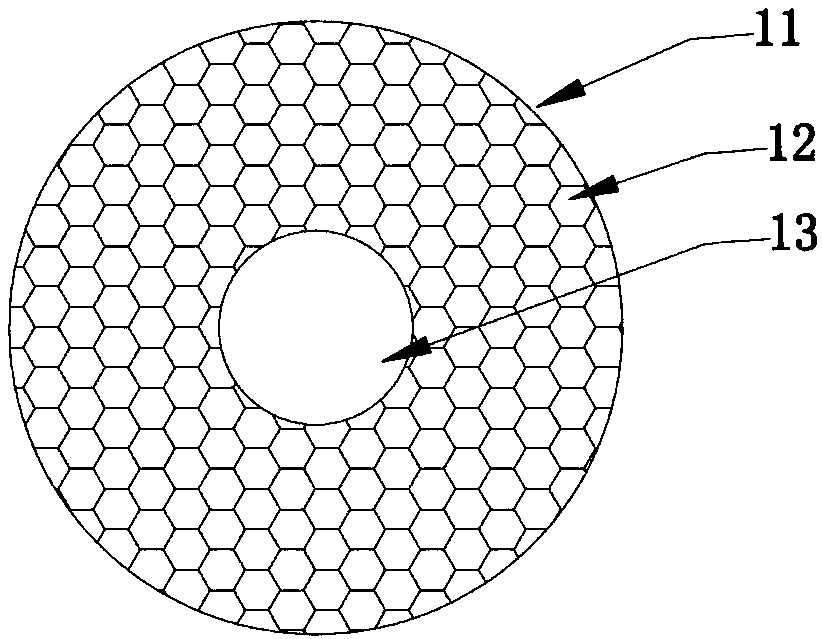

[0023] Such as Figure 1 to Figure 4 Shown, a kind of card washing equipment of TF card comprises housing 1 and is arranged on the water tank 2 inside described housing 1, and described water tank 2 is provided with bracket 3 and interlayer carrier plate 4, and described interlayer carries The plate 4 is fixed and suspended in the central area of the water tank 2 through the bracket 3, and several through holes are provided on the interlayer carrier 4, and the products are placed on the interlayer carrier 4, and the center of the bottom of the water tank 2 A stirring device is provided at the place, and the stirring device is a wave wheel 5. The inside of the water tank 2 is also provided with an ultrasonic generator 6 and an active carbon placement box 7. The ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com