Multifunctional nonwoven material for architecture

A multifunctional and architectural technology, applied in the direction of architecture, building components, building structures, etc., can solve problems such as single function, limited popularization and application, complex production process of composite nonwoven materials, etc., to achieve a wide range of choices and a smooth and flat appearance , the effect of activating human cells and autonomic nerves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

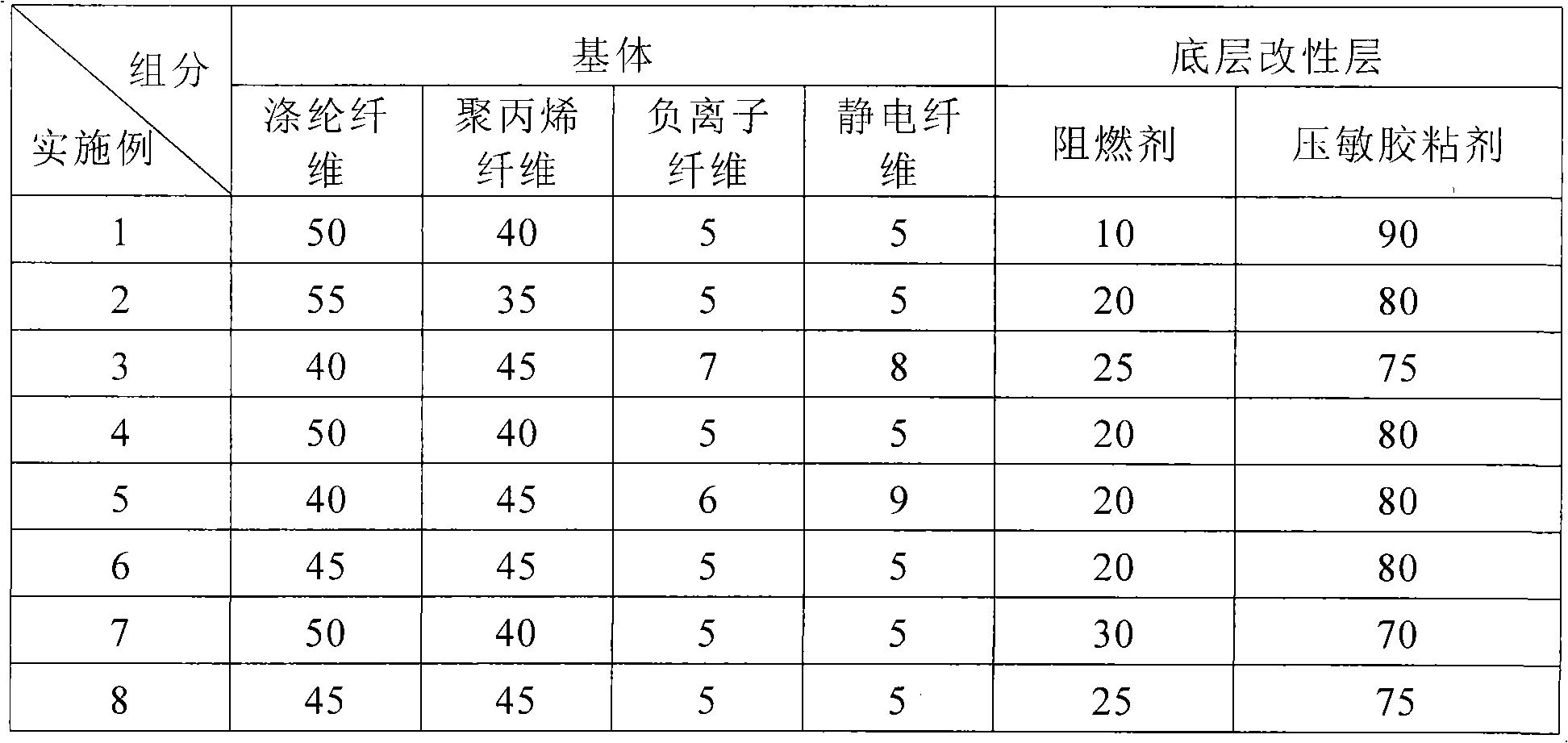

Embodiment 1

[0032] Polyester fibers, polypropylene fibers, anion fibers and antistatic fibers with diameters of 37 μm, 18 μm, 15 μm and 15 μm were selected, and the four kinds of fibers were mixed in a ratio of 50:40:5:5 (mass percentage). After loosening, fine opening, air-flow feeding and carding into a web, pre-needling and main needling reinforcement, then molding and shaping, and then winding to an area density of 500g / m 2 primary products. Configure pressure-sensitive adhesive liquid, which is composed of anionic phosphorus-based flame retardant and acrylate emulsion-type pressure-sensitive adhesive, and the monomer composition of pressure-sensitive adhesive is acrylic acid, diaminoethyl methacrylate and methyl methacrylate The ratio of copolymer emulsion, flame retardant and pressure-sensitive adhesive is 10:90 (mass percentage), and after the rolled primary product is coated with the pressure-sensitive adhesive of the above composition, it is compounded with release paper coated w...

Embodiment 2

[0034] Polyester fibers, polypropylene fibers, anion fibers and antistatic fibers with diameters of 42 μm, 25 μm, 18 μm and 18 μm were selected, and the four kinds of fibers were mixed in a ratio of 55:35:5:5 (mass percentage). After loosening, fine opening, air-flow feeding and carding, after pre-needling and main needling reinforcement, it is molded and shaped, and then wound to an area density of 700g / m 2primary products. Firstly, the rolled primary product is coated with anionic phosphorus-based flame retardant, and then coated with a hot-melt adhesive based on styrene-butadiene-styrene copolymer, the mass percentage of glue and flame retardant It is 80:20, and then compounded with silicone-coated release paper, dried by hot pressing, and then trimmed, then wound to form a self-adhesive non-woven material.

Embodiment 3

[0036] Polyester fibers, polypropylene fibers, negative ion fibers and antistatic fibers with diameters of 42 μm, 25 μm, 18 μm and 18 μm were selected, and the four kinds of fibers were mixed in a ratio of 40:45:7:8 (mass percentage). After loosening, fine opening, air-flow feeding and carding, after pre-needling and main needling reinforcement, it is molded and shaped, and then wound to an area density of 700g / m 2 primary products. The rolled primary product is first coated with an anionic phosphorus-based flame retardant, and then coated with a hot-melt adhesive based on a styrene-isoprene-styrene copolymer base polymer. The mass percentage of glue and flame retardant It is 75:25, and then compounded with silicone-coated release paper, dried by hot pressing, and then trimmed, then wound to form a self-adhesive non-woven material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com