Novel insulating paint for ballast and preparation method of insulating paint

A technology of insulating varnish and ballast, applied in the direction of coating, polyester coating, etc., can solve the problems of uniform paint film coverage, strong adhesion, low production efficiency, poor ballast surface uniformity, etc., and achieve a smooth and smooth appearance , Improve production efficiency, good anti-rust ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

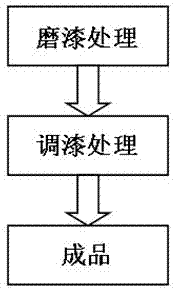

[0018] The specific preparation method is as follows:

[0019] a) Paint grinding treatment, the specific preparation process is: first add 60% heat-resistant unsaturated polyester resin, 7% xylene and 10% mixed dibasic ester solvent into the paint grinding tank, and disperse at a high speed of 2500r / min 15min; then add 20% new titanium dioxide to the above mixed raw materials, and disperse at a high speed of 2500r / min for 30min; finally add glass beads accounting for 30% of the total amount of the above mixture, turn on the cooling water, and disperse at a high speed of 3800r / min for 5h .

[0020] b) Paint letdown treatment, the specific preparation process is: first pour the mixed raw materials prepared in step a) into the paint letdown tank; then add 1.9% curing agent, 0.1% polymerization inhibitor and 0.5% catalyst to the paint letdown tank at one time , 0.2% leveling agent and 0.3% defoamer, and fully stirred, the stirring speed is 2800r / min, and the stirring time is 0.5h...

Embodiment 2

[0022] The specific preparation method is as follows:

[0023] a) Polishing treatment, the specific preparation process is: first add 40% polyimide and polyamideimide mixed resin, 11% xylene and 15% mixed dibasic ester solvent into the grinding paint tank, and use 2500r / min speed of high-speed dispersion for 15 minutes; then add 30% new titanium dioxide to the above mixed raw materials, and disperse at a high speed of 2500r / min for 30min; finally add glass beads accounting for 40% of the total amount of the above mixture, turn on the cooling water, and use 3800r / min Disperse at high speed for 5 hours at min speed.

[0024] b) Paint letdown treatment, the specific preparation process is: first pour the mixed raw materials prepared in step a) into the paint letdown tank; then add 2.2% curing agent, 0.2% polymerization inhibitor and 0.7% catalyst to the paint letdown tank at one time , 0.4% leveling agent and 0.5% defoamer, and fully stirred, the stirring speed is 2800r / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com