Novel stainless steel acid-washing passivation liquid

A technology of pickling passivation and stainless steel, applied in the coating process of metal materials, etc., can solve the problems of strong irritating smell, easy to burn human skin and osteoporosis, unfavorable environmental protection and health, and achieve simple and economical use The effect of reducing the cost of pollution control and reducing the cost of pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

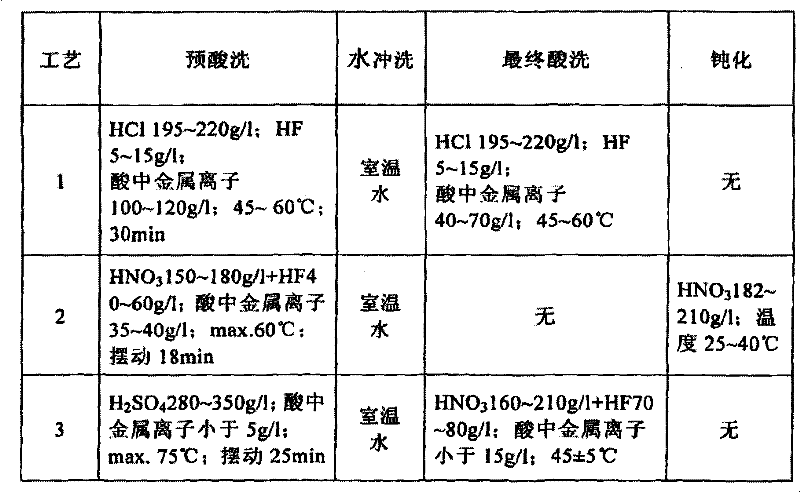

Method used

Image

Examples

Embodiment 1

[0033] A stainless steel pickling passivation solution, its components include: inorganic acid, penetrating agent, oxidizing agent and corrosion inhibitor; their mass ratio is 20:15:15:50.

[0034] The inorganic acid uses hydrochloric acid and nitric acid with a mass ratio of 2:1, wherein the concentration of hydrochloric acid is 30% and the concentration of nitric acid is 98% during preparation. The penetrant is commercially available penetrant M. Both the oxidizing agent and the corrosion inhibitor are commercially available products.

[0035] Mix the above-mentioned inorganic acid, penetrant, oxidant and corrosion inhibitor, stir evenly, and then use it.

Embodiment 2

[0037] A stainless steel pickling passivation solution, its components include: inorganic acid, penetrating agent, oxidizing agent and corrosion inhibitor; their mass ratio is 50:8:12:30.

[0038] The inorganic acid uses potassium pyrophosphate and hydrochloric acid with a mass ratio of 0.8:1, wherein the concentration of hydrochloric acid is 30% during preparation, and potassium pyrophosphate is solid. The penetrant is commercially available penetrant JFC. Both the oxidizing agent and the corrosion inhibitor are commercially available products.

[0039] Mix the above-mentioned inorganic acid, penetrant, oxidant and corrosion inhibitor, stir evenly, and then use it.

Embodiment 3

[0041] A stainless steel pickling passivation solution, its components include: inorganic acid, penetrating agent, oxidizing agent and corrosion inhibitor; their mass ratio is 30-40:10-15:10-15:30-40.

[0042] The mineral acid uses potassium pyrophosphate, sulfuric acid and hydrochloric acid with a mass ratio of 1:1:1, wherein the concentration of sulfuric acid is 98%, the concentration of hydrochloric acid is 30%, and potassium pyrophosphate is solid during preparation. The penetrant is commercially available penetrant M. Both the oxidizing agent and the corrosion inhibitor are commercially available products.

[0043] Mix the inorganic acid, penetrant, oxidizing agent and corrosion inhibitor in the above ratio, stir evenly, and then use it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com