Ultraviolet curing long-alkyl-side-chain-containing acrylate electrophoretic paint, a preparing method thereof and applications of the paint

An acrylate and electrophoretic coating technology, applied in electrophoretic coatings, anti-corrosion coatings, coatings, etc., can solve problems such as poor water resistance, and achieve high gloss, excellent water and alkali resistance, and smooth appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

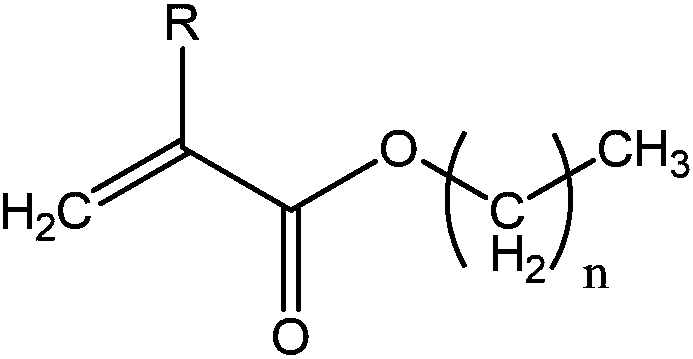

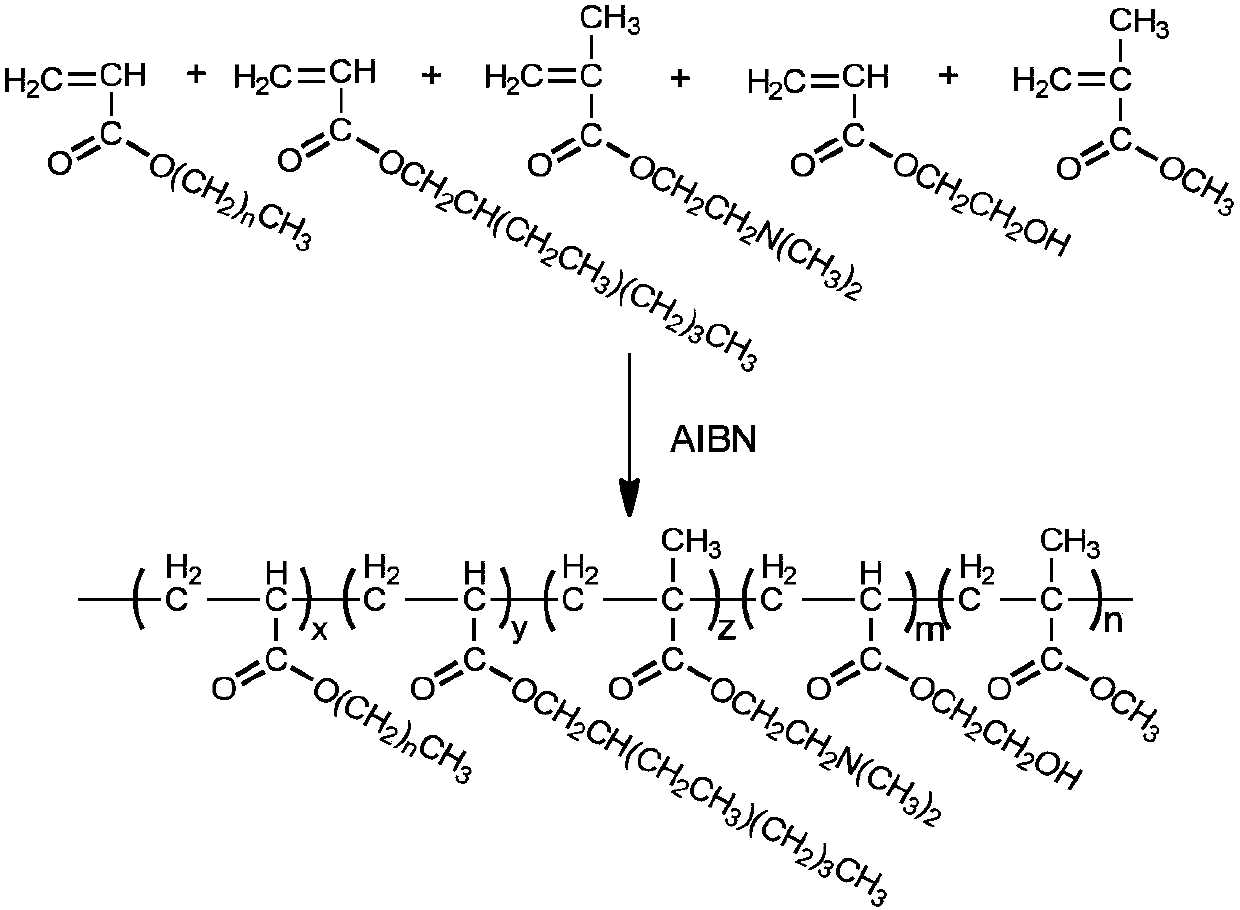

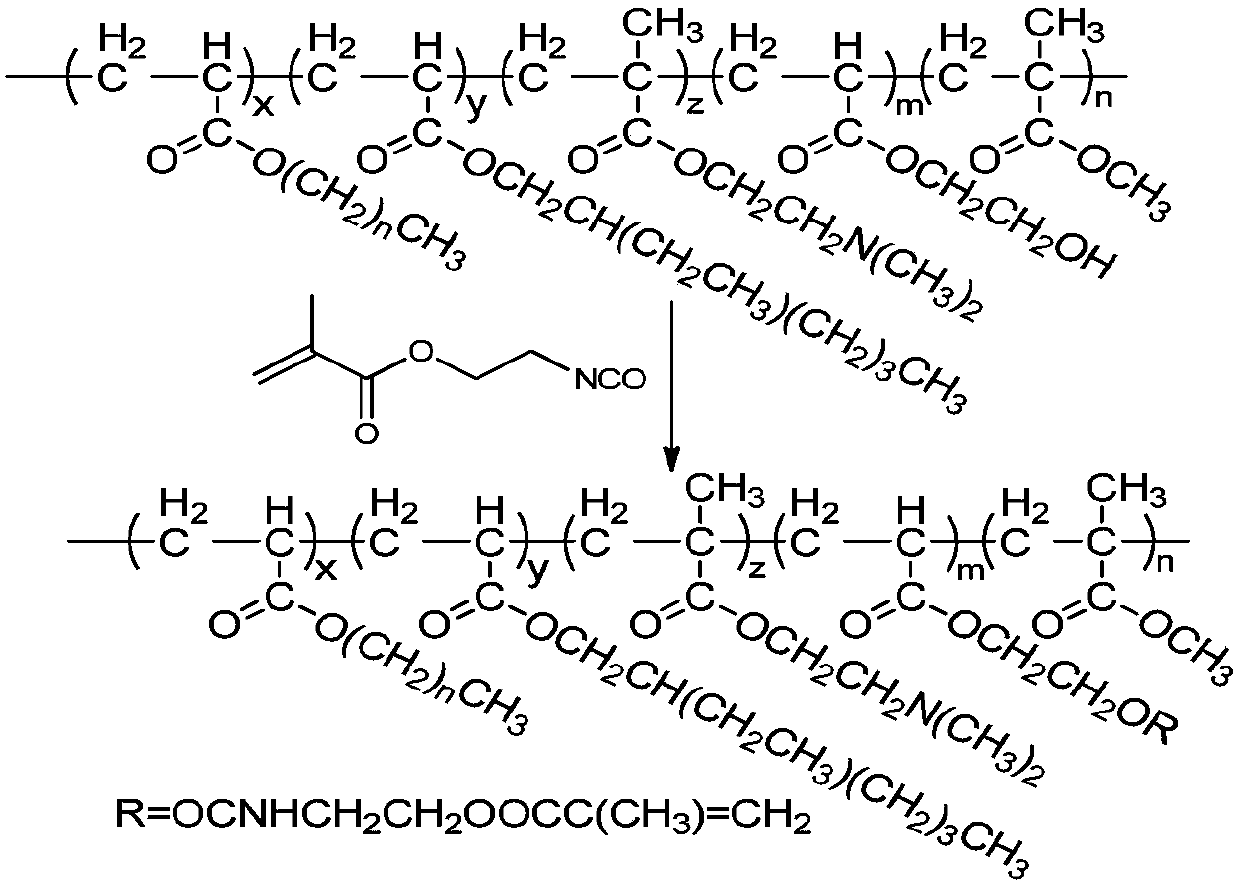

[0031] Preparation of UV-curable waterborne acrylate cathodic electrophoretic coatings containing octadecyl side chains.

[0032] Step 1: Preparation of cationic water-based acrylate photosensitive resin containing octadecyl side chains:

[0033] Under mechanical stirring, 0.81g octadecyl acrylate (accounting for 1% of the total weight of acrylate photosensitive resin) and 9.0g dimethylaminoethyl methacrylate were mixed with 16.2g methyl methacrylate, A mixture of 16.1 g of acrylate-3-hydroxypropyl ester, 21.6 g of isooctyl methacrylate, and 1.84 g of initiator azobisisobutyronitrile (AIBN, 3% of the total weight of acrylate comonomers) was slowly added to the tank. In a reactor with 29.1g of propylene glycol methyl ether acetate, a free radical solution polymerization method was used to react at 120°C for 4 hours until the carbon-carbon double bonds in the reaction system were completely reacted to obtain an acrylate resin solution containing hydroxyl functional groups Then,...

Embodiment 2

[0039] Preparation of UV-curable waterborne acrylate anodic electrophoretic coating containing dodecyl side chains.

[0040] Step 1: Preparation of anionic waterborne acrylate photosensitive resin containing dodecyl side chains:

[0041] Under mechanical stirring, 10.5g lauryl methacrylate (accounting for 10% of the total weight of acrylate photosensitive resin) and 12.1g acrylic acid, 10.0g methyl methacrylate, 5.2g methacrylic acid were mixed with a constant pressure dropping funnel. The mixture of isobornyl ester, 17.0g acrylate-2-hydroxyl ethyl ester, 22.4g n-butyl acrylate, 3.1g initiator azobisisobutyronitrile (AIBN, accounting for 4% of the total weight of acrylate comonomer) was slowly dropped Put into the reactor that 35.6g propylene glycol methyl ether acetate is housed, adopt radical solution polymerization method, react at 70 ℃ for 12 hours, until the carbon-carbon double bond reaction in the reaction system is complete, make the acrylate containing hydroxyl functi...

Embodiment 3

[0047] Preparation of UV-curable waterborne acrylate cathodic electrophoretic coatings containing hexadecyl side chains.

[0048] Step 1: Preparation of cationic water-based acrylate photosensitive resin containing hexadecyl side chains:

[0049] Under mechanical stirring, 3.8g hexadecyl acrylate (accounting for 4% of the total weight of acrylate photosensitive resin) and 9.1g dimethylaminoethyl acrylate, 15.0g methyl methacrylate, 2.5g The mixture of styrene, 19.1g of 2-hydroxyethyl methacrylate, 25.5g of isooctyl acrylate, 3.75g of initiator azobisisobutyronitrile (AIBN, 5% of the total weight of acrylate comonomers) slowly Drop into a reactor containing 32.0g of propylene glycol methyl ether acetate, and react at 90°C for 6 hours by free radical solution polymerization until the carbon-carbon double bonds in the reaction system are completely reacted to obtain hydroxyl functional group-containing acrylic acid Ester resin solution; Then, the temperature of the system is adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com