Cleansing oil of polyglycerol emulsifier and preparation method of cleansing oil

A polyglycerol and emulsifier technology, applied in cosmetic preparations, cosmetics, cosmetics and other directions, can solve the problems of general makeup removal effect, skin irritation, and difficult to clean, and achieve the effect of increasing cleaning effect, enhancing emulsifying performance, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A cleansing oil with polyglycerol emulsifiers, including: Ethylhexyl Palmitate, Polyglyceryl-6-Dicaprate, Glyceryl Triethylhexanoate, Polyglyceryl-10-Dioleate, Caprylic / Capric Acid Sour triglyceride, bilberry seed oil, white pond flower seed oil, sweet orange peel oil, squalane, pentaerythritol tetraester, nanocellulose, and the polyglycerol emulsifier cleansing oil is calculated as: palm 35-55 parts of ethylhexyl acid, 5-10 parts of polyglycerol-6-dicaprate, 4-6 parts of glycerol triethylhexanoate, 15-21 parts of polyglycerol-10-dioleate, Caprylic acid / capric triglyceride 6-8 parts, European bilberry seed oil 4-6 parts, white pond flower seed oil 8-10 parts, sweet orange peel oil 4-6 parts, squalane 5-25 parts, pentaerythritol tetra 7-9 parts of ester, 15-25 parts of nanocellulose.

[0029] The polyglycerol-6-dicaprate undergoes a graft copolymerization reaction with the first active group to generate a new polyglycerol-6-dicaprate polymer, so that the polyglycerol-6-...

Embodiment 2

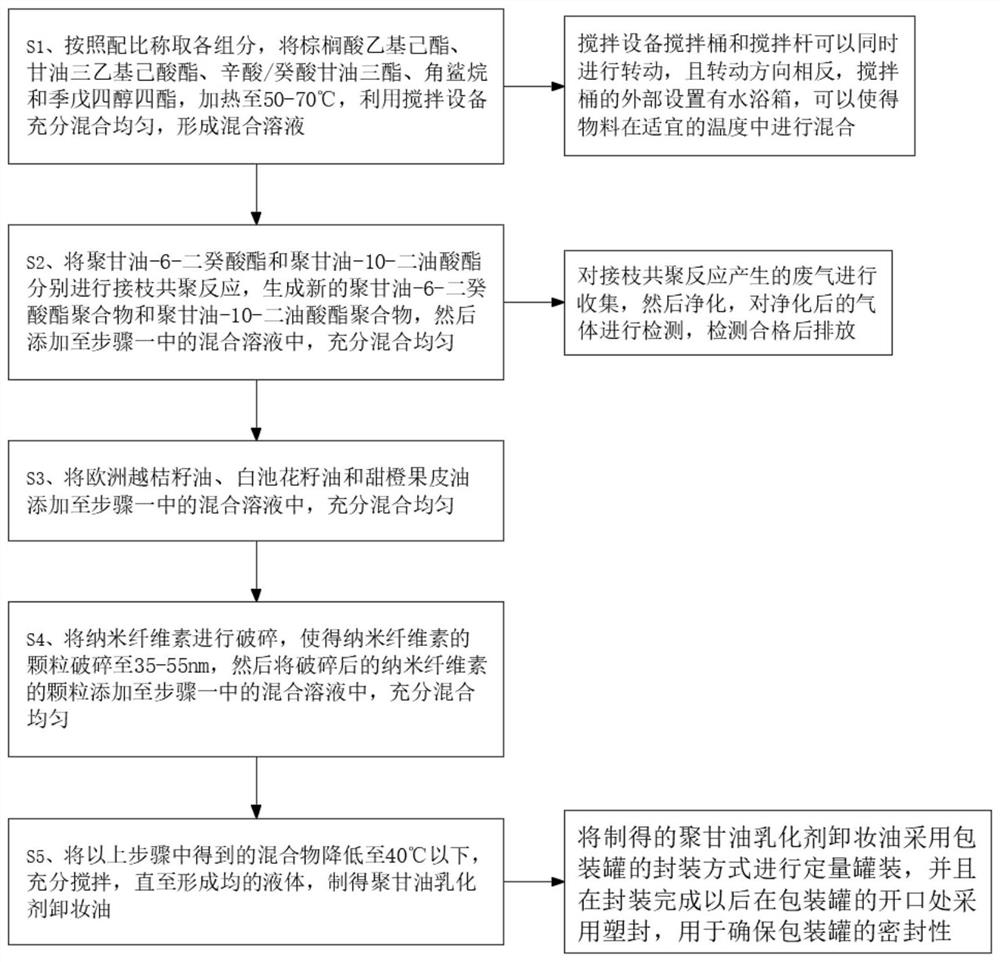

[0042] On the basis of the cleansing oil of a kind of polyglycerol emulsifier that embodiment 1 proposes, as figure 1 Shown, a kind of cleansing oil of polyglycerol emulsifier and preparation method, comprise the steps:

[0043] Step 1. Weigh each component according to the proportion, and heat ethylhexyl palmitate, triethylhexanoate, caprylic / capric triglyceride, squalane and pentaerythritol tetraester to 50-70°C , use stirring equipment to fully mix evenly to form a mixed solution;

[0044] Step 2. Carry out graft copolymerization reaction of polyglycerol-6-dicaprate and polyglycerol-10-dioleate respectively to generate new polyglycerol-6-dicaprate polymer and polyglycerol-10- Dioleate polymer, then add polyglycerol-6-dicaprate polymer and polyglycerol-10-dioleate polymer to the mixed solution in step 1, and mix well;

[0045] Step 3. Add bilberry seed oil, white pond flower seed oil and sweet orange peel oil to the mixed solution in step 1, and mix well;

[0046] Step 4,...

Embodiment 3

[0050] On the basis of a kind of cleansing oil of polyglycerol emulsifier proposed in Example 2 and the preparation method, the stirring equipment in the first step includes a stirring barrel and a stirring rod, and the stirring barrel and the stirring rod can be rotated simultaneously, and The direction of rotation is opposite, so that the mixed materials can be mixed quickly and evenly. The outside of the mixing barrel is equipped with a water bath box, which can make the materials mixed at a suitable temperature;

[0051] The polyglycerol emulsifier cleansing oil prepared in the step 5 is quantitatively packed in a packaging can, and after the packaging is completed, a plastic seal is used at the opening of the packaging can to ensure the tightness of the packaging can.

[0052] By adopting the above scheme, the materials can be stirred quickly and evenly, which improves the work efficiency to a certain extent, and the opening of the packaging tank is sealed with plastic to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com