High-stability wood door water-based epoxy resin coating

An epoxy resin coating, high stability technology, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of easy delamination, etc., and achieve the effect of good adhesion, smooth and smooth coating appearance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A water-based epoxy resin coating for wooden doors with high stability, comprising a first material and a second material, and the weight ratio of the first material to the second material is 10:0.5;

[0018] The raw materials of the first material include: main material 110g, aluminum nitride 2g, melamine resin 5g, magnesium hydroxide 1g, expanded perlite 6g, diatomite 1g, mica powder 4g, zinc oxide 0.5g, composite dispersant 6g, Plasticizer 3g, defoamer 2g, wetting agent 1g, leveling agent 2g;

[0019] The main ingredients include by weight: 60 parts of epoxy resin E-44, 18 parts of water-based acrylic emulsion; the plasticizer includes by weight: 1 part of oxidized polyethylene wax, 5 parts of polyethylene glycol;

[0020] The raw materials of the second material include: 5 g of aminoethyl piperazine, 3 g of propylene glycol butyl ether, 2 g of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, and 40 g of deionized water.

[0021] The composite dispersant is prepared b...

Embodiment 2

[0023] A water-based epoxy resin coating for wooden doors with high stability, comprising a first material and a second material, and the weight ratio of the first material to the second material is 10:1.2;

[0024] The raw materials of the first material include: main ingredient 70g, aluminum nitride 8g, melamine resin 1g, magnesium hydroxide 4g, expanded perlite 2g, diatomite 4g, mica powder 1g, zinc oxide 1.2g, composite dispersant 2g, Plasticizer 7g, defoamer 1g, wetting agent 2g, leveling agent 1g;

[0025] The main ingredients include by weight: 100 parts of epoxy resin E-44, 4 parts of water-based acrylic emulsion; the plasticizer includes by weight: 2 parts of oxidized polyethylene wax, and 1 part of polyethylene glycol;

[0026] The raw materials of the second material include: 9 g of aminoethyl piperazine, 1 g of propylene glycol butyl ether, 4 g of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, and 20 g of deionized water.

[0027] The composite dispersant is prepa...

Embodiment 3

[0029] A water-based epoxy resin coating for wooden doors with high stability, comprising a first material and a second material, and the weight ratio of the first material to the second material is 10:0.6;

[0030] The raw materials of the first material include: main ingredient 100g, aluminum nitride 4g, melamine resin 4g, magnesium hydroxide 2g, expanded perlite 5g, diatomite 2g, mica powder 3g, zinc oxide 0.6g, composite dispersant 5g, Plasticizer 4g, defoamer 1.8g, wetting agent 1.3g, leveling agent 1.6g;

[0031] The main ingredients include by weight: 70 parts of epoxy resin E-44, 14 parts of water-based acrylic emulsion; the plasticizer includes by weight: 1.2 parts of oxidized polyethylene wax, 4 parts of polyethylene glycol;

[0032] The raw materials of the second material include: 6 g of aminoethyl piperazine, 2.5 g of propylene glycol butyl ether, 2.5 g of 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, and 35 g of deionized water.

[0033] The composite dispersan...

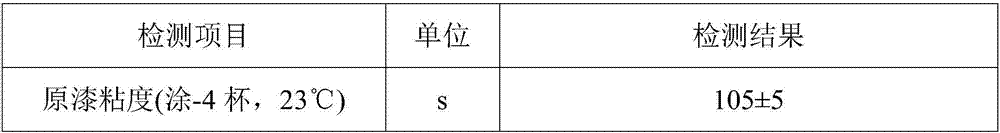

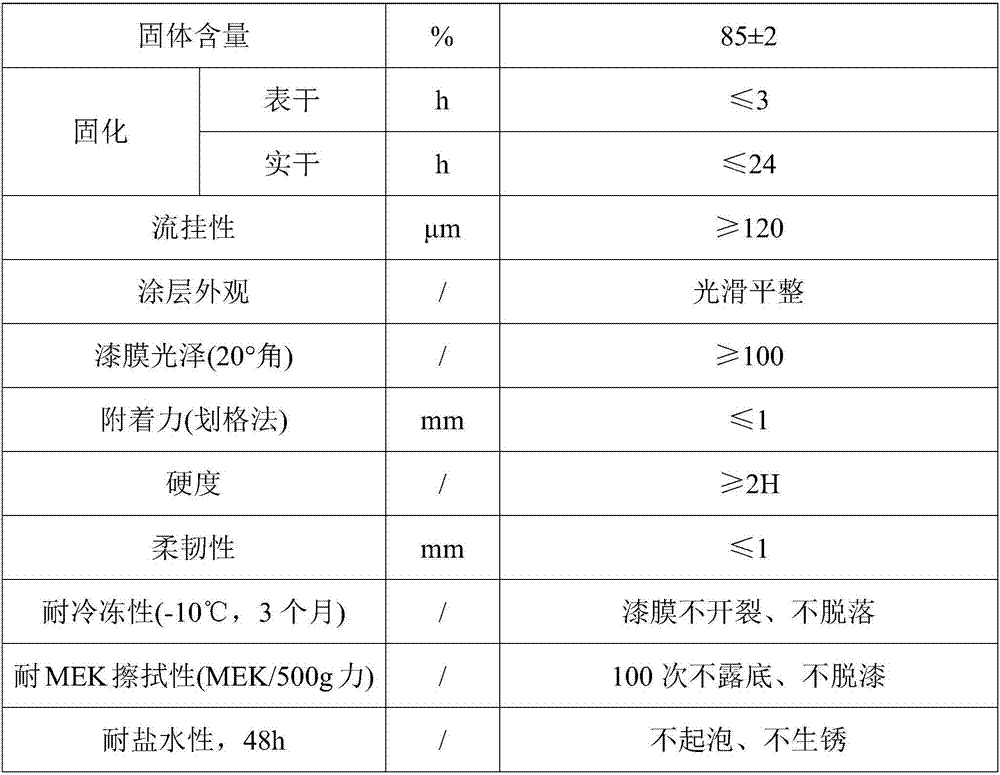

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com