Water-based metallic heavy-duty anticorrosion epoxy interior finish paint for containers and method for preparing water-based metallic heavy-duty anticorrosion epoxy interior finish paint

A water-based epoxy resin, water-based technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of flammable and explosive, obvious odor, and high VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

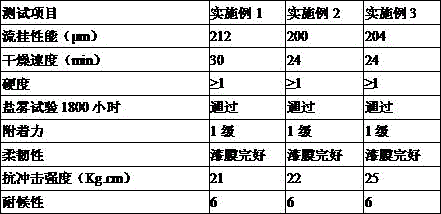

Examples

Embodiment 1

[0035] A water-based metal heavy-duty anti-corrosion epoxy zinc-rich primer for containers. The water-based metal heavy-duty anti-corrosion epoxy zinc-rich primer for containers is composed of the following raw materials in parts by weight:

[0036] 30 parts of water-based epoxy resin;

[0037] 0.5 part of 2,4-dihydroxybenzophenone;

[0038] 0.5 part of hindered amine light stabilizer;

[0039] 0.5 part of pH regulator;

[0040] 0.5 parts of sodium dioctylsulfosuccinate;

[0041] 60 parts of deionized water;

[0042] 0.5 part of organosilane;

[0043] 5 parts of propylene glycol butyl ether;

[0044] 10 parts of water-based fatty amine curing agent.

[0045] A kind of preparation method of described container water-based metal heavy-duty anticorrosion epoxy zinc-rich primer, is characterized in that, described preparation method is:

[0046] (1) Weigh the corresponding raw materials according to the formula;

[0047] (2) Add water-based epoxy resin to the mixer, then a...

Embodiment 2

[0051] A water-based metal heavy-duty anti-corrosion epoxy zinc-rich primer for containers. The water-based metal heavy-duty anti-corrosion epoxy zinc-rich primer for containers is composed of the following raw materials in parts by weight:

[0052] 40 parts of water-based epoxy resin;

[0053] 5 parts of titanium dioxide, 5 parts of superfine talcum powder;

[0054] 1 part of 2-hydroxy-4-methoxybenzophenone;

[0055] 1 part of hindered amine light stabilizer;

[0056] 1 part of pH regulator;

[0057] 0.1 part of sodium dioctyl sulfosuccinate;

[0058] 40 parts of deionized water;

[0059] 0.1 part of organosilane;

[0060] 5 parts of propylene glycol methyl ether acetate;

[0061] 15 parts of water-based fatty amine curing agent.

[0062] A kind of preparation method of described container water-based metal heavy-duty anticorrosion epoxy zinc-rich primer, is characterized in that, described preparation method is:

[0063] (1) Weigh the corresponding raw materials acco...

Embodiment 3

[0068] A water-based metal heavy-duty anti-corrosion epoxy zinc-rich primer for containers. The water-based metal heavy-duty anti-corrosion epoxy zinc-rich primer for containers is composed of the following raw materials in parts by weight:

[0069] 38 parts of water-based epoxy resin;

[0070] 0.8 parts of 2-hydroxyl-4-n-octyloxybenzophenone;

[0071] 0.6 part of hindered amine light stabilizer;

[0072] 0.4 parts of pH regulator;

[0073] 0.4 parts of sodium dioctylsulfosuccinate;

[0074] 50 parts of deionized water;

[0075] 0.3 parts of organosilane;

[0076] 3 parts of propylene glycol butyl ether, 4 parts of propylene glycol methyl ether acetate;

[0077] 6 parts of water-based fatty amine curing agent.

[0078] A kind of preparation method of described container water-based metal heavy-duty anticorrosion epoxy zinc-rich primer, is characterized in that, described preparation method is:

[0079] (1) Weigh the corresponding raw materials according to the formula; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com