Hydroxyalkylamide-cured outdoor type flame retardant powder coating

A technology of hydroxyalkylamide and flame-retardant powder, which is applied in the field of hydroxyalkylamide-cured outdoor flame-retardant powder coatings, and can solve the problem of unpublished outdoor foamable powder coating preparation process and unsuitable flame-resistant and flame-retardant materials In the field of spraying, it can not meet the flame retardant requirements of coatings, etc., and achieve the effect of good low temperature resistance, increased thermal stability, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

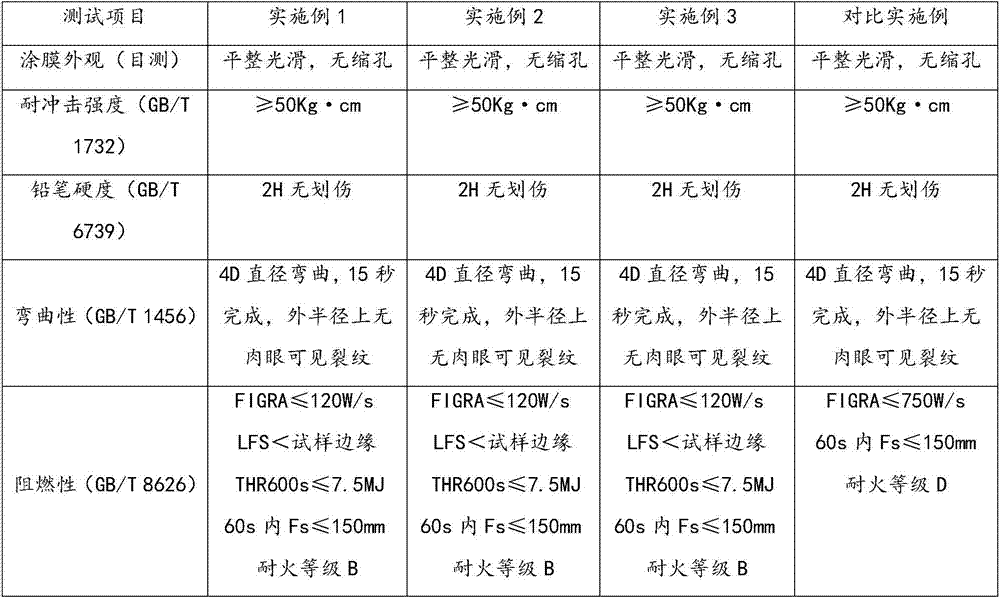

Examples

Embodiment 1

[0027] A hydroxyalkylamide cured outdoor flame retardant powder coating, made of the following components in mass percentage:

[0028] Outdoor polyester resin 65 parts,

[0029] 4 parts of hydroxyalkylamide curing agent,

[0030] Smooth degasser 2 parts,

[0031] Leveling agent 2 parts,

[0032] Compound flame retardant 5 parts,

[0033] 22 parts of pigments and fillers;

[0034] The compound flame retardant is prepared from the following raw materials in parts by weight: 5 parts of aluminum hydroxide, 5 parts of magnesium hydroxide, 16 parts of zinc borate, 32 parts of barium borate, 6 parts of antimony trioxide, and 36 parts of diatom mud;

[0035] The preparation process of the compound flame retardant is as follows: after mixing aluminum hydroxide, magnesium hydroxide, zinc borate, barium borate, antimony trioxide, and diatom mud, knead at 90°C for 20 minutes, take it out, pulverize, Pass through a 80-100 mesh sieve to obtain a compound flame retardant.

Embodiment 2

[0037] A hydroxyalkylamide cured outdoor flame retardant powder coating, made of the following components in mass percentage:

[0038] Outdoor polyester resin 65 parts,

[0039] 4 parts of hydroxyalkylamide curing agent,

[0040] Smooth degasser 2 parts,

[0041] Leveling agent 2 parts,

[0042] Compound flame retardant 10 parts,

[0043] 17 parts of pigments and fillers;

[0044] The compound flame retardant is prepared from the following raw materials in parts by weight: 5 parts of aluminum hydroxide, 5 parts of magnesium hydroxide, 16 parts of zinc borate, 32 parts of barium borate, 6 parts of antimony trioxide, and 36 parts of diatom mud;

[0045] The preparation process of the compound flame retardant is as follows: after mixing aluminum hydroxide, magnesium hydroxide, zinc borate, barium borate, antimony trioxide, and diatom mud, knead at 100°C for 30 minutes, take it out, pulverize, Pass through a 80-100 mesh sieve to obtain a compound flame retardant.

Embodiment 3

[0047] A hydroxyalkylamide cured outdoor flame retardant powder coating, made of the following components in mass percentage:

[0048] Outdoor polyester resin 65 parts,

[0049] 4 parts of hydroxyalkylamide curing agent,

[0050] Smooth degasser 2 parts,

[0051] Leveling agent 2 parts,

[0052] Compound flame retardant 8 parts,

[0053] 20 parts of pigments and fillers;

[0054] The compound flame retardant is prepared from the following raw materials in parts by weight: 5 parts of aluminum hydroxide, 5 parts of magnesium hydroxide, 16 parts of zinc borate, 32 parts of barium borate, 6 parts of antimony trioxide, and 36 parts of diatom mud;

[0055] The preparation process of the compound flame retardant is as follows: after mixing aluminum hydroxide, magnesium hydroxide, zinc borate, barium borate, antimony trioxide, and diatom mud, knead at 90°C for 20 minutes, take it out, pulverize, Pass through a 80-100 mesh sieve to obtain a compound flame retardant.

[0056] Wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com