Patents

Literature

152results about How to "Flat and smooth appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

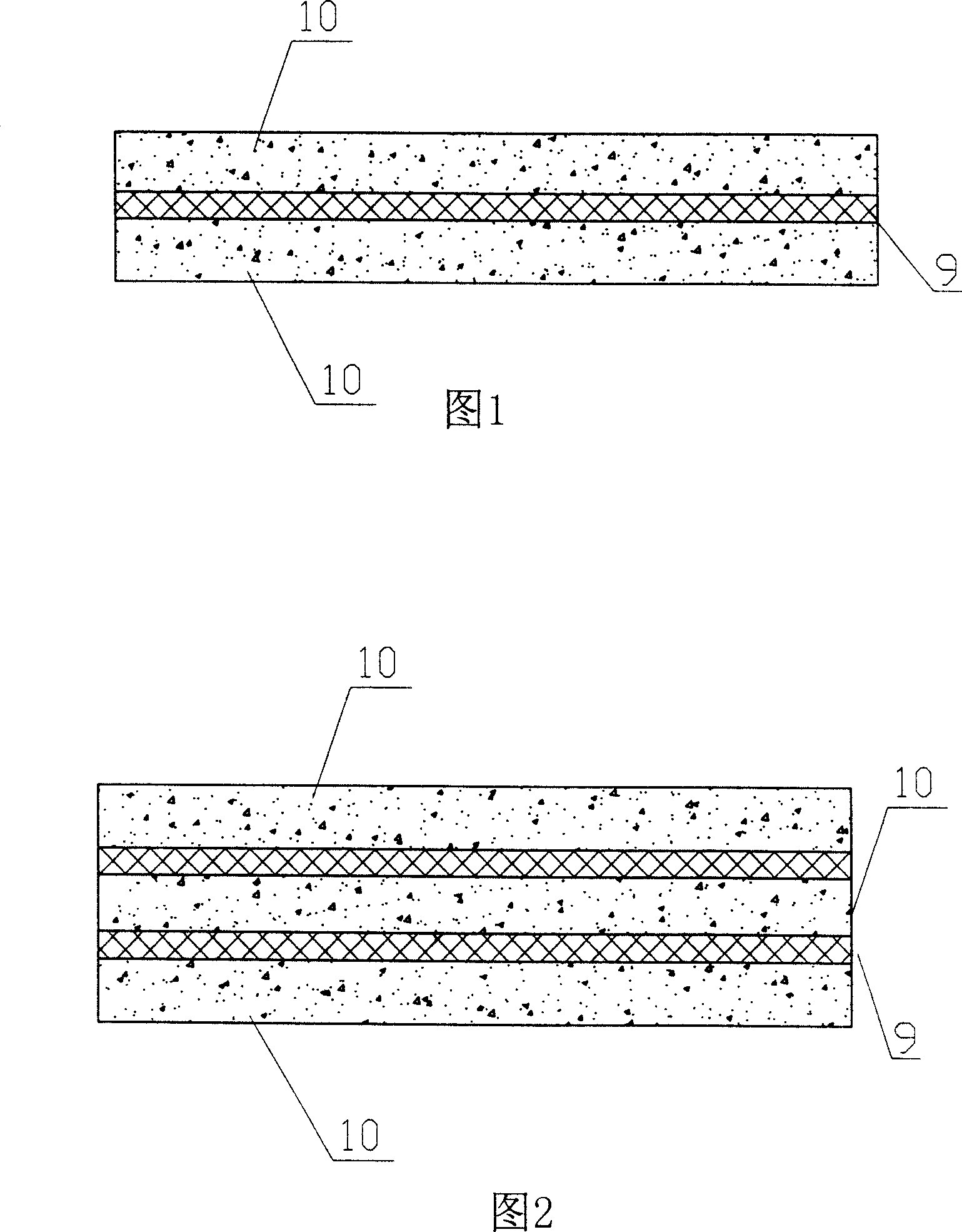

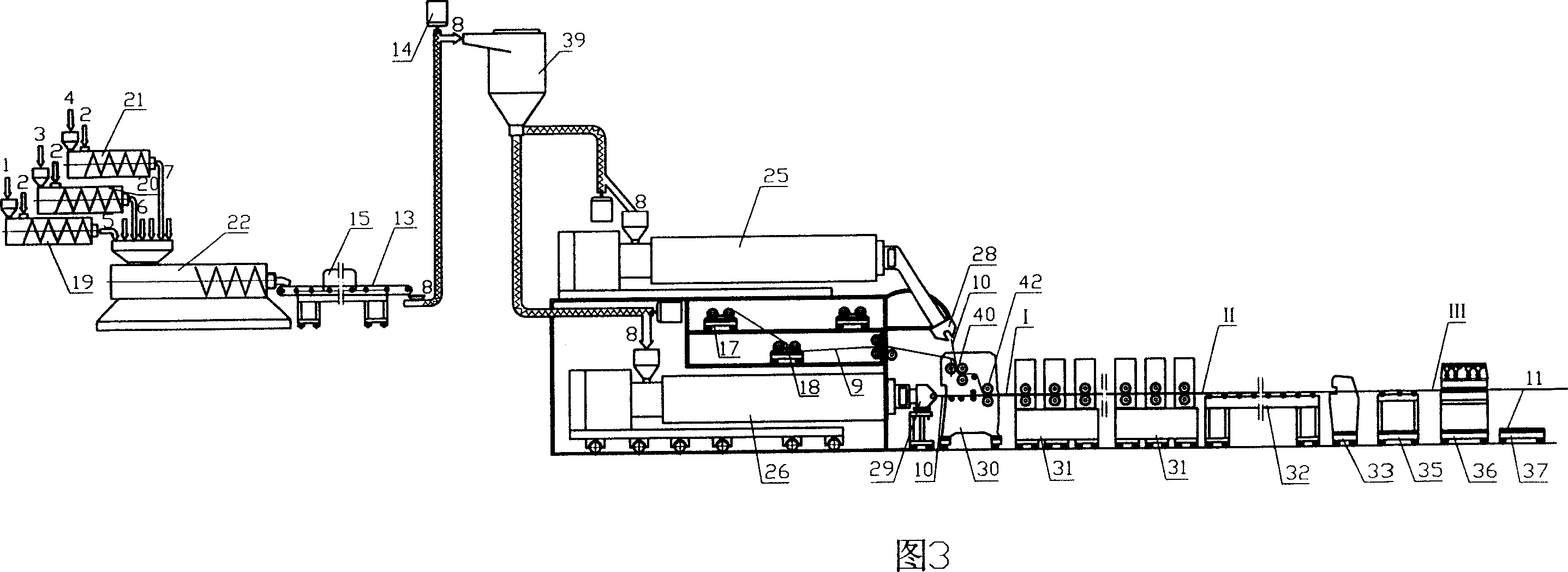

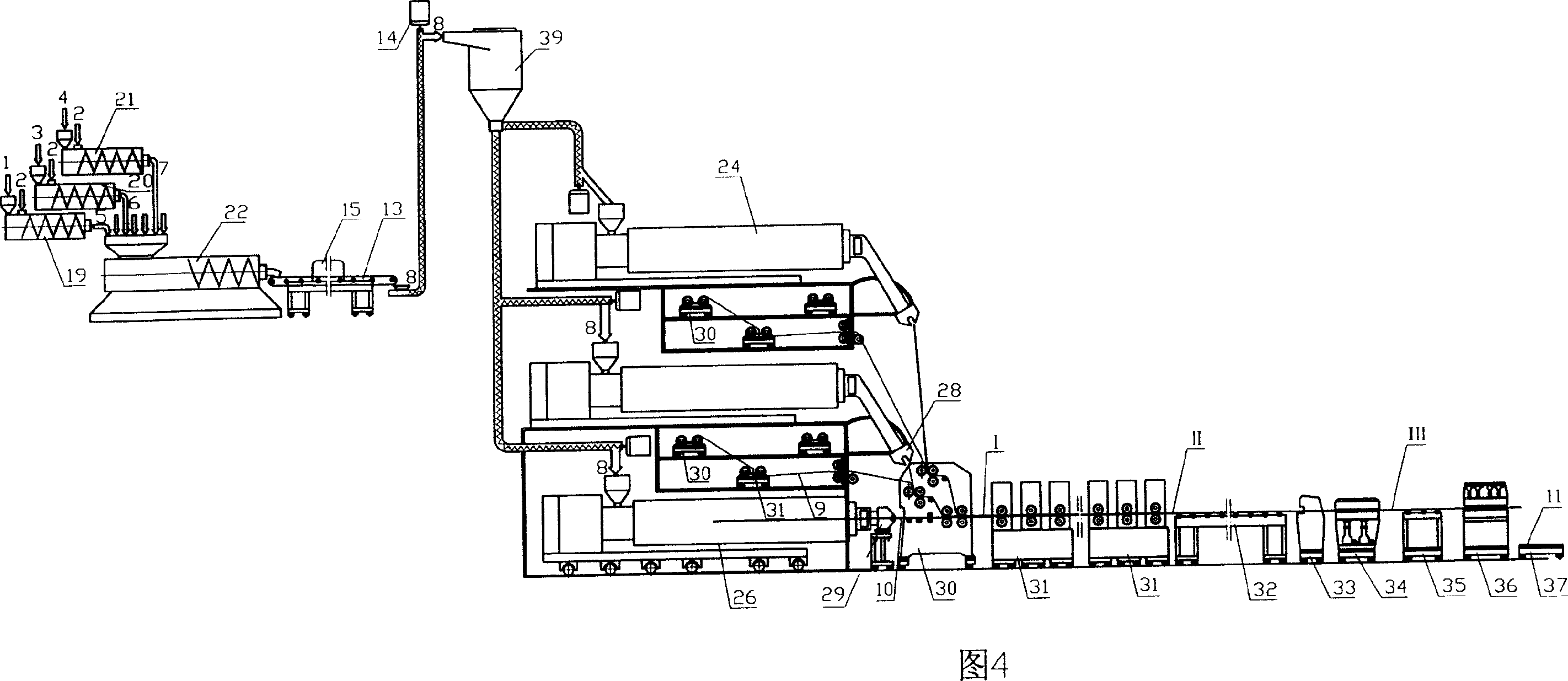

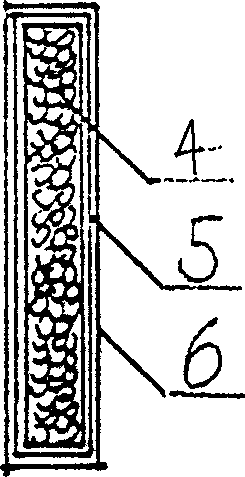

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

Novel membrane spraying preparation for skin trauma and preparation method

InactiveCN101879283AAvoid profuse bleedingPromote healingHydroxy compound active ingredientsAerosol deliveryPolyoxyethylene castor oilPolyvinyl alcohol

Owner:ARMY MEDICAL UNIV

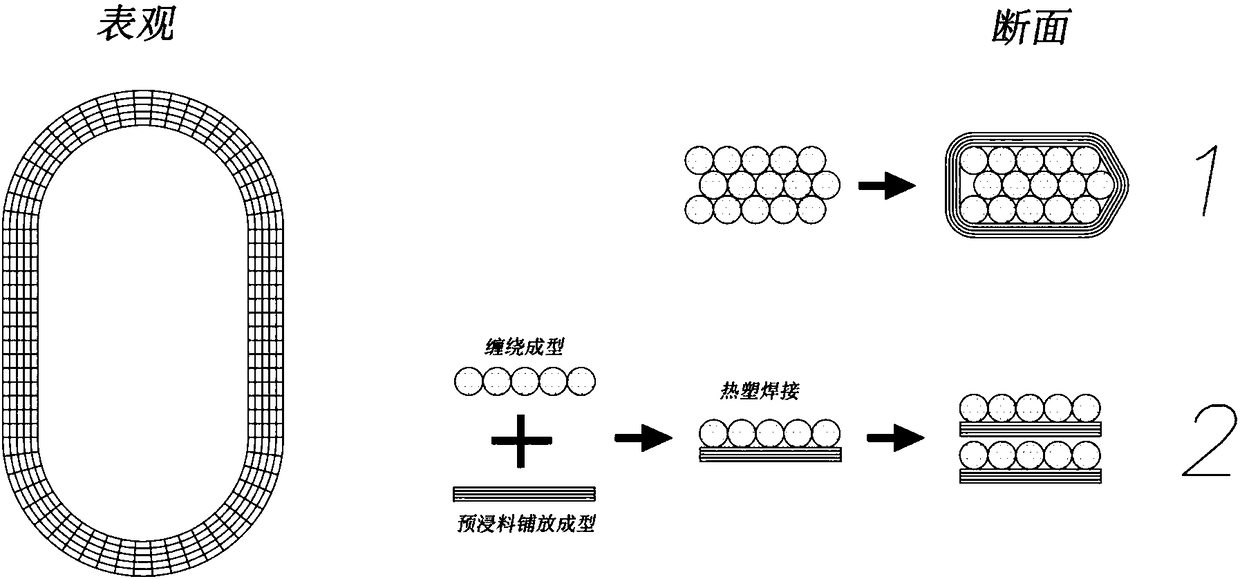

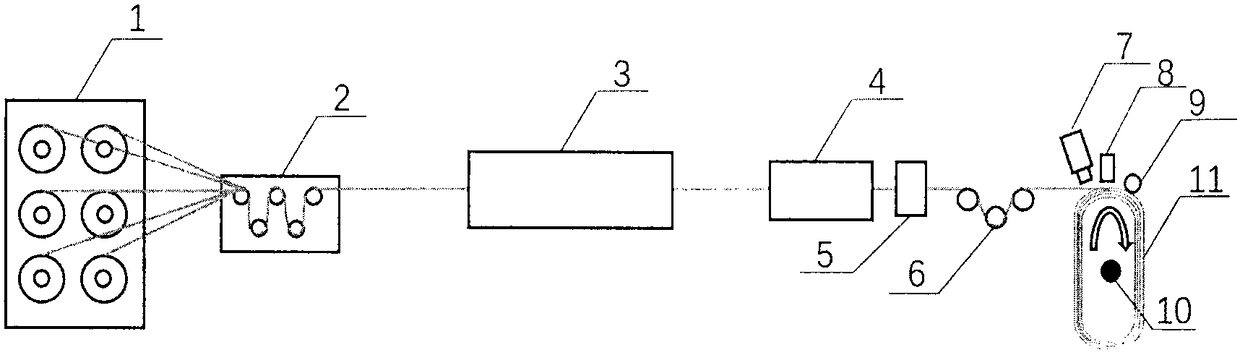

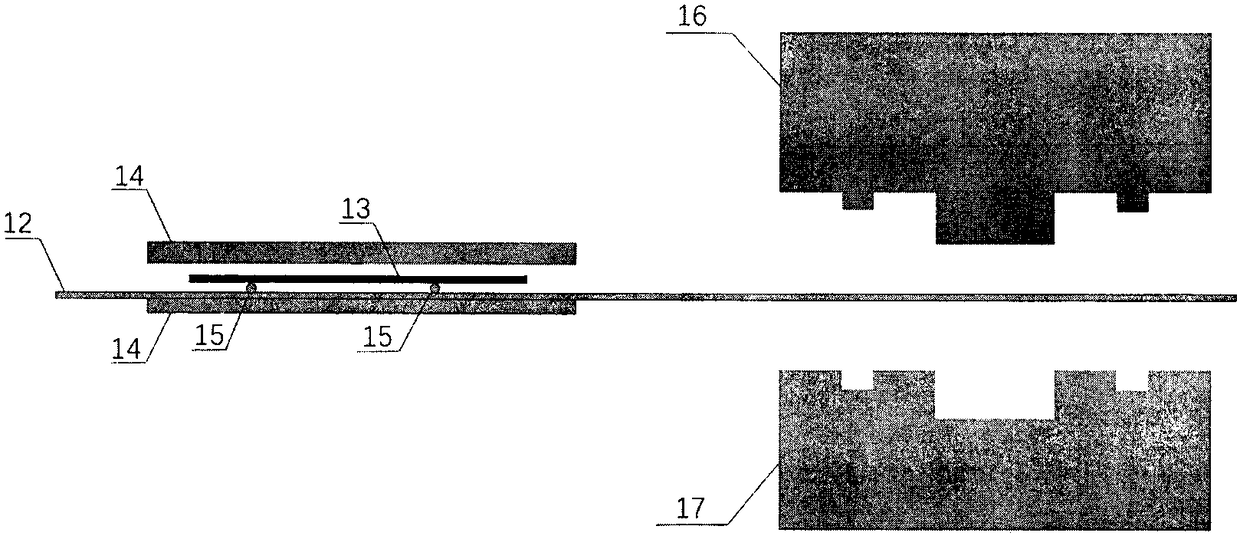

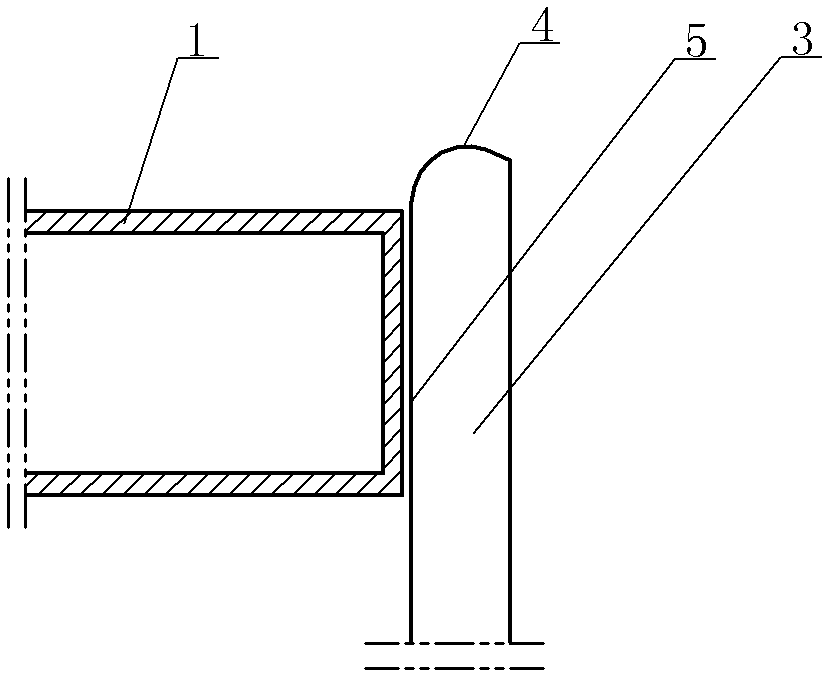

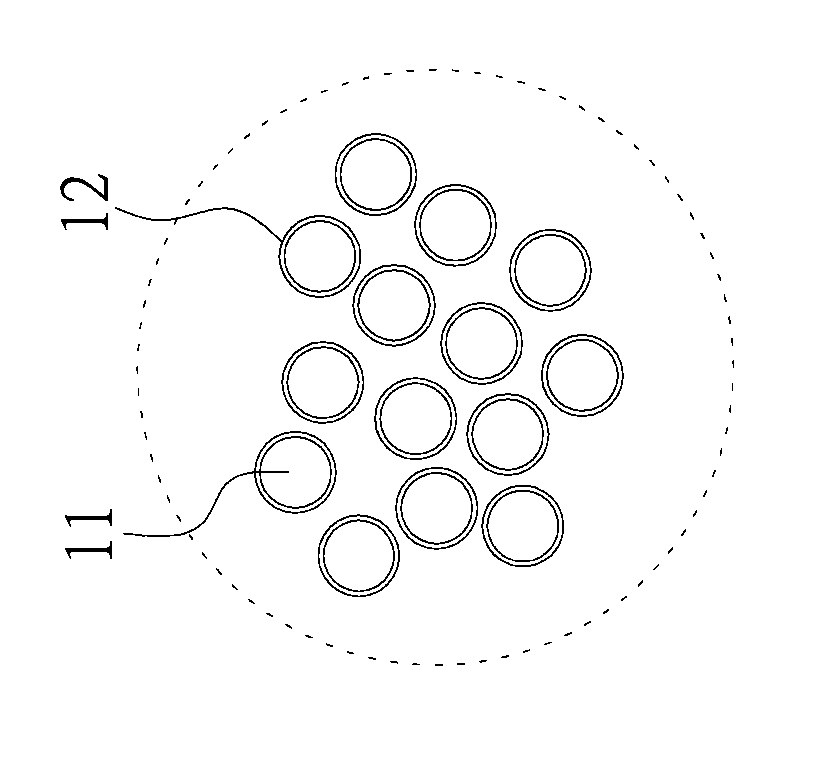

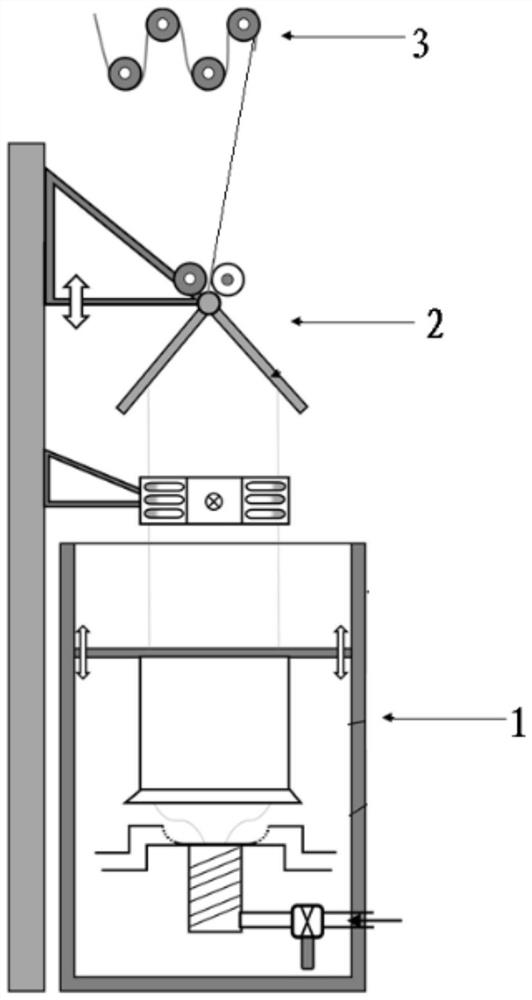

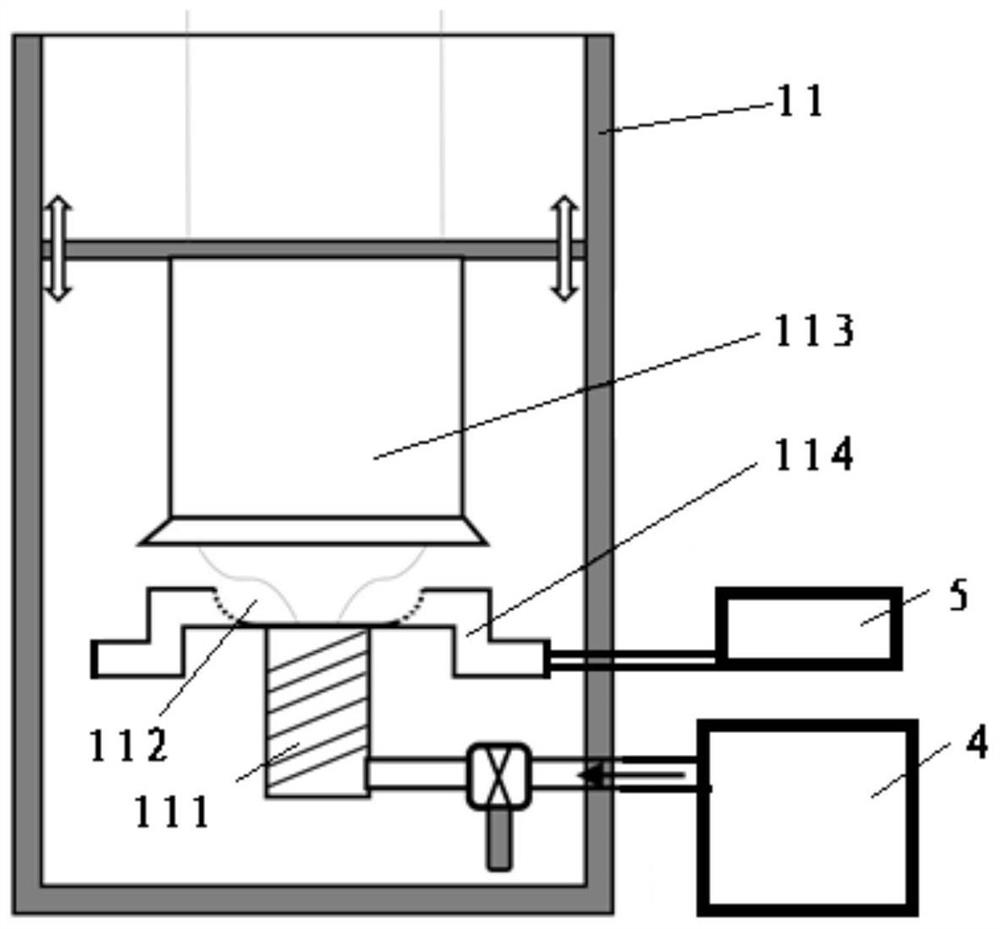

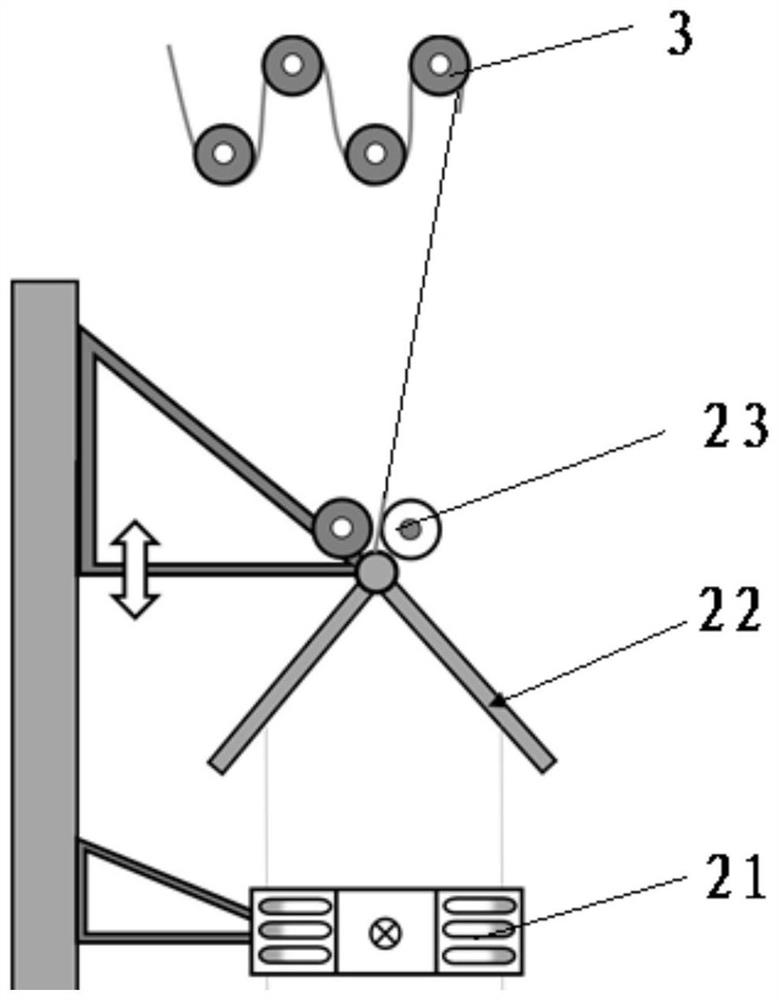

Winding-pressing forming process and device of fiber-reinforced composite material

The invention discloses a winding-pressing forming process and device of a fiber-reinforced composite material. The process comprises the steps: placing filaments, spreading yarns, preheating, dipping, drawing and winding. The forming process comprises the specific steps: fixedly placing a fiber-yarn shaft on a yarn frame, carrying out yarn spreading by a yarn spreading frame, leading the spread fiber yarn to enter a gum-dipping device after preheating, forming a prepreg wire by an outlet of a mold head of the gum-dipping device, then forming a sizing prepreg with smooth surface by a sizing device, drawing the sizing prepreg by a drawing and winding device, winding and sizing by a mold to obtain a pre-formed body, heating the pre-formed body to a needed temperature, pushing into a moldingcavity by a guide rail or a mechanical arm, pressurizing, curing and molding. The winding-pressing forming process and device disclosed by the invention have the beneficial effects that the characteristics of high specific strength and high specific rigidity of the composite material are furthest exerted by a mold-forming process, and the problems of poor mechanical property, weak interlayer connecting property, long manufacturing period and complex manufacture and the like caused by fiber cutting of the traditional fiber-reinforced composite material are solved, so that the application prospect is wide.

Owner:泰安市中研复合材料科技有限公司 +1

Special insulating powder coating for electro-magnetism line and preparation method thereof

InactiveCN101457117AFlat and smooth appearanceGood flexibilityPowdery paintsEpoxy resin coatingsFluidized bedFirming agent

The present invention discloses a insulating powder paint exclusively used on electro-magnetic wires, which includes the following components that measured in weight percentage: epoxy resins 60-70%, firming agent 15-30%, inorganic filler 10-20%, flatting agent 1.0-2.0%, styrax benzoin 0.3-1.0%, curing accelerator 0.8-2.0% and siliceous reinforcing agent 0.1-0.3%. The insulating powder paint exclusively used on electro-magnetic wires can be painted either by electrostatic painting or ebullated bed dipping to obtain round wire and lenticular wire in different specifications with solidification temperature 200 DEG C and solidification time 10 to 30 minutes. The coating layer of the painted electro-magnetic wires has semitransparent neat and smooth appearance, excellent flexibility, favorable corner coverage, excellent electroinsulating property and heatproof property, and can meet level 180 electroinsulating property requirement that prescribed in GB6109.

Owner:GUANGZHOU QINGTIAN INDAL

Anticorrosive decorative fluorocarbon paint and preparation method thereof

The invention relates to anticorrosive decorative fluorocarbon paint and a preparation method thereof. The fluorocarbon paint comprises the following components in part by weight: 40 to 55 parts of fluorocarbon resin, 10 to 25 parts of cross-linked resin, 5 to 20 parts of mixed solvent, 3 to 40 percent of pigment, 0 to 5 parts of delustering powder and 0 to 1 part of aid. Compared with the prior art, the fluorocarbon paint has good corrosion resistance and decoration effect.

Owner:DONGLAI COATING TECH SHANGHAI

Processing process of large-diameter anti-static fiber glass epoxy plastic pipeline

ActiveCN102490369ANo decline in physical strength indexAnti-static performance does not decreaseYarnEpoxy

The invention provides a processing process of a large-diameter anti-static fiber glass epoxy plastic pipeline. The process is characterized in that a carbon fiber felt is uniformly wound on a pipeline die, so that the carbon fiber felt is flatly coated on the outer wall of the pipeline die; after the carbon fiber felt is immersed by epoxy resin, fiber glass high-strength yarns and carbon fiber yarns are spirally wound on the pipeline die, and an anti-static high-strength fiber glass epoxy plastic pipeline produced by high-temperature cure heating after the winding is completed; and in the processing process, the carbon fiber inner felt, the high-strength carbon fiber, the fiber glass and imported epoxy resin are used as raw materials, and wounding formation, steam heating by stages and high-temperature inner die curing formation are adopted. The process comprises the following specific steps: preparing materials; winding the carbon fiber felt; adding carbon fibers; heating with steam by stages; curing and forming; and processing and finishing, thus obtaining a finished product pipeline. The pipeline provided by the invention has the advantages that the anti-static performance, the physical strength index of the material and the anti-corrosion index are not reduced at an environmental temperature of minus 40-120 DEG C, and the anti-static, anti-aging and anti-fatigue service life is not lower than 30 years under the condition that the pipeline is exposed in the sea.

Owner:山东欧森管道科技有限公司

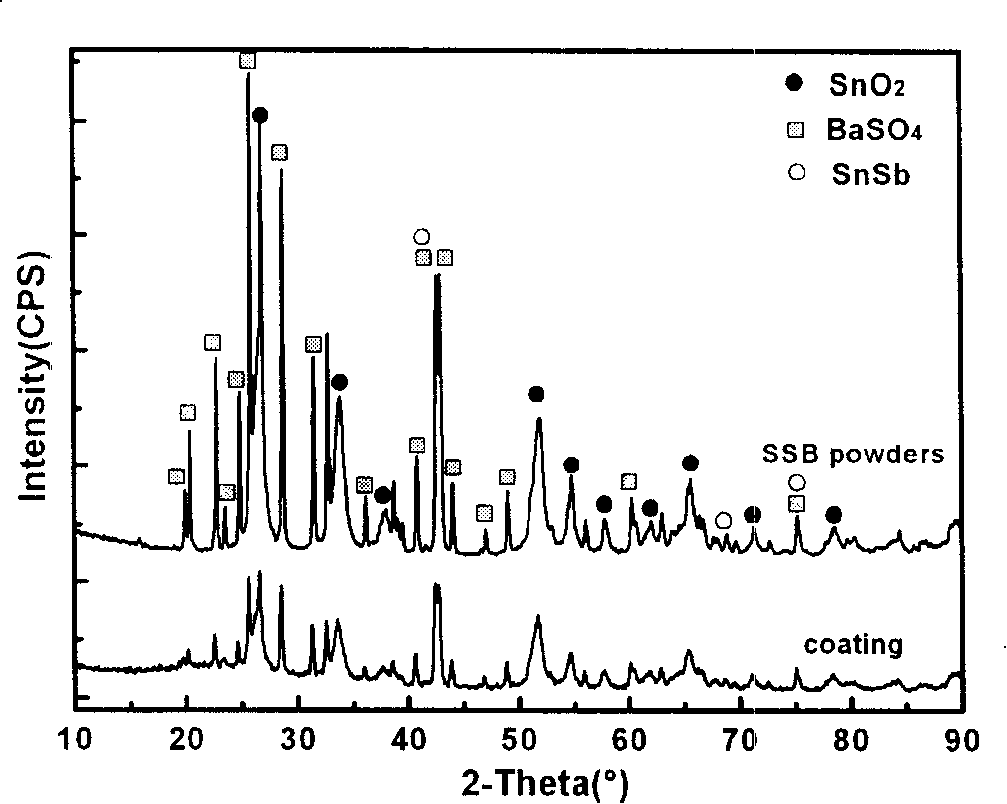

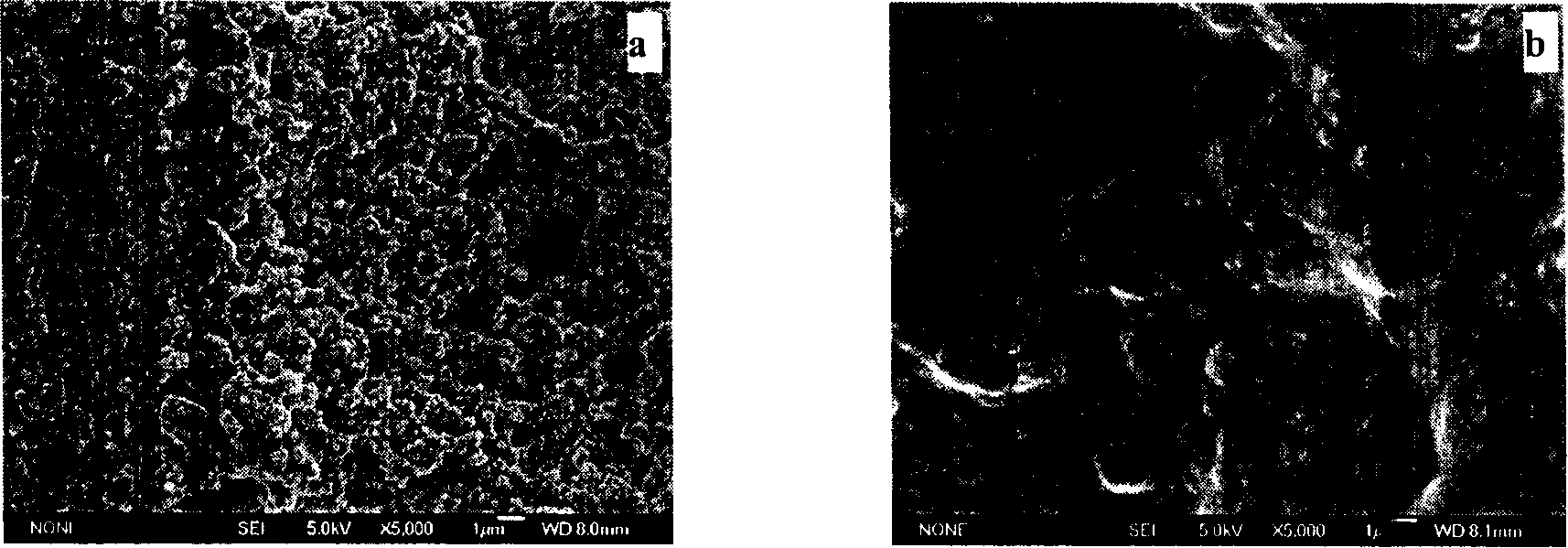

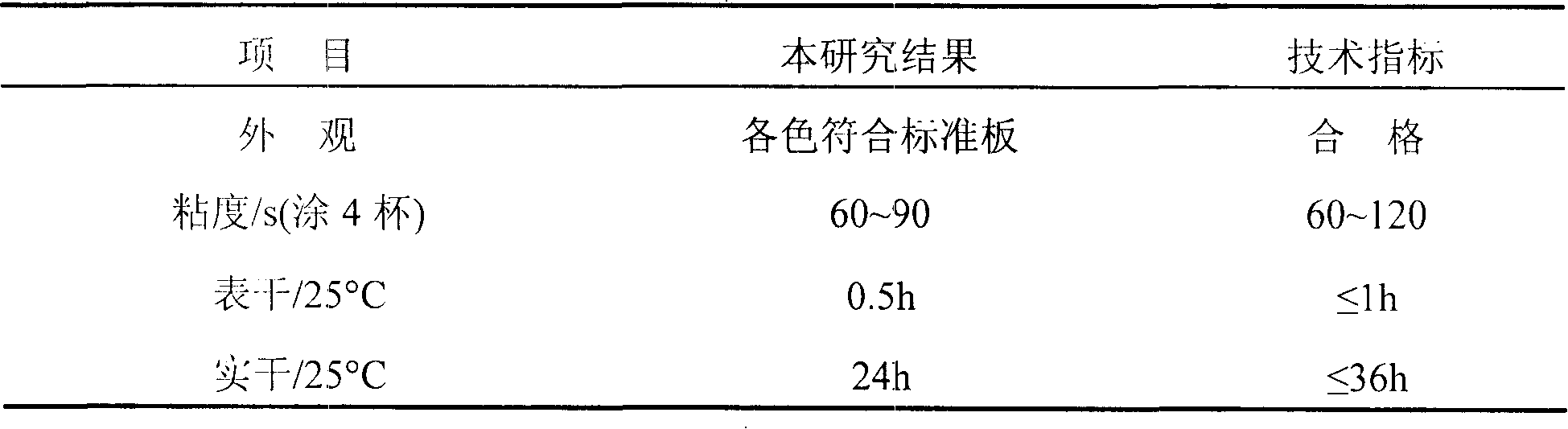

Process for producing composite electrically-conducting paint

InactiveCN101220219AGood dispersionImprove conductivityEpoxy resin coatingsElectrically-conductive paintsCoated surfaceConductive coating

The invention discloses a preparation method of a composite conductive coating. SnCl4.4H2O and SbCl3 are taken as raw materials, high-purity barite is ball milled for 1.5 hours to 7.5 hours; chemical coprecipitation method is adopted for produce a precursor SnO2BaSO4 which is intermingled with Sb; SSB composite conductive power is obtained after being baked for 1.5 hours to 2 hours at a temperature of 600 to 900 DEG C after being dried. The SSB composite conductive power is subject to surface modification with a coupling agent; film forming matter with a weight percentage of 27 to 43 percent and accessory ingredient are dispersed fully; 25 to 45 percent of the SSB composite conductive power with modification surface is added into the disperse system for stirring fully. A diluting agent is put into the mixture for mixing and then the new mixture is sand ground and dispersed for 0.5 hour to 1 hour at a high speed; after the impurity is removed, finished product of conductive coating is obtained. The composite conductive coating prepared by the novel method has the advantages of good constructive property, low sedimentation rate of coating, smooth and plane coating surface and good anti-friction and anti-impact property.

Owner:CENT SOUTH UNIV

Microcellular foam thermoplastic elastomer for high-speed railway damping base plate and preparation method thereof

The invention discloses a microcellular foam thermoplastic elastomer for a high-speed railway damping base plate. The microcellular foam thermoplastic elastomer is prepared from the following raw materials in parts by weight: 20-80 parts of ethylene propylene diene rubber, 20-80 parts of polypropylene, 0.1-10 parts of a crosslinking agent, 0.3-60 parts of a crosslinking catalyst, 0.5-3 parts of a microcellular foaming agent and 1-10 parts of an aid. A molded product in the invention is a closed-pore microcellular foam elastomer product of which the pore diameter is dozens of microns, and has the advantages of smooth and even appearance, independent air bubbles, small foams and no residue of chemical substances. Meanwhile, the weight of the molded product can be reduced by 10-40 percent, absorbed energy can be increased by 3-5 times under the action of impact, and original crack tips can be passivated, so that the toughness of a material is enhanced, fatigue life is prolonged, and the requirements of physical property, elasticity, kinetic energy absorption and the like on the high-speed railway damping base plate can be met.

Owner:宝瑞龙高分子材料(天津)股份有限公司

Corrosion resistant nano coating, corrosion resistant steel and preparation method thereof

ActiveCN1927951AGood coating performanceHigh mechanical strengthRailsCoatingsWeather resistanceUltimate tensile strength

The present invention belongs to the field of iron and steel surface treating technology, and is especially one kind of nanometer anticorrosive paint, its preparation process and steel rail coated with the paint. The nanometer inorganic paint consists of filming material 20-60 wt%, nanometer pigment 3-8 wt%, antirust assistant 5-15 wt%, other assistants 0.025-4 wt%, and deionized water 30-70 wt%. The nanometer inorganic paint has excellent painting performance, high mechanical strength, high anticorrosive performance, high weather resistance, capacity of forming thin smooth coating with certain conducting performance, and other advantages.

Owner:PANZHIHUA IRON AND STEEL

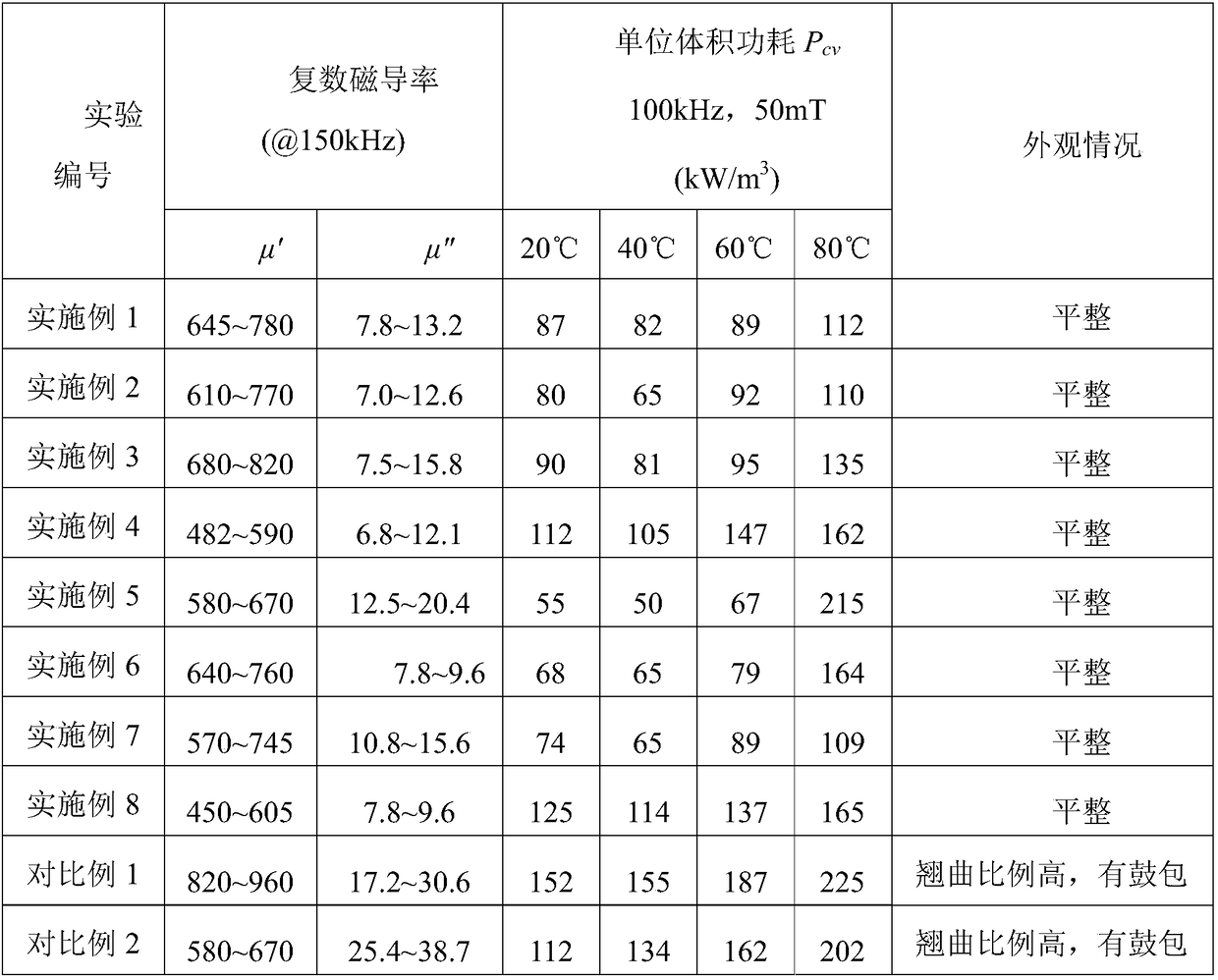

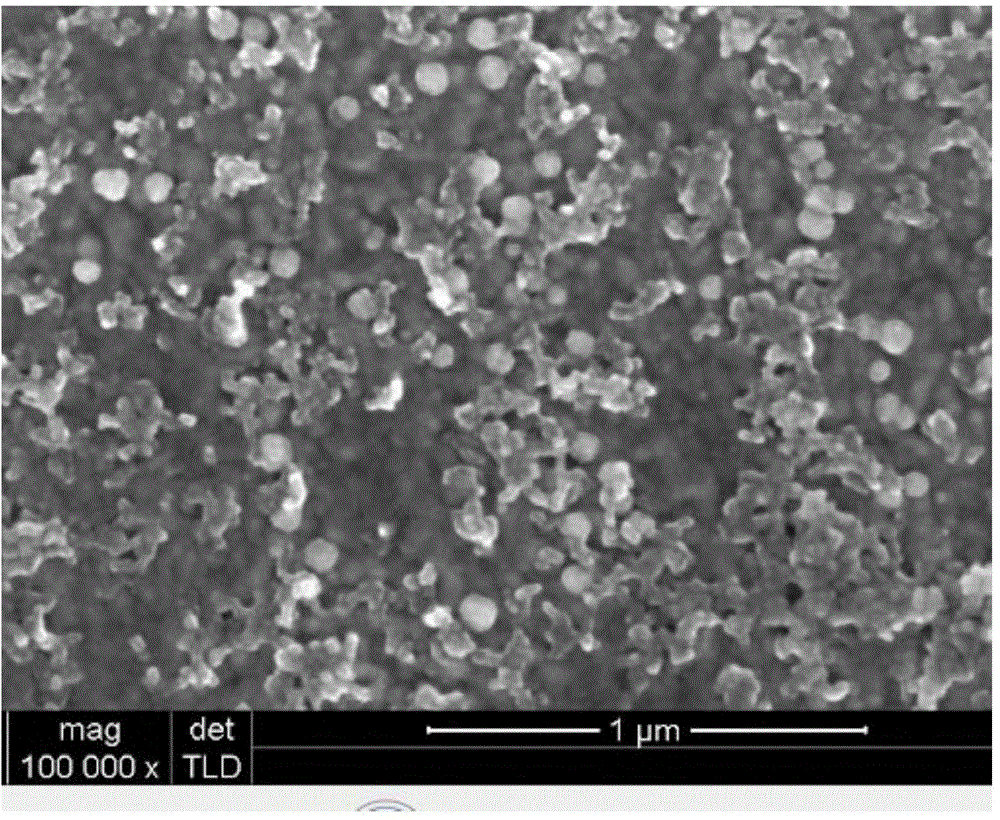

Nickel-zinc soft ferrite for wireless charging and preparation method and application thereof

ActiveCN108164260AImprove the sintering temperature rangeImprove magnetic propertiesInorganic material magnetismShrinkage rateNickel-zinc ferrite

The invention belongs to the field of soft ferrite, and discloses nickel-zinc soft ferrite for wireless charging and a preparation method and application thereof. The ferrite comprises a main component and a doping component, wherein the main component comprises Fe2O3, NiO, ZnO and CuO; the doping component at least comprises one of Nd2O3, Pr6O11, Gd2O3, Dy2O3, Tb2O3, Ho2O3 and Sm2O3; in terms ofthe weight of the main component, the Fe2O3 content of the main component is 64-67wt%, the NiO content thereof is 4-10wt%, the ZnO content thereof is 18-24wt% and the CuO content thereof is 3-9wt%; interms of the weight of the main component, the content of each doping component is 0.02-0.2wt%, and the total addition amount is smaller than or equal to 0.5wt%. Through improvement on the doping component of the nickel-zinc soft ferrite, a thin ferrite magnetic sheet product is sintered densely when T is equal to 0.05-0.2mm, the sintering temperature width is increased, the shrinkage rate is slow during sintering temperature rise, and the appearance is smooth; meanwhile, the power loss per unit volume of the magnetic sheet (power consumption) can be also effectively reduced, the working temperature rise of a wireless charging component can be reduced, and the transmission efficiency can be improved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

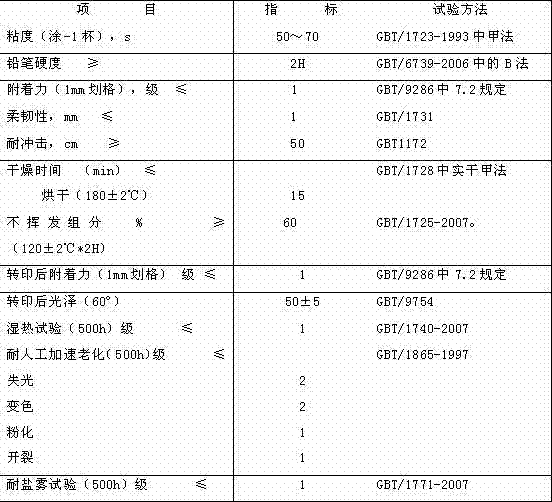

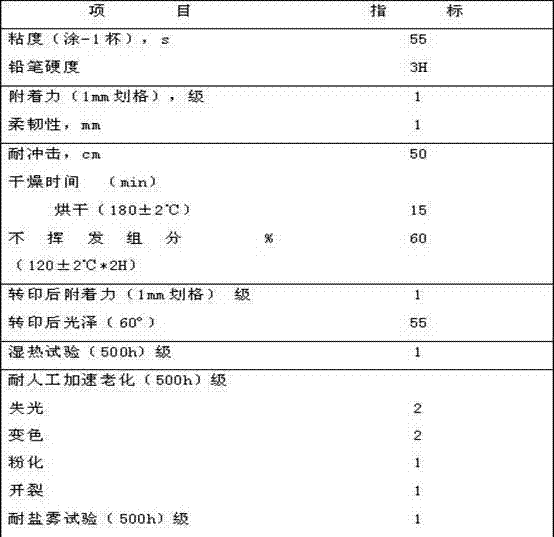

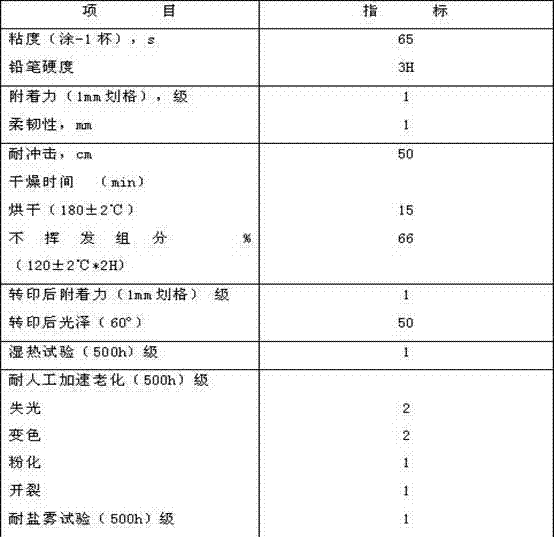

Water-based baking coating for anti-theft door as well as preparation method and application thereof

ActiveCN102492354AMeet environmental protection requirementsGood coating performancePretreated surfacesPolyester coatingsPolymer scienceAcrylic resin

The invention discloses a water-based baking coating for an anti-theft door as well as a preparation method and application thereof. The baking coating comprises the following components in percentage by weight: 30-60% of modified water-soluble polyester resin, 5-30% of special water-soluble acrylic resin, 1-5% of pH regulating aid, 10-30% of amino resin, 1-5% of mixing aid and 10-20% of mixed solvent. The coating disclosed by the invention meets the functional requirements on suitability to the anti-theft door and environment friendliness by crosslinking the modified water-soluble polyester resin, the modified water-soluble acrylic resin and the amino resin and matching with the mixing aid. After the coating is applied to the anti-theft door, the coating effect is good, the appearance is neat and smooth and a vivid effect is achieved; and by the adoption of a spray coating process, the coating is suitable for being applied to various anti-theft doors in various environments under various construction conditions during construction.

Owner:上海华谊涂料有限公司

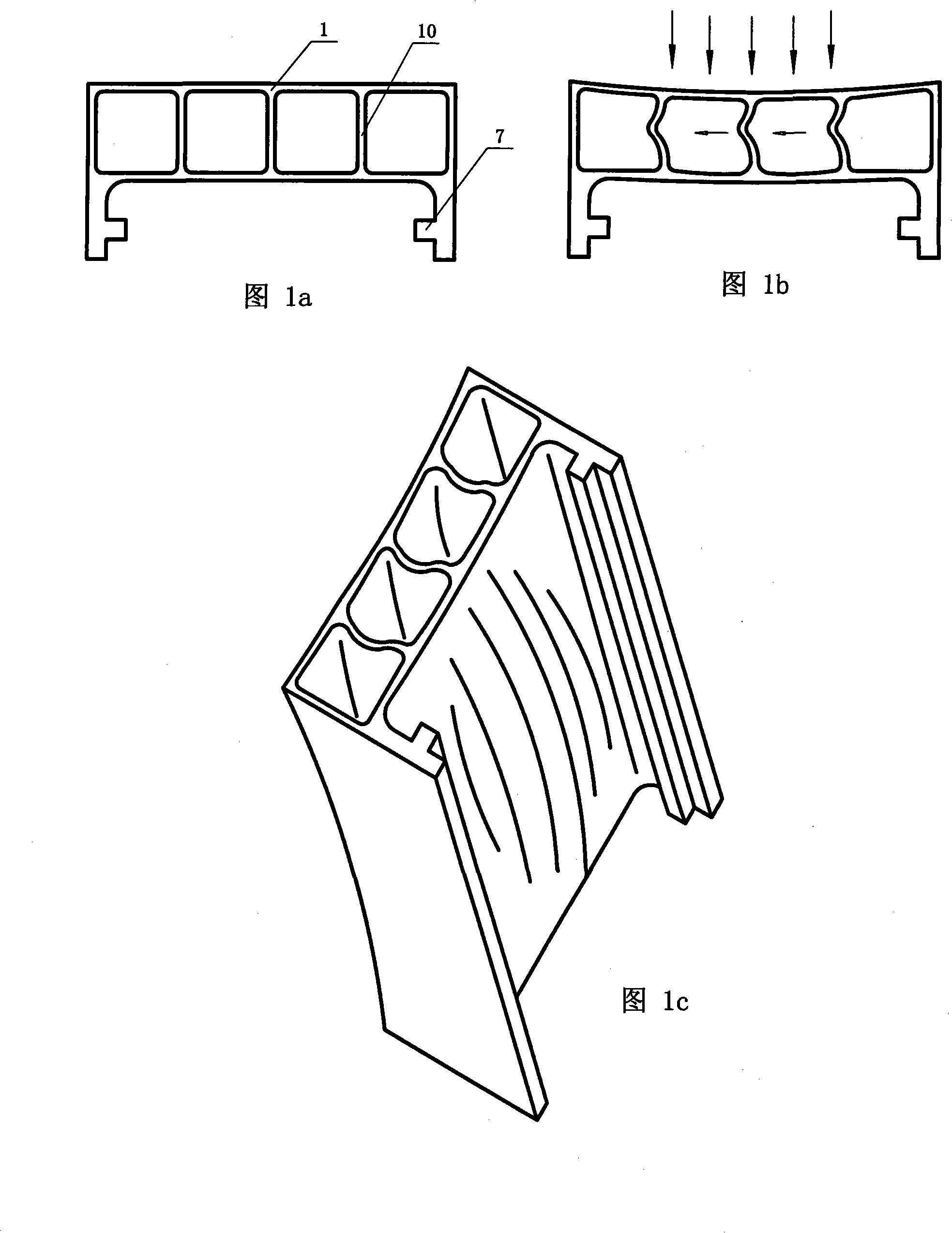

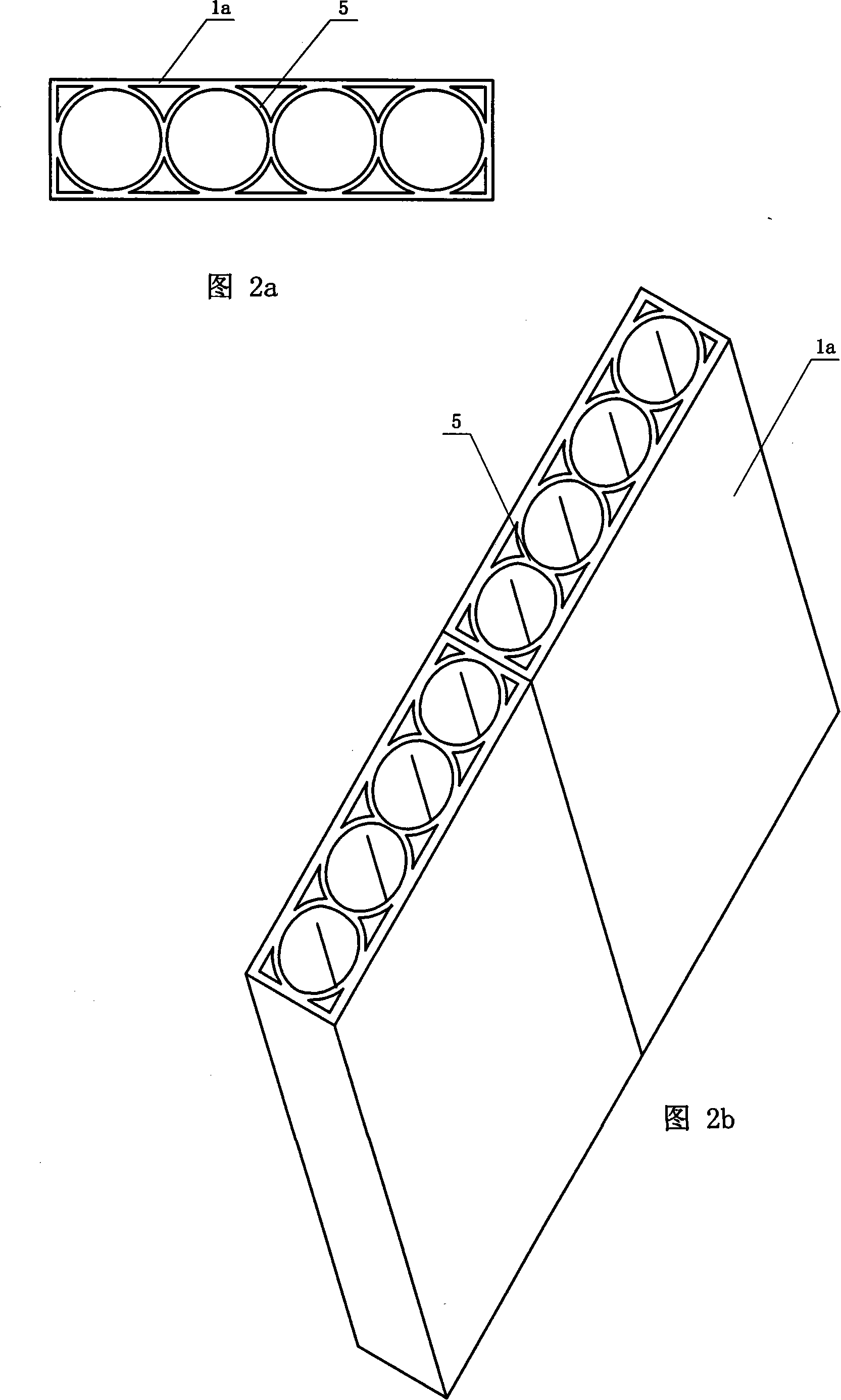

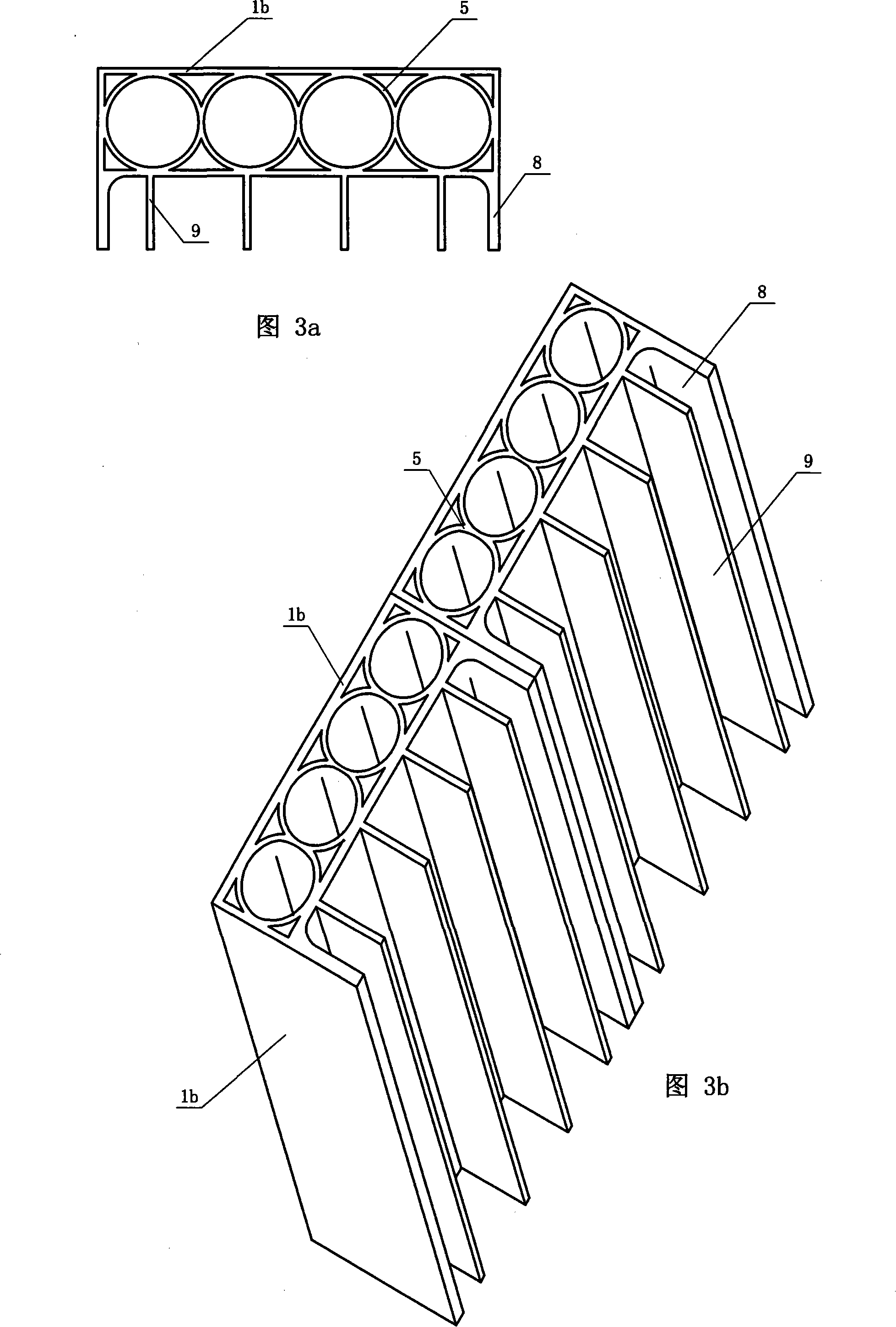

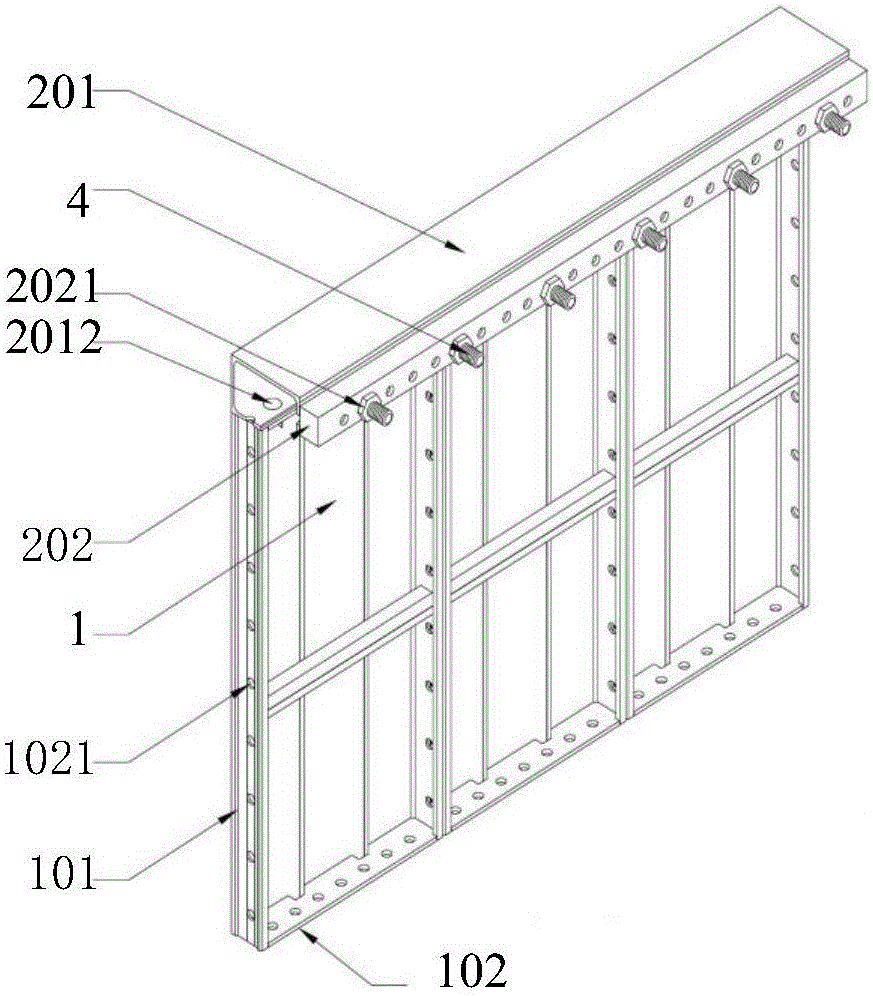

Building combined template

The invention relates to a building modular mould, comprising a hollow box type end-plate enclosed by four sides. Anyone of the following support structural bodies can be chosen in the hollow box type end-plate: a braced girder type support structural body, a support structural body of a hollow connecting multilateral or a combination, a ring or semi-circle ring connecting support structural body and an ellipse ring or semi-ellipse ring connecting support structural body; or a vertical reinforcing plate of a vertical reinforcement is fixed on the lateral face of the hollow box type end-plate; or two-edge vertical reinforcing plate is fixed on the two side edges of the lateral face of the hollow box type end-plate, and a vertical clamping table is arranged on the two-edge vertical reinforcing plate. The invention has the advantages of good integrity, high strength, stable size, high surface hardness, resistance to abrasion, non-deformation, easy rinsing, displacing wood with plastic, heat and cold resistant, anti aging, high degree of finish, repeated turnover of more than 100 times, secondary processing and utilizing, and long practical service life of over fifteen times more than the rubber blanket.

Owner:焦作市柏林建筑模板有限公司

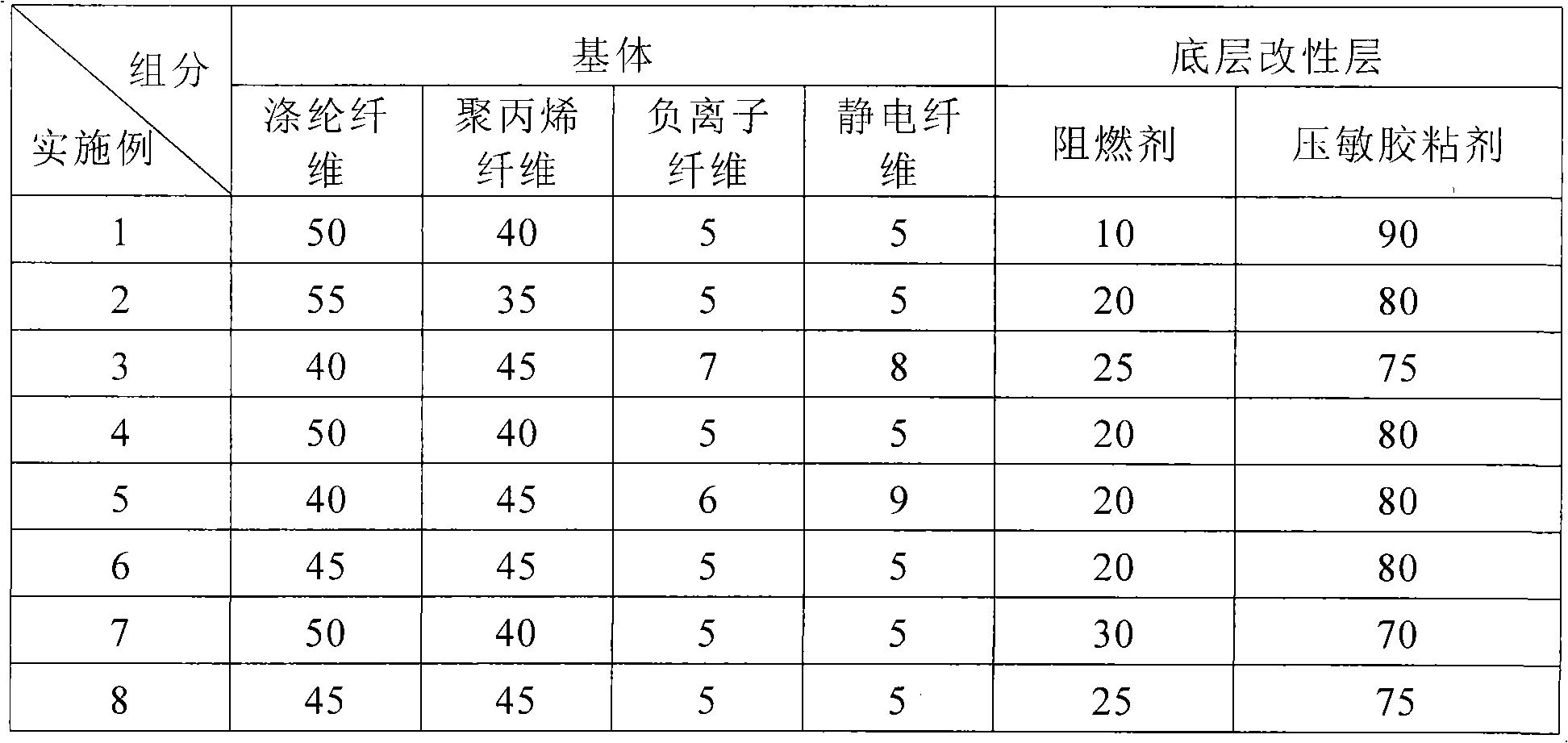

Multifunctional nonwoven material for architecture

InactiveCN101307632AFlat and smooth appearanceGood dimensional stabilityCovering/liningsHeat proofingPolyesterFire resistance

The invention relates to a building multifunctional nonwoven material, which comprises a substrate and a bottom modified layer, wherein, the compositions by mass percentage of the materials of the substrate are: 30 to 70 percent of polyester fibers, 30 to 50 percent of polypropylene fibers, more than 0 percent and less than or equal to 10 percent of negative ion fibers and more than 0 and less than or equal to 10 percent of static fibers; and the bottom modified layer comprises fire retardant. The building multifunctional nonwoven material has the properties of fire resistance, static resistance, heat insulation, sound absorption and friendly environment, and simultaneously is simple and convenient to use, can be cut randomly and can be firmly glued on a metope at any position without the necessity of a constructor. Moreover, the material has beautiful appearance and varied flower patterns and colors and can be used as a novel building decorative material.

Owner:JIAXING UNIV

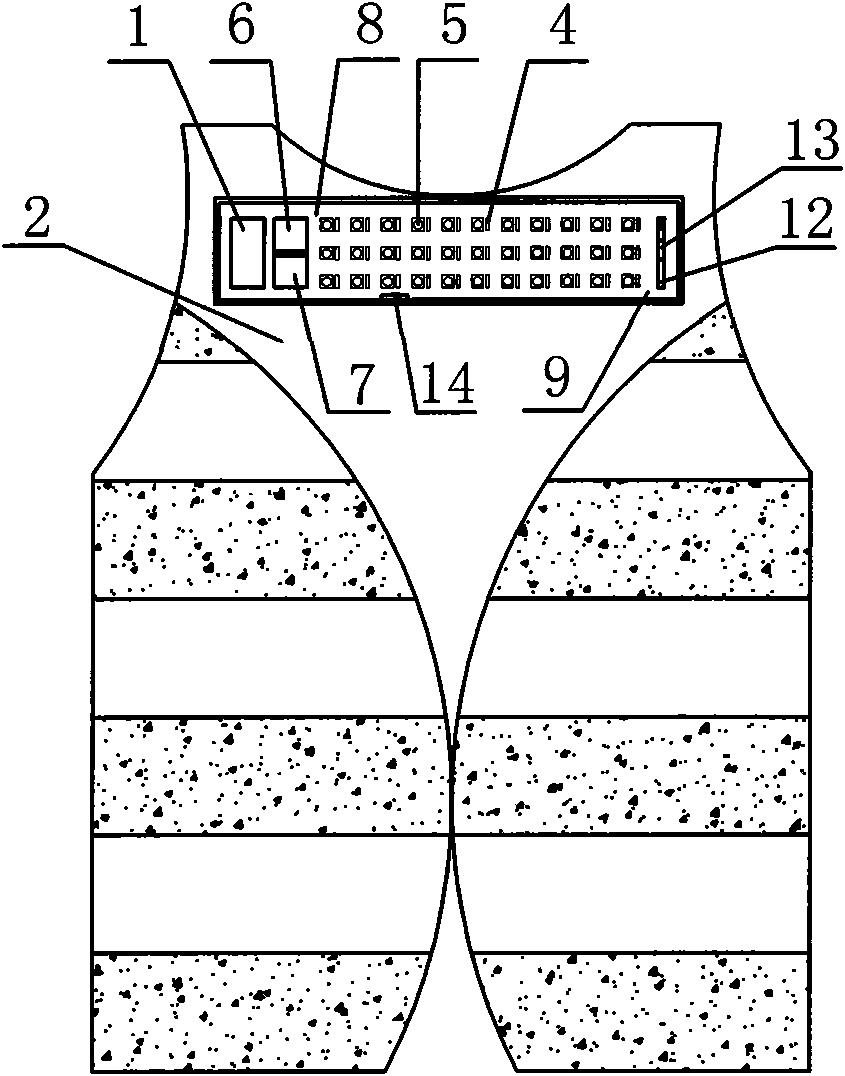

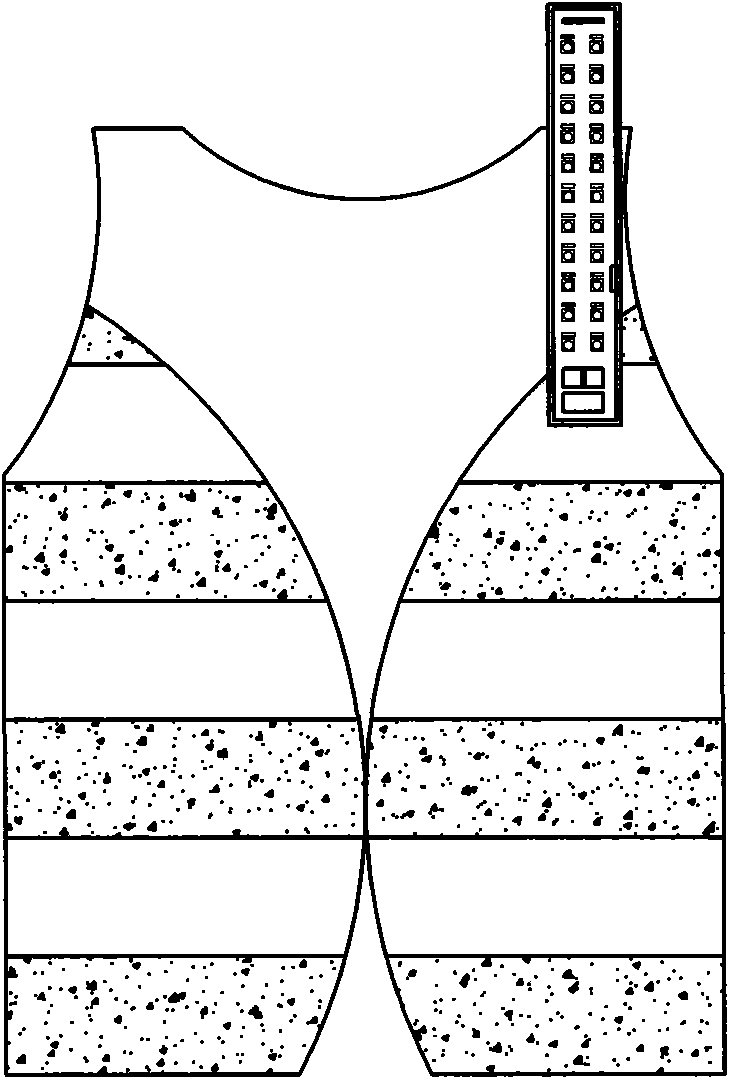

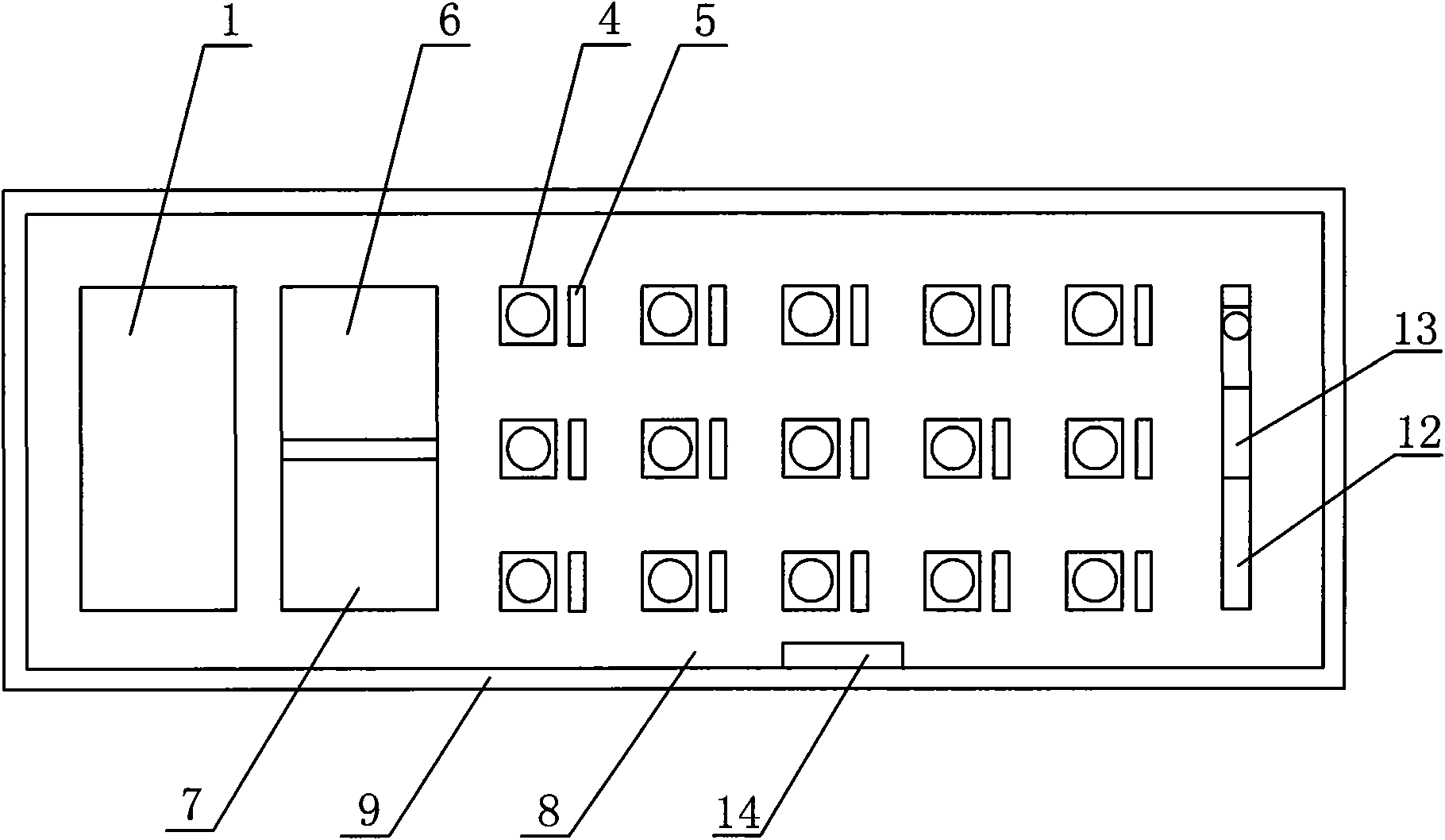

Water life jacket with light-emitting device

InactiveCN101927818AHighly reliable water resistanceFlat and smooth appearanceElectromagnetic wave systemPoint-like light sourceElectrical batteryFlexible circuits

The invention discloses a water life jacket with a light-emitting device, which comprises a life jacket and a light-emitting device fixed on the life jacket. The light-emitting device consists of an internal wireless charging receiving module, a wireless rechargeable battery, a light-emitting diode, a resistor, a light-emitting diode drive circuit, a system control circuit, a flexible circuit board, an externally encapsulated transparent rubber sleeve, a humidity sensor, a touch switch and a wireless positioner, and is externally separated from a wireless power supply module and a power supply; the flexible circuit board is fixedly provided with the wireless chargeable battery, the resistor, and the light-emitting diode which are connected and driven by the light-emitting diode drive circuit and are connected and controlled by the system control circuit; the wireless chargeable battery, the resistor, and the light-emitting diode are connected to form a light-emitting block or a light-emitting rod with a certain shape; the surfaces of the light-emitting block or the light-emitting rod are sealed by the externally encapsulated transparent rubber sleeve; the outside of the externally encapsulated transparent rubber sleeve is provided with the humidity sensor which sends a trigger signal when contacting water to start the system control circuit so as to make the light-emitting device emit light. The water life jacket with the light-emitting device has the advantages of reliable water resistance, convenient charging, small power consumption and long light-emitting time.

Owner:ZUNYI NORMAL COLLEGE

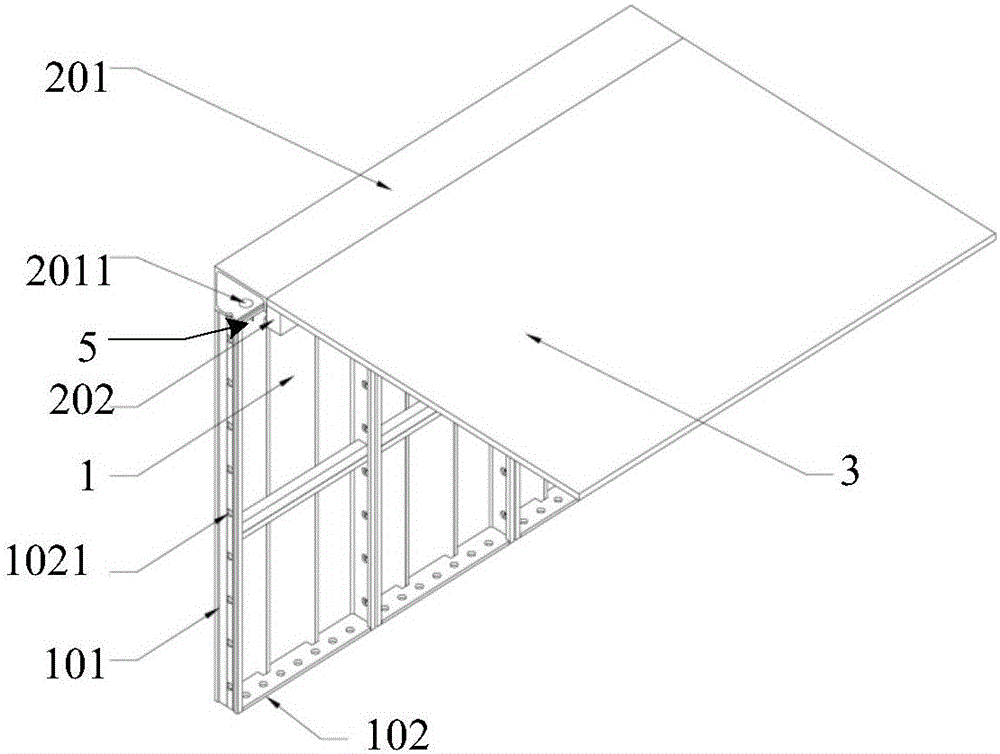

Novel aluminum wood mixed template

ActiveCN105971277AClosely connectedNo slurry leakageAuxillary members of forms/shuttering/falseworksSpecial positionAluminium

The invention discloses a novel aluminum wood mixed template. The novel aluminum wood mixed template comprises an aluminum template body, a wood template body and a connection assembly which is used for connecting the aluminum template body with the wood template body. The aluminum template body and the wood template body are perpendicular to each other. The connection assembly comprises a C-shaped connection plate and a wood beam. The C-shaped connection plate comprises an upper side part, a lower side part, a left side part and a right side part. The left side part and the right side part are located between the upper side part and the lower side part. The left side part is connected with the upper side part and the lower side part perpendicularly. The right side part is connected with the upper side part perpendicularly. The wood beam is fixedly connected with the right side part of the C-shaped connection plate. The aluminum template body is fixedly connected with the lower side part of the C-shaped connection plate through an edge plate on the upper side of the aluminum template body. The wood template body is horizontally fixed to the upper end face of the wood beam, and the left side edge of the wood template body is tightly attached to the right side part of the C-shaped connection plate. The novel aluminum wood mixed template has the advantages of both the aluminum template body and the wood template body. Flexible jointing and conversion of the aluminum template body and the wood template body are ensured. Template erecting in a nonstandard layer and a special position is achieved effectively, and the effect that the condition of slurry leakage of concrete pouring in a joint position does not occur is ensured.

Owner:THE THIRD CONSTR OF CHINA CONSTR FIRST GROUP +1

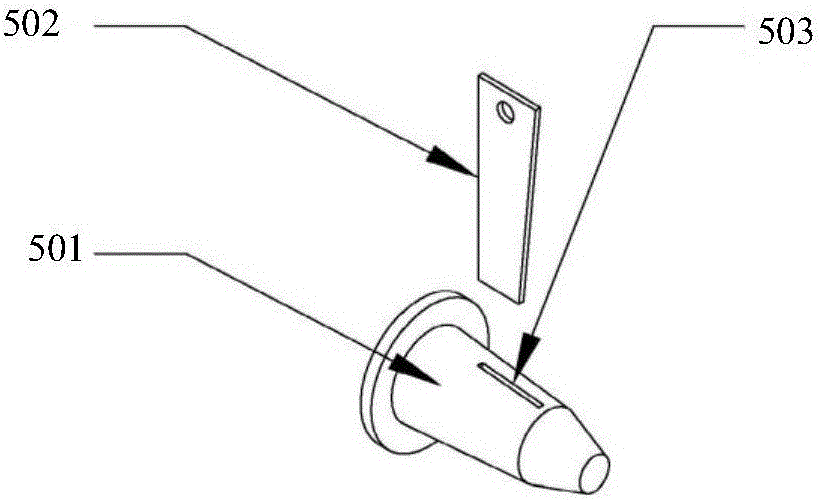

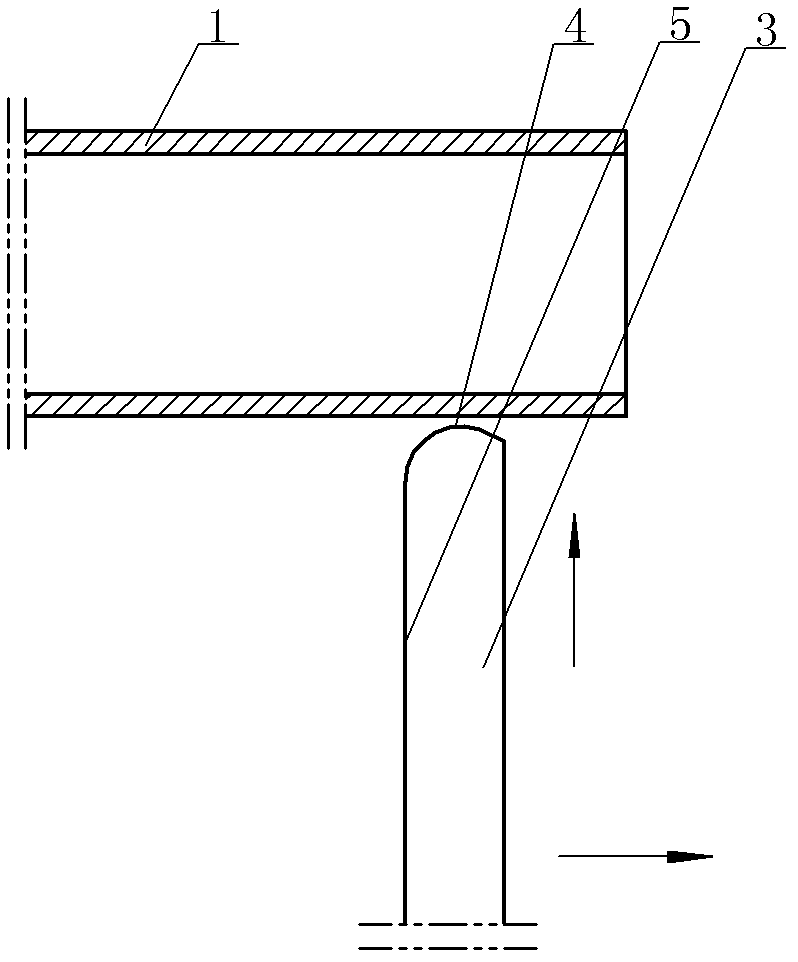

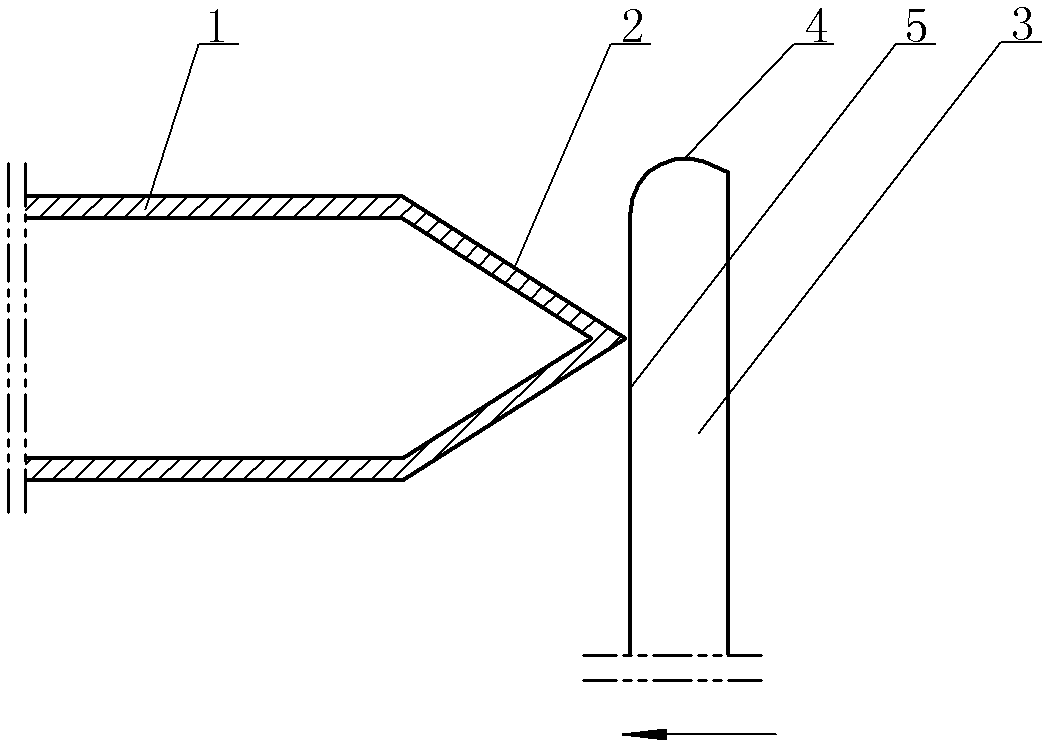

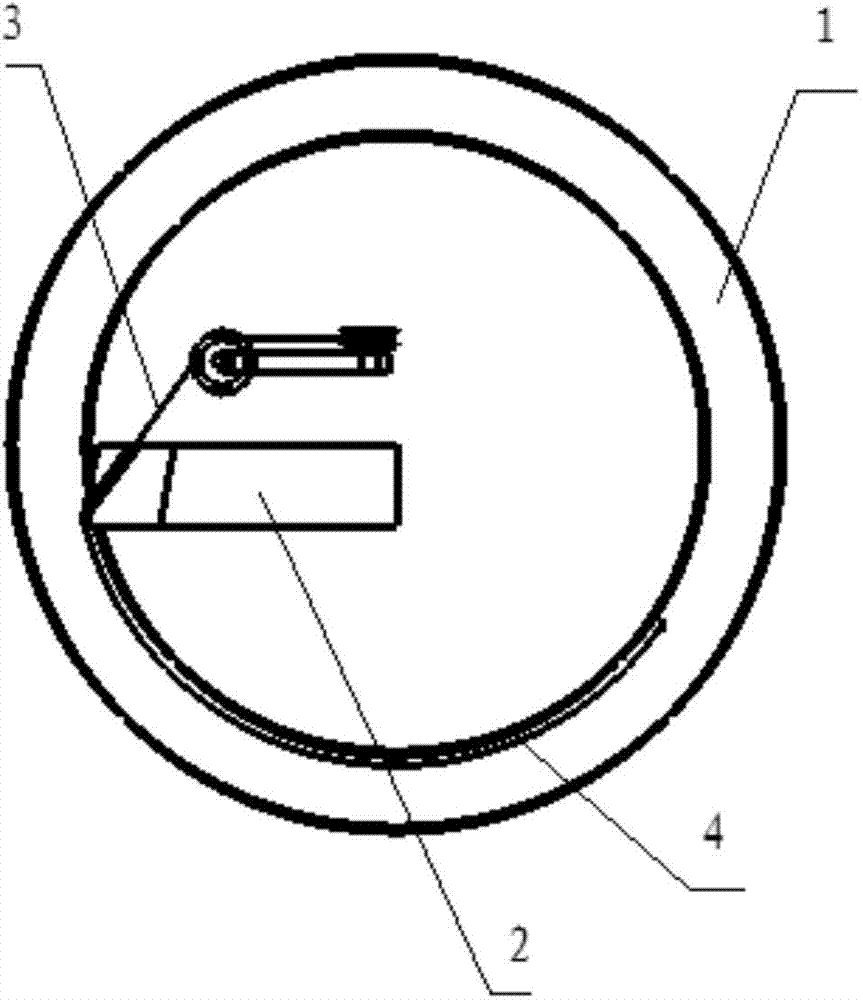

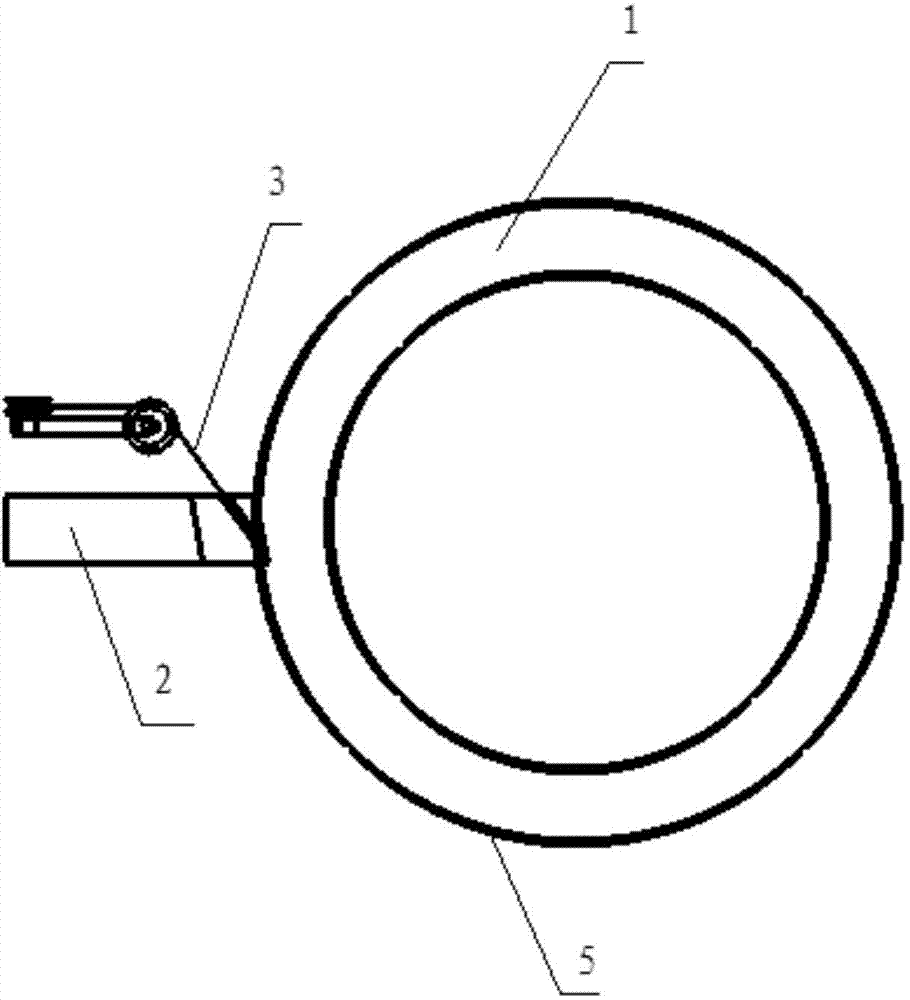

Metal tube seal process

A metal tube seal process mainly resolves the problem that machining stainless steel tubes with large diameters wastes time and energy and is difficult to seal with the existing seal method of a metal pipe fitting port. The metal tube seal process is characterized by including the following process steps: a installing a metal tube (1) in clamping mode in an elastic clamping sleeve capable of rotating on a machine tool; b utilizing a no-cutting-edge tool (3) to extrude a port of the metal tube (1) in high rotation, extruding the port towards the center in the radial direction while moving outwards the no-cutting-edge tool (3) in the axial direction, forming a conical surface and then extruding the conical surface in the axial direction until the port of the metal tube (1) is completely sealed and integrated at a high temperature in melting mode; c utilizing a turning tool to machine the outer end face of the sealed port of the metal tube (1) to be flat. The metal tube seal process changes the previous machining method, achieves sealing the stainless steel tubes with large diameters, saves time and labor, and is simple in working procedures, low in cost, high in machining efficiency and flat and smooth in appearance.

Owner:王平安

Water-based double-component corrosion-resistant industrial paint and production method thereof

The invention discloses a water-based double-component corrosion-resistant industrial paint which is prepared from a component A and a component B. The component A is an acrylic acid epoxy hybrid emulsion prepared by grafting an epoxy group with reaction activity on the acrylic acid main chain, and is 100 parts by weight. The component B is composed of the following components in parts by weight: 20-25 parts of water, 0.1-1.0 part of wetting and dispersing agent, 0.1-0.5 part of defoaming agent, 10-15 parts of antirust pigment, 2-4 parts of functional antirust pigment, 15-25 parts of tinting pigment, 30-35 parts of filler, 8-12 parts of fatty amine curing agent, 1-2 parts of preservative, 0.5-1.0 part of thickener and 0.2-0.5 part of leveling agent. The invention also discloses a production method of the water-based double-component corrosion-resistant industrial paint. The solid content of the water-based double-component corrosion-resistant paint reaches 65% or above, the hardness reaches H, and the adhesion reaches Grade 0. The water-based double-component corrosion-resistant paint can resist water and brine for 7 days, and has favorable solvent resistance and salt spray resistance. The VOC (volatile organic compound) content is less than 50g / l.

Owner:福建百花化学股份有限公司

Pipeline hot melting wire arrangement method

InactiveCN103672276AWill not cause difficultyEasy to operatePipe connection arrangementsSurface layerEngineering

The invention relates to a pipeline hot melting wire arrangement method. The method includes the following steps of embedding metal wires under plastic surface layers in the inner diameter direction or the outer diameter direction of the two ends of a plastic tube and distributing the metal wires in an area to be welded according to the corresponding wire arrangement screw pitch through a wire arrangement knife in the area to be welded of the plastic tube, reserving one section of each end of each metal wire to be exposed out of the corresponding plastic surface layer, and conducting welding after the metal wires are well distributed, and cutting off the sections, exposed out of the plastic surface layers of the plastic tube, of the two ends of each metal wire after the welding is completed. The method is easy and rapid to operate, short in welding time, low in construction cost, level and smooth in appearance after welding and good in welding effect. Even when broken wires exist in the wire arrangement process, the metal wires which have been already embedded can be easily drawn out through the reserved wire heads, the wires can be arranged again, and the difficulty of recovering and separating the metal wires can not occur.

Owner:TIANJIN QINGTAI HOISTING EQUIP

Ropivacaine nano particle, preparation method thereof and optimizing experimental method of effect of the ropivacaine nano particle

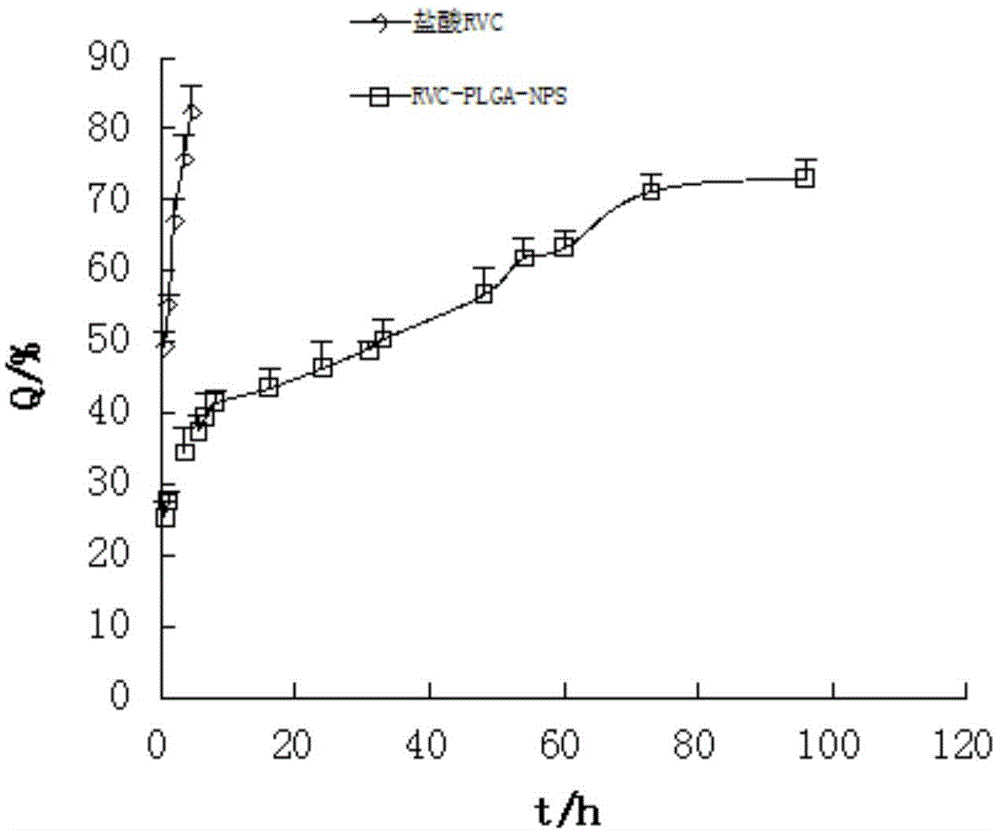

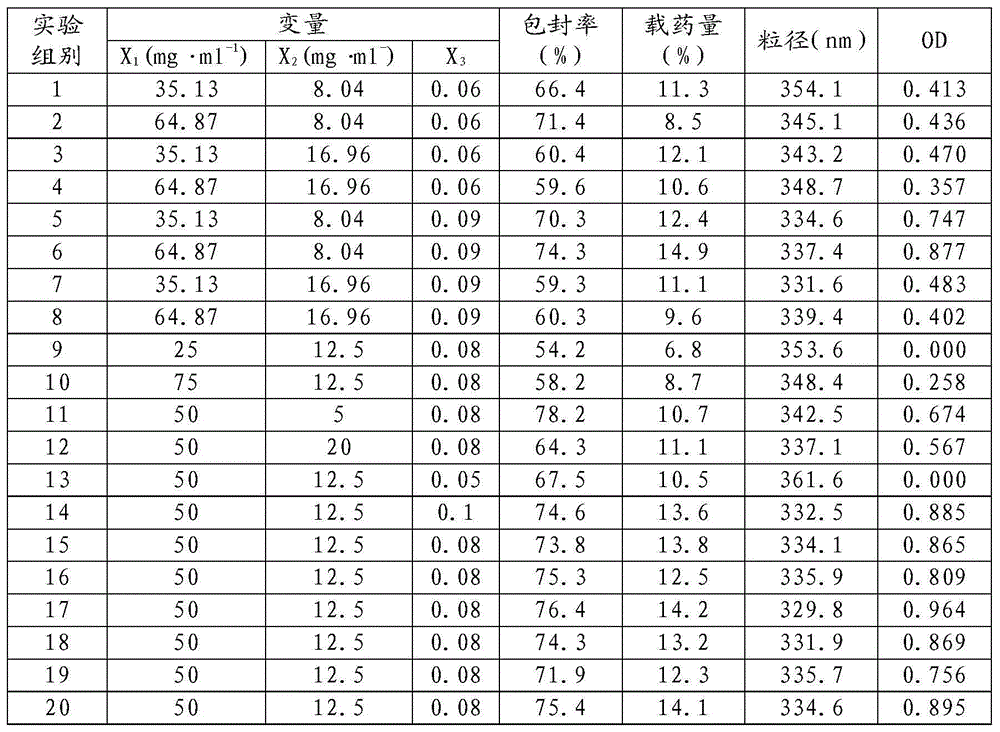

ActiveCN104146972AAvoid damageHigh encapsulation efficiencyPowder deliveryAnaestheticsFreeze-dryingPolyvinyl alcohol

The invention relates to the field of preparation of medicines and particularly relates to ropivacaine nano particles, a preparation method thereof and an optimizing experimental method of effects of the ropivacaine nano particles. The preparation method comprises following steps: (A) dissolving ropivacaine free alkali and polylactic acid-polyglycollic acid segmented copolymer in dichloromethane to form an organic phase while a polyvinyl alcohol solution is employed as an aqueous phase; (B) performing evaporation to a white emulsion at 30-40 DEG C to remove the organic phase to obtain a pale blue opalescence suspension liquid; and (C) performing centrifugal separation to the pale blue opalescence suspension liquid to obtain a precipitate, washing the precipitate, and performing ultrasonic dispersion and a vacuum freeze-drying process to obtain the ropivacaine nano particles. By means of the prepration method of the ropivacaine nano particles, an in-vitro releasing research proves that the ropivacaine nano particles has a releasing rate being about 73% in 96 h, a slow-releasing effect is quite good and a pain-relieving requirement on acute pains, such as post-operation pain and the like, can be satisfied just through one-time dosing.

Owner:FUZHOU GENERAL HOSPITAL OF NANJING MILITARY COMMAND P L A

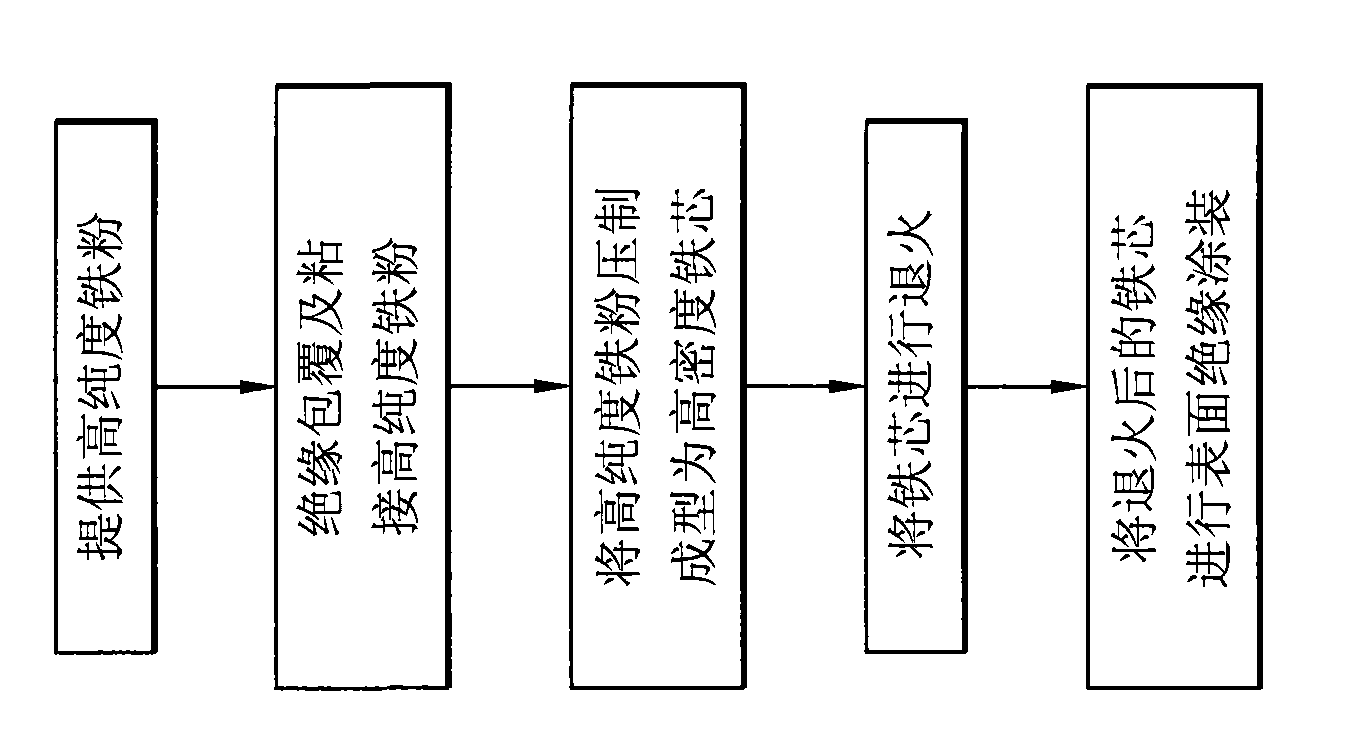

Method for manufacturing iron core and iron core product

InactiveCN101604885AFlat and smooth appearanceReduce eddy current lossManufacturing dynamo-electric machinesAdhesiveVolumetric Mass Density

The invention relates to a method for manufacturing an iron core, comprising the following steps: firstly, providing high-purity iron powder with the iron content of above 99 percent (weight); coating and splicing the high-purity iron powder with high temperature resistant isolating adhesive in an insulating mode; molding the high-purity iron powder into a high-intensity iron core; annealing the iron core; and coating the surface of the annealed iron core in an insulating mode. Therefore, the high-purity iron powder has excellent performances of high fill density, excellent liquidity and large compression. The eddy current loss of the iron core is less than that of the iron core of traditional silicon-steel plates, and the iron core can replace the prior iron core in both performance and cost at high-frequency environment, thereby satisfying the using requirement of motors and ensuring energy-saving effect. The invention also provides an iron core product.

Owner:乔智电子股份有限公司

Film blow molding device and liquid crystal polymer film manufactured by same

The invention provides a film blow molding device and a liquid crystal polymer film manufactured by the same, and relates to the technical field of blow molding processes. The film blow molding device comprises a blow molding unit, a traction adjusting unit and an annealing unit. The blow molding unit comprises a heat preservation box body, and an annular mold head, a heat preservation blow molding air ring and a sizing heat preservation cylinder are sequentially and coaxially arranged in the heat preservation box body from bottom to top; and meanwhile, the traction adjusting unit is arranged on the blow molding unit, and the traction adjusting unit pulls film bubbles obtained through blow molding to the annealing unit through an annular opening formed in the upper portion of the heat preservation box body. Therefore, by means of the film blow molding device, the film blow molding process can be conducted under the heat preservation condition, the cooling and curing speed of a liquid crystal polymer blank film is effectively reduced, and the problems that when a liquid crystal polymer film is blown through an existing preparation method, the film is prone to being broken in the blowing process, the thickness is uneven, and the MD / TD anisotropy of the film is serious are solved.

Owner:NINGBO CHANGYANG TECH

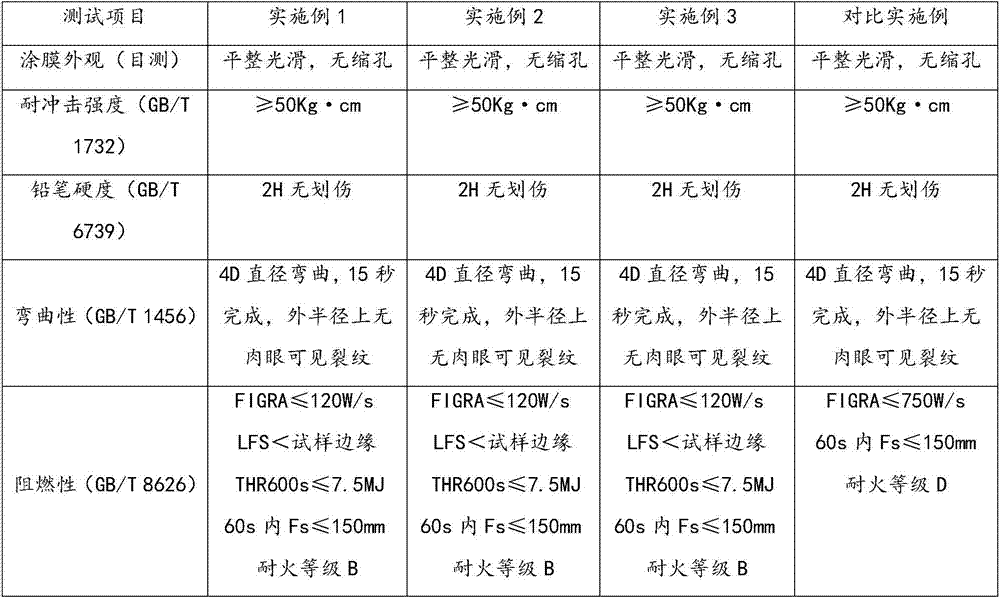

Hydroxyalkylamide-cured outdoor type flame retardant powder coating

InactiveCN107141980ALow thermal conductivityDelayed transmissionFireproof paintsPowdery paintsAbsorption capacityAntimony trioxide

The invention discloses hydroxyalkylamide-cured outdoor type flame retardant powder coating which is prepared from the following components in parts by mass: 65 parts of outdoor polyester resin, 4 parts of a hydroxyalkylamide curing agent, 2 parts of a smooth degassing agent, 2 parts of a leveling agent, 5-10 parts of a compound flame retardant and 17-22 parts of pigments and fillers, wherein the compound flame retardant is prepared from the following raw materials in parts by weight: 5 parts of aluminum hydroxide, 5 parts of magnesium hydroxide, 16 parts of zinc borate, 32 parts of barium borate, 6 parts of antimony trioxide and 36 parts of diatom mud. The powder coating provided by the invention adopts the self-made compound flame retardant, so that the obtained coating has low thermal conductivity, can reduce the speed of heat transfer to a protected substrate, can also effectively isolate oxygen, increases heat absorption capacity, has excellent flame retardancy, and does not affect coating leveling, weather resistance, impact resistance and other properties.

Owner:六安捷通达新材料有限公司

Method for producing hot-box resin for casting

The invention relates to a method for producing hot-box resin for casting. The method comprises the following steps of heating to melt and dissolve phenol, adding into a reaction kettle, and starting a stirrer; sequentially adding a formaldehyde aqueous solution and furfuryl alcohol; adjusting the pH value of the feed liquid to 9-10 by use of alkaline liquid; opening a steam valve, heating and timing for heat preservation; further adding 1 / 2 of the alkaline liquid, and timing for heat preservation for 30 minutes; after the heat preservation, cooling to 80 DEG C, adjusting the pH value to 4.5-5.5 by use of formic acid, and performing vacuum dehydration; adding urea, heating to 90-95 DEG C, and timing for heat preservation for 60 minutes; cooling to 70 DEG C, adding furfuryl alcohol and a modifier, and stirring; cooling to 40 DEG C, adding a reinforcing agent, and adding an aqueous solution of sodium hydroxide to adjust the pH value to 7-8; and continuously stirring for 15 minutes, discharging, packaging and storing. The method provided by the invention has the advantages of uniqueness, low gas generation, low free aldehyde content, high strength and good moisture resistance, and is suitable for medium and small sand cores.

Owner:KOCEL GROUP +1

Novel insulating paint for ballast and preparation method of insulating paint

The invention discloses novel insulating paint for ballast and a preparation method of the insulating paint. The insulating paint contains the components in percentage by weight: 40-60% of resin, 7-11% of xylene, 10-15% of mixed dibasic ester solvent, 20-30% of novel titanium white, 1.9-2.2% of curing agent and 1.1-1.8% of adjuvants. The preparation method comprises the following steps: (a) grinding paint; and (b) preparing paint. According to the novel insulating paint for the ballast and the preparation method of the insulating paint, disclosed by the invention, the insulating paint is excellent in performance, has strong adhesive power and good rust resistance and can enable the ballast to have a flat, smooth and non-yellowing appearance after paint dipping; the preparation method is simple and convenient and meets the process requirements on one-dipping and one-baking, and thus, the production efficiency can be doubled.

Owner:KUNSHAN FENFA INSULATING MATERIALS

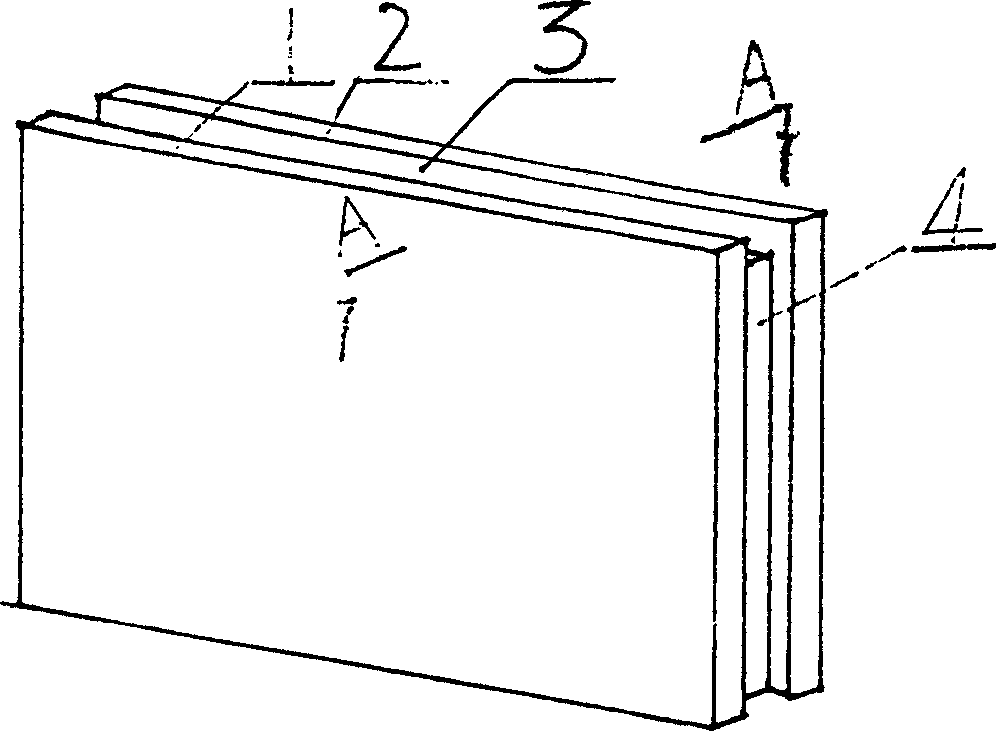

Light-weight small building block as sandwich of wall and its production method

InactiveCN1181250CHigh strengthImprove seismic performanceConstruction materialCeramic shaping apparatusReinforced concreteSandwich board

Owner:李顺安 +2

High-performance polyester resin powder coating and preparation method thereof

InactiveCN107880743AGood weather resistanceFlat and smooth appearancePowdery paintsPolyester coatingsRutileBinding force

The invention provides a high-performance polyester resin powder coating. The coating is prepared from, by weight, 35-45 parts of polyester resin, 10-20 parts of triglycidyl isocyanurate, 10-20 partsof rutile type titanium dioxide, 10-20 parts of barium sulfate, 5-15 parts of calcium carbonate, 1-5 parts of flow smoothing agent and 1-5 parts of 1.0% silane coupling agent. According to the high-performance polyester resin powder coating, the polyester resin is used as a raw material basis, auxiliary materials such as curing agent, pigments, padding and addition agent are added, the polyester resin powder coating is prepared through scientific and reasonable matching. The invention further provides a preparation method of the powder coating. The method is simple and easy to implement, the prepared powder coating is smooth and flat in appearance, high in binding force with basic materials, resistant to impact, resistant to scratch, good in anti-bending performance and excellent in weather resistance, and the high-performance powder coating meets multi-aspect requirements of the market.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Sliding plate lubricant and preparation method thereof

InactiveCN104232284ASuspension stabilityEasy chimerismThickenersAdditivesSodium BentoniteBoron carbide

The invention discloses a sliding plate lubricant coating sliding plates of a sliding gate system of a steel ladle and a tundish to reduce the friction coefficient between the sliding plates. The sliding plate lubricant comprises the following components in parts by weight: 2-4 parts of xanthan gum, 2-4 parts of guar gum, 0.1-0.5 part of sodium polyacrylate, 2-5 parts of styrene-acrylic emulsion, 85-90 parts of water, 0.5-1 part of sodium bentonite, 0.1-0.5 part of tween, 5-10 parts of sodium silicate, 5-10 parts of potassium silicate, 5-10 parts of sodium dihydrogen phosphate, 5-10 parts of carbon black, 0.1-0.5 part of isothiazolinone, 2-5 parts of boron carbide and 25-35 parts of crystalline flake graphite. The sliding plate lubricant is prepared by stirring and ball-milling. The sliding lubrication and the high-temperature oxidation resistance of the sliding plates can be improved by virtue of the sliding plate lubricant.

Owner:泰州优耐特新材料有限公司

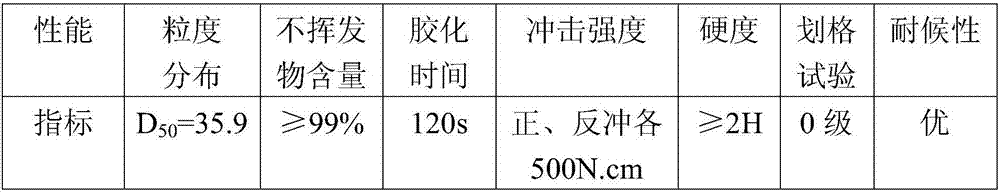

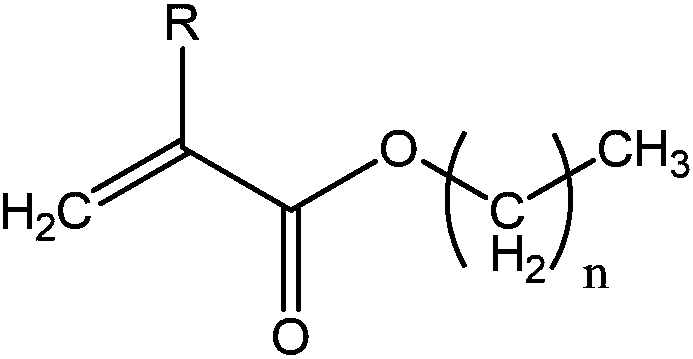

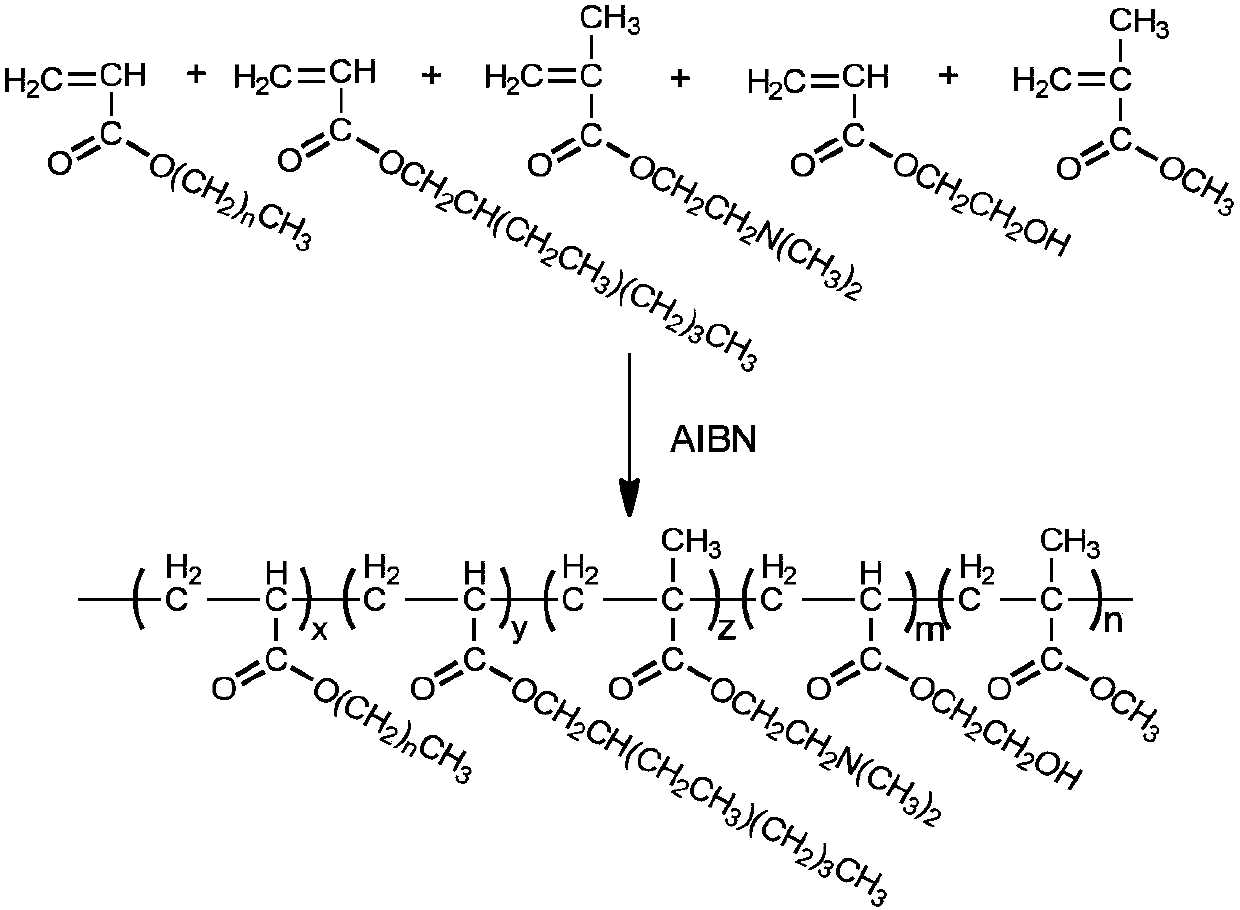

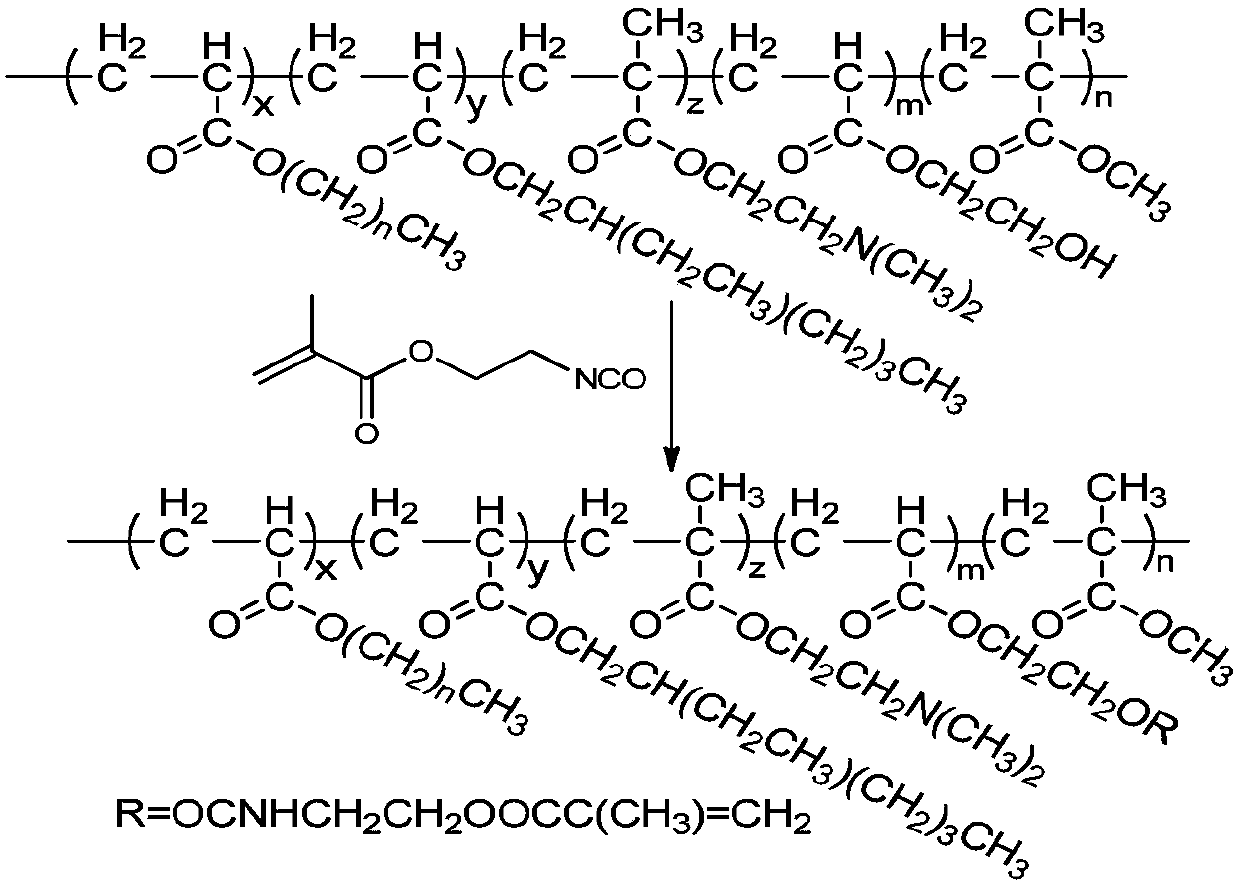

Ultraviolet curing long-alkyl-side-chain-containing acrylate electrophoretic paint, a preparing method thereof and applications of the paint

ActiveCN107746444AFlat and smooth appearanceHigh glossAnti-corrosive paintsPaints for electrolytic applicationsUltravioletUltraviolet radiation

The invention relates to ultraviolet curing long-alkyl-side-chain-containing acrylate electrophoretic paint, a preparing method thereof and applications of the paint. The waterborne acrylate electrophoretic paint comprises hydrophobic long alkyl side chains. The hydrophobic long alkyl side chains are provided by a long-chain alkyl (meth)acrylate monomer. The paint prepared by the method is particularly suitable for thermally sensitive matrixes having low requirements on curing temperature. Paint film formed by ultraviolet radiation curing contains hydrophobic long alkyl side chain units, and has good surface waterproof, corrosion resistant and decoration functions. The paint can be applied in the fields of surface waterproofing, corrosion preventing and decoration of metal workpieces, suchas hardware, bicycles and automobiles.

Owner:SOUTH CHINA UNIV OF TECH

New technique of wrapping and sulfurizing rubber hose

A winding technology for sulfurizing rubber pipe features that the polyester film instead of fabric is used as the external pressing material when the rubber pipe is sulfurized. Said polyester fiml is prepared from poly-terephthalate through drying, fusing while extruding out, bidirectionally drawing and heating treating. The finished rubber pipe has high compactness and smooth external surface.

Owner:上海华瑞橡胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com