Novel aluminum wood mixed template

A technology of mixing formwork and aluminum formwork, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

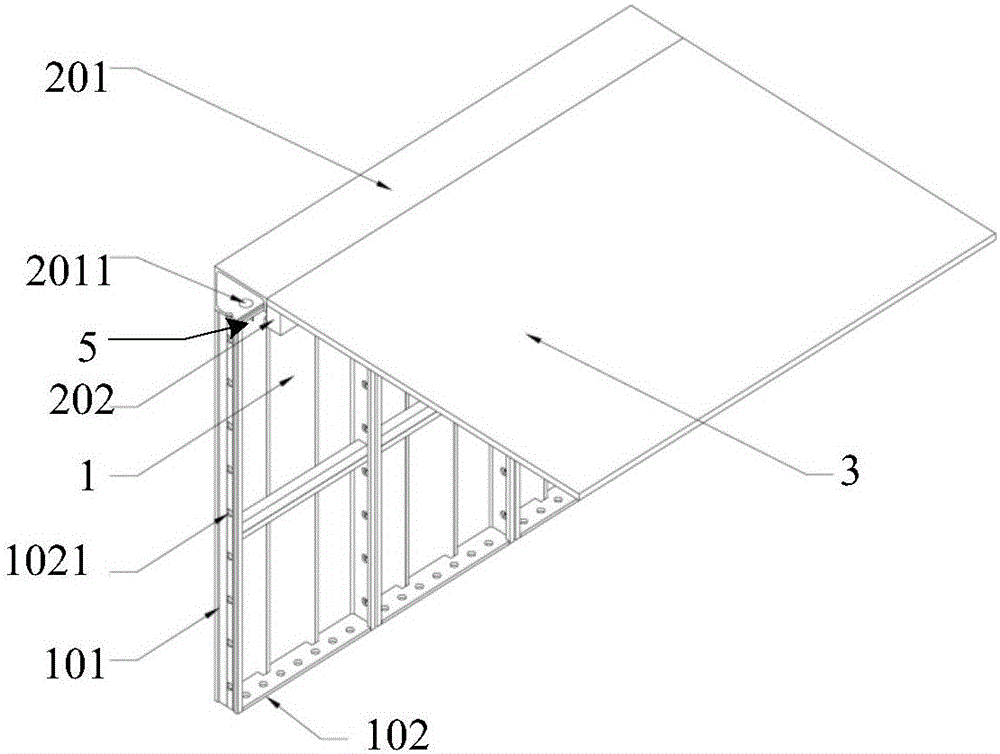

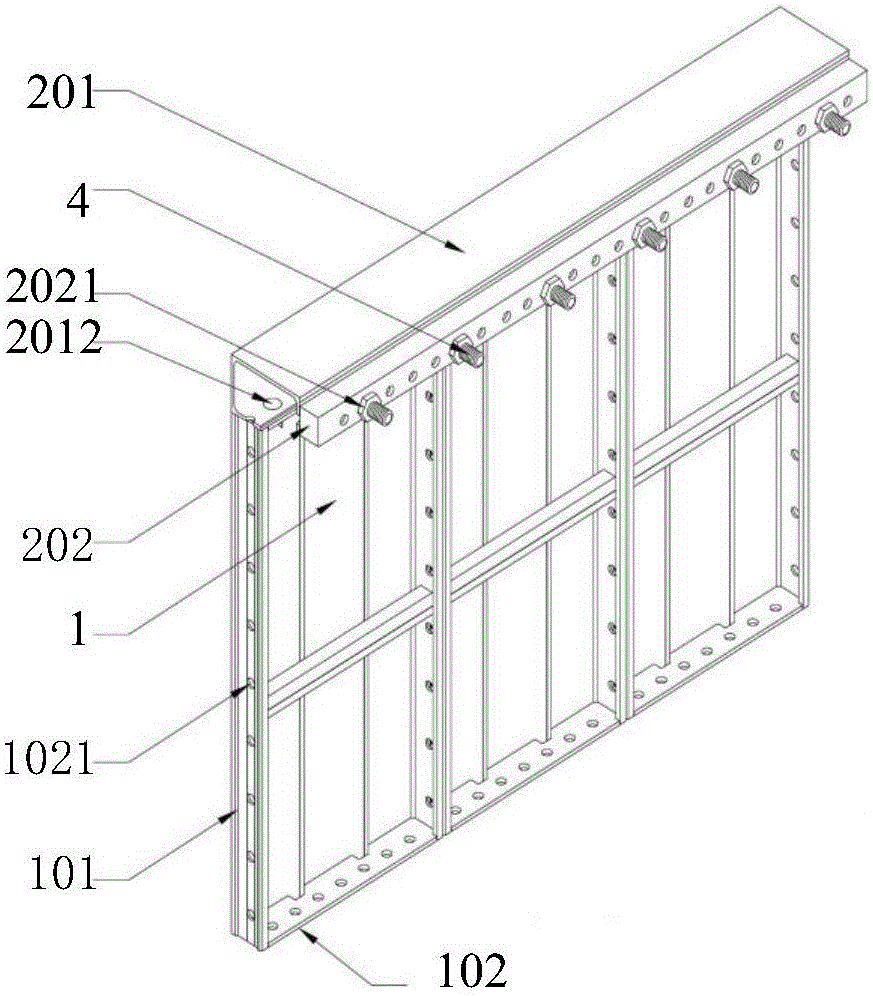

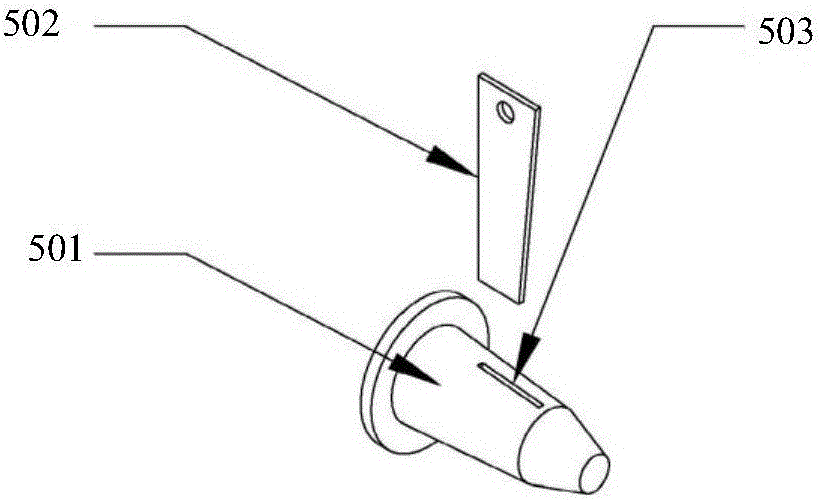

[0029] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0030] Aiming at the performance characteristics of the aluminum formwork and the wood formwork, the invention provides a mixed formwork which has both the advantages of the aluminum formwork and the wood formwork. The novel aluminum-wood mixed formwork of the present invention realizes the close connection of the aluminum formwork and the wood formwork, ensures no grout leakage in the poured concrete at the joint position, and has a flat and smooth appearance and excellent texture. The main idea of the present invention is to design the aluminum formwork, wood formwork, and connection components respectively, and then connect the aluminum formwork and the wood formwork closely through the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com