Metal tube seal process

A metal tube and process technology, applied in the field of metal tube sealing technology, can solve the problems of time-consuming, laborious, difficult sealing, etc., and achieve the effects of simple process, low cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

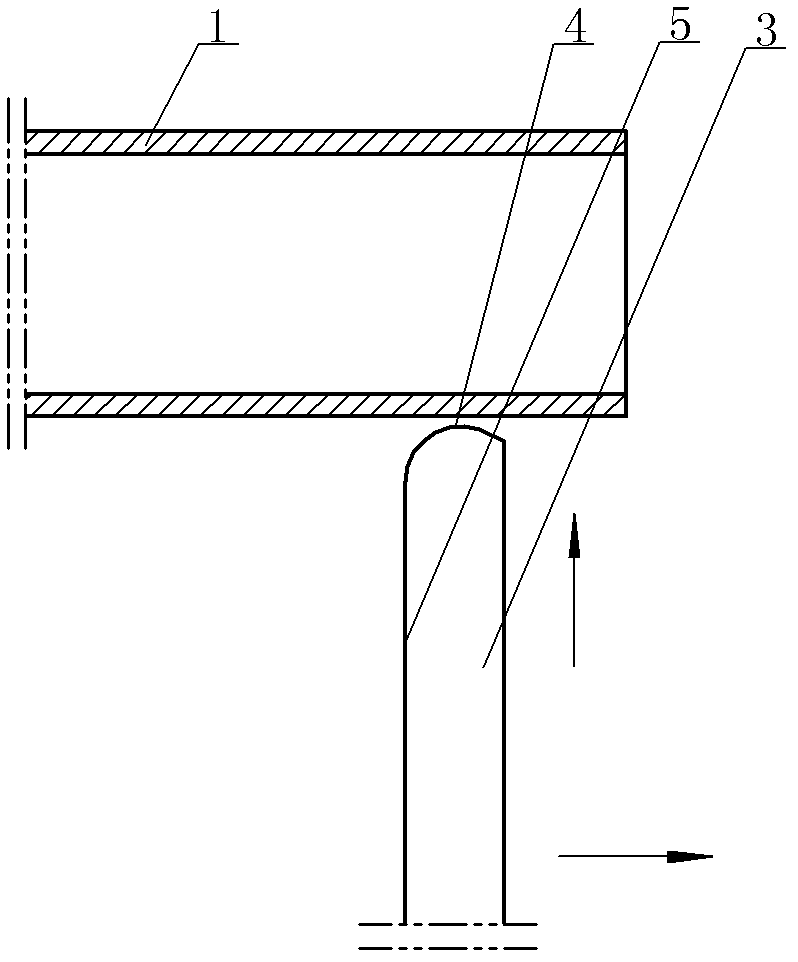

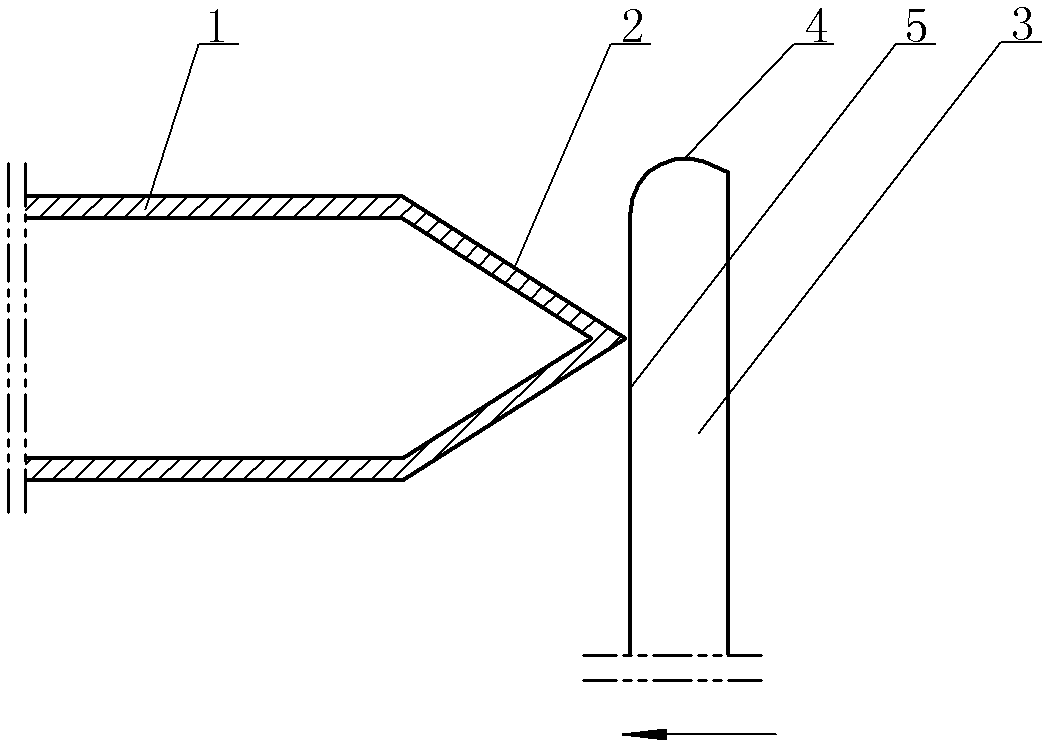

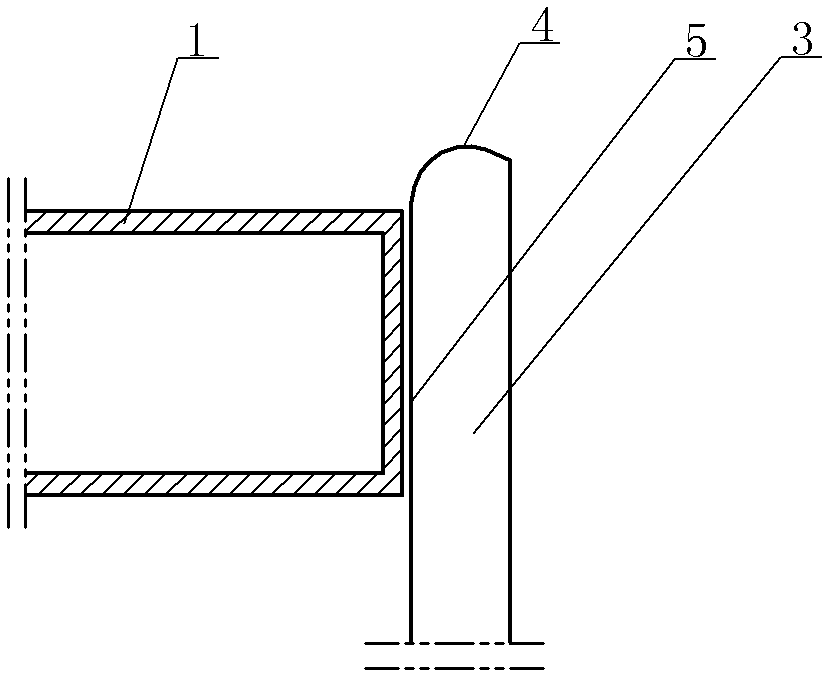

[0015] Depend on figure 1 combine figure 2 , image 3 As shown, the metal tube sealing process steps are as follows:

[0016] a. Clamp the metal pipe 1 in a rotatable elastic jacket on the machine tool;

[0017] b. Using a bladeless cutter 3 with a front end extrusion surface 4 and a side extrusion surface 5, using the front end extrusion surface 4 of the bladeless cutter 3 to radially extrude the high-speed rotating metal pipe 1 toward the center of the metal pipe 1, and At the same time, the bladeless cutter 3 is moved axially toward the outer end of the port of the metal pipe 1, and the heat generated by the friction between the metal pipe 1 and the bladeless cutter 3 softens the port of the metal pipe 1, and the port of the metal pipe 1 gradually moves toward its center. Deformation to form a conical surface 2; use the side of the edgeless tool 3 to squeeze the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com