Light-weight small building block as sandwich of wall and its production method

A lightweight, block technology, used in ceramic molding machines, building materials, manufacturing tools, etc., can solve the problems of indoor moisture return, inability to form shaped products, and unsatisfactory application, to improve the overall strength and earthquake resistance, convenient The effect of factory processing and production, construction and building is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

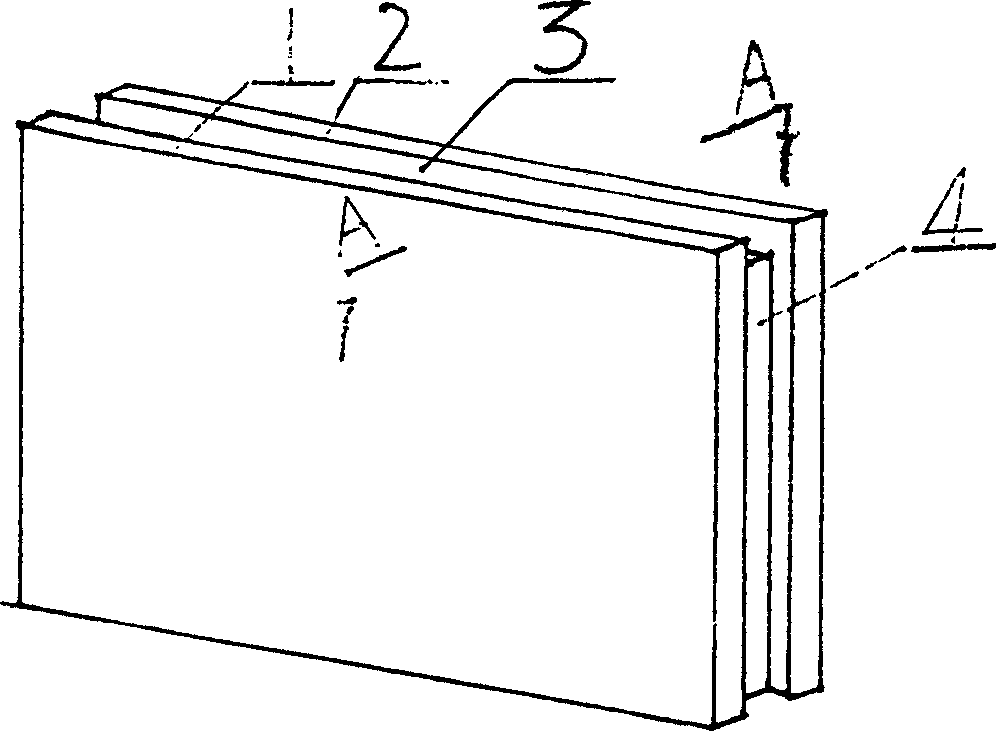

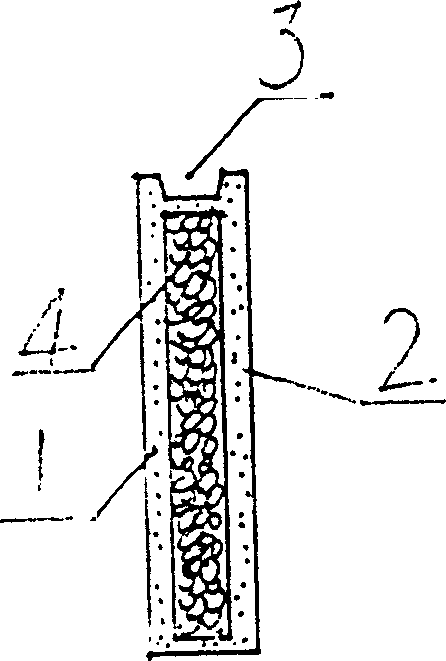

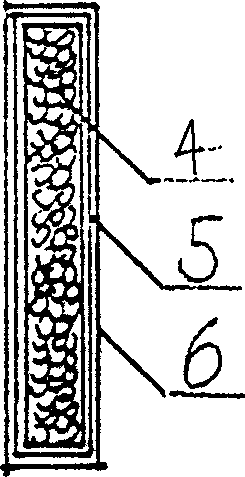

[0015] The present invention comprises rectangular core plate inner layer 4 and rectangular left and right cement product surface layers 1, 2, such as figure 1 , 2 shown. The core board inner layer 4 is sandwiched between the left and right cement product surface layers 1 and 2 and integrated with the left and right cement product surface layers 1 and 2, and the core board inner layer 4 and the left and right cement product surface layers Between 1 and 2, there is a building adhesive layer 5 with cement as an admixture and a cement slurry bonding layer 6 other than the building adhesive layer 5, such as image 3 shown. The inner layer of the core board can adopt polystyrene foam board. The shape around the block thickness direction of the present invention, the bottom surface is a plane, and the front, back and top have grooves 3 that are used to pour vertical or horizontal reinforced concrete along the vertical thickness direction.

[0016] The block technology of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com